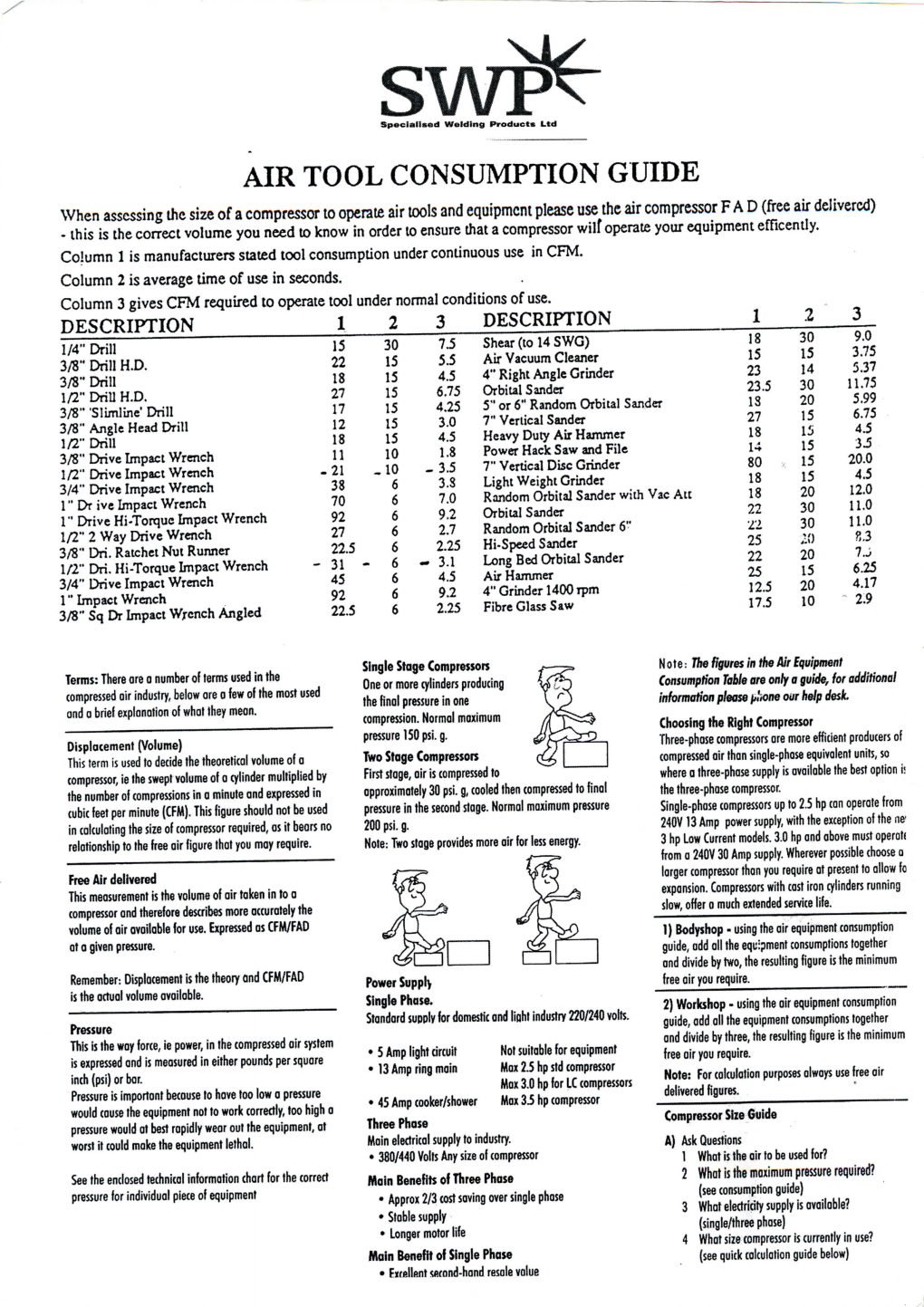

Air Tool Consumption Guide

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Rafael A. Barrantes QAS 515 Human Factors Pneumatic Rivet Gun Exchange Program on the C-17 Program November 29, 2005

