B (62%.E44their Attorney Patented Jan

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Batio3 Based Materials for Piezoelectric and Electro-Optic Applications

BaTiO3 based materials for Piezoelectric and Electro-Optic Applications by Ytshak Avrahami B.Sc. Materials Science and Engineering, B.A. Physics (Cum Laude) Technion – Israel Institute of Technology, 1995 M.Sc. Materials Science and Engineering Technion – Israel Institute of Technology, 1997 SUBMITTED TO THE DEPARTMENT OF MATERIALS SCIENCE AND ENGINEERING IN PARTIAL FULFILLMENT OF THE REQUIREMENTS FOR THE DEGREE OF DOCTOR OF PHILOSOPHY IN ELECTRONIC, PHOTONIC AND MAGNETIC MATERIALS JANUARY 2003 © 2003 Massachusetts Institute of Technology All rights reserved 2 Abstract BaTiO3 based materials for Piezoelectric and Electro-Optic Applications by Ytshak Avrahami Submitted to the Department of Materials Science and Engineering on February 13, 2003 in Partial Fulfillment of the Requirements for the Degree of Doctor OF Philosophy in Electronic, Photonic and Magnetic Materials ABSTRACT Ferroelectric materials are key to many modern technologies, in particular piezoelectric actuators and electro-optic modulators. BaTiO3 is one of the most extensively studied ferroelectric materials. The use of BaTiO3 for piezoelectric applications is, however, limited due to the small piezoelectric coefficient of the room temperature-stable tetragonal phase. Furthermore, research on BaTiO3 for integrated optics applications remains sparse. In this work Zr-, Hf-, and KNb- doped BaTiO3 materials were prepared in a composition range that stabilizes the rhombohedral phase. These materials were prepared as bulk polycrystals using a standard solid-state reaction technique in order to test the piezoelectric and dielectric properties. Some compositions were then chosen for thin film deposition. The films were deposited using pulsed laser deposition on MgO and SOI substrates. Growth orientation, remnant strain and optical properties were then measured. -

1. Introduction Barium Titanate (Batio3) Is a Versatile Elctroceram

ARCHIVESOFMETALLURGYANDMATERIALS Volume 54 2009 Issue 4 B. WODECKA-DUŚ∗, D. CZEKAJ∗ FABRICATION AND DIELECTRIC PROPERTIES OF DONOR DOPED BaTiO3 CERAMICS OTRZYMYWANIE I WŁAŚCIWOŚCI DIELEKTRYCZNE DONOROWO DOMIESZKOWANEJ CERAMIKI BaTiO3 Barium titanate BaTiO3 is a common ferroelectric material which adopts the perovskite structure type ABO3. It is widely utilized to manufacture a variety of electronic components. In the present study lanthanum-doped BaTiO3 compositions with ◦ x=0.1 mol.% and x=0.3 mol.%, in Ba1−xLaxTi1−x/4O3 were prepared by free sintering method in air at temperature T=1350 C. The grain size distribution and morphology of the powders were studied as well as the X-ray diffraction analysis was performed to confirm formation of the desired crystalline structure. Temperature dependence of dielectric permittivity was studied in the temperature range of ferroelectric-paraelectric phase transition. Keywords: Ba1−xLaxTi1−x/4O3, donor doped, dielectric permittivity, ferroelectric ceramics Tytanian baru BaTiO3 jest przedstawicielem tlenowooktaedrycznych związków o strukturze krystalicznej typu perowskitu ABO3. Materiał ten charakteryzuje się wieloma interesującymi właściwościami, które można modyfikować poprzez zmianę składu chemicznego oraz optymalizację technologii otrzymywania. Przedmiotem niniejszej pracy było otrzymanie metodą swobodnego spiekania (T=1350◦C) na bazie półprzewodnikowego BaTiO3, domieszkowanego donorowo lantanem, roztworu stałego o składzie Ba1−xLaxTi1−x/4O3, dla koncentracji x=0,1 mol.% i x=0,3 mol.%. Celem zoptymalizowania warunków technologicznych przeprowadzono analizę ziarnową proszków. Wykorzy- stując metodę dyfrakcji promieni rentgenowskich (metoda XRD) zbadano strukturę krystaliczną, przeprowadzono identyfikację fazową oraz wyznaczono średni wymiar krystalitów otrzymanego roztworu stałego o różnej zawartości lantanu. Zbadano również temperaturowe zależności stałych dielektrycznych w obszarze przemiany fazowej oraz określono parametry ferroelektryczne otrzymanej elektroceramiki. -

