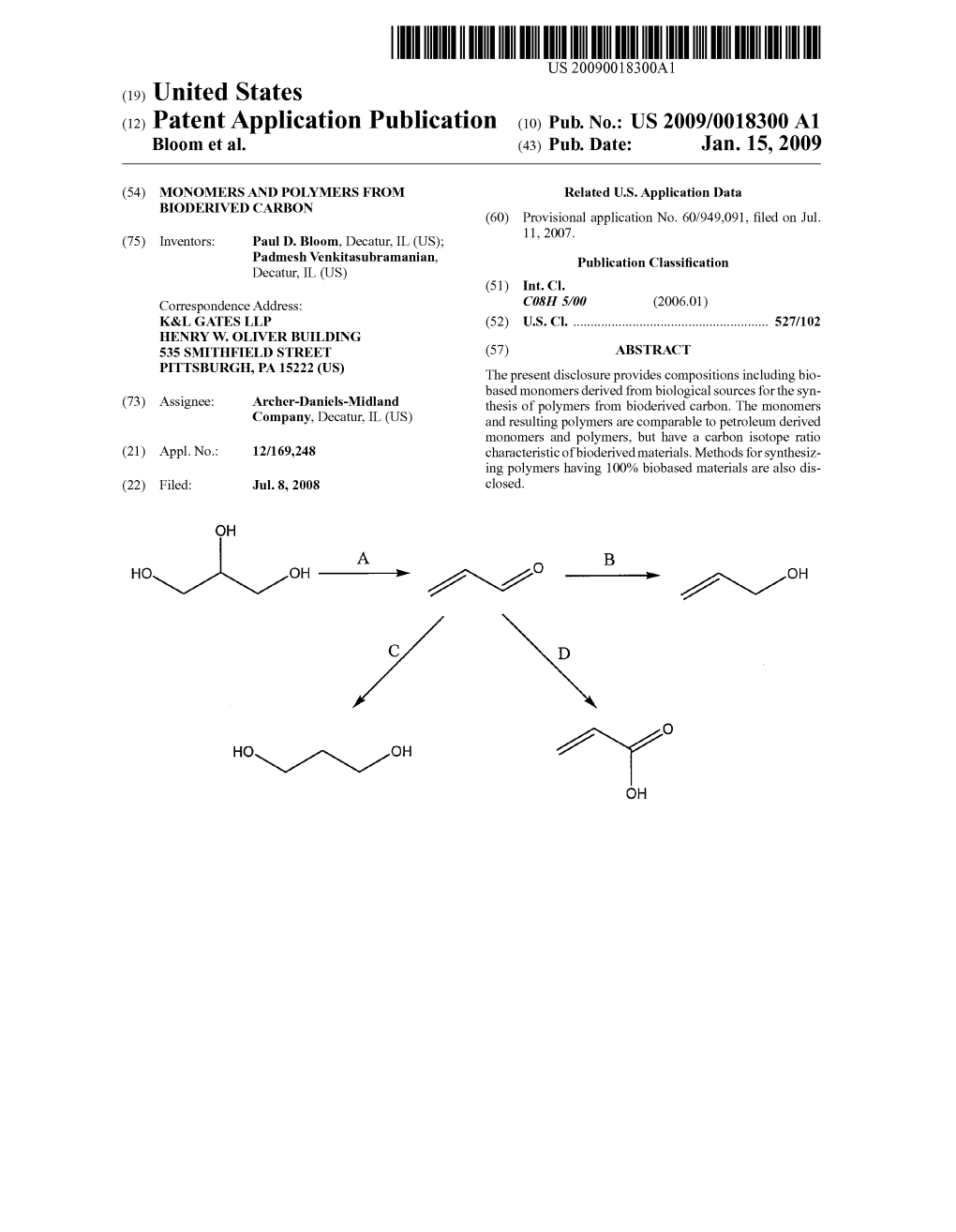

(12) Patent Application Publication (10) Pub. No.: US 2009/0018300 A1 Bloom Et Al