Rafael A. Barrantes QAS 515 Human Factors Pneumatic Rivet Gun Exchange Program on the C-17 Program November 29, 2005 History Charles Brady King of Detroit invented the pneumatic hammer in 1890. In the late 1800’s and early 1900’s the rivet guns where were used in the rail road industry. The guns were used on small rivets on locomotives as well as swaging and sealing boiler tubes. The guns were also used for breaking old welds in thin steel. The first successful all metal airplane was built in 1915 in Germany by Junkers. The first American metal airplane to be produced in large numbers was the Ford Tri-Motor. The planes were built from 1926 thru 1933. With the advent of the metal plane, rivets were used as the primary fastener to bond skins to primary structure. Process Description Riveting is a two person task. One person is typically inside the aircraft and the other outside. The workers switch between riveting and holding a bucking bar behind the rivet. Workers communicate verbally with or without radio head sets. Workers drive approximately 400-600 rivets per day. The holes to be riveted are drilled out then reamed out to final hole size with a hand drill. The rivets are then placed in the open hole. The bucking bar is positioned behind the rivet by one worker and the rivet gun is held at the head of the rivet by the other worker. The rivet gun operator then squeezes the trigger in several short bursts to drive the rivet into place. -

Construction Manual, Which, Together with a Complete Set of Drawings Will Help You to Accomplish This Wonderful Feat: to Build and Fly Your Own Two-Seat Aircraft

FOREWORD Dear Builder: Congratulations on your decision to build a Zenith aircraft. Here is the construction manual, which, together with a complete set of drawings will help you to accomplish this wonderful feat: to build and fly your own two-seat aircraft. The first part of the manual deals with some of the tools required for this project and the procedure with which to use them efficiently. Materials and hardware are also presented as well as tips on workmanship, corrosion protection and tolerances. The second part is a progressive step-by-step construction guide; beginning with the rudder assembly, it describes every aspect of airframe construction. The last part of this manual is a “weight and balance form”. The drawings and manual have been laid out to allow the average builder to understand them without having to write or call the designer or factory. They are not "perfect" or in color but supply all the information required completing your aircraft to the design specifications. It is important to remember that builders have used the proposed building sequence successfully for over two decades. It would therefore be wise to use this experience and stick to the sequence. The secret of good progress is not to work like crazy in sudden short-lived spurts; it lies in steady and continuous effort. Homebuilding your aircraft is a tremendously rewarding hobby. You are the one with enough courage to do what others only dream of. Homebuilding is a useful, educational and recreational activity. While learning, you will enjoy building, and then flying... and you are contributing to the progress of aviation. -

Hand Tools 8 21 12 Paginated.Fm

280 Pearlgreen Corporation Tools, Hand The Industrial Supply Group Gooseneck Crow Bar STANLEY TOOLS Phillips Bit Wonder Bar 2” Length • S-2 tool steel • Rockwell Hardness 60-64 • Length: 2 in. Contoured bar. Ideal for pulling nails, prying, lifting, scraping. Bevelled nail slot both ends. 4 per box., Width: 1 3/8 in., Length: 12 1/2 in. Mfg. No. Size PG No. 45008 #1 BIT-PX1 Mfg. No. PG No. 45010 #2 BIT-PX2 55-515 ST55-515 45012 #3 BIT-PX3 Fully painted black gooseneck wrecking bar. Used to open crates and boxes. STANLEY TOOLS Slotted Bit Nail Puller Handle Diameter Length Mfg. No. (in.) (in.) PG No. MM2332 ¹⁄₂ 12 BAR-12 • S-2 tool steel MM2342 ⁵⁄₈ 18 BAR-18 • Rockwell Hardness 60-64 ³⁄₄ MM2352 24 BAR-24 • Length: 1 in. MM2362 ³⁄₄ 30 BAR-30 • Double end puller features 90 deg. and 30 deg. offset claws MM2372 ³⁄₄ 36 BAR-36 • Fully sharpened claw tips Mfg. No. Size PG No. Stripping Bar • Size: 5/8 in. 45020 #6 - 8 BIT-S06 • Overall Length: 11 in. 45022 #8 - 10 BIT-S08 45024 #10 - 12 BIT-S10 Mfg. No. PG No. Spanner Bit 55-035 ST55-035 48 in. Stripping Bar with Claw Philips Bit Mfg. No. PG No. 1168800 BAR-48 Security Bit, Fits all power and hand held bit drives, various sizes Straight Crow Bar • S-2 tool steel • Rockwell Hardness 60-64 Mfg. No. Size (in.) PG No. • Length: 1 in. 1916 #6 SPANNER-B06 1918 #8 SPANNER-B08 1920 #10 SPANNER-B10 Mfg. No. Size PG No. -

