Cohoe Radio Observatory, Alaska ~ Part 3, Guyed Tower Installation Whitham D

Total Page:16

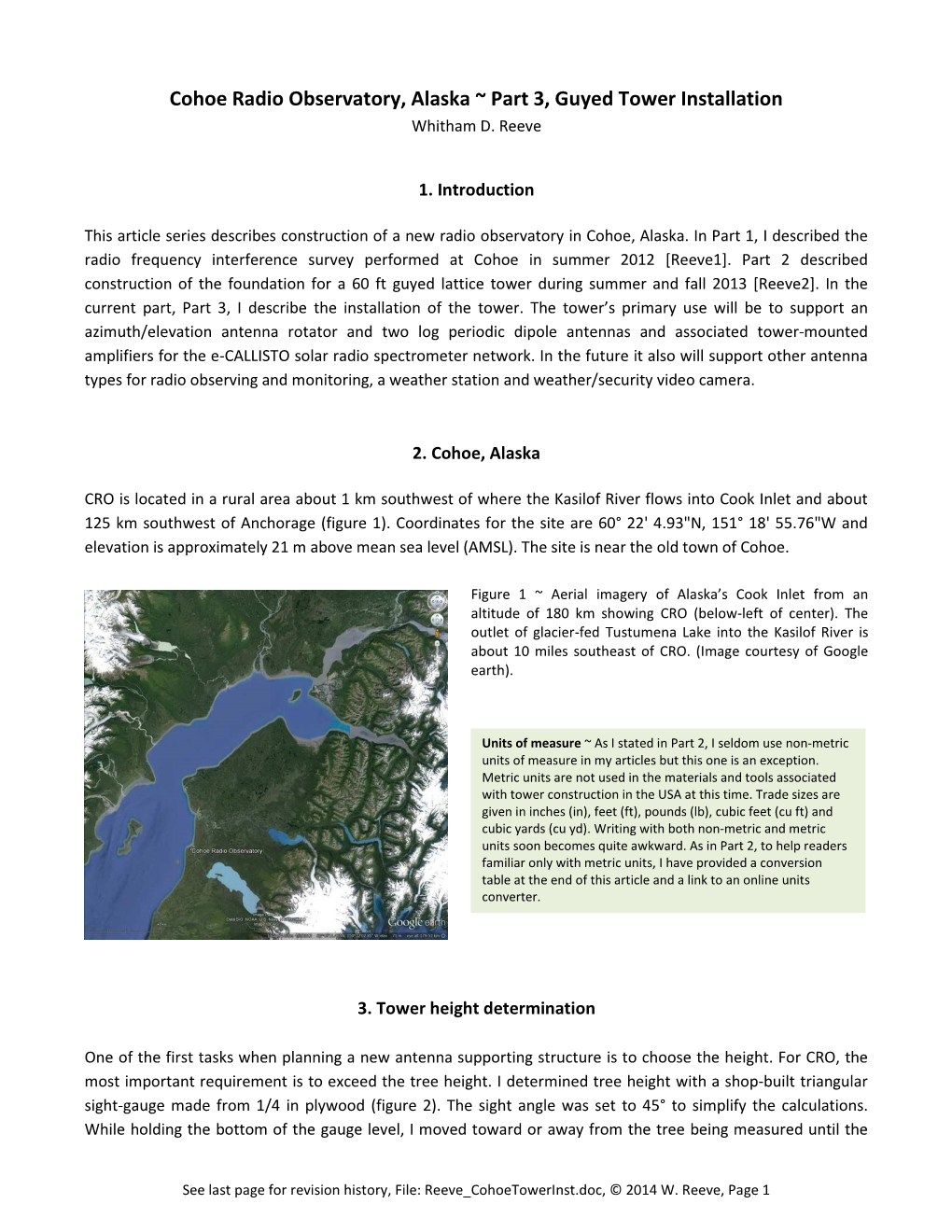

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

The Construction of a High-Rise Development Using Volumetric Modular Methodology

ctbuh.org/papers Title: The Construction of a High-Rise Development Using Volumetric Modular Methodology Author: Phillip Gardiner, Managing Director, Irwinconsult Subjects: Architectural/Design Building Case Study Construction Economics/Financial Keywords: Design Process Economics Modular Construction Sustainability Publication Date: 2015 Original Publication: The Future of Tall: A Selection of Written Works on Current Skyscraper Innovations Paper Type: 1. Book chapter/Part chapter 2. Journal paper 3. Conference proceeding 4. Unpublished conference paper 5. Magazine article 6. Unpublished © Council on Tall Buildings and Urban Habitat / Phillip Gardiner The Construction of a High-Rise Development Using Volumetric Modular Methodology Phillip Gardiner, Managing Director, Irwinconsult The SOHO Tower is a 29-level modular building the cost and shortage of a skilled construction Another driver was the foundation in Darwin, in the far north of Australia, a workforce led to a decision to investigate a conditions. Darwin is underlain cyclonic region. The building was designed to volumetric modular alternative, with modules predominantly by a crust of soft Porcellanite incorporate a basement and eight floors built delivered complete with all finishes, joinery rock overlying softer Cretaceous sedimentary with conventional reinforced concrete followed and fittings. It was essential however that deposits of Phyllite to a very significant by 21 levels of volumetric modular apartments. the building layout and appearance not be depth. Buildings have been typically founded The modules were constructed and fully finished changed in any substantial way. This was a on pads or rafts founded in the soft rocks in Ningbo, China and shipped to Darwin. Unlike significant challenge. at bearing pressures that would not cause most modular systems, a concrete floor was unacceptable levels of settlement. -