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

1 Fundamentals of Polymer Chemistry

1 Fundamentals of Polymer Chemistry H. Warson 1 THE CONCEPT OF A POLYMER 1.1 Historical introduction The differences between the properties of crystalline organic materials of low molecular weight and the more indefinable class of materials referred to by Graham in 1861 as ‘colloids’ has long engaged the attention of chemists. This class includes natural substances such as gum acacia, which in solution are unable to pass through a semi-permeable membrane. Rubber is also included among this class of material. The idea that the distinguishing feature of colloids was that they had a much higher molecular weight than crystalline substances came fairly slowly. Until the work of Raoult, who developed the cryoscopic method of estimating molecular weight, and Van’t Hoff, who enunciated the solution laws, it was difficult to estimate even approximately the polymeric state of materials. It also seems that in the nineteenth century there was little idea that a colloid could consist, not of a product of fixed molecular weight, but of molecules of a broad band of molecular weights with essentially the same repeat units in each. Vague ideas of partial valence unfortunately derived from inorganic chem- istry and a preoccupation with the idea of ring formation persisted until after 1920. In addition chemists did not realise that a process such as ozonisation virtually destroyed a polymer as such, and the molecular weight of the ozonide, for example of rubber, had no bearing on the original molecular weight. The theory that polymers are built up of chain formulae was vigorously advocated by Staudinger from 1920 onwards [1]. -

“Polyols: a Primer for Dietetic Professionals” Is a Self-Study

1 “Polyols: A primer for dietetic professionals” is a self-study module produced by the Calorie Control Council, an accredited provider of continuing professional education (CPE) for dietetic professionals by the Commission on Dietetic Registration. It provides one hour of level 1 CPE credit for dietetic professionals. The full text of the module is in the notes section of each page, and is accompanied by summary points and/or visuals in the box at the top of the page. Directions for obtaining CPE are provided at the end of the module. 2 After completing this module, dietetic professionals will be able to: • Define polyols. • Identify the various types of polyols found in foods. • Understand the uses and health effects of polyols in foods. • Counsel clients on how to incorporate polyols into an overall healthful eating pattern. 3 4 Polyols are carbohydrates that are hydrogenated, meaning that a hydroxyl group replaces the aldehyde or ketone group found on sugars. Hydrogenated monosaccharides include erythritol, xylitol, sorbitol, and mannitol. Hydrogenated disaccharides include lactitol, isomalt, and maltitol. And hydrogenated starch hydrolysates (HSH), or polyglycitols (a wide range of corn syrups and maltodextrins), are formed from polysaccharides (Grabitske and Slavin 2008). 5 Nearly 54 percent of Americans are trying to lose weight, more than ever before. Increasingly, they are turning toward no- and low-sugar, and reduced calorie, foods and beverages to help them achieve their weight loss goals (78% of Americans who are trying to lose weight) (CCC 2010). Polyols, found in many of these foods, are becoming a subject of more interest. 6 They are incompletely digested , therefore are sometimes referred to as “low- digestible carbohydrates.” Polyols are not calorie free, as there is some degree of digestion and absorption of the carbohydrate. -

LIBRARY. This Thesis Has Been Approved for the Department of Chemical Engineering and the College of Engineering and Technology

~.. STUDY OF A COUNTER-ROTATING, INTERMESHING EXTRUDER AS A POLYCONDENSATION REACTOR /" A Thesis Presented to the Faculty of The College of Engineering and Technology Ohio University In Partial Fulfilment of the Requirements for the Degree Master of Science by Edward R. Crowe November, 1992 LIBRARY. This Thesis has been approved for the Department of Chemical Engineering and the College of Engineering and Technology Associate Prof Chem1cal Engineering Dean of the College of Engineering and Technology iii Abstract An experimental study and model development have been performed to better understand the reactive extrusion of polyethylene terephthalate. A process was developed using a 34 mm counter-rotating twin screw extruder to depolymerize a commercial grade of polyethylene terephthalate into an acceptable pre-polymer for reactive extrusion experiments. Residence time d Ls'tr Ibut.Lon experiments were conducted at different screw speeds and feed rates to characterize the flow patterns of the extruder. Based on these results an idealized plug-flow model was developed to simulate this process. An experimental design using the controllable process variables of zone temperature, feed rate and nitrogen flow sweeping across the surface of the polymer melt was developed to stUdy the individual effects of each of these variables as well as any interactive effects. The results indicate that the feed rate and nitrogen flow have an effect on the degree of polymerization of the product. However, the stUdy clearly shows the dominant effect to be ,the average residence time of the polymer melt in the vent zone. The idealized plug-flow model presents a reasonable representation of this process. -

