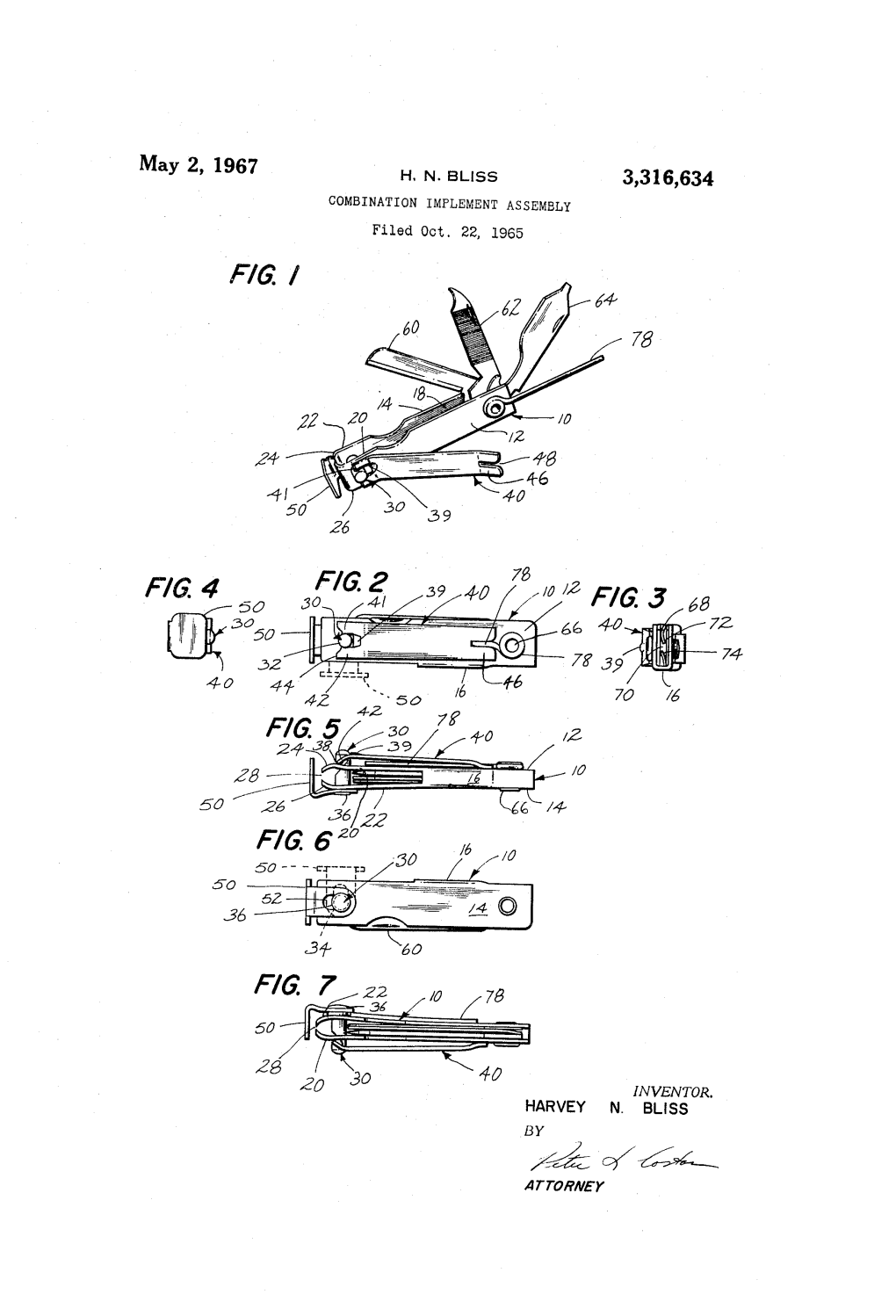

May 2, 1967 H, N. BLISS 3,316,634 COMBINATION IMPLEMENT AS SEMBLY Filed Oct

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Manicure Catalogue

CATALOGO RBB MANICURE EXTRA LINE Articles carefully produced and checked by our artisans, forged with the best materials in the sector to satisfy every professionist. MANICURE SCISSORS 244 C Cuticle scissors curved 244 R Cuticle scissors straight 246 C Nail scissors curved 246 R Nail scissors straight 244 LC Cuticle scissors curved pointed tips 244 LR Cuticle scissors straight pointed tips 245 LC Nail scissors curved pointed tips 244 246 244L 245L 310/1/3,5R Cuticle scissors straight 9 cm 310/1/3,5C Cuticle scissors curved 9 cm 310/1/4R Cuticle scissors straight 10 cm 310/1/4C Cuticle scissors curved 10 cm 225/1/4 Moustache scissors 320/1/4 Ear & nose scissors 326/1/4 326/1/4 Toenail scissors 225/1/4 320/1/4 310 244L CICOGNA SCISSORS 244L 235/1/3,5 “Cicogna” scissors 9 cm 235/1/4,5 “Cicogna” scissors 11 cm 235/1 TWEEZERS 470 Fantasy professional tweezers 471 Color professional tweezers 471 6472 Professional tweezers 470 6472 NIPPERS 322/I/4 mm3 Cuticle nippers blade 3 mm 322/I/4 mm5 Cuticle nippers blade 5 mm 322/I/4 mm7 Cuticle nippers blade 7 mm 322/I/4 mm9 Cuticle nippers blade 9 mm 322/P/4 Cuticle nippers 10 cm 324/P/4 Nail nippers 10 cm 324/P/4,5 Nail nippers 11 cm 324/P/5 Nail nippers 12 cm 322/I/4 322/P/4 324/P 325/BO/5,5 Toenail nippers 14 cm 325/BI/5,5 Nail nippers 14 cm 325/X/4,5 Nail nippers pointed 11 cm 325/X/5 Nail nippers pointed 12 cm 1 325/BO/5,5 325/BI/5,5 325/X CATALOGO RBB MANICURE INOX EXTRA LINE Line produced with stainless steel, which allows complete sterilization, completed with the highest quality professional accessories. -

