Sport Aviation Article

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Alone Across the Atlantic

® 8 - DECEMBER 2013 www.kitplanes.com RV Atlantic Across in an in Swage Fittings Swage Secure? Cables Your Are the Adventure FT A Alone T REVIEW H ’S GUIDE SHOP R E H Easy Fiberglass Prep Aerodynamic Bookworm Tire Changing 101 T Soaring on Homemade Wings 2014 BUYER’S GUIDE2014 ISSUE! N • • • I HP-24 FLIG HP-24 BUYE Over 350 Planes Listed! Planes 350 Over 2014 KIT AIRCR KITPLANES DECEMBER 2013 Kit Buyer’s Guide • Transatlantic RV-8 • HP-24 Sailplane • Design to Fit • Swagelocks • Dawn Patrol • Testing to DO-160 • Home Shop Machines BELVOIR PUBLICATIONS Enjoy the Freedom of Homebuilt Aircraft Weather the Storm with SkyView’s IFR Capabilities Redundant flight instruments that automatically cross-check each other • ADS-B traffic and weather in-flight • SkyView network modules that detect wiring faults without losing capability • Li-Ion backup batteries that keep your SkyView system up when the power goes down • Autopilot with fully coupled ILS and GPS WAAS/LPV approaches. SkyView should already be your IFR platform of choice. But if that’s not enough, SkyView 7.0 introduces geo-referenced instrument approach charts, airport diagrams, and the best mapping software we’ve ever built. Go Fly! www.DynonAvionics.com 425-402-0433 [email protected] Seattle,Washington December 2013 | Volume 30, Number 12 Annual Buyer’s Guide, Part 1 26 2014 KIT AIRCRAFT BUYER’S GUIDE: The state of the kit world is sound. By Paul Dye and Mark Schrimmer. 38 KIT AIRCRAFT QUICK REFERENCE: A brief overview of available kit aircraft for 2014. Compiled by Richard VanderMeulen and Omar Filipovic. -

Just Aircraft Superstol a Helio for the Light-Sport Set

The Spirit of Homebuilt Aviation I www.eaa.org Vol.2 No.8 I August 2013 Just Aircraft SuperSTOL A Helio for the light-sport set When the Kit Doesn’t Arrive E-LSA—Make It Your Way The ULPower Six-Cylinder Engine More About Sawtooth Climbs Tower Frequency It’s Time to Celebrate By Jack Pelton It’s time for Oshkosh, the best week of the year. And, as instead of shrinking. People are so dedicated to preserving always, we have many reasons to celebrate our love of all fl ying history that restoration projects once thought to be things that fl y. impossible are now almost routine. During the rest of the year it’s easy for me, and I’m sure Even the standard category airplanes nearly all look their you, too, to become bogged down by the steady drumbeat best. No airplane owner wants to fl y to Oshkosh without of bad news and threats to personal aviation from all cor- fi rst washing and polishing his airplane and making it look ners. And at EAA we are always on guard to protect our as good as it possibly can. All pilots who fl y to Oshkosh freedom to fl y and to keep personal aviation accessible take immense pride in their airplane and their accomplish- to as many people as possible. But at Oshkosh, during ments as pilots no matter what they fl y. AirVenture, is the time to recognize just how successful we have been. In 1975 Tom Poberezny was named chairman of the Oshkosh fl y-in. -

The Bucker "Jungmann"

STRAIGHT AND LEVEL Cubs, the Champs and Chiefs, the of insurance, but it's not expensive for 120s, 140s, 170s and 180s, the T all of us. I have a J-3 Cub insured for Crafts, Luscombes, Ercoupes, Vag $1 million liability at a cost of $363 per abonds, Clippers, Pacers and Tri-Pac year. My insurance broker tells me that ers, etc. all make flying relatively low this amount would insure most of the cost. two-place aircraft listed above for pilots by Bob Lickteig To make my point I checked the vari with tail dragger experience. My au ous aviation publications that carry tomobile insurance costs three times classified sales ads. I considered only that much and for less coverage. Again, the individual ads where an asking price we must consider this reasonable. was stated. Realistically we all know With regard to hangars, most of our High Cost of Flying - How High? that when a sale is made the price usu kinds of aircraft do not need heated and At the February Board of Directors ally comes down before money well-lighted hangars. I have seen two meeting the current cost of flying was changes hands. and even three aircraft in the same again discussed. The cost of new gen The asking price in these classifieds hangar, which again makes the rent eral aviation aircraft, fuel , hangar or tie ads were averaged, considering aircraft reasonable. down rent, insurance plus maintenance with comparable total time, engine time, Many of us who fly these fun and annual inspection is high and there and remarks regarding overall general machines are capable of and do per seems to be no end. -

