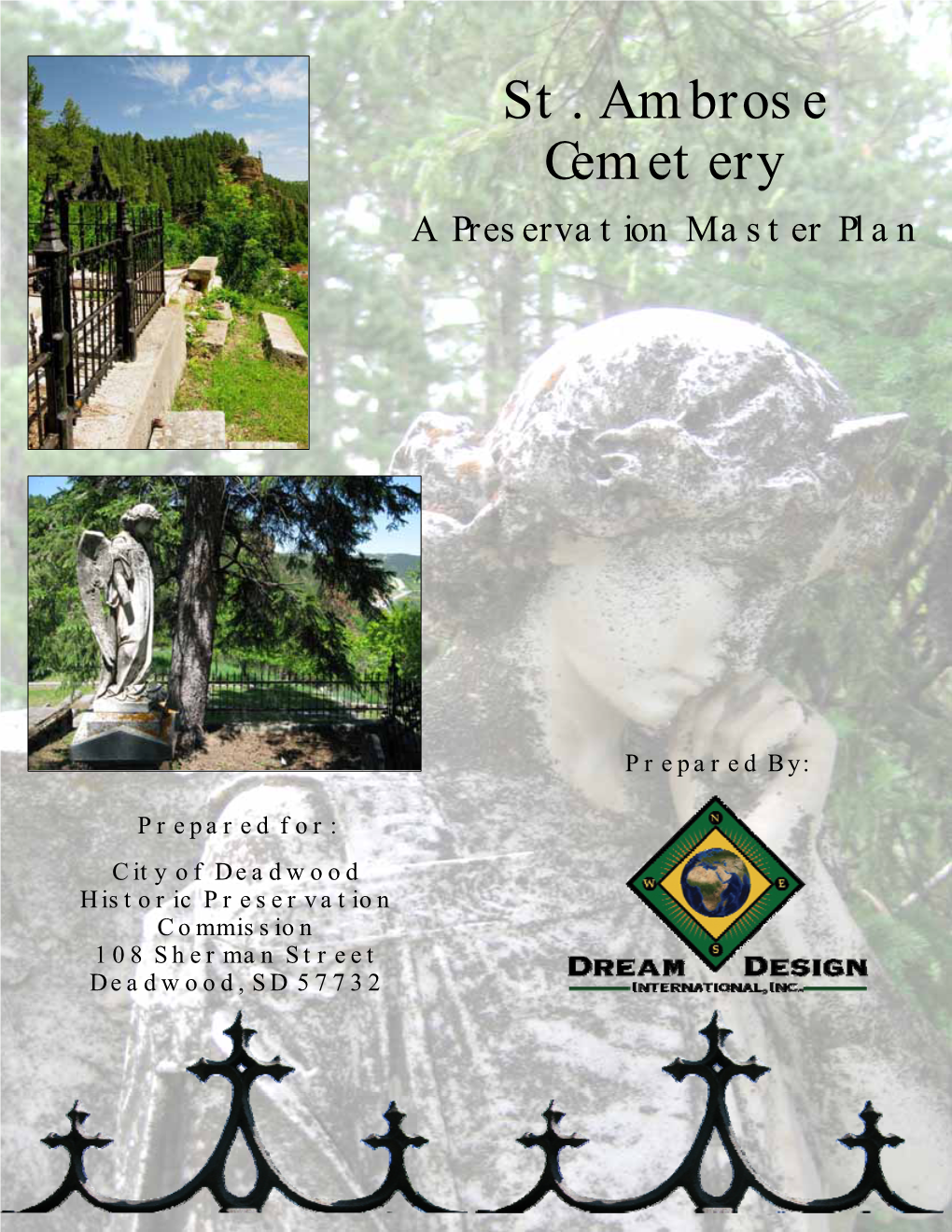

St. Ambrose Cemetery a Preservation Master Plan

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Midwest Historical & Genealogical Society Wichita, Kansas