PO Box 101 Banora Point, NSW Australia 2486 NAIL SNAIL

Media Contact Contact Person: Julia Christie Contact Email: [email protected] , [email protected] Phone Number: 0421860045 Website: www.nail-snail.com Postal Address: PO Box 101 Banora Point, NSW Australia 2486 FOR IMMEDIATE RELEASE NAIL SNAIL: THE SOLUTION TO THE AGE-OLD PROBLEM OF TRIMMING TINY NAILS THIS REVOLUTIONARY NEW 3-IN-1 BABY NAIL TRIMMER PROVIDES A SAFE, EASY AND QUICK OPTION FOR TRIMMING THE NAILS OF NEWBORNS, INFANTS AND CHILDREN. AUSTRALIAN FAMILY-RUN BUSINESS, CHRISTIE AND CHRISTIE, IS LAUNCHING A KICKSTARTER CAMPAIGN ON FEBRUARY 15 TO RAISE FUNDS FOR THE FIRST PRODUCTION RUN OF THIS INNOVATIVE NEW PRODUCT. February 15, 2017, Gold Coast, Australia: Today, Christie & Christie, an Australian, family owned company, is proud to announce the launch of their Kickstarter campaign for the Nail Snail, the first substantial change in nail clipper design for over a century. This product, which will change the face of child nail care, is designed to provide a safe, quick and easy method by which to trim the nails of newborns, babies, and children up to 5 years old. Mother of two, Julia Christie, who, after the birth of her first child, realized the enormity of this problem facing parents the world over, invented the Nails Snail. The spark of a new idea was followed by years of hard work, dedication, and much research and development. The Nail Snail is a multi-purpose 3-in-1 tool that allows easy fingernail and toenail trimming, nail filing and under nail cleaning. Features such as the easy grip handle, compact construction, and innovative ‘V’ shaped precision trimmer to allow multi directional cutting, make this product the best option for the care of babies’ nails. -