Preparation of Barium Strontium Titanate Powder from Citrate

APPLIED ORGANOMETALLIC CHEMISTRY Appl. Organometal. Chem. 13, 383–397 (1999) Preparation of Barium Strontium Titanate Powder from Citrate Precursor Chen-Feng Kao* and Wein-Duo Yang Department of Chemical Engineering, National Cheng Kung University, Tainan, 70101, Taiwan TiCl4 or titanium isopropoxide reacted with INTRODUCTION citric acid to form a titanyl citrate precipitate. Barium strontium citrate solutions were then BaTiO3 is ferroelectric and piezoelectric and has added to the titanyl citrate reaction to form gels. extensive applications as an electronic material. It These gels were dried and calcined to (Ba,Sr)- can be used as a capacitor, thermistor, transducer, TiO3 powders. The gels and powders were accelerometer or degausser of colour television. characterized by DSC/TGA, IR, SEM and BaTiO3 doped with strontium retains its original XRD analyses. These results showed that, at characteristics but has a lower Curie temperature 500 °C, the gels decomposed to Ba,Sr carbonate for positive temperature coefficient devices under and TiO2, followed by the formation of (Ba,Sr)- various conditions. TiO3. The onset of perovskite formation oc- Besides solid-state reactions, chemical reactions curred at 600 °C, and was nearly complete at have also been used to prepare BaTiO3 powder. 1 1000 °C. Traces of SrCO3 were still present. Among them the hydrolysis of metal alkoxide , The cation ratios of the titanate powder oxalate precipitation in ethanol2, and alcoholic prepared in the pH range 5–6 were closest to dehydration of citrate solution3 are among the more the original stoichiometry. Only 0.1 mol% of the attractive methods. In 1956 Clabaugh et al.4 free cations remained in solution. -

Synthesis of Barium Titanate from Titanyl Acylate Precursor by Sol-Precipitate Method Thandar Win', Kyaw Naing2 and Khin Mar Tunj

MM 1000115 Jour. Myan. Acad. Arts & Sc. 2008 Vol. VI. No. 1 Synthesis of Barium Titanate from Titanyl Acylate Precursor by Sol-precipitate Method Thandar Win', Kyaw Naing2 and Khin Mar TunJ Abstract Nanometersize barium titanates (BaTiO3:BT) powders can be obtained by sol-precipitate method in the presence of polyoxyethylene (20) sorbiton monooleate (Tween-80) as a polymeric surface modifier in a strong alkaline solution (pH > 13) . FT-IR, TG/ DTA, SEM and XRD were used to investigate the effects of the surfactant influence on the morphology of the obtained BaTiO3 powders. With adding surfactant, a slower rate of hydroiyzatibn is observed and the rate of condensation is slower. The addition of Tween-80 surfactant in general leads to the formation of smaller particle size of BaTiO3 (70-100 nm). Without adding surfactant, larger particle size of BaTiO3 (100-200 nm) was obtained. The nanometersize BaTiO3 powders were readily sintered at 1000-1200°C. Raman-active modes of tetragonal phase BT were detected from Raman spectra of BaTiO3 between 800°C to 1200°C. Key words: Barium Titanates, sol-precipitate method, Tween-80, tetragonal-phase, Raman Spectra Introduction Barium titanate crystallizes in a perovskite structure is an important electronic ceramic. Barium titanate (BaTi(>3 : BT) naoncrystals have great advantages over micrometer size ceramic powders when the thickness of a single ceramic layer decreases to less than 2fxm. Low temperature synthesis has provided on exciting possibility for high purity, homogeneous, and ultrafine BaTiO3 nonoparticles. BT nonocrystals have been synthesized by Using a hydrothermal method, sol-gel processing, the oxalate route, microwave heating, a micro-emulsion process and a polymeric precursor method. -

Thermogravimetric Study of Barium Titanate James Nicholas Lingscheit Iowa State University