View Our Welding Kit Catalog

PARTSMASTER WILL KEEP YOU RUNNING MILITARY CATALOG MILITARY OPERATIONS DEPLOYMENT READY SOLUTIONS • Partsmaster sells to the Army, Navy, Air Force, Marines, and National Guard. • Partsmaster military solutions are created by veterans. • Partsmaster hires experienced veterans to help grow the expanding military business. Rob Ramsey Stan Blitz Director of Military Accounts Army Account Manager Chief Warrant Officer 4, Retired Chief Warrant Officer 3, Retired US Army US Army Ray Larry Channel Manager Sergeant First Class, Retired US Army PARTSMASTER MAINTENANCE REPAIR OPERATING SUPPLY Partsmaster is a specialty MRO (Maintenance, Repair and Operating Supply) company dedicated to making our customers’ work easier. Our superior products are developed with a focus on increased productivity, asset longevity, safer user experience, and environmental responsibility. Partsmaster sells industrial maintenance supplies for welding, concrete repairs, specialty abrasives, fasteners and hardware, hand tools and cutting tools. Partsmaster was established in 1968 as a division of NCH Corporation, a global leader in industrial and commercial maintenance products and services since 1919. NCH has over 8,000 employees, with offices and manufacturing plants located on five continents. NCH is relied upon by companies in over 50 countries to solve maintenance problems with the most innovative and effective products and services. NCH GLOBAL NORTH AMERICA EUROPE COVERAGE 2 COUNTRIES 26 COUNTRIES 1,133 SALES ASSOCIATES 2,134 SALES ASSOCIATES • Founded in 1919 • Family -

Roof Side Rail Supercrew

3/23/2021 2021 F-150 501-28 Roof Sheet Metal Repairs 2021 F-150 Removal and Installation Procedure revision date: 10/8/2020 Roof Side Rail - SuperCrew Special Tool(s) / General Equipment 6.5 mm Drill Bit Polydrive Bit Socket Self-Piercing Rivet (SPR) Remover/Installer Belt Sander Blind Rivet Gun Hot Air Gun Locking Pliers Materials Name Specification Metal Bonding Adhesive - TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B Seam Sealer - TA-2-B, 3M™ 08308, LORD Fusor® 803DTM Removal WARNING: Electric vehicles damaged by a crash may have compromised high voltage safety systems and present a potential high voltage electrical shock hazard. Exercise caution and wear appropriate Personal Protective Equipment (PPE) safety gear, including high voltage safety gloves and boots. Remove all metallic jewelry, including watches and rings. Isolate the HV system as directed by the Ford Emergency Response Guide for the vehicle. Failure to follow these instructions may result in serious personal injury or death. NOTICE: Battery electric vehicle (BEV), hybrid electric vehicle (HEV) and plug-in hybrid electric vehicle (PHEV) contain a high-voltage battery. Before cutting or welding near the high-voltage battery it must be removed to avoid damage. 1. WARNING: Before beginning any service procedure in this manual, refer to health and safety warnings in section 100-00 General Information. Failure to follow this instruction may result in serious personal injury. Refer to: Health and Safety Precautions (100-00 General Information, Description and Operation). Refer to: High Voltage System Health and Safety Precautions - Overview (100-00 General Information, Description and Operation). -