Evaluating Skyscraper Design and Construction Technologies on an International Basis

EVALUATING SKYSCRAPER DESIGN AND CONSTRUCTION TECHNOLOGIES ON AN INTERNATIONAL BASIS by Saad Allah Fathy Abo Moslim B.Sc., Mansoura University, Egypt, 1984 M.Eng., The University of British Columbia, Canada, 2000 A THESIS SUBMITTED IN PARTIAL FULFILLMENT OF THE REQUIREMENTS FOR THE DEGREE OF DOCTOR OF PHILOSOPHY in THE FACULTY OF GRADUATE AND POSTDOCTORAL STUDIES (Civil Engineering) THE UNIVERSITY OF BRITISH COLUMBIA (Vancouver) November 2017 © Saad Allah Fathy Abo Moslim, 2017 Abstract Design and construction functions of skyscrapers tend to draw from the best practices and technologies available worldwide in order to meet their development, design, construction, and performance challenges. Given the availability of many alternative solutions for different facets of a building’s design and construction systems, the need exists for an evaluation framework that is comprehensive in scope, transparent as to the basis for decisions made, reliable in result, and practical in application. Findings from the literature reviewed combined with a deep understanding of the evaluation process of skyscraper systems were used to identify the components and their properties of such a framework, with emphasis on selection of categories, perspectives, criteria, and sub-criteria, completeness of these categories and perspectives, and clarity in the language, expression and level of detail used. The developed framework divided the evaluation process for candidate solutions into the application of three integrated filters. The first filter screens alternative solutions using two-comprehensive checklists of stakeholder acceptance and local feasibility criteria/sub-criteria on a pass-fail basis to eliminate the solutions that do not fit with local cultural norms, delivery capabilities, etc. The second filter treats criteria related to design, quality, production, logistics, installation, and in-use perspectives for assessing the technical performance of the first filter survivors in order to rank them. -

