CHAPTER III Solder Joint Reliability Assessment

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Isothermal Fatigue Properties of Sn--Ag--Cu Alloy Evaluated By

Materials Transactions, Vol. 46, No. 11 (2005) pp. 2309 to 2315 Special Issue on Lead-Free Soldering in Electronics III #2005 The Japan Institute of Metals Isothermal Fatigue Properties of Sn–Ag–Cu Alloy Evaluated by Micro Size Specimen Yoshiharu Kariya1, Tomokazu Niimi2;*, Tadatomo Suga3 and Masahisa Otsuka4 1Ecomaterials Center, National Institute for Materials Science, Tsukuba 305-0044, Japan 2Graduate School of Shibaura Institute of Technology, Tokyo 108-8548, Japan 3Department of Precision Engineering, School of Engineering, The University of Tokyo, Tokyo 113-8656, Japan 4Materials Science and Engineering Department, Shibaura Institute of Technology, Tokyo 108-8548, Japan Micro-bulk fatigue testing developed to investigate the fatigue lives and damage mechanisms of Sn–3.0Ag–0.5Cu and Sn–37Pb solder alloys. The fatigue life of micro-bulk solder obeyed Manson–Coffin’s empirical law, and the fatigue ductility exponents were about 0.5 for both Sn–Ag–Cu and Sn–Pb alloys. The fatigue life of Sn–3.0Ag–0.5Cu alloy was 10 times longer than that of Sn–37Pb alloy under symmetrical cycling at 298 K, although fatigue resistance of Sn–3.0Ag–0.5Cu alloy was not very superior under asymmetrical wave and elevated temperature condition. The fatigue crack was developed from extrusion and intrusion of slip band in Sn–3.0Ag–0.5Cu alloy, while the crack was observed at colony boundary and grain boundary in Sn–37Pb alloy. The difference in damage mechanism may affect the susceptibility to fatigue life test condition of reversibility. (Received May 23, 2005; Accepted October 11, 2005; Published November 15, 2005) Keywords: solder, lead-free solder, fatigue life, miniature testing, tin–silver–copper, tin-lead, damage mechanism, crack initiation, micro-bulk 1. -

Temperature Cycling and Fatigue in Electronics

Temperature Cycling and Fatigue in Electronics Gilad Sharon, Ph.D. [email protected] 9000 Virginia Manor Road, Suite 290, Beltsville, Maryland 20705 | Phone: (301) 474-0607 | Fax: (866) 247-9457 | www.dfrsolutions.com ABSTRACT The majority of electronic failures occur due to thermally induced stresses and strains caused by excessive differences in coefficients of thermal expansion (CTE) across materials. CTE mismatches occur in both 1st and 2nd level interconnects in electronics assemblies. 1st level interconnects connect the die to a substrate. This substrate can be underfilled so there are both global and local CTE mismatches to consider. 2nd level interconnects connect the substrate, or package, to the printed circuit board (PCB). This would be considered a “board level” CTE mismatch. Several stress and strain mitigation techniques exist including the use of conformal coating. Key words: temperature cycling, thermal cycling, fatigue, reliability, solder joint reliability. INTRODUCTION The excessive difference in coefficients of thermal expansion between the components and the printed board cause a large enough strain in solder and embedded copper structures to induce a fatigue failure mode. This paper discusses the solder fatigue failure mechanism and the associated PTH (plated through hole) fatigue failure. The solder fatigue failure is more complicated due to the many solder materials and different solder shapes. Figure 1 shows an example of a solder fatigue failure in a cross section of a ball grid array (BGA) solder ball with the corresponding finite element model. The predicted location of maximum strain corresponds to the same location of solder fatigue crack initiation. Discussion CTE Mismatch Any time two different materials are connected to one another in electronics assemblies, there is a potential for CTE mismatch to occur. -

