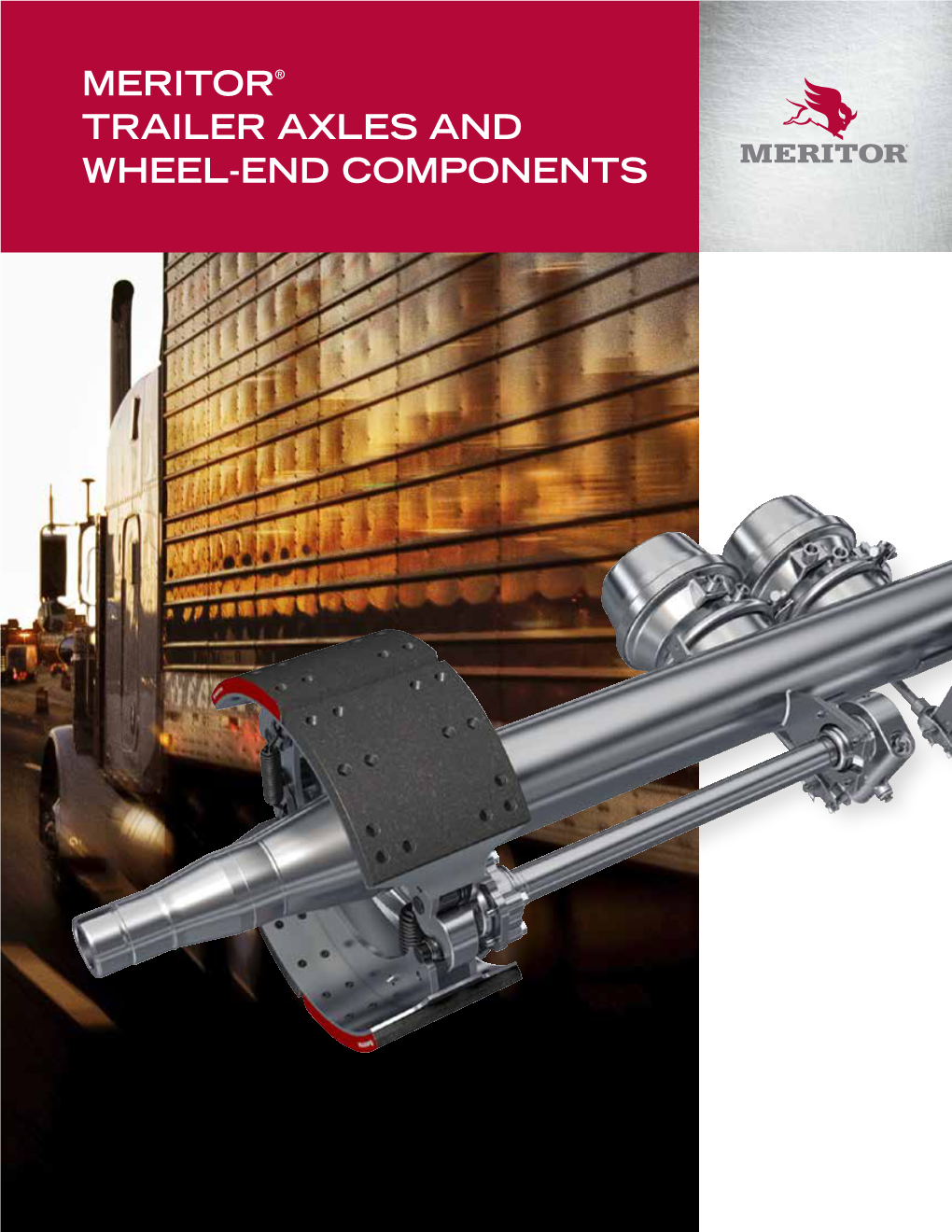

Meritor® Trailer Axles and Wheel-End Components Trailer-Performance Technology Based on a Century of Experience

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Typical Brake Disc and Brake Pad Damage Patterns and Their Root Causes