Fiction Fix 12 April Gray Wilder

University of North Florida UNF Digital Commons Fiction Fix Department of English Fall 2012 Fiction Fix 12 April Gray Wilder Steven Sherrill Jon Pearson Anne Germanacos Doug Barry See next page for additional authors Follow this and additional works at: http://digitalcommons.unf.edu/fiction_fix Part of the Creative Writing Commons, and the Fine Arts Commons Suggested Citation Last, First. "Article Title." Fiction Fix 12 (2012): pages. Web. Date accessed. http://digitalcommons.unf.edu/fiction_fix/4 This Book is brought to you for free and open access by the Department of English at UNF Digital Commons. It has been accepted for inclusion in Fiction Fix by an authorized administrator of UNF Digital Commons. For more information, please contact Digital Projects. © Fall 2012 All Rights Reserved Authors April Gray Wilder, Steven Sherrill, Jon Pearson, Anne Germanacos, Doug Barry, Sheila MacAvoy, William Ryan Hilary, Emma Silverman, Nicomedes Austin Suarez, Allie Marini Batts, Anne-Marie Thweatt, Marjorie Dawn Gilchrist-Young, Janae Green, Andrew F. Sullivan, Elisha Wagman, Gene Fehler, William LaPage, Neil Dvorak, Doruk Onvural, Kate LaDew, Sam Diaz, and David Higginbotham This book is available at UNF Digital Commons: http://digitalcommons.unf.edu/fiction_fix/4 FICTION FIX 12 Fiction Fix 12, Fall 2012 www.fictionfix.net [email protected] Editorial Advisor Mark Ari Editor-in-Chief April Gray Wilder Managing Editor Alex Pucher Graphic Literature Editor Russell Turney Assistant Editors Jessica Bayne April Hutchinson Blair Romain Commissioning Editor Ann Marie Byrd Contributing Editor Chrissy Rand Copyeditor Joanna Ring Assistant Copyeditor Sam Bilheimer Editorial Assistants Leah Clancy Heather Stafford Readers Faith Diller Nicole Dominguez Patricia Parrow Brianna Meewes Ben Wolfson Typesetting & Design April Gray Wilder Copyright 2012 Fiction Fix. -

(12) United States Patent (10) Patent No.: US 7,020,964 B2 Han Et Al

US007020964B2 (12) United States Patent (10) Patent No.: US 7,020,964 B2 Han et al. (45) Date of Patent: Apr. 4, 2006 (54) NAIL CLIPPER AND NAIL CUTTER, LEVER 796,389 A 8/1905 Wright AND SUPPORTING SHAFT FOR THE SAME 806,037 A 11, 1905 Wilcox 1,085,569 A * 1/1914 Casse ............................ 30, 28 (76) Inventors: Jeong Sik Han, c/o BOCAS Inc., 62-7 2,477,782 A 8, 1949 Bassett ...................... 132,755 Ogeum-Dong, Songpa-Ku, Seoul (KR) 2,995,820 A 8, 1961 Pocoski ......................... 30, 28 3,042,047 A 7/1962 Plaskon ..................... 132,755 138-856; Gyoung Hee Kim, c/o 3,555,675 A 1/1971 Jurena ........................... 30, 28 BOCAS Inc., 62-7 Ogeum-Dong, 5,226,849 A 7/1993 Johnson ......................... 30, 28 Songpa-Ku, Seoul (KR) 138-856 5.488,772 A 2f1996 Dababneh et al. 5,832,610 A * 11/1998 Chaplick ....................... 30, 28 (*) Notice: Subject to any disclaimer, the term of this 5,870,826 A 2, 1999 Lewan .......................... 30, 28 patent is extended or adjusted under 35 6,173,497 B1 1/2001 Domenge U.S.C. 154(b) by 52 days. 6,523,545 B1* 2/2003 Rende ....................... 132,755 2002/0092.172 A1* 7/2002 Park .............................. 30, 28 (21) Appl. No.: 10/730,910 FOREIGN PATENT DOCUMENTS (22) Filed: Dec. 10, 2003 JP 57-27.204 2, 1982 JP 11-169227 6, 1999 (65) Prior Publication Data JP 2002-142853 5, 2002 WO O2/398.44 5, 2002 US 2004/O 111893 A1 Jun. 17, 2004 WO O2/O67720 9, 2002 (30) Foreign Application Priority Data * cited by examiner Dec. -

