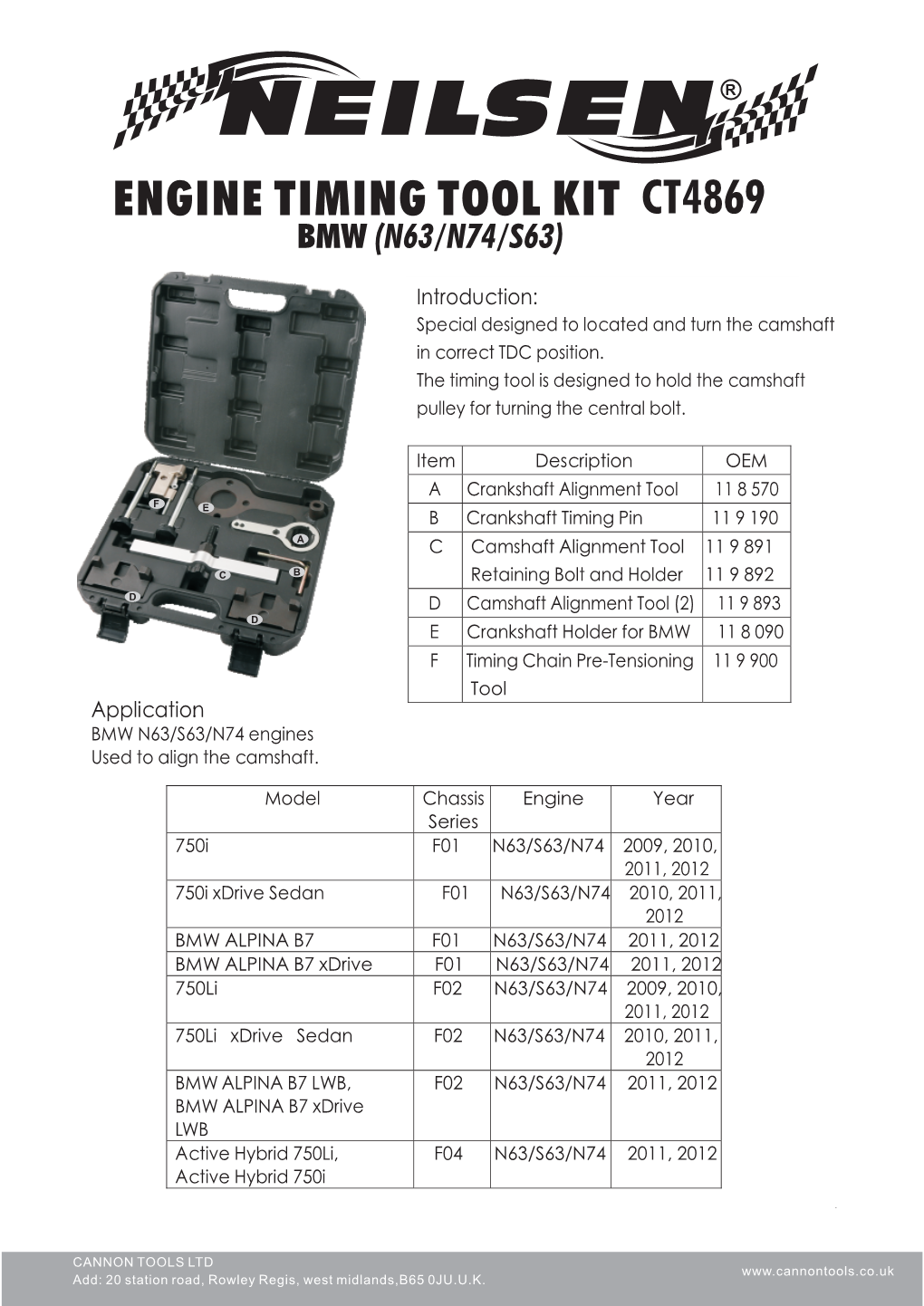

Engine Timing Tool Kit Ct4869

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

MOTORES CODIGOS 7E

CODIGO MAESTRO DE MOTORES Y TRANSMISIONES CREADO POR: ING. FERNER A. MORALES ABREU AGOSTO 2007-JUNIO 2017 MODEL AÑO CODIGO PETROL ENGINE DIESEL ENGINE TRANSMISION MARCA ACURA 2.5TL 95-98 UA1 2.5L G25A4 B7XA 99-03 UA4 2.5L J25A B7WA / MPYA 2004-2008 UA6 3.2L J32A3 BDGA 2009-present UA8 3.5L J35Z6 BK3A / BK4A CDX 2016-PRESENT 1.5L T 8 speed dual clutch CL 97-99 YA1 3.0L J30A1 / 2.2L F22B1 / 2.3L F23A1 A6VA / B6VA 2001-2003 YA4 3.2L J32A1 / J32A2 (type-s) MGFA CSX 2006-2011 CSX 2.0L K20Z2 / 2.0L D20Z3 (Type-S) MPMA (06-09) / SPCA (10-11) B4RA (97-00) / M4RA (97-98) / S4RA EL 97-00 MB4 1.6L D16Y8 (98-00) BDRA (99-00) 2001-2005 MB5 1.7L D17A2 B46A 1.5L LDA/LEA (hybrid) / 2.0L R20A (auto) M9DA 5 Speed (13-15) / S9FA 5 ILX 2013-Present DE1 / 2.4L K24Z7 (manual) / 2.4L K24W7 (16- speed CVT / M4JA 8 speed (16-) ) INTEGRA 86-89 DA1 1.6L D16A1 CA / P1 1.6L B16A / 1.8L B18A1 / 1.7L B17A1 90-93 DB1 RO / MPRA GS-R / 1.8L B18B1 1.8L B18B1 / 1.8L B18C5 TYPE R / 1.8L 94-99 DB7 B18C VTEC / 1.8L B18C1 / 1.8L B18C3 / MP7A / S4XA 1.8L B18C5 (USA) 2000-2001 DB8 1.8L B18B1 SKWA LEGEND 86-90 KA6 2.5L C25A / 2.7L C27A G4 / L5 / PL5X 92-95 KA8 3.2L C32A MPYA MDX 2001-2006 YD1 J35A3 / J35A5 (04-06) MDKA 2007-2012 YD2 3.7L J37A1 BDKA 2013-Present YD3 3.5L J35Y5 9HP48 (2016-) J4A4 Standard 5 Spd Honda (90-94) / NSX 1990-2005 NSX 3.0L V6 / 3.5L Twin-turbo hybrid SR8M Standard 5 Spd Honda RDX 2007-2012 TB1 2.3L K23A1 Turbo BWEA / BT3A 3.0L J30Y1 (china) / 3.5L J35Y / J35Z2 B8CA (AWD) 6 speed / B8BA 2013- TB2 (2013-2015) FWD 6speed RL 96-98 KA9 3.5L C35A M5DA 99-2004 -