Midwest Historical & Genealogical Society Wichita, Kansas 1894Wichita City Directory TRANSCRIBED BY NANCY LOU WELSHIMER FINCHAM Pg. 186 (cont’d) Advertisement - Deam Abstract Co. Abstracters of Land Titles, North West Basement of Court House Advertisement - T. B. Glosser, Tailor and Furnisher, 145 N Main Advertisement - Wholesale & Retail Sporting Goods, W. C. Williams, 119 E Douglas - I - ILER JOHN, railroader, residence room 5 above 601 east Douglas Imboden Adam H, com trav Bemis Bros St Louis, r 341 n Fourth Imboden Miss Evelyn, student, r 215 n Emporia Imboden Hiram, (Oliver & Imboden) City Roller mills, 623 e Douglas, r 215 n Emporia Imboden Keener, electrician ab 248 n Main, r 341 n Fourth Imholz Jacob, wagonmaker 122 n Fourth, r 200 w Douglas Pg. 187 Advertisement - Kansas Steam Laundry 122-124 S Lawrence. ‘Phone 195. Hotel Work A Sp cialty. Advertisement - T. B. Glosser, Tailor and Furnisher, 145 N Main Advertisement - A. M. Carr, 253 N Main St. Wholesale & Retail. Difficult Repairing. Nickeling, Enameling. Bicycles built to Order, Bicycles. Imhoof Mary, housekeeper, r 304 s Water Inglehart Chas, com trav, r ab 254 n Market Ingles D F, physician, r 3431 n Fifth Ingram R C, student, r 702 Pattie Ingram Y S, janitor, r 702 Pattie Innes Wm, (White House Dry Goods Co) 116 n Main, r 327 n Topeka Ireland Miss Gertie, r ab 158 n Main Ireland Miss Pearl, r ab 158 n Main Ireland s C, patrolman, r ab 158 n Main Irish C L, mechanic, r 1245 n Water Irvin A A, meat shop 822 e Douglas, r 347 Wabash Irving School, cor Sixteenth and Lawrence -

Clear Concise Construction Advice Chicago Cincinnati Milwaukee Indianapolis 200 W

CLEAR CONCISE CONSTRUCTION ADVICE CHICAGO CINCINNATI MILWAUKEE INDIANAPOLIS 200 W. Wrightwood Ave. 11257 Williamson Rd. N49W13545 Campbell Dr. 4330 Hull St., Ste. 300 Elmhurst, IL 60126 Cincinnati, Ohio 45241 Menomonee Falls, WI 53051 Indianapolis, IN 46226 630-530-9600 513-489-6710 262-781-0799 317-542-8400 WWW.GLENROCKCOMPANY.COM DIVISION 3: CONCRETE BASF Construction Chemicals CETCO Building Materials CME, Inc. EPS & XPS Foam Insulation Concrete Cleaners Anti-Corrosion Rebar Coatings Euclid Chemical Corporation IMCO Technologies, Inc. Emecole, Inc. Adhesives & Epoxies Chemical Anchors Sealers & Water Repellents Sika Corporation Quickcrete Companies IMCO Technologies Curing Compounds Mechanical Anchors SS Threaded Rod WR Meadows, Inc. ITW Red Head ACH Foam Technologies Repair Mortars Injection Resins Waterstops Dow Chemical Helifix Masonry Anchors Prosoco Inc. Wet / Dry Process Shotcrete Foam Expansion Joints Expansion Joint Systems King Packaged Materials Simpson Anchor Systems CTS Rapid Set Cement Sacraficial Galvanic Anodes Caulks & Sealants Crack Repair Accessories Xypex, Inc. Vector Technologies, Inc. GCP Applied Technologies Floor Hardeners DIVISION 4: MASONRY Arbortech GCP Applied Technologies Helifix Stone Anchors Tuckpointing Mortar Mechanical Anchors Conproco Corporation Rectorseal Prosoco Inc. SS Drip Edge Caulks & Sealants Liquid / Sheet Flashing Materials Dow Chemical Hohmann & Barnard Spec Mix Masonry Mortar (Type M,N,O,S) Cavity Wall Insulation Water Repellents Emseal Joint Systems IPCO Heckmann Building Products Masonry & Stone Cleaners Natural Stone Repair Materials Cell / Weep Vents Bonstone Materials Corp. BASF Construction Chemicals York Manufacturing Architectural Wall Coatings Chemical Anchors Termination Bar GE Silicones Mortar Net Mortar Colors Helical Anchors DIVISION 7: THERMAL AND MOISTURE PROTECTION Carlisle Coatings & Waterproofing BASF Construction Chemicals Sika Corporation Air / Vapor Barriers Architectural Wall Coatings Mastics CETCO Building Materials Prosoco Inc. -

