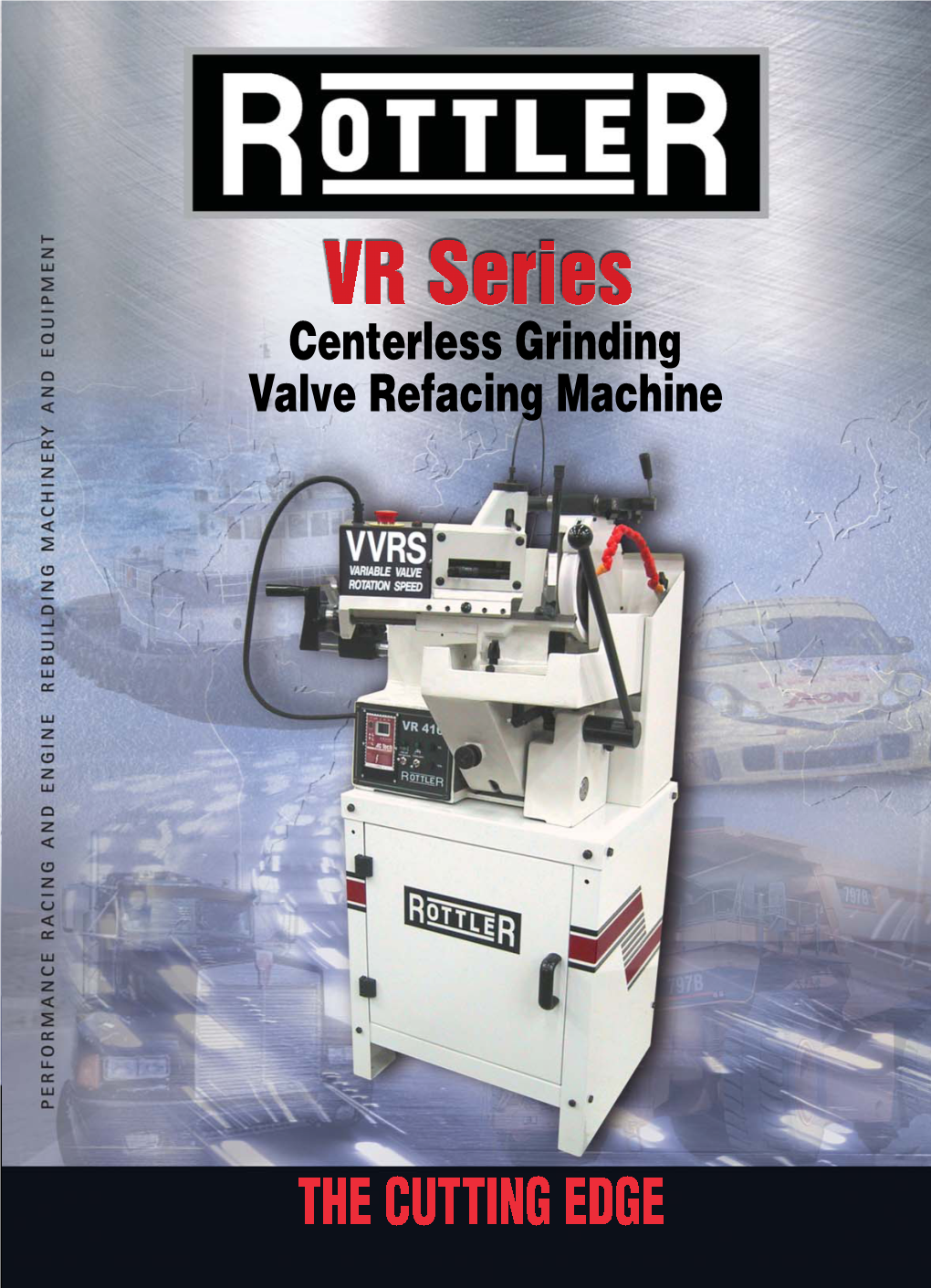

Centerless Grinding Valve Refacing Machine

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Manufacturing Processesprocesses