HDPE: High Density Polyethylene LDPE

Abbreviations: HDPE: high density polyethylene LDPE: low density polyethylene PET: polyethylene terephthalate PP: polypropylene PS: polystyrene PVA: polyvinyl alcohol PVC: polyvinyl chloride addition polymerization: a chemical reaction in which simple molecules are linked together to form long chain molecules. amorphous: non-crystalline polymer or non-crystalline areas in a polymer. Bakelite: a polymer produced by the condensation of phenol and formaldehyde. branched polymer: polymer having smaller chains attached to the polymer backbone. cellulose: a natmal polymer found in wood and other plant material. composite polymer: a filled or reinforced plastic. condensation polymer: one in which two or more molecules combine resulting in elimination of water or other simple molecules, with the process being repeated to form a long chain molecule. configuration: related chemical structme produced by the making and breaking ofprimary valence bonds. copolymer: a macromolecule consisting of more than one type of building unit. creep: cold flow of a polymer. cross-linking: occms when primary valence bonds are formed between separate polymer molecules. crystalline polymer: polymer with a regular order or pattern of molecular arrangement and a sharp melting point. dimer: a polymer containing two monomers. domains: sequences or regions in block copolymers. elastomer: a type of polymer that exhibits rubber-like qualities. Ekonol: a moldable, high temperatme polymer. end group: functional group at the end of a chain in polymers, e.g. carboxylic group. extrusion: a fabrication process in which a heat-softened polymer is forced continually by a screw through a die. filler: a relatively inert material used as the discontinuous phase of a polymer composite. free radical: A chemical component that contains a free electron which covalently bonds with a free electron on another molecule. -

Synthesis of Functionalized Polyamide 6 by Anionic Ring-Opening Polymerization Deniz Tunc

Synthesis of functionalized polyamide 6 by anionic ring-opening polymerization Deniz Tunc To cite this version: Deniz Tunc. Synthesis of functionalized polyamide 6 by anionic ring-opening polymerization. Poly- mers. Université de Bordeaux; Université de Liège, 2014. English. NNT : 2014BORD0178. tel- 01281327 HAL Id: tel-01281327 https://tel.archives-ouvertes.fr/tel-01281327 Submitted on 2 Mar 2016 HAL is a multi-disciplinary open access L’archive ouverte pluridisciplinaire HAL, est archive for the deposit and dissemination of sci- destinée au dépôt et à la diffusion de documents entific research documents, whether they are pub- scientifiques de niveau recherche, publiés ou non, lished or not. The documents may come from émanant des établissements d’enseignement et de teaching and research institutions in France or recherche français ou étrangers, des laboratoires abroad, or from public or private research centers. publics ou privés. Logo Université de cotutelle THÈSE PRÉSENTÉE POUR OBTENIR LE GRADE DE DOCTEUR DE L’UNIVERSITÉ DE BORDEAUX ET DE L’UNIVERSITÉ DE LIEGE ÉCOLE DOCTORALEDE SCIENCES CHIMIQUES (Université de Bordeaux) ÉCOLE DOCTORALE DE CHIMIE (Université de Liège) SPÉCIALITÉ POLYMERES Par Deniz TUNC Synthesis of functionalized polyamide 6 by anionic ring-opening polymerization Sous la direction de Stéphane CARLOTTI et Philippe LECOMTE Soutenue le 30 octobre 2014 Membres du jury: M. PERUCH, Frédéric Directeur de recherche, Université de Bordeaux Président M. HOOGENBOOM, Richard Professeur, Ghent University Rapporteur M. MONTEIL, Vincent Chargé de recherche, Université Claude Bernard Rapporteur M. YAGCI, Yusuf Professeur, Istanbul Technical University Examinateur M. AMEDURI, Bruno Directeur de recherche, Institut Charles Gerhardt Examinateur M. SERVANT, Laurent Professeur, Université de Bordeaux Invité Preamble This PhD had been performed within the framework of the IDS FunMat joint doctoral programme. -