Catalog 4.Cdr

Auto Tools BMW SPECIAL TOOLS Auto Tools BMW SPECIAL TOOLS No.130301 No.130606 No.130204 No.151803 No.151701 No.164202 BMW camshaft alignment tool( M52TU, M54, M56) BMW Secondary chain tensioner locking tools set(M62) BMW Camshaft alignment tool (M40 42 50 60 62 70 ) BMW valve pressure spring installer/ remover (N20/N55) BMW Fuel injector install& remove tool (N55) BMW N63 Timing tool Use with UN-130105 to fix on the camshaft BMW engine models M42 & M50: Includes For fixing the camshaft chain tensioner Special designed to remove and install the Special designed to install and remove the Timing chain Pre-Tensioning Preload tool for Special design for using before installing the 2 blocks swive lock plate & locking pin for s Applicable: BMW M60, M62(VANOS) pressure spring on intermediate lever injector in N55 engine BMW N63 timing tool accurate engine etting camshaft timing Applicable: BMW N20 ,N26, N55 BM number: 130270 Applicable: BMW engine models M52TU, Engine models M40 & M70: Includes plate & BM number: 117110 Applicable: BMW N55 engine Ean: 4048769031510 M54, M56 locking pin for setting camshaft timing BMW engine models M60&M62 : Includes 2 blocks swivel lock plate & locking pin for setting camshaft timing No.151702 No.151703 No.131207 No.151901 No.151902 No.164203 BMW Fuel injector install& remove tool (N20,N55) BMW fly wheel holder BMW fan clutch tool BMW VOLVO fuel tank lid remover BMW fuel tank lid remove tool BMW N63 Fuel injector tool Special designed to install and remove the Special designed to fix the flywheel when Remove -