MANUFACTURINGMANUFACTURING PROCESSESPROCESSES - AMEM 201 – Lecture 10 : Machining Processes Grinding and other Abrasive Machining Processes DR. SOTIRIS L. OMIROU Abrasive Machining Abrasive machining uses tools that are made of tiny, hard particles of crystalline materials. Abrasive particles have irregular shape and sharp edges. The workpiece surface is machined by removing very tiny amounts of material at random points where a particle contacts it. By using a large number of particles, the effect is averaged over the entire surface, resulting in very good surface finish and excellent dimension control , even for hard, brittle workpieces. Abrasive machining is also used to machine brittle materials . Such materials cannot be machined easily by conventional cutting processes since they would fracture and crack in random fashion. 2 1 The main uses of grinding and abrasive machining 1. To improve the surface finish of a part manufactured by other processes. Examples: (a)A steel injection molding die is machined by milling. The surface finish must be improved for better plastic flow, either by manual grinding using shaped grinding tools, or by electro-grinding. (b) The internal surface of the cylinders of a car engine are turned on a lathe. The surface is then made smooth by grinding, followed by honing and lapping to get an extremely good, mirror-like finish. (c) Sand-paper is used to smooth a rough cut piece of wood. 3 The main uses of grinding and abrasive machining 2. To improve the dimensional tolerance of a part manufactured by other processes Examples: (a)ball-bearings are formed into initial round shape by a forging process; this is followed by a grinding process in a specially formed grinding die to get extremely good diameter control (≤ 15µm). -

GRINDING Abrasive Machining

GRINDING Abrasive machining: •The oldest machining process - “abrasive shaping” at the beginning of “Stone Era”. •Free sand was applied between two moving parts to remove material and shape the stone parts. Grinding: • Removing of metal by a rotating abrasive wheel. (Very high speed, Shallow cuts) • the wheel action similar to a milling cutter with very large number of cutting points. •Grinding was first used for making tools and arms. SURFACE GRINDING: Depth of Cut: 2-5 thou, 50-125 microns Work Table reciprocates beneath the wheel, Longitudinal feed Wheel crossfeed (Transverse feed) and infeed What makes the grinding different? Large number of cutting edges that are very small and made of abrasive grits. The cutting edges cut simultaneously. Very fine and shallow cut are only possible good surface finish (<Ra=0.8) and dimensional accuracy Finishing and important Operation Abrasive grits are extremely hard very hard material can be machined. e.g. hardened steel, glass, carbides, ceramics etc. Features with strict tolerance and surface finish are machined by grinding. e.g. Turbine Blade Fir-tree, Bearing seat diameters, tool making, tool repair, etc. Mesh sizes: 4 240 for grinding 240 600 for honing & lapping The shape of the grain affects accuracy of the grain screening GRINDING WHEELS Abrasive bonded together in a disk (wheel) three main factors influence the performance of the grinding wheel: a) Abrasive material b) Bonding material c) Structure Abrasives different for: Grinding (Bonded wheel) Honing (Bonded, very fine) Snagging (Bonded, belted) Lapping ( Free abrasives) Abrasive grains are bonded together to form tools (wheels) Abrasive NATURAL & MANUFACTURED A. -

5.1 GRINDING Definitions

UNIT-V GRINDING AND BROACHING 5.1 Grinding Definitions Cutting conditions in grinding Wheel wear Surface finish and effects of cutting temperature Grinding wheel Grinding operations Finishing Processes Introduction Finishing processes 5.1 GRINDING Definitions Abrasive machining is a material removal process that involves the use of abrasive cutting tools. There are three principle types of abrasive cutting tools according to the degree to which abrasive grains are constrained, bonded abrasive tools: abrasive grains are closely packed into different shapes, the most common is the abrasive wheel. Grains are held together by bonding material. Abrasive machining process that use bonded abrasives include grinding, honing, superfinishing; coated abrasive tools: abrasive grains are glued onto a flexible cloth, paper or resin backing. Coated abrasives are available in sheets, rolls, endless belts. Processes include abrasive belt grinding, abrasive wire cutting; free abrasives: abrasive grains are not bonded or glued. Instead, they are introduced either in oil-based fluids (lapping, ultrasonic machining), or in water (abrasive water jet cutting) or air (abrasive jet machining), or contained in a semisoft binder (buffing). Regardless the form of the abrasive tool and machining operation considered, all abrasive operations can be considered as material removal processes with geometrically undefined cutting edges, a concept illustrated in the figure: The concept of undefined cutting edge in abrasive machining. Grinding Abrasive machining can be likened to the other machining operations with multipoint cutting tools. Each abrasive grain acts like a small single cutting tool with undefined geometry but usually with high negative rake angle. Abrasive machining involves a number of operations, used to achieve ultimate dimensional precision and surface finish. -