WGP 107 (18) Offshore Oil and Gas Platforms

Corporate Solutions WGP 107 (18) Offshore Oil and Gas platforms Eric Brault - Energy Practice Leader PROTECT PREVENT SERVE RESOLVE PARTNER OFFSHORE OIL& GAS PLATFORMS IMIA WGP 107 (18) Part icipant s: Eric Brault – AXA Coporate Solutions - Chairman Ma r t in Ka u t h - Partner Re Mark Mackay - AXA Corporate Solutions Al a i n Padet - AXA Corporate Solutions Mik e McMahon - Charles Taylor Consultant Mohamed F. El-Ai l a h - Qatar General Ins Javier Rodriguez Gomez - Reinsurance Consultancy Mexico Roman Emelyanov - SOGAZ Insurance Group Thomas Friedrich – Munich Re Eve Ong - Helvetia Stephan Lämmle – Munich Re – Sponsor 2 PROTECT PREVENT SERVE RESOLVE PARTNER Technical description of Offshore Plat forms Construction process and components Information needed and Underwriting Consideration Pure Insurance Aspect s MPL Considerat ions and Accumulation driving system Ex am p l e of Loss Recommendat ions Conclusion 3 Executive summary The development of an oil field is a broad complex subject, which needs strong analysis. The Presentation is a overhaul view of the risks assessment, concerning the construction of the offshore platforms. We do not focused on specific subjects such as: Covers of the drilling of wells , risk inherent to the research for new oilfield, operation of the platforms, processes for NG and oil, pressurizing, storage, market absorption and dismantling ... We pay attention on the risks to anticipate and balance the construction phase, weather and sea condition impact, importance of the design, the safety systems, details on the MPL scenarios during the construction, putting in place of the platform and starting of operation phase. The MWS role and his importance is also described. -

No Longer Just a Hole in the Ground the Adaptive Re-Use of Derelict Quarries

1 NO LONGER JUST A HOLE IN THE GROUND The Adaptive Re-Use of Resource Depleted Quarries Catherine McCandless Urban Nature and City Design Professor Anne Whiston Spirn MIT 4.213J/11.308J Fall 2013 2 Table of Contents ABSTRACT 3 Introduction 4 Quarrying Activity 5 Cases 6 1. Brownstone Park 7 2. Quarry Falls 9 3. Bellwood Quarry 11 4. Butchart Gardens 13 5. Groundscraper Hotel 15 Conclusion from Cases 17 Looking Forward 18 REFERENCES 19 3 Abstract A quarry is an area from which rocks such as marble, limestone, and granite are extracted for industrial use. Once depleted of their desired resources, quarries are frequently abandoned. The resulting gaping holes can fill with water and form dangerous quarry lakes while others are turned into unsightly landfills. When quarries are in close proximity to urban environments, inhabitants are subjected to pollution and noise, and the undeniable eyesore of an abandoned quarry remains long after excavation is completed. Sustainable redevelopment has become a shining solution for these abandoned, resource-depleted quarries. Dozens of cities in America and abroad have undertaken adaptive re-use projects to transform quarries into a variety of public and private spaces. The potential new uses for these expanses of land include sites for research and education, aquaculture, recreational activities, storage, industry and housing. The goal of my research is to encourage the rehabilitation of land disturbed by quarrying by making the areas suitable for new sustainable land uses. I will examine cases that successfully transformed resource-depleted quarries into commercial and residential communities, and will discuss how further to improve future redevelopment of quarries with greater consideration to environmental impact and biodiversity. -

NMB Bank Headquarters the Impressive Performance of a Green Building W ILLIAM B ROWNING

Reprinted with pemission from the Urban Land Institute the Urban Land Institute www.uli.org In project design and construction, “green” means putting environmen- June June 1992 tal concerns first. Doing so ENVIRONMENT can mean big pay offs, as this Amsterdam office building proves. NMB Bank Headquarters The Impressive Performance of A Green Building W ILLIAM B ROWNING hen Nederlandsche Middenstandsbank (NMB), then the number four bank in the Netherlands, felt the need, in 1978, for a W new image and a new headquarters, its board of directors set out some unusual criteria. The board asked for an organic building that would integrate art, natural materials, sunlight, green plants, energy conservation, low noise levels, and water, reports Tie Liebe, head of Maatschappij voor Bedrijfsobjecten (MBO), NMB’s real estate develop- ment subsidiary. Per vote of the bank’s employees, the new headquarters would be built in a growing area south of Amsterdam. An integrated team instructed to work across disciplines–an architect, a construction engineer, a landscape architect, an energy expert, and artists– worked for three years designing the building. Construction began in 1983 and was completed in 1987. The NMB building is no monolithic tower. To the contrary, its 538,000 square feet (50,000 square meters) of office space housing 2,400 employees is broken up into a series of 10 slanting towers arranged in an irregular S-curve with gardens and courtyards interspersed. Portions of the complex are supported by a 301,280-square-foot structure (28,000 square meters) containing parking and service areas. Restaurants and meeting rooms line the internal “street” that connects the towers on the mezzanine level. -