Iowa State University Capstones, Theses and Retrospective Theses and Dissertations Dissertations 1973 Thermogravimetric study of barium titanate James Nicholas Lingscheit Iowa State University Follow this and additional works at: https://lib.dr.iastate.edu/rtd Part of the Chemical Engineering Commons Recommended Citation Lingscheit, James Nicholas, "Thermogravimetric study of barium titanate " (1973). Retrospective Theses and Dissertations. 5029. https://lib.dr.iastate.edu/rtd/5029 This Dissertation is brought to you for free and open access by the Iowa State University Capstones, Theses and Dissertations at Iowa State University Digital Repository. It has been accepted for inclusion in Retrospective Theses and Dissertations by an authorized administrator of Iowa State University Digital Repository. For more information, please contact [email protected]. INFORMATION TO USERS This material was produced from a microfilm copy of the original document. While the most advanced technological means to photograph and reproduce this document have been used, the quality is heavily dependent upon the quality of the original submitted. The following explanation of techniques is provided to help you understand markings or patterns which may appear on this reproduction. 1. The sign or "target" for pages apparently lacking from the document photographed is "Missing Page(s)". If it was possible to obtain the missing page(s) or section, they are spliced into the film along with adjacent pages. This may have necessitated cutting thru an image and duplicating adjacent pages to insure you complete continuity. 2. When an image on the film is obliterated with a large round black mark, it is an indication that the photographer suspected that the copy may have moved during exposure and thus cause a blurred image. -

Temperature-Stable Barium Titanate Ceramics

Electrocomponent Science and Technology (C)Gordon and Breach Science Publishers Ltd. 1976, Vol. 2, pp. 241-247 Printed in Great Britain TEMPERATURE-STABLE BARIUM TITANATE CERAMICS CONTAINING NIOBIUM PENTOXIDE IAN BURN Research and Development Laboratories, Sprague Electric Company, North Adams, Massachusetts U.S.A. (Received May 27, 19 75) Niobium is known to lower the Curie point and broaden the permittivity peak of barium titanate. However, the distribution of niobium in sintered barium titanate is often not homogeneous, being influenced by such preparation variables as large cation/small cation stoichiometry and firing conditions. In addition to these factors, it was found that, at least up to about 5 mol % Nb, the distribution of niobium in the barium titanate grains could be regulated by small amounts (<1 mol %) of oxides of Co, Mg, Ni or Mn. These oxides appear to form niobates that produce high permittivity solid solutions in the "skins" of the barium titanate grains and permit dielectrics to be obtained with permittivity K 2000,) stable to within +-10% over the temperature range -55C to 125C. INTRODUCTION principal impurities. A small amount of work was also done with a similar barium titanate $ with comparable The influence of niobium on the temperature impurity level but small BaO/TiO2 ratio (0.99). Up dependence of the permittivity of barium titanate has to about 5 mol % niobium oxide (NbO2.s) was added been described by several authors. -a Some to the barium titanate powder together with various inconsistencies in the earlier data 1,2 have been other oxides in amounts less than 1 mol %. -

Preparation of Homogeneously-Doped Barium Titanate

Preparation of homogeneously-doped barium titanate Sven van der Gijp Gijp, Sven van der Preparation of homogeneously-doped barium titanate ISBN: 90-36511798 Copyright © Sven van der Gijp, Enschede, The Netherlands PREPARATION OF HOMOGENEOUSLY-DOPED BARIUM TITANATE PROEFSCHRIFT ter verkrijging van de graad van doctor aan de Universiteit Twente, op gezag van de rector magnificus, prof. dr. F.A. van Vught, volgens besluit van het College voor Promoties in het openbaar te verdedigen op donderdag 10 september 1998 te 13.15 uur. door Sven van der Gijp geboren op 27 maart 1971 te Amstelveen dit proefschrift is goedgekeurd door de promotor prof. dr. ir. H. Verweij en de assistent promotor dr. A.J.A. Winnubst The investigations described in this thesis were supported financially by Philips. Summary Doped barium titanate is used frequently in several types of electrical devices. The electrical behaviour of barium titanate ceramics strongly depend on the composition and the microstructure. In this thesis mainly the application of zirconium doped barium titanate as a pulse-generating device is described. Next to this also the application of barium titanate in multilayer ceramic capacitors is briefly discussed. Finally the prepa- ration of homogeneously doped barium titanate powder is described as well as the mi- crostructure and the related properties of the ceramic. In chapter 1 the ferroelectric behaviour of barium titanate as well as the influence of dopants on the dielectric behaviour and more specific on the position of the Curie- temperature are described. The physical background on the use of barium titanate for application in lamp starters and in multilayer ceramic capacitors is also discussed. -