Tools for Tile & Stone Catalog

TOOLS FOR TILE & STONE CONTRACTORS CUTTING, PROFILING & POLISHING TH Since 1986 Celebrating 35 Years Providing Better Solutions to the Professional VERSION 6 CONTACT US WELCOME Alpha Professional Tools® was founded in 1986 and has become a leading manufacturer of quality tools for professionals in the natural/engineered stone, porcelain, ceramic, glass, construction, marine and automotive industries. Alpha® provides the best products for cutting, drilling, shaping and polishing all types of materials. In addition to providing the best products in the industry, Alpha Professional Tools® offers a variety of services to support their products. Company Contact Information: Headquarters & 16 Park Drive Training Center: Franklin, NJ 07416 Hours of Operation (EST): 8:30 a.m. - 5:00 p.m. Telephone No: 201-337-3343 Toll-Free No: 800-648-7229 Fax No: 201-337-2216 Toll Free Fax No: 800-286-0114 E-mail Orders to: Contact Us: [email protected] www.alpha-tools.com [email protected] [email protected] Follow Us: Sales Contacts by Territory – [email protected] Caribbean 201-337-3343 Ohio Valley 440-364-3759 Canada 519-546-9861 Pacific 800-648-7229 International 201-337-3343 South 480-848-6808 Midwest 630-849-7105 Southeast 678-977-1147 Northeast 973-830-7681 Southern CA 925-428-1292 Northern CA 925-428-1292 TABLE OF CONTENTS TOOLS STONE CUTTER • ESC-125, Wet Stone Cutter .......................................................................................2 • Countertop Trim Kit ....................................................................................................4 -

All Currently Licensed Contractors by License Type

All Currently Licensed Contractors by License Type Contractor Status Company Name Company Address Company Phone License Type Description License Expiration ID Number Number Date 11656 A ADT LLC DBA ADT SECURITY 1151 SOUTHPOINT CIRCLE, SUITE E, (561) 322-4878 ALARM SYSTEM 12/31/2020 SERVICES VALPARAISO, IN 46385 INSTALLERS 4926 A INTERFACE SECURITY 3773 CORPORATE CENTER DR, EARTH CITY, MO 314-595-0100 ALARM SYSTEM 4926 12/31/2020 SYSTEMS LLC 63045 INSTALLERS 12163 A ALLIED ASPHALT 534 E 37TH AVE, UNIT 383, HOBART, IN 46342 (219) 427-7280 ASPHALT 12/31/2020 4128 A ASPHALT SERVICE CONTRACT 616 WEST AVENUE H, , GRIFFITH, IN 46319 (219) 924-8181 ASPHALT 4128 12/31/2020 INC 12590 A CHICAGO ASPHALT REPAIR 1888 N TREVINO TERRACE, VERNON HILLS, IL (773) 491-8641 ASPHALT 12/31/2020 60061 3640 A ECONOMY PAVING 209 68TH PLACE, , SCHERERVILLE, IN 46375 708-481-1380 ASPHALT 3640 12/31/2020 4656 A FRITZ CARTAGE & ASPHALT INC 458 E. 161ST STREET, , SOUTH HOLLAND, IL (708) 331-7553 ASPHALT 4656 12/31/2020 60473 12122 A G & G ASPHALT MAINTENANCE, 2627 LANCELOT LANE, DYER, IN 46311 (219) 765-4514 ASPHALT 12122 12/31/2020 INC. 12612 A HOBART SEALCOATING AND 1224 W 7TH PL, HOBART, IN 46342 (219) 310-0346 ASPHALT 12/31/2020 ASPHALT 11797 A JIF PAVING 11908 108TH PLCE, ST JOHN, IN 46373 (708) 307-0953 ASPHALT 12/31/2020 5443 A OLSON CONSTRUCTION INC 2239 SUMMER ST, , HAMMOND, IN 46324 2195311646 ASPHALT 5443 12/31/2020 5548 A PERM-A-SEAL P.O.BOX 1216, , SOUTH HOLLAND, IL 60473 (708) 333-8838 ASPHALT 5548 12/31/2020 4689 A RISTICH ASPHALT PAVING 714 JUNCTION -