Teacher Background

Teacher Background Inquiry Description In many parts of the world today, notably in Asia, societies are rapidly transforming. A major part of this transformation is urbanization, the flocking of people from the countryside to cities. A sign of this transformation is the construction of tall buildings. Since the Lincoln Cathedral surpassed the Pyramids of Egypt in 1300 CE, all of the tallest buildings in the world were in Europe and North America. Then, in 1998, the Petronas Towers opened in Kuala Lumpur, Malaysia. Today the five tallest buildings are in Asia (One World Trade Center in New York City is #6) These areas are being transformed because of their integration into the world economic system that itself was the result of the Industrial Revolution in the 19th century in Western societies and the subsequent growth and expansion of those western societies. Interestingly, tall buildings, known as skyscrapers, were a sign of urbanization and industrial growth in Europe and North America at that time. This unit explores the connections between industrialization, urbanization, and skyscrapers, and how it was that skyscrapers were able to be built when and how they were. Key areas of attention will be building materials and related technologies that allowed for taller structures. Teachers are encouraged to use the following notes as they prepare for this unit, and additional secondary resources are listed at the end of this document. Historical Background Agriculture and Monumental Architecture In the long arc of human history, there are two interesting phenomena that might seem separate, but in hindsight are closely related. On the one hand, people have continually intensified their food production, leading to the ability to sustain larger populations on the same amount of land with fewer direct food producers. -

Town of Provincetown Zoning By-Laws

TOWN OF PROVINCETOWN ZONING BY-LAWS Provincetown Planning Board September 1, 1978 Last Updated: August 18, 2021 Town of Provincetown, Massachusetts – Zoning By-laws Page 2 Amendments Adoption Revisions APPROVED BY TOWN APPROVED BY THE APPROVED BY TOWN APPROVED BY THE MEETING ATTORNEY GENERAL MEETING ATTORNEY GENERAL November 13, 1978 April 6, 1979 April 6, 2009 ATM July 14, 2009 March 10, 1980 November 8, 2010 STM February 22, 2011 March 9, 1981 December 16, 1981 April 4, 2011 June 20, 2011 March 8, 1982 July 12 and 13, 1982 October 24, 2011 STM November 3, 2011 October 27, 1982 January 11, 1983 April 2, 2012 ATM May 7, 2012 March 14, 1983 April 26, 1983 October 21, 2013 STM January 13, 2014 March 12, 1984 July 5, 1984 April 7, 2014 ATM May 15, 2014 March 11, 1985 June 11, 1985 April 6, 2015 ATM May 19, 2015 June 10, 1985 August 19, 1985 October 26, 2015 STM December 10, 2015 October 15, 1985 January 31, 1986 April 4, 2016 ATM July 11, 2016 March 10, 1986 April 11, 1986 April 3, 2017 ATM July 6, 2017 October 27, 1986 November 25, 1986 September 13, 2017 STM January 11, 2018 March 9, 1987 April 17, 1987 April 2, 2018 ATM July 18, and Oct 12, 2018 March 14, 1988 May 19, 1988 October 29, 2018 STM February 22, 2019 March 13, 1989 June 5, 1989 April 1, 2019 ATM May 6, 2019 March 12, 1990 May 7 and June 8, 1990 May 1, 2021 ATM August 18, 2021 April 1, 1991 June 12, 1991 April 6, 1992 July 2, 1992 November 5, 1992 January 11, 1993 April 7, 1993 July 13, 1993 October 27, 1993 January 7, 1994 April 1, 1996 May 6, 1996 October 28, 1996 November -