Typical brake disc and brake pad damage patterns and their root causes www.meyle.com Good brakes save lives! The consequences of choosing the wrong or low-grade brake parts can be dramatic. Only use the brake components specified for the given vehicle application. Brake system repairs may only be performed by skilled and trained personnel. Adhere to the vehicle or brake manufacturer‘s specifications at all times. MEYLE Platinum Disc: When installing new brake components, observe the All-new finish. No degreasing. following: Fit and go. > Always replace brake pads along with brake discs. > Always replace all brake discs and pads per axle. All MEYLE brake discs come as ready-to-mount assemblies, most of > Be careful to bed in new brake discs and pads properly. them featuring the locating screw. They do not require degreasing > Avoid unnecessary heavy braking on the first 200 kilometres. and are resistant to rim cleaners. Cutting-edge paint technology > Brake performance may be lower on the first 200 driven made in Germany provides MEYLE Platinum Discs with long-term kilometres. anti-corrosion protection while adding a brilliant appearance. Further refinement of the tried-and-tested MEYLE finish has led to Check for functional reliability after installation: environmentally-friendly production processes. > Pump brake pedal until it becomes stiff. > Pedal travel must not vary at constant pedal load after pedal has MEYLE Platinum Discs – the safety solution engineered by one been depressed several times. of the industry‘s leading experts in coated brake discs. > Check wheels for free rotation. > Check brake fluid level in expansion tank and top up, if required. -

A Review of Rear Axle Steering System Technology for Commercial Vehicles

연구논문 Journal of Drive and Control, Vol.17 No.4 pp.152-159 Dec. 2020 ISSN 2671-7972(print) ISSN 2671-7980(online) http://dx.doi.org/10.7839/ksfc.2020.17.4.152 A Review of Rear Axle Steering System Technology for Commercial Vehicles 하룬 아흐마드 칸1․윤소남2*․정은아2․박정우2,3․유충목4․한성민4 Haroon Ahmad Khan1, So-Nam Yun2*, Eun-A Jeong2, Jeong-Woo Park2,3, Chung-Mok Yoo4 and Sung-Min Han4 Received: 02 Nov. 2020, Revised: 23 Nov. 2020, Accepted: 28 Nov. 2020 Key Words:Rear Axle Steering, Commercial Vehicles, Centering Cylinder, Tag Axle Steering, Maneuverability Abstract: This study reviews the rear or tag axle steering system’s concepts and technology applied to commercial vehicles. Most commercial vehicles are large in size with more than two axles. Maneuvering them around tight corners, narrow roads, and spaces is a difficult job if only the front axle is steerable. Furthermore, wear and tear in tires will increase as turn angle and number of axles are increased. This problem can be solved using rear axle steering technology that is being used in commercial vehicles nowadays. Rear axle steering system technology uses a cylinder mounted on one of rear axles called a steering cylinder. Cylinder control is the primary objective of the real axle steering system. There are two types of such steering mechanisms. One uses master and slave cylinder concept while the other concept is relatively new. It goes by the name of smart axle, self-steered axle, or smart steering axle driven independently from the front wheel steering. All these different types of steering mechanisms are discussed in this study with detailed description, advantages, disadvantages, and safety considerations. -

Meritor® Tire Inflation System (Mtis) by Psi™ Including Meritor Thermalert™

MERITOR® TIRE INFLATION SYSTEM (MTIS) BY PSI™ INCLUDING MERITOR THERMALERT™ PB-9999 TABLE OF CONTENTS Control Box ............................................................................................................6 Exploded Views ......................................................................................................2 Guidelines for Specifying the Correct Kits for the Meritor Tire Infl ation System ......4 Hoses .....................................................................................................................8 Hubcaps ................................................................................................................11 Lights ....................................................................................................................6 Press Plug Kits ......................................................................................................9 Retrofi t Kit .............................................................................................................3 Through-Tees and Stators ......................................................................................8 Tools ......................................................................................................................10 Numerical Parts Listing .........................................................................................12 CONTROL BOX ASSEMBLY DUAL WHEEL END ASSEMBLY 2 U.S. 888-725-9355 Canada 800-387-3889 MERITOR TIRE INFLATION SYSTEM RETROFIT KIT Qty. Per Qty. Per Tandem Tandem -

Adaptive Brake by Wire from Human Factors to Adaptive Implementation

UNIVERSITY OF TRENTO Doctoral School in Engineering Of Civil And Mechanical Structural Systems Adaptive Brake By Wire From Human Factors to Adaptive Implementation Thesis Tutor Doctoral Candidate Prof. Mauro Da Lio Andrea Spadoni Mechanical and Mechatronic Systems December 2013 - XXV Cycle 1 Adaptive Brake By Wire From Human Factors to Adaptive Implementation 2 Adaptive Brake By Wire From Human Factors to Adaptive Implementation Table of contents TABLE OF CONTENTS .............................................................................................................. 3 LIST OF FIGURES .................................................................................................................... 6 LIST OF TABLES ...................................................................................................................... 8 GENERAL OVERVIEW .............................................................................................................. 9 INTRODUCTION ................................................................................................................... 12 1. BRAKING PROCESS FROM THE HUMAN FACTORS POINT OF VIEW .................................... 15 1.1. THE BRAKING PROCESS AND THE USER -RELATED ASPECTS ......................................................................... 15 1.2. BRAKE ACTUATOR AS USER INTERFACE ................................................................................................. 16 1.3. BRAKE FORCE ACTUATION : GENERAL MOVEMENT -FORCE DESCRIPTION ...................................................... -