2001 ACURA Sample VIN: 19UYA31581L000000

2009 ACURA Sample VIN: JH4KB26569C000000 Model: KB265 BODY TYPE MODEL BASE PRICE ACURA MDX Station Wagon (SUV) YD282 $40,990 Station Wagon (SUV) with Technology Package YD286 45,040 Station Wagon (SUV) with Technology Package and Entertainment System YD284 46,790 Station Wagon (SUV) with Sport Package YD287 47,140 Station Wagon (SUV) with Sport Package and Entertainment System YD288 48,890 ACURA RDX Station Wagon (SUV) TB182 33,895 Station Wagon (SUV) with Technology Package TB185 37,195 ACURA RL 4 Door Sedan KB265 46,680 4 Door Sedan with Technology Package KB266 50,300 4 Door Sedan − Hawaii KB263 50,300 4 Door Sedan with Collision Braking System KB266 54,100 ACURA TL – 4 x 2 4 Door Sedan UA862 34,955 4 Door Sedan with Technology Package UA865 38,685 ACURA TL – All Wheel Drive 4 Door Sedan UA962 38,505 4 Door Sedan with Technology Package UA965 42,235 4 Door Sedan with Technology Package and High Performance Tires UA965 43,235 ACURA TSX 4 Door Sedan CU256, CU266 29,160 4 Door Sedan with Technology Package CU256, CU266 32,260 2009 AUDI Sample VIN: WAUHF78P39A000000 Model: HF78 BODY TYPE MODEL BASE PRICE AUDI A3 Station Wagon/6 Speed Transmission HE_8, HF_8 $26,920 Station Wagon/6 Speed Transmission − Premium HE_8, HF_8 28,420 Station Wagon/6 Speed Transmission − S-Line HE_8, HF_8 28,920 Station Wagon/Automatic Transmission HE_8, HF_8 28,400 Station Wagon/Automatic Transmission − Premium HE_8, HF_8 29,900 Station Wagon/Automatic Transmission − S-Line HE_8, HF_8 30,400 AUDI A3 QUATTRO – 4 x 4 Station Wagon – 4 cyl. -

Isley V. BMW of North America, LLC Et

Case 2:19-cv-12680-ES-MAH Document 1 Filed 05/17/19 Page 1 of 53 PageID: 1 UNITED STATES DISTRICT COURT DISTRICT OF NEW JERSEY THOMAS ISLEY, on behalf of himself and all others similarly situated, Civil Action No.: Plaintiff, v. CLASS ACTION COMPLAINT BMW OF NORTH AMERICA, LLC and BAVARIAN MOTOR WORKS AG, JURY TRIAL DEMANDED Defendants. The allegations herein are based on personal knowledge as to Plaintiff’s own conduct and are made on information and belief as to all other matters based on an investigation by counsel. INTRODUCTION 1. This is a putative class action against BMW of North America, LLC (“BMW NA”) and Bavarian Motor Works AG (“BMW AG”) (collectively “BMW”) on behalf of individuals who purchased or leased a 2012-present BMW automobile equipped with any variant of the N63TU engine, including certain model years of the BMW 5 Series, 6 Series, 7 Series, X5, and X6 (the “Class Vehicles”).1 2. BMW cars containing the N63TU engines and its subsequent variants are defective and were deceptively marketed and sold to consumers. As described in greater detail 1 Upon information and belief, the Class Vehicles include the rear-wheel drive and all-wheel drive variants of the following BMW models: 2013-2019 750i/750Li, 2013-2018 650i, 2013- 2019 650i Gran Coupe, 2013-2016 550i GT, 2014-2016 550i, 2017-2019 M550i, 2018-2019 M850i, 2014-2019 X5, 2014-2019 X6, and 2018-2019 X7. 1 Case 2:19-cv-12680-ES-MAH Document 1 Filed 05/17/19 Page 2 of 53 PageID: 2 below, BMW cars equipped with BMW’s turbocharged V8 engines have long suffered from a defect causing excessive oil consumption (the “Oil Consumption Defect”). -