Levers Around the House Page 48

Grade 7 Page 47 CIBL Levers Around NC Essential the House Standard 7.P.2.4 Throughout the guide teaching tips are in red. Overview Over a few class periods, this three-part activity introduces students to levers and the concept of mechanical advantage. On the first day, before learning about levers, students are presented with nail clipper bases without the lever attached, are asked to use it to cut a nail, and then to draw the tool as-is, labeling the drawing to show where force is applied and where it is used. Next, they receive the clipper lever, assemble it, use it, and learn that the job is easier. They then redraw the clippers with the lever, again showing where force is applied and where it is used. After this exploration, students go through similar steps with scissors. On the next day, students again have clippers, scissors, and their drawings. This time they identify the levers in these objects, measure distances that both ends of the lever travel, and develop some ideas about how the levers might make things easier, including the concept of work. Objectives •Students can explain that levers make it possible to apply more force. •Students can demonstrate the mechanical advantage (increased efficiency) of a lever, using less force over a greater distance to produce more force over a shorter distance. NC Essential 7.P.2.4 Explain how simple machines such as inclined planes, pulleys, levers Science Standards and wheels and axles are used to create mechanical advantage and increase efficiency. Science Background This activity explores ways to do some simple things more easily. -

Swiss Army Knives

Distributed in the United States by: Wenger NA 15 Corporate Drive Orangeburg NY 10962 Tel: 800-431-2996, 845-365-3500 Fax: 845-425-4700 (General Correspondence) 845-365-3743 (Orders only) www.WengerNA.com SWISS ARMY KNIVES 2007 New Product Introductions The Genuine Swiss Army Knife™ The Genuine Swiss Army Knife™ Item #883 EvoGrip 16 EVOGRIP EvoGrip 18 EVOGRIP INTRODUCING I Weight 2.6 oz. I Weight 3.1 oz. EVOGRIP 16811 16814 S S N N O O I I T T C C N N U U F F 4 5 1 The Evolution Series represented 1 – – S S T a dramatic and unique redesign of the T N N E E M M E venerable Swiss Army knife by employing a new, E L L P P M M I smart ergonomic handle. Now, Wenger is taking the I 0 1 1 next step in the progression of the Evolution 1 platform with EvoGrip. By adding rubber to the most critical areas of the handle, the knife’s safety, performance and functionality have been Actual size 3.25" Actual size 3.25" increased again. Ergonomic handles with rubber • 2.5" Blade • 2.4" Springless scissors with Ergonomic handles with rubber • 2.5" Blade • 2.75" Double-cut wood saw, serrated, self-sharpening design • Patented locking screwdriver, cap lifter, • 2.4" Springless scissors with serrated, self-sharpening design • Patented wire stripper • Can opener • Nail file, nail cleaner • Phillips® head locking screwdriver, cap lifter, wire stripper • Can opener • Nail file, nail screwdriver • Reamer, awl • Toothpick • Tweezers • Key ring cleaner • Phillips® head screwdriver • Reamer, awl • Toothpick • Tweezers • Key ring EvoGrip 10 EVOGRIP EvoGrip S54 EVOGRIP EvoGrip S557 EVOGRIP I 16810 Weight 1.9 oz. -

Victorinox SAK Directory VICTORINOX 1884 - 2021 MORE THAN 130 YEARS of EXPERIENCE and LIVED SWISS TRADITION

MAKERS OF THE ORIGINAL SWISS ARMY KNIFE | ESTABLISHED 1884 Victorinox SAK Directory VICTORINOX 1884 - 2021 MORE THAN 130 YEARS OF EXPERIENCE AND LIVED SWISS TRADITION The little red pocket knife, with Cross & Shield emblem in design and quality, but also in their ability to serve on the handle is an instantly recognisable symbol of as reliable companions on life’s adventures, both great our company. In a unique way, it conveys excellence and small. in Swiss crafts manship, and also the impressive Today, the full range of Victorinox knives is comprised expertise of more than 2,000 employees worldwide. of over 1,200 models. The range is presented in The principles by which we do business, are as two, separate catalogs: «Swiss Army Knives» and relevant today as they were in 1897 when our company «Household and Professional Knives». We are pleased founder, Karl Elsener, developed the «Original Swiss to offer this streamlined assortment, with our best, Army Knife»: functionality, innovation, iconic design and perhaps future classics. and uncompromising quality. Our commitment to these principles for more than 130 years has allowed Carl Elsener us to develop products that are not only extraordinary CEO Victorinox 6 10 12 SMALL POCKET KNIVES SWISS CARDS MEDIUM POCKET KNIVES 58 mm Companion 6 Classic 10 84 mm Original Swiss Army Knives, Small Models 12 INFORMATION 65 mm Companion 9 Lite 10 85 mm Evolution 14 Nailcare 11 91 mm Original Swiss Army Knives, Large Models 18 Quattro 11 93 mm Pioneer 26 26 27 33 34 SPORTS LARGE POCKET KNIVES SWISS TOOLS ACCESSORIES Golf Tool 26 111 mm Workman 28 Swiss Tool Spirit 31 Pouches 34 130 mm Ranger 28 Swiss Tool 32 Knife Sharpeners 35 PACKAGING There are two types of packaging for pocket knives: Standard packaging and blister packaging. -