CBN & Diamond Grinding Wheels

1 CBN & Diamond Grinding Wheels 2 3 Contents 4 6 24 About the CBN and Diamond For company Grinding Wheels users NAXOS-DISKUS Diamond and Application form Schleifmittelwerke GmbH Cubic Boron Nitride Technical information The DVS TECHNOLOGY GROUP Application-specific development at NAXOS-DISKUS Grinding wheel construction The key component: AUMENTO bonding Technical specification 4 5 About the company NAXOS-DISKUS NAXOS-DISKUS Schleifmittelwerke the extensive experience of the The The DVS TECHNOLOGY GROUP is With a unique combination of GmbH was founded as NAXOS- DVS mechanical engineering and made up of Germany-based compa- machining technologies, tooling Schleifmittelwerke UNION in Frankfurt in 1871, and production companies, a fact which DVS TECHNOLOGY nies focusing on the turning, gear innovation and production experi- cutting, grinding and gear honing ence for the machining of vehicle manufactures precision grinding GmbH is clearly refl ected in the quality GROUP technologies. Besides engineering powertrain components DVS is one tools for greatly differing applica- and design of the grinding wheels. and manufacturing machine tools as of the leading system suppliers in tions. The product range covers Special products such as mill well as grinding and honing tools, the industry. abrasive wheels for double face wheels, leather polishing rollers, DVS operates two production sites where automotive parts are The DVS TECHNOLOGY GROUP grinding, outer diameter grinding, nurit rollers and bulk abrasives machined in series production has more than 1,000 employees centerless grinding as well as gear supplement the extensive range of exclusively on DVS machines. This worldwide. On key markets like grinding and gear honing, from products. -

Ct 250 Nd Soluble Oil for Machining/Grinding Applications on All Metals - Chlorinated

METAL WORKING FLUID | TECHNICAL DATA SHEET CT 250 ND SOLUBLE OIL FOR MACHINING/GRINDING APPLICATIONS ON ALL METALS - CHLORINATED PRODUCT DESCRIPTION APPLICATION CT 250 ND is a water emulsifiable, soluble oil cutting and grinding fluid. CT 250 ND exhibits a balanced lubrication regime of both boundary lubricant additives and chlorine for extreme pressure requirements. CT 250 ND forms a clean and stable emulsion in all water types and is formulated with a non- formaldehyde biocide to extend the serviceable sump life of the emulsion. CT 250 ND combines tenacious film strength with improved cooling capacity found only in water reducible products. It is particularly well suited for a variety of cutting and grinding operations such as broaching, tapping, gear shaping, deep drilling, boring, screw machining, end milling, and reaming of hard steels and nickel alloys. CT 250 ND is applicable for use on both ferrous and non-ferrous metals. COMPATIBLE METALS Cast Iron Carbon Steel FEATURED BENEFITS Tool Steel • Unusually tight emulsion for a soluble oil. Improves wetting and cooling Stainless Steel for superior tool life. Aluminum • Reduced Consumption: A stable tight emulsion reduces usage from carry Titanium Inconel out when compared with other soluble oils. Bronze • Additive Independent: No need for tank side pH buffers, emulsifiers, or Copper costly and hazardous biocides Brass • Cost effective regardless of whether you have individual sumps or large central systems MACHINING CAPABILITIES • Applicable for both ferrous and non-ferrous metal applications -