Board Level Reliability Assessment of Thick Fr-4 Qfn

BOARD LEVEL RELIABILITY ASSESSMENT OF THICK FR-4 QFN ASSEMBLIES UNDER THERMAL CYCLING by TEJAS SHETTY Presented to the Faculty of the Graduate School of The University of Texas at Arlington in Partial Fulfillment of the Requirements for the Degree of MASTER OF SCIENCE IN MECHANICAL ENGINEERING THE UNIVERSITY OF TEXAS AT ARLINGTON DECEMBER 2014 Copyright © by Tejas Shetty 2014 All Rights Reserved ii DEDICATION This thesis is dedicated to my family. I also dedicate this thesis to my teachers from whom I have learnt so much. iii ACKNOWLEDGEMENTS I would like use this opportunity to express my gratitude to Dr. Dereje Agonafer for giving me a chance to work at EMNSPC and for his continuous guidance during that time. It has been a wonderful journey working with him in research projects and an experience to learn so much from the several conference visits. I also thank him for serving as the committee chairman. I would like to thank Dr. A. Haji-Sheikh and Dr. Kent Lawrence for serving on my committee and providing numerous learning opportunities. I would like to extend a special appreciation to Fahad Mirza, who was not only the PhD mentor but also a good friend who helped me throughout my thesis and academics. I want to thank all the people I met at EMNSPC and for their support during my time. Special thanks to Sally Thompson, Debi Barton, Catherine Gruebbel and Louella Carpenter for assisting me in almost everything. You all have been wonderful. I would like to thank Alok Lohia and Marie Denison for their expert inputs while working on the SRC funded project, the result of which is part of this thesis. -

Thermal Fatigue Assessment of Lead-Free Solder Joints Qiang Yu, M

Thermal Fatigue Assessment of Lead-Free Solder Joints Qiang Yu, M. Shiratori To cite this version: Qiang Yu, M. Shiratori. Thermal Fatigue Assessment of Lead-Free Solder Joints. THERMINIC 2005, Sep 2005, Belgirate, Lago Maggiore, Italy. pp.204-211. hal-00189474 HAL Id: hal-00189474 https://hal.archives-ouvertes.fr/hal-00189474 Submitted on 21 Nov 2007 HAL is a multi-disciplinary open access L’archive ouverte pluridisciplinaire HAL, est archive for the deposit and dissemination of sci- destinée au dépôt et à la diffusion de documents entific research documents, whether they are pub- scientifiques de niveau recherche, publiés ou non, lished or not. The documents may come from émanant des établissements d’enseignement et de teaching and research institutions in France or recherche français ou étrangers, des laboratoires abroad, or from public or private research centers. publics ou privés. Thermal Fatigue Assessment of Lead-Free Solder Joints Qiang YU and Masaki SHIRATORI Department of Mechanical Engineering and Materials Science Yokohama National University Tokiwadai 79-5, Hodogaya-ku, Yokohama, 240-8501, Japan Phone:+81-45-339-3862 FAX: +81-45-331-6593 E-mail: [email protected] ABSTRACT attracted attention. In this study, the relationship between the In this paper the authors have investigated the thermal fatigue voids and fatigue strength of solder joints was examined using reliability of lead-free solder joints. They have focused their mechanical shear fatigue test. Using the mechanical shear attention to the formation of the intermetallic compound and fatigue test, the effect of the position and size of voids on its effect on the initiation and propagation behaviors of fatigue fatigue crack initiation and crack propagation has been cracks. -