Official Catalogue of Exhibitors

o t wmmM% DEPARTHENT OF lAWEACTVKI^S UMYERSAL EXPOSITION ^AINT LOUIS 19 .^^04 '/, 'II i I OFFICIAL CATALOGUE OF EXHIBITORS ^(^ UNIVERSAL EXPOSITION ST. LOUIS, U. S. A. 1904 DIVISION OR EXHIBITS FREDERICK J. V. SKIFF, Director Department D MANUFACTURES MILAN H. HULBERT, Chief FIRST EDITION PUBLISHED FOR THE COMMITTEE ON PRESS AND PUBLICITY BY THE OFFICIAL CATALOGUE COMPANY (INC.) ST. LOUIS. 1904 » fi » J) , • o 1 J %^^ A^" H\vi'2 V\^ ' ps^ga. jj ' jiiin 'lag'j LIBRARY of CONGRESS Two Copies Received * MAY 13 1904 Copyrlffht Entry CLASS^ CL-XXc. No. COPY B COPYRIGHT, 1904. BY THE LOUISIANA PURCHASE EXPOSITION COMPANY, FOR THE OFFICIAL CATALOGUE COMPANY. .! •! • PREFACE. It is estimated that more than a million objects exposed in the various displays installed within the Palaces of the Universal Exposition of St. Louis, 1904. To properly classify, group and arrange alphabetically all of the exhibits of an Expo- sition of such international scope, is a task of character and proportions as to make it quite impossible to provide a complete catalogue of these exhibits on the opening day of the Exposition. This edition of the Official Catalqgue is, therefore, presented preliminary to the revised and complete catalogue which will be ready and issued within a few weeks, and to the preparation of which, in realization of its extraordinary value as a docu- ment of general and commercial reference, especial care is being given. The present volume, however, it is believed, represents the most complete cata- logue ever presented at the opening of an International Exposition. It capably serves the purpose for which it is designed, as an early index of the infinite variety of interesting exhibits which are the concrete evidences of the industrial, educational and artistic advancement of the world. -

Builders Tools & Accessories

BUILDERS TOOLS & ACCESSORIES CONSTRUCTEURS OUTILS ET ACCESSOIRES Great Deals On Building supplies SHOP NOW & SAVE CONTENT Pages Tile Cutter & Accessories 286 Laminate Cutter & Accessories 290 Floor Roller Tools 294 Floor Scraper & Accessories 296 Glass & Tile Nipper 298 Glass Cutter Tool & Accessories 300 Tile Spacers & Tile Installation Tools 301 Tile Grout Removal Tools & Accessories 306 Grout Bag & Clean Up Accessories 307 Tile Grouting Sponge 308 Sawhorse & Brackets 310 Drywall Lifting Tools & Accessories 312 Drywall Sanding & Abrasive Accessories 315 Drywall Taping & Installation Accessories 318 Magnesium Bull Float & Accessories 320 Caulking Guns & Accessories 322 Pointed & Brick Trowels 326 Margin Trowels 328 Tuck Pointer Trowels 330 Concrete Groover 331 Drywall Trowel 332 Pool Trowels 333 Notched Trowels 336 Masonry Tools & Accessories 342 Grout & Cement Floats 344 Plastering Hawks & Taping Knives 348 Putty Knives - Flexible Blades 350 Mixing Paddles & Mud Pans 352 Tool Boxes and Storage 355 Bags, Pouches & Belts 358 Tarpaulins 365 Fencing & Barriers 370 Glass & Tile Nippers 372 Drywall Tools & Accessories 373 Plaster & Finishing Trowels 374 Tuck Pointer & Concrete Edgers 375 Floats & Plastering Hawk Accessories 380 Drywall Tools & Accessories 384 Grouting Tools & Mixing Paddles 385 Tile Cutter & Accessories Professional Tile Cutter 4-Ball Bearing Revolutionary Sliding High Mechanism Leverage Handle Tungsten-Alloy Japanese Cutting Wheel Over 10,000 linear feet of cut with a single wheel! Rubber Padded Bed Reinforced Heavy Duty -