1976 Technical Documentation Locomotive Truck Hunting M.Pdf

TECHNICAL DOCUMENTATION LOCOMOTIVE TRUCK HUNTING MODEL V. K. Garg OHO G. C. Martin P. W. Hartmann J. G. Tolomei mnnnn irnational Government-Industry 04 - Locomotives ch Program on Track Train Dynamics R-219 TE C H N IC A L DOCUMENTATION rnn nnn LOCOMOTIVE TRUCK HUNTING MODEL V. K. Garg G. C. Martin P. W. Hartmann a a J. G. Tolomei dD 11 TT|[inr i3^1 i i H§ic§ An International Government-Industry Research Program on Track Train Dynamics Chairman L. A. Peterson J. L. Cann Director Vice President Office of Rail Safety Research Steering Operation and Maintenance Federal Railroad Administration Canadian National Railways G. E. Reed Vice Chairman Director Committee W. J. Harris, Jr. Railroad Sales Vice President AMCAR Division Research and Test Department ACF Industries Association of American Railroads D. V. Sartore or the E. F. Lind Chief Engineer Design Project Director-Phase I Burlington Northern, Inc. Track Train Dynamics Southern Pacific Transportation Co. P. S. Settle Tack Tain President M. D. Armstrong Railway Maintenance Corporation Chairman Transportation Development Agency W. W. Simpson Dynamics Canadian Ministry of Transport Vice President Engineering W. S. Autrey Southern Railway System Chief Engineer Atchison, Topeka & Santa Fe Railway Co. W. S. Smith Vice President and M. W. Beilis Director of Transportation Manager General Mills, Inc. Locomotive Engineering General Electric Company J. B. Stauffer Director M. Ephraim Transportation Test Center Chief Engineer Federal Railroad Administration Electro Motive Division General Motors Corporation R. D. Spence (Chairman) J. G. German President Vice President ConRail Engineering Missouri Pacific Co. L. S. Crane (Chairman) President and Chief W. -

Anti-Lock Brake System (ABS)

Anti-lock Brake System (ABS) Anti-lock Brakes (US:EX, Canada: EX-R) Your car is equipped with an Anti-lock Braking System (ABS). This system helps you to maintain stopping and steering control. It does this by helping to prevent the wheels from locking up during hard braking. The ABS is always "ON." It requires no special effort or driving technique. You will feel a pulsation in the brake pedal when the ABS activates. Activation varies with the amount of traction your tires have. On dry pavement, you will need to press on the brake pedal very hard before you feel the pedal pulsation, that means the ABS has activated. However, you may feel the ABS activate immediately if you are trying to stop on snow or ice. Under all conditions, the ABS is helping to prevent the wheels from locking during hard braking so you can maintain steering control. You should continue to press on the brake pedal with the same force. You may feel a slight movement of the brake pedal just after you start the engine. This is the ABS working. The ABS is self-checking. If anything goes wrong, the ABS indicator on the instrument panel comes on (see ABS page 45). This means the Anti-lock function of the braking system has shut down. The brakes still work like a conventional system providing normal stopping ability. You should have the dealer inspect your car as soon as possible. The ABS works by comparing the speed of the wheels. When replacing tires, use the same size originally supplied with the car. -