Dedtru® Centerless Grinding Product Line

Price List PL UNISON CORPORATION DedTru® Centerless Grinding Product Line Model C Model PGF DedTru Grinding Fixture Plunge Grind Fixture Model C6 Model IGF DedTru Grinding Fixture Internal Grind Fixture 1601 Wanda Avenue Ferndale, MI 48220 Phone: 248-544-9500 Fax: 248-544-7646 Website: www.unisoncorp.com Email: [email protected] 1 DedTru ® Centerless Grinding Product Line The description of Unison Corporation’s DedTru Centerless Grinding product line is presented in the following information. Please contact any member of our Marketing Department to request a detailed quotation for each machine. DedTru ® Systems, 6x18 Grinder DedTru Centerless Grinding Systems (388-0000) includes the DedTru Basic 6 x 18 Grinder with a hole through the column for longer parts; Model C DedTru Unit, dual sine base assembly, 3 hp spindle, coolant system with FilTru Tank Assembly and FilTru Coolant Settling Tank, 1/4” carbide blades for throughfeed (with guides), plunge and infeed work from 1/4” to 1-1/4” diameter, one part stop, one pressure roll assembly, work light and wheel guarding for up to 2” wide wheel. Arranged for 230 or 460 volt (when ordering specify voltage), 3 phase, 60 Hz power supply. For manual operation; maximum part diameter with optional accessories 4”. (For diameters to 5” add increased height for grinder, page 9, and 078-0000 (page 6), for diameters from .031” to 1/4” (tooling accessories, page 5). Shipping Weight and Dimensions: 1345 lbs/46” x 56” x 82” high DedTru Centerless Grinding System with Model PGF Unit ( 399-0000) is the same as a Model 388-0000 except it is equipped with a Model PGF DedTru Unit with quick change 5” x 2” regulating roll. -

Dedtru Parts Brochure

Price List PL Unison Corporation DedTru® Centerless Grinding Product Line Model C Model PGF DedTru Grinding Fixture Plunge Grind Fixture Model IGF Internal Grind Fixture Model C6 DedTru Grinding Fixture 1601 Wanda Avenue Ferndale, MI 48220 Phone: (248) 544-9500 Fax: (248) 544-7646 Email: [email protected] Website: www.newunison.com 1 DedTru ® Centerless Grinding Product Line The prices for New Unison Corporation’s DedTru Centerless Grinding product line are presented in the following information. Please contact any member of our Marketing Department to request a detailed quotation for each machine. All prices are for equipment prepared for domestic shipment and are EXW Ferndale, Michigan, U.S.A. The company reserves the right to change prices as required without prior notification. DedTru ® Systems, 6x18 Grinder DedTru Centerless Grinding Systems includes the DedTru Basic 6 x 18 Heavy-Duty Grinder with a hole through the column for longer parts; Model C DedTru Unit, dual sine base assembly, 3 hp spindle, coolant system with FilTru Tank Assembly and FilTru Coolant Settling Tank, 1/4” carbide blades for throughfeed (with guides), plunge and infeed work from 1/4” to 1-1/4” diameter, one part stop, one pressure roll assembly, work light and wheel guarding for up to 2” wide wheel. Arranged for 230 or 460 volt (when ordering specify voltage), 3 phase, 60 Hz power supply. For manual operation; maximum part diameter with optional accessories 4”. (For diameters to 5” add increased height for grinder, page 9, and 078-0000(page 6), for diameters from .031” to 1/4” (tooling accessories, page 5). -

Machinery List Rev

Machinery list Page a Rev. I9 Document Title: Machinery list Rev.: I9 Date: 22 Nov 2019 The information contained herein is proprietary of OMA S.p.A. and shall not be reproduced or disclosed or in whole or in part or used for any purpose other than that for which it is supplied without written authorization of OMA S.p.A. This Document consists of 30 pages. Machinery list Page b Rev. I9 Table of Contents 1.0 INTRODUCTION ................................................................................................................................... 1.1 2.0 OMA PLANTS ...................................................................................................................................... 2.1 3.0 MECHANICAL PARTS MANUFACTURING ............................................................................................. 3.2 3.1 MILLING MACHINES .................................................................................................................................. 3.2 3.2 LATHING MACHINES .................................................................................................................................. 3.6 3.3 DRILLING MACHINES ................................................................................................................................. 3.9 3.4 GRINDING MACHINES ............................................................................................................................. 3.10 3.5 HONING / LAPPING / SHARPENING ........................................................................................................ -