National Register of Historic Places Multiple Property Documentation Form

NPS Form 10-900-b OMB No. 1024-0018 (Revised March 1992) United States Department of the Interior National Park Service National Register of Historic Places Multiple Property Documentation Form This form is used for documenting multiple property groups relating to one or several historic contexts. See instructions in How to Complete the Multiple Property Documentation Form (National Register Bulletin 16B). Complete each item by entering the requested information. For additional space, use continuation sheets (Form 10-900-a). Use a typewriter, word processor, or computer, to complete all items. X New Submission Amended Submission A. Name of Multiple Property Listing Park County, Colorado, Historic Cemeteries B. Associated Historic Contexts (Name each associated historic context, identifying theme, geographical area, and chronological period for each.) Historic Cemetery Development in Park County, Colorado, 1859-1965 C. Form Prepared by name/title R. Laurie Simmons and Thomas H. Simmons organization Front Range Research Associates, Inc. date October 2016 street & number 3635 W. 46th Ave. email [email protected] telephone 303-477-7597 city or town Denver state Colorado zip code 80211 D. Certification As the designated authority under the National Historic Preservation Act of 1966, I hereby certify that this documentation form meets the National Register documentation standards and sets forth requirements for listing of related properties consistent with the National Register criteria. This submission meets the procedural and professional requirements -

AIA Continuing Education Units Offered

AIA Continuing Education Units Offered WHERE ALL YOUR BUILDING BEGINS Brick, Stone, Landscape, Masonry And More The Success of Your Project Begins at the Source— Quality Materials from Illinois Brick Company For more than three decades, architects, contractors, builders, landscapers and homeowners have put their confidence in the quality products and services of Illinois Brick Company. That’s because professionals know that start to finish, their projects are only as good as the materials they use to build them. For this reason, we provide only the finest quality, superior class brick, stone, landscape, masonry and building supplies in the Chicagoland area for the entire scope of both residential and commercial projects. And that’s why Illinois Brick Company is where your building begins. CALL 708-237-5600 Page 2 Illinois Brick Company Page 3 To schedule a course at your place of business Visit www.illinoisbrick.com Home Page or under Documents and fill out the form Fax (708) 237-5632 / [email protected] or contact your Sales Representative ____________________________________________ Below is the information we would need from you (Some seminars require a minimum attendance) Date(s) Requested Option 1_________________ Option 2__________________ Option 3________________ Course Header:_____________________________________________________________ Course Title:_______________________________________________________________ Number of people attending:____________________________ Location for course to be held at: Address__________________________________________________________________ -

Edmar Diamond Blade Training Manual 2 What Is a Diamond Blade?

DIAMOND BLADE BASICS Edmar Diamond Blade Training Manual 2 What is a Diamond Blade? Continuous Turbo Segmented Edmar Diamond Blade Training Manual 3 What is a Diamond Blade? The blade core is a precision-made steel disc which may or may not have slots. Blade cores are tensioned so that the blade will run straight at the proper cutting speed. Proper tension also allows the blade to remain flexible enough to bend slightly under cutting pressure and then go back to it’s original position. Diamond segments or rims are made up of a mixture of diamonds and metal powders. The diamonds used in bits and blades are man-made (synthetic) and are carefully selected for their shape, quality, friability, and size. These carefully selected diamonds are then mixed with a powder consisting of metals such as cobalt, iron, tungsten, carbide, copper, bronze, and other materials. This mixture is then molded into shape and then heated at temperatures from 1700˚ to 2300˚ under pressure to form a solid metal part called the “bond” or “matrix.” The segment or rim is slightly wider than the blade core. This side clearance allows the cutting edge to penetrate the material being cut without the steel dragging against the sides of the cut. After the blade is assembled it is “opened,” “broken in,” or, “dressed” by grinding the edge concentric to the center. This exposes the diamonds that will be doing the work and establishes the cutting direction as noted by the direction of the arrow stamped into the blade. Edmar Diamond Blade Training Manual 4 Edmar Diamond Blade -