Polymer Exemption Guidance Manual POLYMER EXEMPTION GUIDANCE MANUAL

United States Office of Pollution EPA 744-B-97-001 Environmental Protection Prevention and Toxics June 1997 Agency (7406) Polymer Exemption Guidance Manual POLYMER EXEMPTION GUIDANCE MANUAL 5/22/97 A technical manual to accompany, but not supersede the "Premanufacture Notification Exemptions; Revisions of Exemptions for Polymers; Final Rule" found at 40 CFR Part 723, (60) FR 16316-16336, published Wednesday, March 29, 1995 Environmental Protection Agency Office of Pollution Prevention and Toxics 401 M St., SW., Washington, DC 20460-0001 Copies of this document are available through the TSCA Assistance Information Service at (202) 554-1404 or by faxing requests to (202) 554-5603. TABLE OF CONTENTS LIST OF EQUATIONS............................ ii LIST OF FIGURES............................. ii LIST OF TABLES ............................. ii 1. INTRODUCTION ............................ 1 2. HISTORY............................... 2 3. DEFINITIONS............................. 3 4. ELIGIBILITY REQUIREMENTS ...................... 4 4.1. MEETING THE DEFINITION OF A POLYMER AT 40 CFR §723.250(b)... 5 4.2. SUBSTANCES EXCLUDED FROM THE EXEMPTION AT 40 CFR §723.250(d) . 7 4.2.1. EXCLUSIONS FOR CATIONIC AND POTENTIALLY CATIONIC POLYMERS ....................... 8 4.2.1.1. CATIONIC POLYMERS NOT EXCLUDED FROM EXEMPTION 8 4.2.2. EXCLUSIONS FOR ELEMENTAL CRITERIA........... 9 4.2.3. EXCLUSIONS FOR DEGRADABLE OR UNSTABLE POLYMERS .... 9 4.2.4. EXCLUSIONS BY REACTANTS................ 9 4.2.5. EXCLUSIONS FOR WATER-ABSORBING POLYMERS........ 10 4.3. CATEGORIES WHICH ARE NO LONGER EXCLUDED FROM EXEMPTION .... 10 4.4. MEETING EXEMPTION CRITERIA AT 40 CFR §723.250(e) ....... 10 4.4.1. THE (e)(1) EXEMPTION CRITERIA............. 10 4.4.1.1. LOW-CONCERN FUNCTIONAL GROUPS AND THE (e)(1) EXEMPTION................. -

Polyols Have a Variety of Functional Properties That Make Them Useful Alternatives to Sugars in Applications Including Baked Goods

Polyols have a variety of functional properties that make them useful alternatives to sugars in applications including baked goods. Photo © iStockphoto.com/Synergee pg 22 09.12 • www.ift.org BY LYN NABORS and THERESA HEDRICK SUGAR REDUCTION WITH Polyols Polyols are in a unique position to assist with reduced-sugar or sugar-free reformulations since they can reduce calories and complement sugar’s functionality. ugar reduction will be an important goal over the of the product’s original characteristics may still be main- next few years as consumers, government, and in- tained with the replacement of those sugars by polyols. Sdustry alike have expressed interest in lower-calorie In addition, excellent, good-tasting sugar-free products and lower-sugar foods. The 2010 Dietary Guidelines for can be developed by using polyols. Polyols are in a unique Americans put a strong emphasis on consuming fewer position to assist with reduced-sugar or sugar-free refor- calories and reducing intake of added sugars. The In- mulations; since they are only partially digested and ab- stitute of Medicine (IOM) held a public workshop in sorbed, they can reduce calories and complement sugar’s November 2010 to discuss ways the food industry can functionality. Polyols provide the same bulk as sugars and use contemporary and innovative food processing tech- other carbohydrates. Additionally, polyols have a clean, nologies to reduce calorie intake in an effort to reduce sweet taste, which is important since consumers are not and prevent obesity, and in October 2011 recommended likely to sacrifice taste for perceived health benefits. Poly- front-of-package labeling that includes rating the product ols have a host of other functional properties that make based on added sugars content. -