Sanyo-Seiki Co., Ltd

Sanyo‐Seiki Co., Ltd. ロゴ Precision Parts and Various Bushing Core Technology MD/Toshiyuki Hikono (President) ・Small,High-quality,Precision machining Location/A19-4 Kurosaki Kaga Ishikawa 922-0565 ・Various bushing TEL +81 (761) 75 - 1011 ・Maximum diameter φ200 ×length 300 FAX +81 (761) 75 - 1134 ・Maximum thickness of 250×300×300 URL https://www.isico.or.jp/virtual/ ・Aluminum(2024, 5052, 6061, 7075, etc) E-Mail [email protected] ・Stainless steel(303, 304, 440C, 630, etc) Sales Rep./Hirokazu Hikono (Senior Managing Director) ・Titanium,Inconel,Hastelloy,Permalloy Quality Rep./Tetsuji Sano (Department) ・Bronze, Copper ・Resin Capital/30million Jap.yen ・Forging, Castings Employee/M : 20 F : 8 Total : 28 Major Products Selling Points Aircraft parts ・Delivery as a finished part with mill sheet, special process, Space equipment parts inspection report. Hydraulic equipment parts ・Reduction of the total cost for bushing. Semiconductor manufacturing equipment parts ・Perfect finishing. LCD manufacturing equipment parts ・All processing handled in-house. Industrial machinery parts ・Reliable delivery management and quality control management. Major Clients Aircraft manufacturers Hydraulic equipment manufacturers Proposal Details Semiconductor manufacturing equipment manufacturers ・Hoping to expand small parts machining in the fields of Industrial machinery manufacturer aircraft Certification Specifications JISQ9100:2016 ・On-time delivery, and quality is the highest priority. ・Offering products made with general-purpose machines such as ordinary lathe, milling machine, or cylindrical grinder MachineryNos. Machinery Nos. Vertical Machining CenterMILLAC-M511V 2 Horizontal Milling Machine STM-2H 3 machin. 〃MILLAC-45V 1 4-head drilling machine 40M(KRT340) 2 ・Burrs can be removed through a finishing process that uses 〃MILLAC-3VA 3 Cylindrical Grinding Machine GUP-32-50 2 a microscop. -

The Benefits of Thread Rolling SEE PAGE 15 SEE PAGE

PURCHASING’S GATEWAY TO NEW SOURCES No. 248 FREE SUBSCRIPTION KEEPING PURCHASING DECISION MAKERS INFORMED 25,000+ readers read THE GATEWAY in over 7,500 companies February 2020 SEE PAGE 3 SEE PAGE The Benefits Of Thread Rolling SEE PAGE 15 SEE PAGE COVER PHOTO : UNITED CENTERLESS GRINDING & THREAD ROLLING | 25 Rosenthal St | East Hartford, CT 06108 Fresh Air Ventilation Systems designed by VentilationUSA LLC CONTENTS FEBRUARY 2020 | ISSUE 248 Ventilation Without Losing Heat! ™ COMPANY SHOWCASE with BPE Air-To-Air Heat Exchanger 03 United Grinding & Thread Rolling PUBLICATION MANAGER Matthias Roberge INDUSTRY INSIGHTS EDITORIAL DIRECTOR SOLUTIONS Chris Hislop 15 Applying Pressure: The Benefits of Thread Rolling • Humidity Issues ART DIRECTOR • Air Quality Issues Adam Kaufmann INDUSTRY NEWS • Odors Into Offices ONLINE MARKETING • Saving Energy $$$$$$$$$$ 22 Regional Press Adam Kaufmann Beau Pingree • Employees Health Concerns 24 Upcoming Events • Lack Of Breathable Fresh Air • Utilize Compressor Heat 24 Classifieds ADVERTISING INQUIRIES (877) 463-4020 28 Research and development (Mushield Company) [email protected] Hours: 9am-5pm Mon-Fri MAILING ADDRESS February. The month for lovers. CALL NOW: 800-622-8078 WWW.VENTUSA.COM 871 Islington Street, B105 Portsmouth, NH We’re not sure how that relates, but it’s the first thing that popped into our 03801 minds when brainstorming began for the introductory blurb for this particular FRESH AIR VENTILATION SYSTEMS issue. That said, maybe it’s a good time to tell your employees, vendors, and SOLUTIONS partners how much you appreciate their hard work. It’s cold here in the FOR FREE SUBSCRIPTIONS northeast – this is opportunity to warm up the floor, which, who knows, may • Cold Drafts www.thegatewaymag.com increase productivity! Go ahead, spread some love. -