Specifiers & Installers Guide to TORSION BAR APPLICATIONS

Specifiers & Installers Guide To TORSION BAR APPLICATIONS WELCOME Thank you for specifying Sauber Torsion Bars. By choosing us as your stability partner, you derive the following benefits: * Improved Stability * Stability is safety, and safety is our first concern. A Sauber Torsion Bar can eliminate unwanted counterweight, offering your users an extra safety margin. Because Sauber bars don't rigidize the chassis frame, they always provide a smooth, quiet ride. * Long Life * Premium bronze and galvanized components. Bushings guaranteed and replaced as/if needed for 10 years. 10 Year parts coverage when inspected at no greater than four month intervals. * Excellent Documentation * Our comprehensive applications charts, installation instructions and detailed drawings provide the vital information you and your installers need in an organized format. * Superior Support * Toll-free phone and fax service from anywhere in North America provides easy access to the resources of our organization through your personal company representative. * Lower Life Cycle Costs * Since it takes less time to mount our bar, its installed cost can actually be less than other alternatives. Sauber Torsion Bars are designed and built to last as long as your chassis. * Extensive Inventory * Our inventory power puts our bar on the floor just when you want it. Your production schedule can't wait on your suppliers, and with us as your partner, it won't. * More Choices * Underframe or overframe, nobody provides more installation options than we do. More choices mean a better -

Road Map for the Future Making the Case for Full-Stability

ROAD MAP FOR THE FUTURE MAKING THE CASE FOR FULL-STABILITY Bendix Commercial Vehicle Systems LLC 901 Cleveland Street • Elyria, Ohio 44035 1-800-247-2725 • www.bendix.com/abs6 road map for the future : making the case for full-stability TABLE OF CONTENTS 1 : Important Terms ............................................... 3-4 2 : Executive Summary ............................................. 5-7 3 : Understanding Stability Systems .................................. 8-12 4 : The Difference Between Roll-Only and Full-Stability Systems ...........13-23 5 : Stability for Straight Trucks/Vocational Vehicles ......................24-26 6 : Why Data Supports Full-Stability Systems ..........................27-30 7 : The Safety ROI of Stability Systems ................................31-33 8 : Recognizing the Limitations of Stability Systems ......................34-37 9 : Stability System Maintenance .....................................38-40 10 : Stability as the Foundation for Future Technologies ...................41-42 11 : Conclusion .................................................. 43-44 12 : Appendix A: Analysis of the “Large Truck Crash Causation Study” ..... 45-46 13 : About the Authors ................................................47 road map for the future : making the case for full-stability 1 : 1 2 IMPORtant teRMS Directional Instability Before delving into information about the The loss of the vehicle’s ability to follow the driver’s steering, technological differences acceleration or braking input. between commercial vehicle -

Knowing Your Chassis V2

1 2 3 4 5 Top 10 attributes customer desire in a diesel motorhome chassis: 1. Reliability of the chassis 2. Chassis warranty 3. Stable ride 4. Overall driving comfort 5. Confident handling 6. Reputation of the service network 7. Reputation of the chassis manufacturer 8. Durability of parts 9. Responsiveness of company to customers 10. Number of authorized service locations 6 7 All warranties are comppyletely transferable www.freightlinerchassis.com 8 9 10 www.freightlinerchassis.com 11 12 Are you in this picture? Are you enjoying the many benefits the FCOC has to offer? Join today! Come visit the FCCC display after the seminar 13 Topics include: Air brake system Electrical system Maintenance intervals Weight distribution Vehicle storage guidelines Much much more! Contact: Debbie Moore at 864-206-8267 or via Email at [email protected] Or register on-line at: www.freightlinerchassis.com Click on “Motorhome” Click on “Owner Info” tab to register 14 We are Driven By You - our customer! 15 •CttIfContact Informa tion •Tire Care •Weight Distribution •Allison Transmission •Air Brake System •Pre-Trip Inspection •Reference Material 16 Visit our web site at www.freightlinerchassis.com 17 18 19 Tire Care The most important factor in maximizing the life of your tires is maintaining proper inflation pressure. An under-inflated tire will build up excessive heat that may go beyond the prescribed limits of endurance of the rubber and the radial cords. Over inflation will reduce the tire's footprint on the road, reducing the traction, braking capacity and handling of your vehicle. An over-inflated tire will also cause a harsh ride, uneven tire wear and will be more susceptible to impact damage. -

2018 GMC SIERRA DENALI (1500) FAST FACT Sierra Denali Customers' Number One Reason for Purchase Is Exterior Design. BASE PRIC