History of the First Ferroelectric Oxide, Batio3

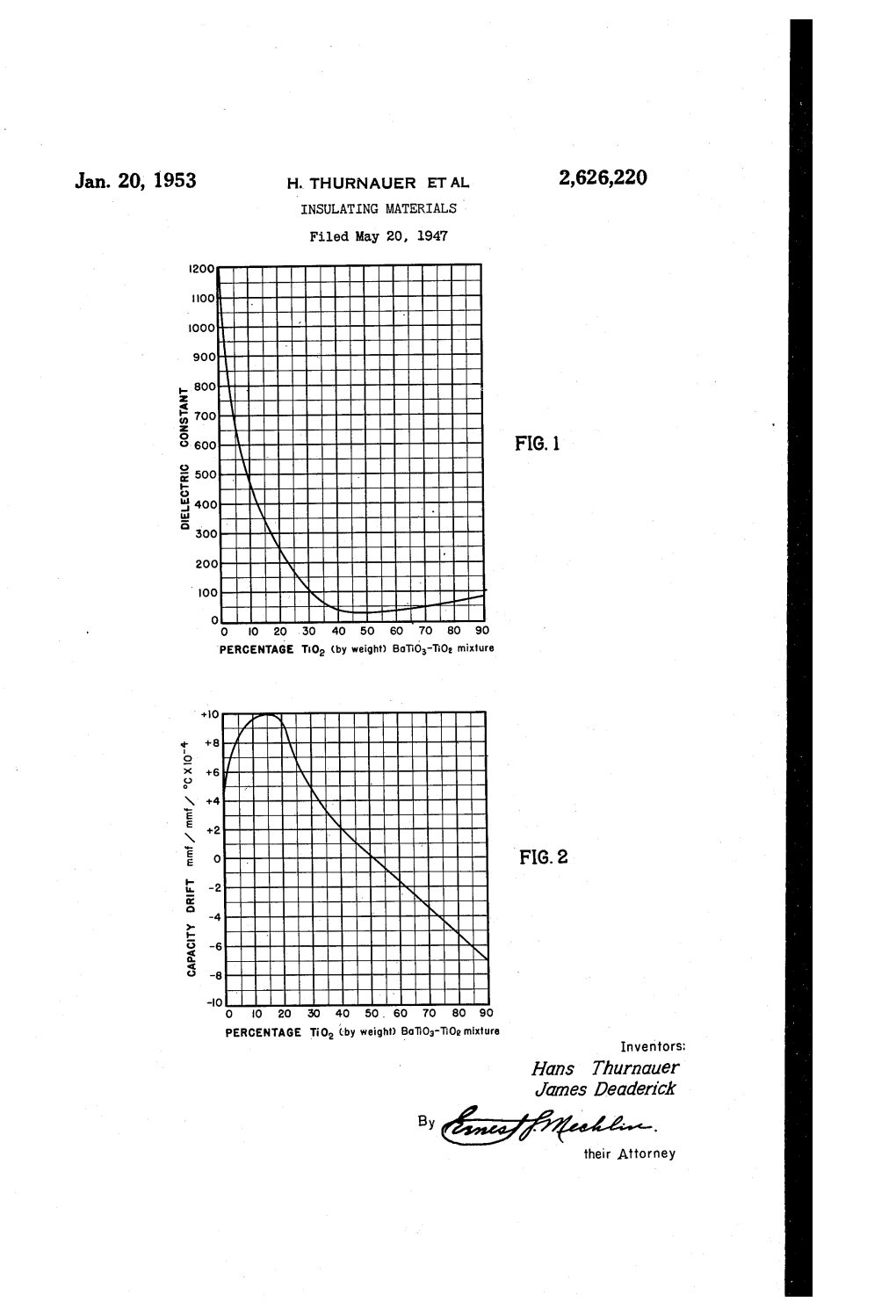

History of the First Ferroelectric Oxide, BaTiO 3 C.A. Randall, R.E. Newnham, and L.E. Cross Materials Research Institute The Pennsylvania State University University Park, PA 16802 USA BaTiO 3 is the most widely used ferroelectric material, and even sixty years after its discovery, it is the most important multilayer ceramic dielectric. The objective of this short paper is to indicate some of the chronologically important scientific contributions enhancing the understanding and use of BaTiO 3. BaTiO 3 was discovered during World War II in 1941 and 1944 in the United States, Russia, and Japan. At least in the U.S.A., the research was accelerated because of the war. At that time, mica was used in most capacitors, but U-boats threatened the supplies of mica to the U.S.A. from South America. The initial reports were based on doping studies of TiO 2 with BaO, which produced ceramic materials with enhanced dielectric permittivities. The mixed oxides were made by Thurnaurer and Deaderick at the American Lava Co. as early as 1941, the filing date of U.S. Patent No. 2,429,588. (1) The high permittivities were found by measurements made at the Erie Resistor Company, with dielectric constant exceeding 1000, ten times greater than any other ceramic known at that time, such as TiO 2 ( εr=110). Later, more precise studies were reported by Wainer and Solomon in the United States, Ogawa and Waku in Japan, and Wul and Goldman in Russia. (2,3,4) It has been speculated that German scientists failed to identify BaTiO 3 because of space charge polarization caused by differences in ore extraction methods for TiO 2. -

Barium Titanate.Pdf (394.6Kb)

Barium Titanate & Barium Titanate/Aluminum Oxide Ceramics... Barium Titanate and Barium Titanate/Aluminum Oxide Ceramics for Capacitors and Transducers Lewis E. Brigman and Jake Pedretti | Seniors B.S. in Manufacturing Engineering Abstract An inexpensive solid-state powder compaction and sintering method to make barium titanate disc structures for use in capacitors and piezoelectric transducers was researched. Barium titanate powders were uniaxially pressed to 20,000 lbf into discs and sintered over 1,100 to 1,400°C for different times. The discs were characterized for density, capacitance, and output voltage characteristics under uniaxial compression. The output voltage exhibited an exponential relationship with disc thickness. The experimental relative permittivity revealed a trend with percent porosity similar to the theoretical predictions. To strengthen BaTiO3 against cracking during mechanical and electrical loading, BaTiO3/xAl2O3 (x = 0, 5, 10 and 15 percent by weight) composites were prepared by ball-milling, compaction, and sintering (1,250°C and 1,350°C, 1h and 4h). The density and flexural strength of sintered