AUCTION DATE MONDAY, MAY 18, 2020 9:00 A.M

FARM MACHINERY CONSIGNMENT AUCTION DATE MONDAY, MAY 18, 2020 9:00 a.m. CHANGE: Sale Location: 2 miles East of Beloit, KS on #9 Hwy. John Deere 9610 Combine Various Ford Hub Caps Heat Gun, Safety Glasses, Misc. John Deere 7200 Maxi-Emerge 12 Row Mercury XR6 150 HP Black Max Outboard Grinder Wheels, Basin Wrench, Etc. Planter Boat Motor Washer Hose, Door knobs, AC Hose Haybuster 1000 Tub Grinder 4-In-1 John Deere Skid Steer Bucket Pop Rivet Gun, Multimeter Crustbuster 15' No-Till Drill Gravely 60" Lawn Mower Sockets, Files,Clevis Winkel Loading Chute 1979 WW 16' Stock Trailer Automatic Fuel Hose Handle Terra-Gator 1664T Dry Spreader 1977 Ford F-150 Ranger, 4X4, 351=Auto Grease Gun, Brake Shoes Westfield 100-41 PTO Auger John Deere L110 Riding Mower w/Bagger, Micrometer, Electric Drill Sunflower 9434 Drill 282 Hours 24" Rigid Pipe Wrench 1992 48' Curtain Trailer Solar Coolant Recycler Model 5055 7 Assorted Gear Pullers 1999 48' Curtain Trailer Tire Stand Toolbox w/Contents 48' Curtain Trailer Dog Crate Flat of Pliers & Nippers Case IH Flexhead Row Finders Several New Shocks (2) Metal Trays Few Hedge Posts Grill Guard Hammer/Hatchet John Deere 1600A Moco Pull Swing Seat Covers (2) Flats of Misc. Tools Swather 2 Sets of Goodyear Wrangler 275/65R18 (3) Plastic Tubs John Deere 346 Square Baler, Wire- Accu- LT225/75R16 Tires Flat of Various Tools mulator LT275/65R18 Tires/Rims Flat w/Hitch & Balls Kent Series V, 26' Field Cultivator Goodrich 275/65R18 All Terrain Flat of Various Wrenches Skid Steer Bale Claw XL Semi Tires 285/75R 24.5 Flat of -

HHE Report No. HETA-94-0425-2513, Gulfstream Aerospace Corporation, Savannah, Georgia

ThisThis Heal Healthth Ha Hazzardard E Evvaluaaluationtion ( H(HHHEE) )report report and and any any r ereccoommmmendendaatitonsions m madeade herein herein are are f orfor t hethe s sppeeccifiicfic f afacciliilityty e evvaluaaluatedted and and may may not not b bee un univeriverssaalllyly appappliliccabable.le. A Anyny re reccoommmmendaendatitoionnss m madeade are are n noot tt oto be be c consonsideredidered as as f ifnalinal s statatetemmeenntsts of of N NIOIOSSHH po polilcicyy or or of of any any agen agenccyy or or i ndindivivididuualal i nvoinvolvlved.ed. AdditionalAdditional HHE HHE repor reportsts are are ava availilabablele at at h htttptp:/://ww/wwww.c.cddcc.gov.gov/n/nioiosshh/hhe/hhe/repor/reportsts ThisThis HealHealtthh HaHazzardard EEvvaluaaluattionion ((HHHHEE)) reportreport andand anyany rreeccoommmmendendaattiionsons mmadeade hereinherein areare fforor tthehe ssppeecciifficic ffaacciliilittyy eevvaluaaluatteded andand maymay notnot bbee ununiiververssaallllyy appappapplililicccababablle.e.le. A AAnynyny re rerecccooommmmmmendaendaendattitiooionnnsss m mmadeadeade are areare n nnooott t t totoo be bebe c cconsonsonsiideredderedidered as asas f fifinalnalinal s ssttataatteteemmmeeennnttstss of ofof N NNIIOIOOSSSHHH po popolliilccicyyy or oror of ofof any anyany agen agenagencccyyy or oror i indndindiivviviiddiduuualalal i invonvoinvollvvlved.ed.ed. AdditionalAdditional HHEHHE reporreporttss areare avaavaililabablele atat hhtttpp::///wwwwww..ccddcc..govgov//nnioiosshh//hhehhe//reporreporttss This Health Hazard Evaluation (HHE) report and any recommendations made herein are for the specific facility evaluated and may not be universally applicable. Any recommendations made are not to be considered as final statements of NIOSH policy or of any agency or individual involved. Additional HHE reports are available at http://www.cdc.gov/niosh/hhe/reports HETA 94-0425-2513 NIOSH INVESTIGATORS: July 1995 Pete Fatone, M.S. -