Sweet Sensations by Judie Bizzozero | Senior Editor

[Confections] July 2015 Sweet Sensations By Judie Bizzozero | Senior Editor By R.J. Foster, Contributing Editor For many, terms like “reduced-sugar” or “sugar-free” do not go with the word “candy.” And yet, the confectionery industry is facing growing demand for treats that offer the taste people have grown to love without the adverse health effects they’re looking to avoid. Thankfully, there is a growing palette of ingredients from which candy makers can paint a new picture of sweetness that will be appreciated by the even most discerning of confectionery critics. SUGAR ALCOHOLS Also referred to as polyols, sugar alcohols are a common ingredient in reduced-sugar and sugar-free applications, especially confections. Funny thing, they’re not sugars or alcohols. Carbohydrate chains composed of monomeric, dimeric and polymeric units, polyols resemble both sugars and alcohols, but do not contain an ethanol molecule. All but two sugar alcohols are less sweet than sugar. Being only partially digestible, though, replacing a portion of a formulation’s sugar with a sugar alcohol reduces total calories without losing bulk (which can occur when replacing sugar with high-intensity sweeteners). Unique flavoring, texturizing and moisture-controlling effects also make polyols well-suited for confectionery products. Two very common and very similar monomeric polyols are sorbitol and mannitol. Present in a variety of fruits and vegetables, both are derived from products of cornstarch hydrolysis. Sorbitol is made via hydrogenation of glucose, which is why sorbitol is sometimes referred to as glucitol. Mannitol is created when fructose hydrogenation converts fructose into mannose, for which the final product, mannitol, is named. -

DIVISION 15 Adulteration Adulteration of Food

DIVISION 15 Adulterationof food B.15.001. A food named in column III of an item of Table I to this Division is adulterated if the substance named in Column I of that item is present therein or has been added thereto in an amount exceeding the amount, expressed in parts per million, shown in column II of that item for that food. 22-1-81 B.15.002. (1) Subject to subsections (2) and (3), a food is adulterated if an agricultural chemical or any of its derivatives is present therein or has been added thereto, singly or in any combination, in an amount exceeding 0.1 part per million, unless it is listed and used in accordance with the tables to Division 16. (2) Subject to subsection (3), a food is exempt from paragraph 4(d) of the Act if the only agricultural chemicals that are present therein or have been added thereto are any of the following: (a) a fertilizer; (b) an adjuvant or a carrier of an agricultural chemical; (c) an inorganic bromide salt; (d) silicon dioxide; 8-3-79 (e) sulphur; or (f) viable spores of Bacillus thuringiensis Berliner. 26-1-98 (3) A food named in column IV of an item of Table II to this Division, a food that contains any such food or a food made from a product of any such food is exempt from the application of paragraph 4(d) of the Act if the agricultural chemicals named in columns I and II of that item are present in or have been added to the food in an amount not exceeding the maximum residue limit set out in column III of that item. -

POLYMERS Polymers Are Substances Whose Molecules Have High Molar Masses and Are Composed of a Large Number of Repeating Units

www.scifun.org POLYMERS Polymers are substances whose molecules have high molar masses and are composed of a large number of repeating units. There are both naturally occurring and synthetic polymers. Among naturally occurring polymers are proteins, starches, cellulose, and latex. Synthetic polymers are produced commercially on a very large scale and have a wide range of properties and uses. The materials commonly called plastics are all synthetic polymers. Polymers are formed by chemical reactions in which a large number of molecules called monomers are joined sequentially, forming a chain. In many polymers, only one monomer is used. In others, two or three different monomers may be combined. Polymers are classified by the characteristics of the reactions by which they are formed. If all atoms in the monomers are incorporated into the polymer, the polymer is called an addition polymer. If some of the atoms of the monomers are released into small molecules, such as water, the polymer is called a condensation polymer. Most addition polymers are made from monomers containing a double bond between carbon atoms. Such monomers are called olefins, and most commercial addition polymers are polyolefins. Condensation polymers are made from monomers that have two different groups of atoms which can join together to form, for example, ester or amide links. Polyesters are an important class of commercial polymers, as are polyamides (nylon). POLYETHYLENE Polyethylene is perhaps the simplest polymer, composed of chains of repeating –CH2– units. It is produced by the addition polymerization of ethylene, CH2=CH2 (ethene). The properties of polyethylene depend on the manner in which ethylene is polymerized. -