Packing Ideas for Operation Christmas Child: Girls/Boys 10-14 Years

Packing Ideas for Operation Christmas Child: Girls/Boys 10-14 years: Do Not Include: Candy; toothpaste; used or damaged items; war-related items such as guns; knives; military figures; chocolate or food; fruit rolls or other fruit snacks; drink mixes (powdered or liquid); liquids or lotions; medications or vitamins; breakable items such as snow globes or glass containers; aerosol cans. A “WOW” Item: • Doll (consider including accessories such as doll clothes or a small doll bed.) • Deflated Soccer ball (Make sure to include a manual air pump so that the ball can be re-inflated.) • Stuffed animal • Toy truck or boat • An outfit of clothing to wear • Small musical instrument (such as a harmonica or woodwind recorder.) • Backpack Personal Care Items: • Comb/ Hairbrush • Washcloth • Bar soap (packaged and/or in a container) • Adhesive bandages (Colorful ones can help a child be more willing to wear a bandage. Do not include liquid antibiotic ointment.) • Reusable plastic containers: cup, water bottle, plate, bowl, blunt-edged utensils (Consider filling an empty container with non-liquid items such as hair bows, bracelets, sunglasses, or washcloths or maximize the space.) • Non-liquid lip balm • Flashlight (solar-powered or hand-crank; if battery operated, be sure to include extra batteries of the type needed) • Compact mirror • Nail clipper and file • Stick deodorant • Washable/reusable cloth menstrual pads School Suplies: • Pencils/Pens • Small manual pencil sharpener • Colored pencils/Crayons/Markers • Erasers • Pencil case • Notebooks/Blank -

120 Dog Training Videos

® 120 DOG TRAINING VIDEOS Visit Our 10,000 Page Website Leerburg.com ED FRAWLEY Meet Ed Frawley’s Ed Frawley Philosophy Owner of Leerburg® on Dog Training Copyright 2005 Kennel and Video I look at people who train dogs and lump them into three main categories. These categories can be placed on a sliding scale. The first category, on the left, is the group of people who beg or bribe their dogs to do something by offering food or toy reward. Don’t get me wrong, I use food and toys in training, but I also use distractions and corrections. These people use neither. The problem with this group is that the dogs often choose not to do what’s asked because they don’t think the reward is worth the task. These dogs end up being pushy, dominant and often antisocial dogs. They are the dogs that are turned in to animal shelters as being unmanageable when in fact they act the way they do as a result of ineffective training. At the other end of the scale, on the right side, is the second category of people. These are trainers who intimidate or force their dogs to do what they want. I call them the old school “yank and crank” trainers. Leerburg® Kennel and Video is owned by Ed Frawley. Ed has owned German Shepherds (GSD) for 45 years. Since 1978 he has bred over They put a choke collar on a dog and force it to do everything. Many 350 litters of German working bloodline GSD’s. -