Automated Property System Article Codes Article Code Category

AUTOMATED PROPERTY SYSTEM ARTICLE CODES ARTICLE CODE CATEGORY BRACELET BRACEL A* BROOCH, PIN PIN A* BUCKLE BUCKLE A* CHARM, JEWELRY CHARM A* CUFF LINKS C LINK A* EARRINGS EARRIN A* GEMS GEMS A* NECKLACE NECKLA A* PENDANT/LOCKET PENDAN A* PIN, BROOCH PIN A* RING RING A* WATCH WATCH A* BICYCLE SHOCKS SHOCKS B BOY 1 SPEED BIKE B01 B BOY 2 SPEED BIKE B02 B BOY 3 SPEED BIKE B03 B BOY 4 SPEED BIKE B04 B BOY 5 SPEED BIKE B05 B BOY 6 SPEED BIKE B06 B BOY 7 SPEED BIKE B07 B BOY 8 SPEED BIKE B08 B BOY 9 SPEED BIKE B09 B BOY 10 SPEED BIKE B10 B BOY 11 SPEED BIKE B11 B BOY 12 SPEED BIKE B12 B BOY 13 SPEED BIKE B13 B JUNE 2009 AUTOMATED PROPERTY SYSTEM ARTICLE CODES ARTICLE CODE CATEGORY BOY 14 SPEED BIKE B14 B BOY 15 SPEED BIKE B15 B BOY 16 SPEED BIKE B16 B BOY 17 SPEED BIKE B17 B BOY 18 SPEED BIKE B18 B BOY 19 SPEED BIKE B19 B BOY 20 SPEED BIKE B20 B BOY 21 SPEED BIKE B21 B BOY 22 SPEED BIKE B22 B BOY 23 SPEED BIKE B23 B BOY 24 SPEED BIKE B24 B BOY 26 SPEED BIKE B26 B BOY 27 SPEED BIKE B27 B BOY 28 SPEED BIKE B28 B BOY 30 SPEED BIKE B30 B BOY 32 SPEED BIKE B32 B BOY 36 SPEED BIKE B36 B GIRL 1 SPEED BIKE G01 B GIRL 2 SPEED BIKE G02 B GIRL 3 SPEED BIKE G03 B GIRL 4 SPEED BIKE G04 B GIRL 5 SPEED BIKE G05 B GIRL 6 SPEED BIKE G06 B GIRL 7 SPEED BIKE G07 B GIRL 8 SPEED BIKE G08 B GIRL 10 SPEED BIKE G10 B GIRL 12 SPEED BIKE G12 B JUNE 2009 AUTOMATED PROPERTY SYSTEM ARTICLE CODES ARTICLE CODE CATEGORY GIRL 15 SPEED BIKE G15 B GIRL 16 SPEED BIKE G16 B GIRL 18 SPEED BIKE G18 B GIRL 19 SPEED BIKE G19 B GIRL 20 SPEED BIKE G20 B GIRL 21 SPEED BIKE G21 B GIRL -

CASS-Tools-Library.Pdf

CASS Tools Library Carpentry and Woodworking • Awl • Bars (cat's paw, crowbar, pry bar, ripping chisel, tack puller) • Butt marker (3 1/2" & 4") • Cabinet scraper • Chalk line • Chisels, gouges & parting tools • Dado set • Door installation kit • Doweling jig • Drills • Gutter cleaner • Hammers (brick, drywall, ballpeen, dead-blow, framing, mallets, shingle hatchet, sledge, curved claw, tack) • Hinge Template • Levels (torpedo, 2', 3', 4', 6', laser) • Marking gauge • Measuring wheel • Nail puller, nail set • Planes (block, bench, spokeshave, rabbet) • Roofing spades (shingle remover) • Rasps (surform tool) • Saws (back, compass, coping, crosscut, hacksaw, jab, keyhole, miter [with box], rod, shortcut) • Screwdrivers (off-set, Phillips, Robertson, slotted, Torx, Yankee) • Screw extractor & drill bit set • Squares (combination, rafter, carpenter's, Tri-square, Universal square) • Stapler, tack hammer • Stud finders (stud sensor) • Tape measure • Water level Clamps • 2-Way Edging Clamp • Assembly Square • Angle clamp • Bar clamp 1 • C-clamp • Cabinet clamp • Edge clamp • Hand screw clamp • Quick grip clamp/spreader • Sliding arm clamp • Spring clamp • Steel pipe clamps • Vise grips Concrete and Masonry • Brick hammer, joiner, trowel • Bull float, magnesium • Cement finishing tools (edger, float, groover, hawk, joiner, trowels, tuck pointer) • Cold chisels • Concrete Cutting Saw* • Dust pump (blower for cement dust) • Fresno trowel (with handles) • Leaf blower* • Mason's layout tools (line winder, stretchers, blocks) • Mixing paddle • Mortar -