Predicting Fatigue of Solder Joints Subjected to High Number of Power Cycles

Predicting Fatigue of Solder Joints Subjected to High Number of Power Cycles Craig Hillman1, Nathan Blattau1, Matt Lacy2 1 DfR Solutions, Beltsville, MD 2 Advanced Energy Industries, Fort Collins, CO Abstract Solder joint reliability of SMT components connected to printed circuit boards is well documented. However, much of the testing and data is related to high-strain energy thermal cycling experiments relevant to product qualification testing (i.e, -55C to 125C). Relatively little information is available on low-strain, high-cycle fatigue behavior of solder joints, even though this is increasingly common in a number of applications due to energy savings sleep mode, high variation in bandwidth usage and computational requirements, and normal operational profiles in a number of power supply applications. In this paper, 2512 chip resistors were subjected to high (>50,000) number of short duration (<10 min) power cycles. Environmental conditions and relevant material properties were documented and the information was inputted into a number of published solder joint fatigue models. The requirements of each model, its approach (crack growth or damage accumulation) and its relevance to high cycle fatigue are discussed. Predicted cycles to failure are compared to test results as well as warranty information from fielded product. Failure modes were confirmed through cross-sectioning. Results were used to evaluate if failures during accelerated reliability testing indicate a high risk of failures to units in the field. Potential design changes are evaluated to quantify the change in expected life of the solder joint. Solder Joint Fatigue Prediction - Theory Degradation of solder joints due to differential expansion and contraction of joined materials has been a known issue in the electronics industry1 since the basic construction of modern electronic design was finalized in the late 1950’s / early 1960’s. -

Viscoplastic Finite-Element Simulation to Predict the Solder

VISCOPLASTIC FINITE-ELEMENT SIMULATION TO PREDICT THE SOLDER JOINT FATIGUE LIFE OF DIFFERENT FLASH MEMORY DIE STACKING ARCHITECTURES YONG JE LEE Presented to the Faculty of the Graduate School of The University of Texas at Arlington in Partial Fulfillment of the Requirements for the Degree of MASTER OF SCIENCE IN MECHANICAL ENGINEERING THE UNIVERSITY OF TEXAS AT ARLINGTON May 2006 ACKNOWLEDGEMENTS I would like to first express my deepest gratitude to my advisor, Dr.Dereje Agonafer. His patience, encouragement, and in-depth knowledge in the engineering field have provided invaluable input into completing the project. I also want to thank Dr. A.Haji-Sheikh and Dr. Kent Lawrence for taking the time to review this thesis and being a part of my thesis committee. I would also like to thanks Dr. Mohammad M Hossain in EMNSPC. His advice and suggestions allowed me to understand and implement my research in an efficient manner. April, 4, 2006 ii ABSTRACT VISCOPLASTIC FINITE-ELEMENT SIMULATION TO PREDICT THE SOLDER JOINT FATIGUE LIFE OF DIFFERENT FLASH MEMORY DIE STACKING ARCHITECTURES Publication No. ______ YONG JE LEE, M.S. The University of Texas at Arlington, 2006 Supervising Professor: Dereje Agonafer This thesis focuses on the viscoplastic finite-element simulation to predict the solder joint fatigue life of different die stacking architectures for flash memory products. Four different stacked package architectures were evaluated as follows: pyramid, rotated, and spacer stacking, while interconnection (solder joint) was held constant. Number of dies for all four stacking configurations were varied from three, five and seven. To keep the package height constant, the die and die attach thickness were varied and the resulting effects on the stresses were investigated. -

A Systems Approach to Solder Joint Fatigue in Spacecraft Electronic Packaging Differential Expansion Induced Fatigue Resulting from Temperature Cycling Is a Leading R

Reprinted from June 1991, Vol. 113, Journal of Electronic Packaging A Systems Approach to Solder Joint Fatigue in Spacecraft Electronic Packaging Differential expansion induced fatigue resulting from temperature cycling is a leading R. G. Ross, Jr. cause of solder joint failures in spacecraft. Achieving high reliability flight hardware Jet Propulsion Laboratory requires that each element of the fatigue issue be addressed carefully. This includes defin- California Institute of Technology ing the complete thermal-cycle environment to be experienced by the hardware, develop- Pasadena, CA 91109 ing electronic packaging concepts that are consistent with the defined environments, and validating the completed designs with a thorough qualification and acceptance test pro- gram. This paper describes a useful systems approach to solder fatigue based principally on the fundamental log-strain vs log-cycles-to-failure behavior of fatigue. This fundamen- tal behavior has been useful to integrate diverse ground test and flight operational ther- mal-cycle environments into a unified electronics design approach. Each element of the approach reflects both the mechanism physics that control solder fatigue, as well as the practical realities of the hardware build, test, delivery, and application cycle. Introduction Mechanical fatigue of electronic component solder joints is involve filling the gap between the part and the board with a an important failure mechanism that must be dealt with carefully high-thermal-conductivity heat transfer material such as alumina in any high reliability electronic packaging design. Spacecraft or copper. Figure 3 illustrates the application of copper heat electronic hardware is particularly vulnerable because the op- conductors under high-dissipation DIP packages. -