A Guide to Pet Products and Grooming. by Wahl

A guide to pet products and grooming. by Wahl Effective brushing forms the basis of good grooming – usually twice weekly dependent on the breed and coat. The process of brushing and combing will distribute the oils from your dog’s skin throughout the coat. Giving your dog a bath is not an essential element of caring for your dog. However, it is an effective method in removing dead or loose hair, reducing dirt and debris from the coat and improving any unpleasant odours. Regardless of breed, all dogs have claws which grow constantly and may, at times need some attention to prevent discomfort or injury. It is possible to take care of this at home with the correct tools and advice. There are very few dogs that will not benefit from a little trimming at some time in their lives. Trimmers are ideal to cut the hair around the feet and pads or for dogs with long hair around their mouth and chin which needs trimming for hygiene. A well clipped dog not only looks good, but will also be more comfortable in hot weather and less prone to collecting dirt, mud and debris in a long, unkempt coat. ABOUT WAHL Wahl Clipper Corporation has been manufacturing grooming equipment for almost 100 years. An international industry leader for high quality, animal grooming products, our range of clippers and trimmers have been designed and developed to meet the needs of professionals and home users. For pet lovers at home we have a highly successful range of lightweight, quiet clippers and trimmers, durable grooming tools and effective shampoos designed specifically for pet owners and built to last for years. -

Gift Manicure Perfect Eyes Pedicure Men's Care Baby

Finest quality made in Solingen FinestFeinste quality Qualität made aus in Solingen Solingen E. u. W. Niegeloh GmbH & Co KG Phone + 49 - (0) 212- 222 4120 Postfach 190409 Fax + 49 - (0) 212 - 10060 Mangenbergerstrasse 330 [email protected] D-42655 Solingen www.niegeloh.com Contents Prologue ________________________________________ 4 For the Baby _____________________ 34 The well-groomed man ______________________ 36 Our Scissors Hair Cutting Scissors ______________________ 40 Topinox __________________________________________ 6 Make-up artists ______________________ 42 Inox Style n4 ____________________________________ 8 Presentations ______________________ 48 Inox Style Titanium ________________________________ 10 Niegeloh worldwide _____________________ 50 Inox ____________________________________________ 12 basic ___________________________________________ 14 Nail Files / Manicure ______________________________ 16 Nail Clippers ______________________________ 22 Nail Nippers ______________________________ 24 Everything for smooth feet _________________________ 26 Tweezers ______________________________ 28 2 3 All scissors, nippers and clippers are individually tested modern technology und tradition Tempering process for precision and sharpness. of nail scissors When producing our scissors, tweezers, nippers, files and feet care products, we use alloyed steel. Products made by Niegeloh Solingen are known for their ultimate quality combined with customer - friendly prices. Our staff, the workmanship and product knowledge are Solingen quality is without the main capital of the company. question for our employees Scissors blanks Craftsmen‘s work is supported by the most sophisticated in production process technical equipment. Personal well-being at the job guarantees perfect workmanship which brings high quality results, leading the priority list of the company management. Consequently, all suitable technical solutions and investments are made to avoid waste, to save energy and to reduce the use of chemical substances to an absolute minimum. -

The Catalog. Echte Tradition Seit 1920

The catalog. Echte Tradition seit 1920. Edition 2020 / 2021 G&F 2020: The 3rd and 4th generation leading the Solingen-based family business together (Katharina, Peter and Christiane Giesen). 2 Table of content. Foreword 4 - 5 Range of products Handmade straight razors 8 - 25 Men’s Shaving 28 - 39 Safety Razor 1920 28 - 35 Beard and shaving care 1920 36 - 37 Timor® Razorblade 38 - 39 Women’s Shaving 40 - 47 Safety Razor ZÓE 40 - 43 Shaving care ZÓE 44 - 45 Razorblade ZÓE 46 - 47 UNISEX Shaving 50 - 57 Safety Razor Gentle Shaver 50 - 55 Gentle Shaver Razorblade 56 - 57 Timor® Shaving accessories 58 - 71 Timor® Gift box 74 - 79 Timor® Manicure and Pedicure 80 - 95 Housewares utilities 98 - 103 Becoming a customer 104 - 105 3 Since 1920, all you need for a great shaving experience. 100 years Giesen & Forsthoff. A few months ago we stumbled over our 50th anniversary publication from 1970. It was published just half a year after the moon landing and even before major events like the Olympic Games in Munich 1972 and the football world cup 1974 in Germany. The publication brings back nice memories and is indeed a historical document for our Solingen-based family business. Back then, led in the 2nd generation, we were able to make our mark as a manufacturer of fine shaving and manicure products. This success was always based on consistency, quality and cohesion. Back then, I was accompanying my father and followed him into management. Today, 50 years later, it is my daughter leading the Giesen & Forsthoff together with myself into the future.