2018 GMC SIERRA DENALI (1500) FAST FACT Sierra Denali customers’ number one reason for purchase is exterior design. BASE PRICE $53,900 (2WD – incl. DFC) EPA VEHICLE CLASS Full-size truck NEW FOR 2018 • Exterior colors: Quicksilver Metallic and Red Quartz Tintcoat • Tire pressure monitor system now includes tire fill alert VEHICLE HIGHLIGHTS • Sierra Denali is offered exclusively as a crew cab in 2WD and 4WD models, with a 5’ 8” box or 6’ 6” box (6’ 6” box only with 4WD) • Standard LED headlamps with GMC signature LED daytime running lights, thin-profile LED fog lamps and LED taillamps • Signature Denali chrome grille, unique 20-inch wheels, 6-inch chrome assist steps, unique interior decorative trim, a polished stainless steel exhaust outlet, body-color front and rear bumpers and a factory-installed spray-on bed liner with a three-dimensional Denali logo • High-tech interior with an exclusive 8-inch-diagonal Customizable Driver Display – with unique Denali-themed screen graphics at start-up – that can show relevant settings, audio and navigation information in the instrument panel • Denali-specific interior details include script on the bright door sills and embossed into the front seats, real aluminum trim, Bose audio system, heated and ventilated leather-appointed front bucket seats, heated steering wheel and a power sliding rear window with defogger • Denali Ultimate Package is available on 4WD models and includes 6.2L engine, 22-inch aluminum wheels, power sunroof, trailer brake controller, tri-mode power steps and chrome recovery hooks • 8-inch-diagonal Color Touch navigation radio with GMC Infotainment includes Apple CarPlay and Android Auto phone projection capability • Available 4G Wi-Fi hotspot (includes three-month/3GB data trial) • Heated and ventilated, perforated leather-trimmed front seats • Heated, leather-wrapped steering wheel • Teen Driver • Wireless charging • Magnetic Ride Control is standard. -

Eaton® Repair Information

® Eaton October, 1991 Hydrostatic Transaxle Repair Information A 751, 851, 771, and 781 Transaxle 1 The following repair information applies to mance. Work in a clean area. After disassem- the Eaton 751, 851,771, and 781 series hydro- bly, wash all parts with clean solvent and blow static transaxles. the parts dry with air. Inspect all mating sur- faces. Replace any damaged parts that could cause internal leakage. Do not use grit paper, files or grinders on finished parts. Note: Whenever a transaxle is disassembled, our recommendation is to replace all seals. Lubricate the new seals with petroleum jelly before installation. Use only clean, recom- mended hydraulic fluid on the finished sur- faces at reassembly. Part Number, Date of Assembly, and Input Rotation Stamped on this Surface 6 The following tools are required for disas- Assembly Date of Part Number Input Rotation Build Code sembly and reassembly of the transaxle. (CW or CCW) • 3/8 in. Socket or End Wrench Customer • 1 in. Socket or End Wrench Part Number XXX-XXX XXX XXXXXX Factory ( if Required ) XXXXXX XX/XX/XX 11 Rebuild • Ratchet Wrench Code • Torque Wrench 300 lb-in [34 Nm] Original Build Factory Rebuild ( example - 010191 ) ( example - 01/01/91 11 ) • 5/32 Hex Wrench 01 01 91 01 01 91 11 • Small screwdriver (4 in [102 mm] to 6 in. Year Number of [150 mm] long) Day Year Times Rebuilt (2) • No. 5 or 7 Internal Retaining Ring Pliers Month Day Month • No. 4 or 5 External Retaining Ring Pliers • 6 in. [150 mm] or 8 In. -

Fault-Tolerant Drive-By-Wire Systems

©1994 PHOTODISC, INC. utomotive systems are increasingly being devel- tonomous functionality. Examples of first steps toward oped with integrated electronic sensors, actua- mechatronic systems for automobiles were the arrival of digi- tors, microcomputers, information processing tally controlled combustion engines with fuel injection in 1979 for single components, and engine, drive- and digitally controlled antilock brake systems (ABS) in 1978. train, suspension, and brake systems. These Today’s combustion engines are completely microcomputer have matured to mechatronic systems that controlled, typically with five electrical, electrohydraulic, or are characterized by the integration of components (hard- electropneumatic actuators and several measured output ware) and signal-based functions (software), resulting in au- variables, taking into account different operating phases such as startup, warming up, idling, and normal operation. Isermann ([email protected]) is with the Institut fuer The only input from the driver is generated by the accelera- Automatisierungstechnik Technische, Universitaet Darmstadt tor pedal and transferred to the throttle (spark-ignition en- Landgraf-Georg-Str. 4, D-64283 Darmstadt, Germany. Schwarz is gines) or the injection pump (diesel engines) wuth Continental Teves, Frankfurt 60488, Germany. Stölzl is with This article begins with a review of electronic driver as- A.T. Kearney Gmbh, Frankfurt 60327,Germany. sisting systems such as ABS, traction control (TCS), elec- 0272-1708/02/$17.00©2002IEEE