BMW Engines Introduction Model

Table of Contents BMW Engines Introduction Subject Page 6 Cylinder Engines . .3 New Generation Engine Designations . .4 Engine Numbering System . .5 N52KP Engine Overview . .6 Technical Data (N52B30M1) . .8 N51 Overview . .9 N54 Engine Overview . .10 Technical Data N54 . .12 Power Output Comparison (N52 to N54) . .13 N55 Engine Overview . .14 Technical Data . .15 Full Load Diagram . .16 Current Models . .17 Engine Designation and Engine Identification . .18 Engine designation . .18 Breakdown of N55 Engine Designation . .19 Engine identification . .19 8 Cylinder Engine . .22 N63B44O0 Engine . .22 Full Load Diagram . .23 Engine Technical Data N62TU vs. N63 . .24 Engine Overview . .25 Engine Designations . .27 Engine identification and serial number . .27 12 Cylinder Engine . .29 N74B60U0 Engine . .29 N74 Engine Features . .30 Technical Data . .31 Full Load Diagram . .32 Engine Overview . .33 Engine Identification . .35 Engine designation . .35 Engine identification and number . .35 Initial Print Date: 09/06 Revision Date: 03/11 BMW Engines Introduction Model: All Production: Start of Production After completion of this module you will be able to: • Identify the most current BMW Engines • Describe the additions to the NG6 engine family • Understand the new engine designations 2 BMW Engines Introduction 6 Cylinder Engines Previously in 2005, BMW introduced the beginning of a new generation (NG) of six cylin- der engines with the N52. Since then, BMW has introduced 3 new variations of the NG6 engine family. N55 Engine The first of the new engines is the N54, which made its debut in the new 3-series coupe in September 2006. The N54 is turbocharged and uses the second generation of direct injection (DI 2). -

Table of Contents N63 Engine Workbook

Table of Contents N63 Engine Workbook Subject Page New BMW 8-Cylinder Technology . .5 Engine Output Chart . .6 Engine Designations . .6 Engine Identification and Serial Number . .6 Engine Technical Data N62TU vs. N63 . .7 Overview of Engine Changes . .8 N63 Engine Mechanical . .10 Engine Housing Components . .11 Crankcase . .11 Oil Pan . .11 Cylinder Head Covers . .12 Cylinder Head . .12 Engine Internal Components . .13 Crankshaft . .13 Timing Gear . .13 Lubrication System . .13 Camshafts . .14 Infinitely Variable Double VANOS . .15 Lubrication System . .16 Advantage of volumetric flow-controlled oil pump . .16 Functional principle of volumetric flow-controlled oil pump . .16 Pressure Relief Valve . .17 Oil Filter . .17 Oil Cooling . .17 Oil Spray Nozzles . .17 Oil spray nozzles for piston crown cooling . .17 Initial Print Date: 04/08 Revision Date: Table of Contents Subject Page Oil spray nozzles for timing chain lubrication . .17 Chain Tensioner . .17 Non-return Valves in Cylinder Head . .17 Crankcase Ventilation System . .18 Crankcase breather, naturally-aspirated engine operation . .18 Crankcase breather, turbocharged operation . .19 Oil Separator . .20 Belt Drive . .21 MSD85 Engine Management . .54 Engine Control Module . .54 Sensors . .55 Oxygen Sensors . .55 Actuators . .56 Electric Fan . .56 Air Management . .58 Air Intake and Exhaust System . .58 Air Intake System . .. -