Hibernia Offshore Oil Platform St

Hibernia Offshore Oil Platform St. John's, Newfoundland, Canada Structural: Bridges & Marine Location: St. John’s, Newfoundland, Canada Contractor: Kiewit with joint venture partner Norwegian Contractors Owner: ExxonMobil Canada (33.125%), Chevron Canada Resources (26.875%), Petro-Canada (20%), Canada Hibernia Holding Corporation (8.5%), Murphy Oil (6.5%) and Norsk Hydro (5%). The Hibernia Oil Field lies approximately 200 miles (315 km) east-southeast of St. John’s, Newfoundland, Canada. When an offshore platform was deemed necessary to tap this rich petroleum resource, engineers and developers faced serious challenges. The project had to meet a tight construction schedule while overcoming the problems of working in extremely cold weather conditions. The structure had to withstand the most severe environmental stresses of freezing and thawing, ice abrasion, wind and wave action, and chemical attack. In addition, the giant structure was required to float, be towed to the site, and after placement withstand the impact of 5.5 million ton iceberg. To satisfy the tough requirements, a reinforced Gravity Base Structure (GBS) was designed. Weighing more than 1.2 million tons, the Hibernia offshore platform is the largest floating structure ever built in North America. The base raft portion of the GBS was built in an earthen “dry dock.” By flooding the dock, the base raft was floated, towed to a deep-water harbor area, anchored, and construction continued. Once completed, this floating giant was towed to the oil field site and set in place on the ocean floor in about 240 ft. (80m) of water. The GBS was designed to be maintenance free for its 30-year life. -

Construction Work Plan

FFY-2021 through FFY-2028 Construction Work Plan Volume XVIII Table of Contents SECTION I FOREWORD - Letter from the Director SECTION II BUDGETARY PROJECTIONS SECTION III BALANCING PROCESS SECTION IV SUMMARY REPORT CONSTRUCTION WORK PLAN SECTION V Sorted by Federal Fiscal Year and by County Presented for Transportation Commission Consideration December 7, 2020 FOREWORD BUDGETARY PROJECTIONS Budgetary Projections CONSTRUCTION WORK PLAN - FFY 2021 through FFY 2028 The budgetary projections utilized for the basis of the fiscally responsible and financially balanced Construction Work Plan were established through a systematic evaluation of the Department’s anticipated State-Aid and Federal-Aid revenues and expenditures. Projections were performed for Federal Fiscal Years 2021 – 2028 with the Federal Fiscal Year defined as beginning October 1st and ending on September 30th. The budgetary projections only address funding that has been historically and/or categorically committed to State, Federal and Interstate highway system improvements and does not address Department initiated set asides or other mandated programs. For the purposes of the initial projections, an estimated baseline State-Aid amount of $282.03 million and an estimated Federal-Aid amount of $401.88 million was utilized as the Fiscal Year 2021 benchmark. The Federal-Aid amount includes a 7.5% projection overstatement to avoid any potential loss of future Federal-Aid funds due to under programming. Of particular note, the annual baseline State-Aid amount available for Construction Work Plan projects is expected to grow to over $384.56 million during the next eight years. As the Federal-Aid benchmark amount will vary based upon the results of the annual Congressional budgeting process, the estimated projections will require further adjustment and we will adapt our Construction Work Plan accordingly. -