composites decreased and porosity content increased as the amount of Al2O3 increased. Because of high incidence of porosity, the composite samples did not develop their full strengthening potential. Recommendations have been made to further expand this research and achieve higher strength in BaTiO3/xAl2O3 composites. Keywords: powder metallurgy, piezoelectric ceramics, composites, capacitance, flexural strength, densification Introduction Barium titanate (BaTiO3) is a ferroelectric ceramic with piezoelectric properties. It is used in multilayer capacitors in TVs, video cameras and computers. It is also used as a piezoelectric transducer in microphones and in power generation devices. The 51 Journal of Student Research standard method to make barium titanate for use in multilayer capacitors involves tape casting of barium titanate slurry into a thin sheet which is dried and a paste or ink containing silver- palladium powder is screen printed. -

Download This Article in PDF Format

E3S Web of Conferences 270, 01011 (2021) https://doi.org/10.1051/e3sconf/202127001011 WFCES 2021 SEM imaging and XPS characterization of doped PVDF fibers Tereza Smejkalová1, Ştefan Ţălu2,*, Rashid Dallaev1, Klára Částková1,3, Dinara Sobola1,3,4, and Anton Nazarov5 1Brno University of Technology, Technická 2848/8, 616 00 Brno, Czech Republic 2The Technical University of Cluj-Napoca, Constantin Daicoviciu Street, no. 15, Cluj-Napoca, 400020, Cluj county, Romania 3Central European Institute of Technology BUT, Purkyňova 123, 612 00 Brno, Czech Republic 4Dagestan State University, Makhachkala, St. M. Gadjieva 43-a, Dagestan Republic 367015, Russia 5Ural State University of Economics, Russian Federation Abstract. Polyvinylidene fluoride (PVDF) is one of the most promising electroactive polymers; it exhibits excellent electroactive behaviours, good biocompatibility, excellent chemical resistance, and thermal stability, rendering it an attractive material for biomedical, electronic, environmental and energy harvesting applications. This work aims to further improve its properties by the inclusion of powders of piezoactive materials. Polyvinylidene fluoride was formed by electrospinning into fibres with a thickness of 1.5-0.3 µm and then examined in a scanning electron microscope. The work offers a description of the current procedure in the preparation of samples and their modification for examination in a scanning electron microscope, characterizes the individual components of doped fibres and deals with specific instruments used for various analytical methods. The work contains a theoretical introduction to the analytical methods to which the samples will be further subjected, such as energy dispersive X-ray spectroscopy (EDX), X-ray photoelectron spectroscopy (XPS). The obtained excellent properties of doped PVDF could be used in the design of sensors. -