Solder Joint Reliability Under Realistic Service Conditions ⇑ P

Microelectronics Reliability 53 (2013) 1587–1591 Contents lists available at ScienceDirect Microelectronics Reliability journal homepage: www.elsevier.com/locate/microrel Solder joint reliability under realistic service conditions ⇑ P. Borgesen a, , S. Hamasha a, M. Obaidat a, V. Raghavan a, X. Dai a, M. Meilunas b, M. Anselm b a Department of Systems Science & Industrial Engineering, Binghamton University, Binghamton, NY 13902, USA b Universal Instruments Corporation, Conklin, NY 13748, USA article info abstract Article history: The ultimate life of a microelectronics component is often limited by failure of a solder joint due to crack Received 24 May 2013 growth through the laminate under a contact pad (cratering), through the intermetallic bond to the pad, Received in revised form 5 July 2013 or through the solder itself. Whatever the failure mode proper assessments or even relative comparisons Accepted 20 July 2013 of life in service are not possible based on accelerated testing with fixed amplitudes, or random vibration testing, alone. Effects of thermal cycling enhanced precipitate coarsening on the deformation properties can be accounted for by microstructurally adaptive constitutive relations, but separate effects on the rate of recrystallization lead to a break-down in common damage accumulation laws such as Miner’s rule. Iso- thermal cycling of individual solder joints revealed additional effects of amplitude variations on the deformation properties that cannot currently be accounted for directly. We propose a practical modifica- tion to Miner’s rule for solder failure to circumvent this problem. Testing of individual solder pads, elim- inating effects of the solder properties, still showed variations in cycling amplitude to systematically reduce subsequent acceleration factors for solder pad cratering. -

Impacts of Cooling Technology on Solder Fatigue for Power Modules in Electric Traction Drive Vehicles

Conference Paper Impacts of Cooling Technology on NREL/CP-540-45957 Solder Fatigue for Power Modules August 2009 in Electric Traction Drive Vehicles Preprint M. O'Keefe National Renewable Energy Laboratory A. Vlahinos Advanced Engineering Solutions To be presented at the 2009 IEEE Vehicle Power and Propulsion Systems Conference Dearborn, Michigan September 7–10, 2009 NOTICE The submitted manuscript has been offered by an employee of the Alliance for Sustainable Energy, LLC (ASE), a contractor of the US Government under Contract No. DE-AC36-08-GO28308. Accordingly, the US Government and ASE retain a nonexclusive royalty-free license to publish or reproduce the published form of this contribution, or allow others to do so, for US Government purposes. This report was prepared as an account of work sponsored by an agency of the United States government. Neither the United States government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States government or any agency thereof. Available electronically at http://www.osti.gov/bridge Available for a processing fee to U.S. -