Canton Zoning By-Laws Section 1.0 Purpose And

CANTON ZONING BY-LAWS SECTION 1.0 PURPOSE AND AUTHORITY 1.1 TITLE This By-law shall be known as the "Zoning By-law of the Town of Canton, Massachusetts," hereinafter referred to as "this By-law." 1.2 PURPOSE. These regulations are enacted to promote the general welfare of the Town of Canton , to protect the health and safety of its inhabitants, to encourage the most appropriate use of land throughout the town, and to increase the amenities of the town, all as authorized by, but not limited by, the provisions of the Zoning Act, G.L. c. 40A, as amended, and Section 2A of 1975 Mass. Acts 808. 1.3 AUTHORITY. This Zoning By-Law is enacted in accordance with the provisions of the General Laws, Chapter 40A, any and all amendments thereto, and by the Home Rule Amendment, Article 89 of the Amendments to the Constitution of the Commonwealth of Massachusetts. 1.4 APPLICABILITY . The use, construction, repair, alteration, height, location, percentage of lot coverage by buildings and structures and the use of land in the Town of Canton are hereby restricted and regulated as herein provided. No building, structure or land shall be used or occupied and no building or structure or part thereof shall hereafter be erected, constructed, reconstructed, moved or structurally altered unless in conformity with the regulations of this By-Law, except those already lawfully existing as provided below. 1.4.1 Applicability; Non-conformities. Except as herein after provided, this Bylaw shall not apply to structures or uses lawfully in existence or lawfully begun, -

Skyscraper Height

Skyscraper Height Jason Barr∗ Rutgers University, Newark [email protected] Rutgers University Newark Working Paper #2008-002 Abstract This paper investigates the determinants of skyscraper height. First a simple model is provided where potential developers desire not only profits but also status, as measured by their rank in the height hi- erarchy. The optimal height in equilibrium is a function of the cost and benefits of building as well as the height of surrounding buildings. Using data from New York City, I empirically estimate skyscraper height over the 20th century. The results show that the quest for status has increased building height by about 15 floors above the non- status profit maximizing height. In addition, I provide estimates of which buildings are “too tall” and by how many floors. JEL Classification: D24, D44, N62, R33 Key words: Skyscrapers, building height, status, New York City ∗I would like to thank Alexander Peterhansl, Howard Bodenhorn, Sara Markowitz and seminar participants at Lafayette College for their helpful comments. I would like to acknowledge the New York City Hall Library, the New York City Department of City Planning and the Real Estate Board of New York for the provision of data. This work was partially funded from a Rutgers University, Newark Research Council Grant. Any errors are mine. 1 1 Introduction Skyscrapers are not simply tall buildings. They are symbols and works of art. Collectively they generate a separate entity—the skyline—which has its own symbolic and aesthetic importance. Despite the initial fears that the attacks of September 11, 2001 would cur- tail construction, skyscrapers continue to be built in large numbers around the globe (Economist, 2006). -

Transportation Hub Will Be a Safe Haven

Issue: 06/29/2015 Transportation Hub Will Be a Safe Haven San Francisco "groundscraper's" robust steel frame engineered to allow immediate reoccupancy after a very strong quake 06/29/2015 By Scott Blair A crane on a trestle lifts an architectural steel assembly, including a 9‐ft‐tall cast node, into place along the perimeter of the $4.5‐billion Transbay Transit Center, which is taking shape in seismically active San Francisco. The node picks, followed by more steel tubes that link to form a four‐and‐a‐half‐block‐long exoskeleton, is repeated more than 300 times. The lateral‐load‐resisting system will allow immediate reoccupancy of the 1,425‐ft x 171‐ft "groundscraper" after the "Big One." The architect for the five‐level bus‐and‐rail hub calls the 304 expressed custom nodes, which weigh from 2 tons to 23 tons each, robust and muscular. "We are trying not to let them look light or delicate because they are anything but [that]," says designer Fred Clarke, senior principal with Pelli Clarke Pelli Architects (PCPA). Designated an essential facility by the city, the four‐and‐a‐half‐block hub must be available for "immediate occupancy after what we're calling a 975‐year earthquake," says Bruce Gibbons, a managing principal of structural engineer Thornton Tomasetti (TT). That is equivalent to a magnitude‐8 temblor on the nearby San Andreas fault, he adds. Using performance‐based seismic design (PBSD), TT followed stringent requirements set forth by the Transbay Joint Powers Authority (TJPA), the public agency set up in 2001 to manage the project.