Synthesis of Barium Titanate Powder Using Nano Sized Titania

ISSN: 2319-8753 International Journal of Innovative Research in Science, Engineering and Technology (An ISO 3297: 2007 Certified Organization) Vol. 3, Issue 6, June 2014 Synthesis of Barium Titanate Powder Using Nano Sized Titania K.R. Kambale1*, A.R. Kulkarni2 , N. Venkataramani3 1 Department of Metallurgy and Materials Science, College of Engineering, Pune, Wellesley Road, Shivaji Nagar, Pune, India. 2 Department of Metallurgical Engineering and Materials Science, Indian Institute of Technology Bombay, Powai, Mumbai, India 3 Department of Metallurgical Engineering and Materials Science, Indian Institute of Technology Bombay, Powai, Mumbai, India ABSTRACT- Barium titanate is a ceramic widely used in electronic industry because of its high dielectric constant and low tangent losses. The main objective of the research work was to synthesize barium titanate from micron sized barium carbonate and titanium oxide having different particle size (0.7 µm, 50-60 nm and 80-90 nm). The calcination temperature of barium titanate was 1150 ºC when micro sized barium carbonate and titanium oxide were used as starting materials. However, calcination temperature decreased to 900 and 950 ºC when micro sized barium carbonate and nano titanium oxide with particle size 50-60 nm and 80-90 nm were used respectively. Formation of phase pure tetragonal barium titanate powder was confirmed using x – ray diffraction (XRD) in each case. The morphology of the powders was studied using scanning electron microscopy (SEM). The particle size of barium titanate reduced from 0.7 µm to 0.5 µm when nano sized titania was used as starting material. KEYWORDS: Barium titanate, particle size, titania, XRD. -

Effect of Strontium on the Structural and Piezoelectric Properties of the Sol Gel Processed Barium Titanate

Journal(of(Materials(and(( J. Mater. Environ. Sci., 2017, Volume 8, Issue S, Page 4945-4962 Environmental(Sciences( ISSN(:(2028;2508( CODEN(:(JMESCN( http://www.jmaterenvironsci.com ! Copyright(©(2017,((((((((((((((((((((((((((((( University(of(Mohammed(Premier(((((( (OuJda(Morocco( Effect of strontium on the structural and piezoelectric properties of the sol gel processed barium titanate A. El ghandouri1, S. Sayouri1, T. Lamcharfi2, L. Hajji3 1Laboratory of Physics, Theoretical and Applied, FSDM B.P. 179, Fez. Morocco 2Laboratory of signals systems and components, FST Street Immouzar, B.P. 2202 Fez, Morocco 3LMCN, F.S.T.G University Cadi Ayyad Marrakech, Morocco Received 25 Jul 2017, Abstract Revised 17 Oct 2017, Accepted 24 Oct 2017 Structural, dielectric and piezoelectric properties of nanopowders of pure and strontium- Keywords doped BaTiO3 (Ba1-xSrx)TiO3 (x = 0.00; 0.10; 0.20 ;0.30 and 0.40), synthesized by the !!(Ba, Sr)TiO3 ceramics, sol gel process, have been investigated. The samples crystallize in the pure perovskite !!Sol Gel, structure and transform from tetragonal to pseudocubic under doping with Sr. The calculated average crystallite size was about 30 nm. Dielectric parameters (dielectric !!Dielectric properties, !!Complex impedance, permittivity and losses) were determined. Sr doping gives rise to a decrease of the ferro- !!PTCR, to-paraelctric transition temperature and to an enhancement of the Positive Temperature Coefficient of Resistivity (PTCR). Piezoelectric parameters were also determined and !!Piezoelectric properties. their thermal behavior investigated. [email protected] ; Phone: +212673785288; 1. Introduction Barium Titanate (BaTiO3) is a perovskite type material, which is known for its various properties: high dielectric constant, ferroelectric behavior below 130 °C, spontaneous polarization and non-linear optical coefficients.