Centerless Grinding Machines

www.kentusa.com Centerless Grinding Machines JHC-12 ∙ JHC-18 ∙ JHC-20 ∙ JHC-24S ∙ JHC-CNC www.kentusa.com Features 1. Main Structure of Machines They are cast of high grade FC-30 iron, melted by advanced induction furnace, then cast in resin cores. In order to ensure stability and rigidity, they are heat-treated with normalizing procedure prior to machining. 2. Hyrdostatic Bearings Precision ground Hydrostatic Bearings: Substantial decrease in heat deformation associated with Hydrodynamic bearings. Minimal friction, lateral displacement and pressure. Extended tool life under heavy cut loads. Grinding Wheel Spindle: The Grinding Wheel Spindle runs on hydrostatic bearings with a high pressure oil film for added precision under heavy loads. It substantially reduces wear while prolonging spindle trueness. SNCM-210H carbon steel hardened beyond HRC60, yielding high torsion resistance. 3. Semi-Hydraulic Float Bearings They are made of SNCM-220H Ni-Cr-Mo alloy steel and case-hardened, carbonized, then computerized sub-zero degree treated, to surface hardness over HRC 62 at 0.04” depth. Core hardness is kept at about HRC 25-30 to ensure consistency of high precision grinding operation. Spindles withstand high torsion and have a long and lasting life. They are made of KJ-4 alloy bushing metal with a three point hydraullic cycle system. The semi-hydraullic float spindle is protected by an oil membrane which results in minimal contract friction. This device is specially designed for high speed and heavy load operation. 4. Regulating Wheel Drive A Japanese servo motor provies control of speeds from 10 to 250RPM and is used for the regulating wheel which can be adjusted to ideal linear speeds. -

Dedtru Centerless Grinding Systems

DedTru Centerless Grinding Systems Model C DedTru Fixture Model 388 6 x 18 base Model PGF DedTru Fixture Model 399 6 x 18 base DedTru Centerless Grinding Systems Unison DedTru® Centerless Grinding Unison DedTru® Centerless Grinding Units which are mounted on our new style surface grinder creates an extremely accurate and versatile grinding system for tool room and job shop applications. With more than 10,000 units worldwide, the DedTru has proven its reliability and provides a cost effective solution for both single piece and large volume centerless grinding operations . Maximum Versatility Designed for applications with conventional Diamond and CBN grinding wheels, the DedTru grinding system provides: ► Thrufeed grinding of cylindrical parts ► Infeed grinding for headed, splined, geared and formed parts ► Secondary operations for steps, forms and tapers requiring precise concentricity, size and roundness ► Tapers and chamfers Parts ranging in diameter 1/32-inch (0.8mm) to 5-inches (125mm) can be handled. With a hole in the column, outboard supports and a variety of options, extended lenghts over 12-inches can be accomodated. Additional Features ► Fast, easy setups ► Internal grinding ► Concentric step grinding Designed For Customer Satisfaction Unison’s commitment to customer satisfaction is evident in both the design and manufacture of our DedTru Centerless Grinding System. We engineer our machines for reliability. All of our DedTru units are backed by New Unison’s one-year limited warranty. Factory training is provided upon request. Unison DedTru Centerless Grinding Systems are built with our new 6” x 18” base ,which provides exceptional accuracy and roundness. Rigid part support insures consistent concentric- ity up to .000050 inch (.0012mm).