Sponsor Classes Instructors Session Code

Session Sponsor Classes Instructors Code Domestic Vehicle Training ACDelco/WTI GM ‐ Diagnosing Multiplexed Data Bus Networks Lee Hammler 105 Diagnosing Complex Network System Failures Network Protocols: CAN, LIN, GMLAN, MOST®, and Repair Methods Focus on Diagnostic Strategies to Hone Problem Solving Skills for Serial Data Failure Modes in Multiplex Networks ACDelco/WTI GM ‐ EVAP Diagnosis Jerry Mungle 305 Overview of Evaporative Emissions and System Controls Fuel Tank Ventilation System, Charcoal Canister, Purge and Vent Valves, Fuel Tank Pressure Sensors Leak Detection Pump (LDP) Strategies and Function of Onboard Refueling Vapor Recovery (ORVR) Engine Off Natural Vacuum (EONV) Diagnosis of P0440, P0442 and Other EVAP System DTCs ACDelco/WTI GM ‐ Diesel Emissions and Exhaust Aftertreatment Lee Hammler 205 Emission Systems and Components Found on Modern Diesel Powered Vehicles Operation of Fuel Injection, Glow Plugs, Intake Air Heaters (IAH), Intake Swirl Valves, and Exhaust Gas Recirculation (EGR) Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Nitrogen Oxides Adsorbing Catalyst (NAC), NOx Storage Catalyst (NSC), Selective Catalytic Reduction (SCR), and Diesel Exhaust Fluid (DEF) Diagnostic Strategies, Known Malfunctions, Real‐World Case Studies, and Diagnostic Exercises ACDelco/WTI GM ‐ Refrigeration Diagnostics and Service Procedures Jerry Mungle 405 Designed for technicians with prior understanding of the refrigerant cycle and system operation, this seminar will provide technicians with techniques and strategies -

Table of Contents N63 Engine Workbook

Table of Contents N63 Engine Workbook Subject Page New BMW 8-Cylinder Technology . .5 Engine Output Chart . .6 Engine Designations . .6 Engine Identification and Serial Number . .6 Engine Technical Data N62TU vs. N63 . .7 Overview of Engine Changes . .8 N63 Engine Mechanical . .10 Engine Housing Components . .11 Crankcase . .11 Oil Pan . .11 Cylinder Head Covers . .12 Cylinder Head . .12 Engine Internal Components . .13 Crankshaft . .13 Timing Gear . .13 Lubrication System . .13 Camshafts . .14 Infinitely Variable Double VANOS . .15 Lubrication System . .16 Advantage of volumetric flow-controlled oil pump . .16 Functional principle of volumetric flow-controlled oil pump . .16 Pressure Relief Valve . .17 Oil Filter . .17 Oil Cooling . .17 Oil Spray Nozzles . .17 Oil spray nozzles for piston crown cooling . .17 Initial Print Date: 04/08 Revision Date: Table of Contents Subject Page Oil spray nozzles for timing chain lubrication . .17 Chain Tensioner . .17 Non-return Valves in Cylinder Head . .17 Crankcase Ventilation System . .18 Crankcase breather, naturally-aspirated engine operation . .18 Crankcase breather, turbocharged operation . .19 Oil Separator . .20 Belt Drive . .21 MSD85 Engine Management . .54 Engine Control Module . .54 Sensors . .55 Oxygen Sensors . .55 Actuators . .56 Electric Fan . .56 Air Management . .58 Air Intake and Exhaust System . .58 Air Intake System . .. -