Validation of VPS-MICRO for Electronic Solder Materials

Validation of Virtual Life Management® for Electronic Solder Materials VEXTEC Corporation 5123 Virginia Way, C-21, Brentwood, TN 37027 Abstract: Electronic failures can result in immediate system shutdown with no advanced fault or warning signal. As a device is operated thermal and/or mechanical loads are induced across the package. These loads are translated from the global package level to the localized interconnect level. VEXTEC’s patented material-based simulation software accounts for real world interconnect variability and predicts probably of failure as a function of device operating time. Interconnect material families have been described within the approach according to their microstructural properties. Although this tool was originally developed and validated based on large structures (i.e., turbine engine components), it is now being used to predict small scale damage accumulation within electronic packages. This paper discusses the various aspects of the simulation approach. By linking manufacturing process variability with microstructural variability, this product can successfully provide a more complete and robust design analysis than typically afforded through traditional testing. Keywords: interconnect; modeling; package; prognosis; solder; thermal fatigue. Introduction: Products are composites of many component elements all combined together to create a final overall product. The reliability of the final system is a function of the reliability of all of the parts, including interconnections between the parts. Disregarding operator error—e.g., a bolt didn’t get tightened, or dials on the production line were grossly miss set—products fail because of a material failure in a component or interconnect. Materials fail because repetitive stress applied over time causes internal micro-structures (e.g. -

Predicting Fatigue of Solder Joints Subjected to High Number of Power Cycles

As originally published in the IPC APEX EXPO Conference Proceedings. Predicting Fatigue of Solder Joints Subjected to High Number of Power Cycles Craig Hillman1, Nathan Blattau1, Matt Lacy2 1 DfR Solutions, Beltsville, MD 2 Advanced Energy Industries, Fort Collins, CO Abstract Solder joint reliability of SMT components connected to printed circuit boards is well documented. However, much of the testing and data is related to high-strain energy thermal cycling experiments relevant to product qualification testing (i.e., -55C to 125C). Relatively little information is available on low-strain, high-cycle fatigue behavior of solder joints, even though this is increasingly common in a number of applications due to energy savings sleep mode, high variation in bandwidth usage and computational requirements, and normal operational profiles in a number of power supply applications. In this paper, 2512 chip resistors were subjected to a high (>50,000) number of short duration (<10 min) power cycles. Environmental conditions and relevant material properties were documented and the information was inputted into a number of published solder joint fatigue models. The requirements of each model, its approach (crack growth or damage accumulation) and its relevance to high cycle fatigue are discussed. Predicted cycles to failure are compared to test results as well as warranty information from fielded product. Failure modes were confirmed through cross-sectioning. Results were used to evaluate if failures during accelerated reliability testing indicate a high risk of failures to units in the field. Potential design changes are evaluated to quantify the change in expected life of the solder joint. Solder Joint Fatigue Prediction - Theory Degradation of solder joints due to differential expansion and contraction of joined materials has been a known issue in the electronics industry1 since the basic construction of modern electronic design was finalized in the late 1950’s / early 1960’s. -