DAR Developer’S Assessment Report

GLOSSARY Air Photo A photograph taken from the air that covers a relatively small area, and which is used in conjunction with other, similar and overlapping photos Archaeologist Someone who studies historical evidence of communities and civilisation Cumulative Effects Effects from one project or site which add to effects from one or more other projects or sites DAR Developer’s Assessment Report DPD Developer’s Project Description Exacerbate Make worse Monitoring The observation, sampling or other measurement of prevailing conditions Mulch Material (usually vegetation, such as grass) used to provide nutrients and protect seeds and young plant shoots Natality Birthing Orthophoto A photograph taken from the air that covers a larger area than an air photo, and which is used in conjunction with other, similar photos that do not overlap but provide a photo map of a region Perma-frost Permanently frozen ground Reclamation Return the ground to a useable condition Rehabilitate Fix, mend or make better Revegetation The process of restoring plants, usually by surface preparation and seed addition Scarify To break up and smooth out the surface Sedimentation The blinding of a stream bed from the settling of fine particles Talus The weathered material (rocks and sediment) that collects at the bottom of an eroding slope TOR Terms of reference and work plan Page 42 of 81 May 2005 APPENDIX B Noise Data Page 68 of 81 May 2005 APPENDIX B Noise Data HEARS NOISE DATA LISTING II (ALPHABETICAL) EQUIPMENT TYPE NOISE CATEGORY LEVEL AH-64, Attack Helicopter steady-state -

Buck Riveting Basics Tools and Techniques

Buck Riveting Basics Tools and Techniques Written by Steve Bryant (2014) Revised by Steve Hingtgen (2021) Overview Solid rivets, also referred to as buck rivets, have been used as the primary fastener type in the construction of aluminum-framed travel trailers for more than 80 years. These trailers (and a few motorhomes) employ a number of construction techniques (including bucked rivets) that have been borrowed from the aircraft industry. Bowlus, Airstream, Curtis Wright, Avion, Silver Streak, Spartan and many other manufacturers have used bucked rivets. These solid rivets are lightweight, strong and inexpensive fasteners. That’s why they were chosen for aluminum aircraft construction and the same advantages hold true for travel trailers. It’s important to note that in order to repair a travel trailer that uses bucked rivets, the interior walls in the vicinity of the bucked rivets under alteration must be removed in order to access the back side of the rivet so that a bucking bar can be used. Another category of rivets, blind rivets (commonly referred to as pop rivets), may be used to repair riveted panels from one side only. The well-known shaveable bulb-tite “Olympic” rivet is in this category. Although, blind rivets have the advantage of convenience, they also have a number of limitations; generally the repair or alteration will not have the same appearance, strength or waterproof characteristics as the original bucked rivet approach. Basic Principles A bucked rivet is a round fastener that attaches two or more pieces of metal together. The rivet is driven by a rivet gun (a specialized pneumatic hammer) with an attached rivet set (strike surface) shaped to match the rounded shape of the manufactured head of the rivet. -

RIVETING EQUIPMENT.Pdf

RIVETING EQUIPMENT Part No. Length Diameters Available Price 470 Series Series Universal Straight Series 470-2 2-1/2” 3/32, 1/8, 5/32, 3/16, 1/4 470-3 3-1/2” 3/32, 1/8, 5/32, 3/16, 1/4, 7/32 470-5 5-1/2” 3/32, 1/8, 5/32, 3/16, 1/4 470-7 7-1/2” 3/32, 1/8, 5/32, 3/16 470-10 10-1/2” 3/32, 1/8, 5/32, 3/16 0470 Series 10 Degree Offset Series 0470-3 3-1/2” 3/32, 1/8, 5/32, 3/16, 1/4 0470-5 5-1/2” 3/32, 1/8, 5/32, 3/16, 1/4 0470-7 7-1/2” 3/32, 1/8, 5/32, 3/16 0470-10 10-1/2” 3/32, 1/8, 5/32, 3/16 Double Offset Series 1470 Series 1470-5 5-1/2” 3/32, 1/8, 5/32, 3/16 1470-7 7-1/2” 3/32, 1/8, 5/32, 3/16 1470-10 10-1/2” 3/32, 1/8, 5/32, 3/16 Flush Rivet Sets 90 3-1/2” 1” Dia. 94 3-1/2” 1-1/4” Dia. 90 Series 95 5-1/2” 1-1/4” Dia. 094 3-1/2” 1-1/4” Dia. 10 degree offset 095 5-1/2” 1-1/4” Dia. 10 degree offset RIVET SET MIX For universal and flush riveting. Fits all .401 rivet guns. STANDARD OFFSET EXTRA LONG The 5 piece mix contains the following sizes: The offset mix contains the following sizes: The extra long mix contains the following 4 3/32”, 1/8”, 5/32”, 3/16” and 1 flush set.