BMW Engines Introduction Model

Table of Contents BMW Engines Introduction Subject Page 6 Cylinder Engines . .3 New Generation Engine Designations . .4 Engine Numbering System . .5 N52KP Engine Overview . .6 Technical Data (N52B30M1) . .8 N51 Overview . .9 N54 Engine Overview . .10 Technical Data N54 . .12 Power Output Comparison (N52 to N54) . .13 N55 Engine Overview . .14 Technical Data . .15 Full Load Diagram . .16 Current Models . .17 Engine Designation and Engine Identification . .18 Engine designation . .18 Breakdown of N55 Engine Designation . .19 Engine identification . .19 8 Cylinder Engine . .22 N63B44O0 Engine . .22 Full Load Diagram . .23 Engine Technical Data N62TU vs. N63 . .24 Engine Overview . .25 Engine Designations . .27 Engine identification and serial number . .27 12 Cylinder Engine . .29 N74B60U0 Engine . .29 N74 Engine Features . .30 Technical Data . .31 Full Load Diagram . .32 Engine Overview . .33 Engine Identification . .35 Engine designation . .35 Engine identification and number . .35 Initial Print Date: 09/06 Revision Date: 03/11 BMW Engines Introduction Model: All Production: Start of Production After completion of this module you will be able to: • Identify the most current BMW Engines • Describe the additions to the NG6 engine family • Understand the new engine designations 2 BMW Engines Introduction 6 Cylinder Engines Previously in 2005, BMW introduced the beginning of a new generation (NG) of six cylin - der engines with the N52. Since then, BMW has introduced 3 new variations of the NG6 engine family. N55 Engine The first of the new engines is the N54, which made its debut in the new 3-series coupe in September 2006. The N54 is turbocharged and uses the second generation of direct injection (DI 2). -

Vysoké Učení Technické V Brně Vidlicové Osmiválcové

VYSOKÉ UČENÍ TECHNICKÉ V BRNĚ BRNO UNIVERSITY OF TECHNOLOGY FAKULTA STROJNÍHO INŽENÝRSTVÍ ÚSTAV AUTOMOBILNÍHO A DOPRAVNÍHO INŽENÝRSTVÍ FACULTY OF MECHANICAL ENGINEERING INSTITUTE OF AUTOMOTIVE ENGINEERING VIDLICOVÉ OSMIVÁLCOVÉ MOTORY BMW BMW EIGHT-CYLINDER VEE-TYPE ENGINES BAKALÁŘSKÁ PRÁCE BACHELOR‘S THESIS AUTOR PRÁCE VIKTOR DOMSKÝ AUTHOR VEDOUCÍ PRÁCE Ing. LUBOMÍR DRÁPAL SUPERVISOR BRNO 2013 Vysoké učení technické v Brně, Fakulta strojního inženýrství Ústav automobilního a dopravního inženýrství Akademický rok: 2012/2013 ZADÁNÍ BAKALÁŘSKÉ PRÁCE student(ka): Viktor Domský který/která studuje v bakalářském studijním programu obor: Strojní inženýrství (2301R016) Ředitel ústavu Vám v souladu se zákonem č.111/1998 o vysokých školách a se Studijním a zkušebním řádem VUT v Brně určuje následující téma bakalářské práce: Vidlicové osmiválcové motory BMW v anglickém jazyce: BMW Eight-cylinder Vee-type Engines Stručná charakteristika problematiky úkolu: Přehled vývoje použité techniky, provedení a hlavních parametrů zážehových vidlicových osmiválcových motorů BMW v kontextu doby a v porovnání se soudobou konkurencí. Cíle bakalářské práce: Přehledně zmapujte vývoj zážehových vidlicových osmiválcových motorů BMW pro osobní automobily. Pojednejte o jejich parametrech, použitých technických řešeních a materiálech také s ohledem na požadavky soudobé legislativy. U vybraných pohonných jednotek proveďte srovnání s konkurenčními motory dané doby. Seznam odborné literatury: [1] LANGE, K. BMW Dimensions: The History of Engines – Engines that made History. 1st edition. Munich: BMW Mobile Tradition, 1999. ISBN 3-932169-05-0. [2] MTZ: MOTORTECHNISCHE ZEITSCHRIFT. Springer Automotive Media. Vedoucí bakalářské práce: Ing. Lubomír Drápal Termín odevzdání bakalářské práce je stanoven časovým plánem akademického roku 2012/2013. V Brně, dne 13.11.2012 L.S. _______________________________ _______________________________ prof. Ing.