Design and Process Optimization for Dual Row QFN

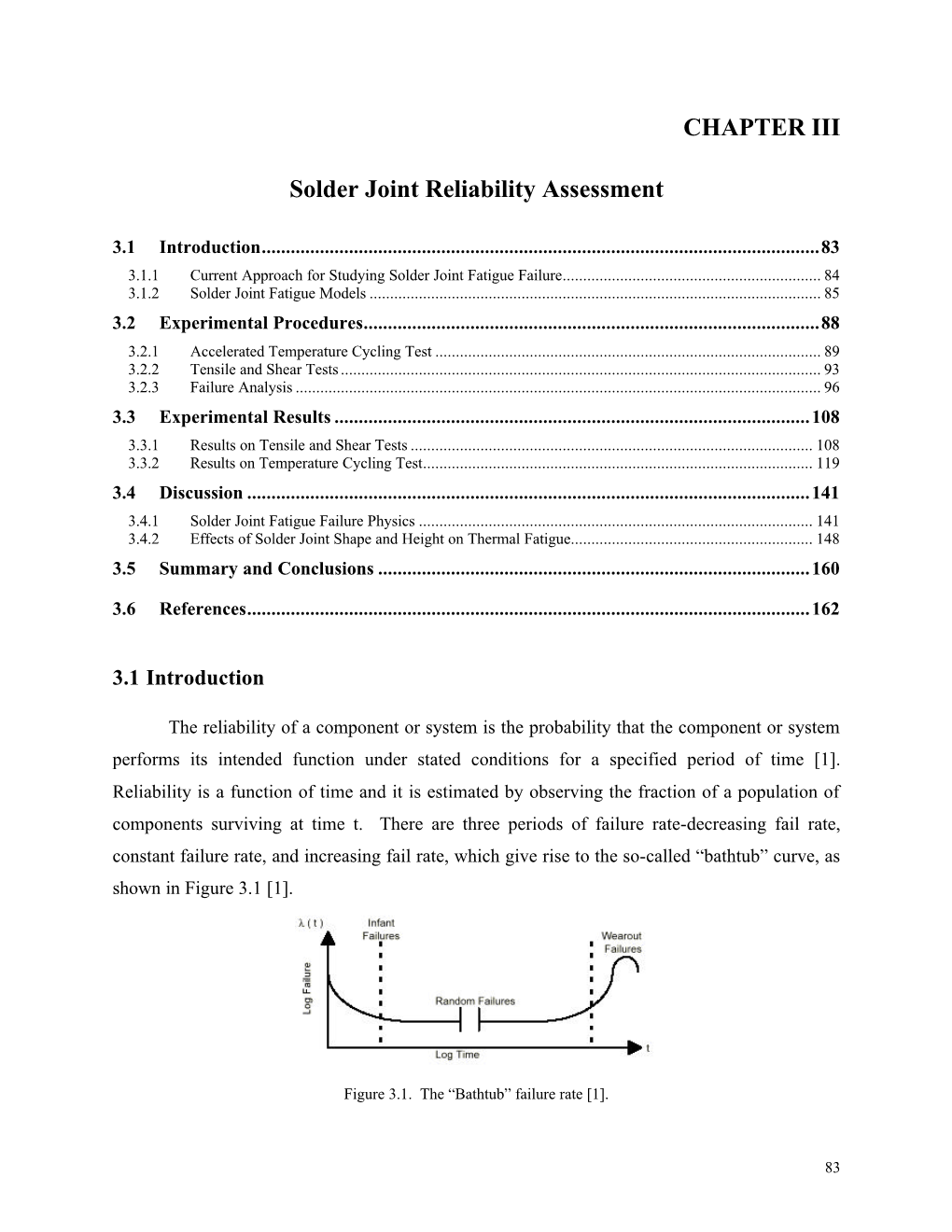

Design and Process Optimization for Dual Row QFN Danny V. Retuta, B.K Lim, H.B. Tan United Test & Assembly Center Ltd (UTAC) 5 Serangoon North Ave 5, Singapore 554916 [email protected], (+65) 65511591 Abstract The continuous advancement in technology and miniaturization of electronic components, hand held and communication devices require superior thermal-electrical performance and miniature packages. An advanced and complicated Integrated Circuit (IC) device often demands increase in number of I/O's while maintaining its small size, footprint and weight. Dual Row Quad Flat No lead (DR-QFN) is an ideal solution for such demanding applications; however, 12x12 TQFP 80L 7x7DR-QFN 76L despite the simplicity of its package structure, it possesses challenges in various assembly processes. This paper Assembly houses that took part in bringing DR-QFN into describes the problems that are associated with the different reality raced towards different directions depending on their concepts of both 'saw' and 'punch' singulated DR-QFN and the available resources and infrastructures. Most players focused corresponding solutions to overcome the barriers. on leadframe design and process development be it ‘punch’ or Lead isolation or separation of 1st and 2nd row of leads ‘saw’ singulated while others took a step ahead by developing has always been the major challenge for saw singulated DR- a non-standard assembly process than can even go beyond QFN (DR-QFN-S) where solder burr and leadfinger two rows. delamination are inherent. Shorting between inner and outer Figure 1 shows how a typical DR-QFN differs from a leads during SMT is also apparent.