Sugar Alcohols a Sugar Alcohol Is a Kind of Alcohol Prepared from Sugars

Sweeteners, Good, Bad, or Something even Worse. (Part 8) These are Low calorie sweeteners - not non-calorie sweeteners Sugar Alcohols A sugar alcohol is a kind of alcohol prepared from sugars. These organic compounds are a class of polyols, also called polyhydric alcohol, polyalcohol, or glycitol. They are white, water-soluble solids that occur naturally and are used widely in the food industry as thickeners and sweeteners. In commercial foodstuffs, sugar alcohols are commonly used in place of table sugar (sucrose), often in combination with high intensity artificial sweeteners to counter the low sweetness of the sugar alcohols. Unlike sugars, sugar alcohols do not contribute to the formation of tooth cavities. Common Sugar Alcohols Arabitol, Erythritol, Ethylene glycol, Fucitol, Galactitol, Glycerol, Hydrogenated Starch – Hydrolysate (HSH), Iditol, Inositol, Isomalt, Lactitol, Maltitol, Maltotetraitol, Maltotriitol, Mannitol, Methanol, Polyglycitol, Polydextrose, Ribitol, Sorbitol, Threitol, Volemitol, Xylitol, Of these, xylitol is perhaps the most popular due to its similarity to sucrose in visual appearance and sweetness. Sugar alcohols do not contribute to tooth decay. However, consumption of sugar alcohols does affect blood sugar levels, although less than that of "regular" sugar (sucrose). Sugar alcohols may also cause bloating and diarrhea when consumed in excessive amounts. Erythritol Also labeled as: Sugar alcohol Zerose ZSweet Erythritol is a sugar alcohol (or polyol) that has been approved for use as a food additive in the United States and throughout much of the world. It was discovered in 1848 by British chemist John Stenhouse. It occurs naturally in some fruits and fermented foods. At the industrial level, it is produced from glucose by fermentation with a yeast, Moniliella pollinis. -

Effects of Polyols on the Quality Characteristics of Sucrose-Free Milk

RSC Advances PAPER View Article Online View Journal | View Issue Effects of polyols on the quality characteristics of sucrose-free milk chocolate produced in a ball mill Cite this: RSC Adv.,2019,9, 29676 Aziz Homayouni Rad,ab Haniyeh Rasouli Pirouzian, *a Nevzat Konar,c Omer Said Tokerd and Derya Genc Polate Sucrose-free milk chocolates containing different types of bulk (isomalt, xylitol and maltitol) and high intensity (Stevia) sweeteners were produced by using a ball mill. The main quality characteristics of the formulated chocolates were evaluated and compared with those of the conventional sample containing sucrose. The Casson model was the best fitting model for the rheological data. Casson viscosity and Casson yield stress were significantly affected by the type of bulking agent in chocolates formulated with xylitol (p < 0.05). However xylitol notably improved the overall acceptability according to the sensory analysis results. Chocolates containing the sucrose replacers demonstrated lower Tonset values and higher enthalpy than the control sample. Sucrose-free chocolates illustrated a higher degree of particle agglomeration. Bulk sweeteners meanwhile seem to have high potential for milk chocolate production Creative Commons Attribution-NonCommercial 3.0 Unported Licence. with low calorie values by using the ball mill technique. Industrial applications: the production of sucrose-free chocolates with conventional methods requires a lot of time and energy. Recently, using alternative methods for chocolate production has been raising interest in many small industries. This study proposed a ball mill method for the preparation of sucrose-free milk chocolates with physiochemical properties almost ranging in the standard limit defined for chocolate.