Repointing Masonry Walls

TM TECHNOLOGY BRIEF October 2002 RESOURCE INFORMATION FROM THE INTERNATIONAL MASONRY INSTITUTE Section 6.2 Repointing Masonry Walls The durability and longevity of masonry is greater than that of any other building material, as evident in the thousands of old brick buildings throughout our neighborhoods and towns. When designed and constructed properly, masonry can last hundreds of years or more. To maximize the life of a masonry building, the mortar joints will need periodic maintenance during the building’s life cycle. As with any building product continuously exposed to the elements, the joints are susceptible to weathering, acids in the rain, seismic movement, building settlement, freezing and thawing cycles, impact damage, and dirt. When visual inspection reveals that the mortar joints are cracking or otherwise deteriorated, restoration is necessary to help maintain the integrity of the wall system. Commonly known as tuckpointing, “repointing” is the preferred term used to describe the process of cutting out deteriorated mortar joints in a masonry wall and filling in those joints with fresh mortar. The goals of a repointing job should be to remove and replace mortar in a way that will main- tain the structural properties of the wall, improve the appearance of the wall, and form weathertight joints. To accomplish this, the architect should produce drawings and specifications that will clearly state the requirements for mortar removal, joint preparation, preparation of pointing mortar, and placing mortar in the joints. For best results, use only contractors employing trained, skilled tuckpointers. Determining Scope The architect should determine the scope of the work with the assistance of the tuckpointing contractor. -

Tuckpointing

(262) 377-4066 Or (414) 220-1111 PROFESSIONAL MASONRY - Done to meet and exceed state building codes. We only use fresh, high quality QUIKRETE™ concrete and mortar mixes to assure a perfect mix every time. The concrete we use contains poly-fiber to help prevent cracking TUCKPOINTING : We remove all deteriorated or otherwise unsound mortar joints by using suitable hand and/or power tools for cutting joints to a minimum depth of ¾ inches. Loose debris in the joints will be removed by brushing, blowing high velocity air into the joints, and/or flooding all joints with water. During removal, a significant amount of dust is created, so we protect affected areas including, but not limited to, air conditioners, shrubbery, open windows, shingles and vehicles. Once the mortar joints have been properly prepared, color matching, high strength, contractor grade, type S mortar will be neatly inserted into the joints. When the new mortar is properly finished and cured, it is cleaned to remove any stain and dirt. WATERPROOFING According to the Brick Industry Association, chimneys require special attention and We will match maintenance to prevent costly damage caused by water penetration. Because the existing chimneys project above the roof line, they are vulnerable to the elements. Nearly mortar color every chimney encountered has signs of water damage! The first step is to determine the cause and then find the best corrective measures. ChimneySave r™, the first product developed specifically for chimneys, has been used successfully by leading chimney professionals for nearly 20 years. It reduces water penetration into the masonry by 99.9%, according to ASTM tests conducted at the University of Wyoming. -

SPEC MIX Tuckpoint Mortar

SPEC MIX, Inc. – Guide Specification Note to User: This section contains macros to aid the editing process. By default Microsoft Word disables macros for virus security reasons. When you open a file that has macros, the yellow message bar appears with a shield icon and the enable content button. To enable these macros, click the Enable Content button. SECTION 04 05 13.91 TUCKPOINT MORTARING (To View Hidden Text, Type CTRL-H) PART 1 - GENERAL 1.1 SECTION INCLUDES A. Standard tuckpoint mortar for existing masonry. B. Colored tuckpoint mortar for existing masonry. 1.2 RELATED SECTIONS A. Section 04 01 20.91 - Unit Masonry Restoration. B. Section 04 05 13 - Masonry Mortaring and Grout C. Section 04 20 00 - Unit Masonry D. Section 04 21 00 - Clay Unit Masonry E. Section 04 22 00 - Concrete Unit Masonry F. Section 04 43 00 - Stone Masonry 1.3 REFERENCES A. American Concrete Institute (ACI): 1. ACI 530.1-02 - Specification for Masonry Structures. B. ASTM International (ASTM): 1. ASTM C 144 - Standard Specification for Aggregate for Masonry Mortar. 2. ASTM C 150 - Standard Specification for Portland Cement. 3. ASTM C 207 - Standard Specification for Hydrated Lime for Masonry Purposes. 4. ASTM C 260 - Standard Specification for Air-Entraining Admixtures for Concrete. 5. ASTM C 270 - Standard Specification for Mortar for Unit Masonry. 6. ASTM C 595 - Standard Specification for Blended Hydraulic Cements. 7. ASTM C 780 - Standard Test Method for Preconstruction and Construction Evaluation of Mortars for Plain and Reinforced Masonry. 8. ASTM C 979 - Standard Specification for Pigments for Integrally Colored Concrete.