Homebuilt Aircraft • Pole D Irectory 2016 To

2016 BUYEr’S GUIDE EXPANDED EDITION KITPLANES DECEMBER Flying a 2015 Taildragger ® 2016 Buyer’s Guide Homebuilt Aircraft • Pole D IRECTORY 2016 to Pole Over 1000 Kits & Plans Listed! • Vortex Generators • Trim and Flaps • Column Buckling • Taildragger Transition • Fuel Injection • Mold Making BELVOIR ENGINH E T EORY DECEMBER 2015 Fuel Injection In the Shop PUBLICATIONS FU EL SYSTEM DESIGN • Wiring Flaps & Trim If It Ain’t Broke… • Mold Making VORTEX GENERATORS Improve Your Cooling www.kitplanes.com December 2015 | Volume 32, Number 12 Annual Buyer’s Guide 17 2016 HOMEBUILT AIRCRAFT DIRECTORY: • Kit and plansbuilt aircraft listings. Compiled by Omar Filipovic. • Different strokes for different folks. By Paul Dye. • What makes a kit complete? By Paul Dye. • Shopping for a second-hand project. By Omar Filipovic. • Buying your first homebuilt aircraft. By Louise Hose. Builder Spotlight 6 LEARNING HOW TO DRAG YOUR TaIL: Making the 6 transition from trigear to tailwheels. By LeRoy Cook. 12 LIGHT AIRCRAFT FUEL SYSTEM DESIGN: Part 1—If it’s not broken, don’t fix it! By Ken Krueger. 52 POLE TO POLE! Around the world over both poles (part 2). By Bill Harrelson. 60 VORTEX GENERATORS FOR COOLING: A simple fix reduced CHTs in a Velocity by 55 degrees. By David G. Ullman. 66 ENGINE ThEORY: Fuel injection—putting pressure into fuel delivery. By Tom Wilson. 97 aSK THE DAR: RV-7A converted to RV-7, importing a Canadian ultralight to the U.S. and registering as an LSA. By Mel Asberry. Shop Talk 72 AIRCRAFT WIRING: Electrical trim and flaps for Experimental aircraft. -

MODEL BUILDER FEBRUARY 1989 FU LL-SIZE PLAN AVAILABLE - SEE PAGE 106 37 Soaring Panel Discussion F

FEBRUARY 1989 Canada volume 19, number 205 LD'S MOST COMPLETE MODEL AIRCRAFT PUBLICATION ONSTRUCTION Id Timer . I f t i 74820 08545 ,n5 C.G. SUPER CHIPMUNK Span, 64," Length, 53" Wing Area, 688 square inches. Flying Weight, 6 to 8 pounds. For four to six channel radios and .45to.60two-cycle,or.60to.90 four-cycle engines. Kit includes formed cowling, wheel fairings and canopy. Optional operations: Raps and retractable landing gear. Suggestions for smoke systems are included. Typical Goldberg. You know what that means. the Super Chipmunk would be a good bet cycle, and you’ll have it all. Stable, sensible and as your first “ low-winger”, you’re Plain and simple, or with all the able. And all you’ve got t absolutely right. bells and whistles, your big, light your new C.G. Super Chipmunk The options you choose weight Chipmunk will come through with flying colors. and level for a few minutes and . set the pace. discover that it is “Typical Goldberg”. The kit and the value But it’s Goldberg with a difference. If you’re a more experienced flyer, The Just turn it loose, and this easy-to- Super Chipmunk's well-designed flap and are “Typical Goldberg”, too. handle Sunday flyer will put on an retract options offer an added dimension If you liked our Anniversary Edition Cub, airshow with all the flash and flair of its of realism. you’re going to love the C.G. Super full-size cousin. And when it comes to power, Chipmunk. All the thrills a .45 to .51 two-cycle, or a .60 four Its beautifully formed molded parts, cycle are just right for solid sport flying. -

The Flightline

The Flightline The Flightline Volume 32,Issue 2 Newsletter of the Propstoppers RC Club AMA 1042 February 2002 Editorial. There are only a few more months to the good weather and we start flying in earnest again so I hope you are working feverishly on you 2002 Auction and Swap Meet airplanes. Just to spur you along I have included the pictures of our flying stalwarts from Sleighton Field on December 4th. At February 5th Meeting Scheduled for Tuesday, February 5 The club business meeting will start at 7:00 PM, and will be abbreviated so the auction can start at 7:30 PM. There will be no show and tell this month. Al Tamburro will again grace us with his auctioneering skills, and Al advises that the auction will be conducted in the same manner as in past years, that is: Sale table – Item sale price marked on tag – 5% of sale price goes to club Auction table – No reserve – 5% of sale price goes to club Items placed on sale table and subsequently auctioned – 10% of sale price goes to club So, go right now to the workshop and dig out the stuff you really don't need so you can share it with us in the auction. th Agenda for Feburary 5 Meeting · Approval of January meeting minutes · Finance report · Membership report Bill and Monica Shellhase and Bob Crowell enjoy a perfect flying day · Field search and Sleighton status report · Indoor flying plans · New business · Club Auction Note, no Show and Tell. If you bring it, Al will sell it! I NSIDE T HIS I SSUE 1 Editorial - Club Auction etc. -

Kitplanes Template

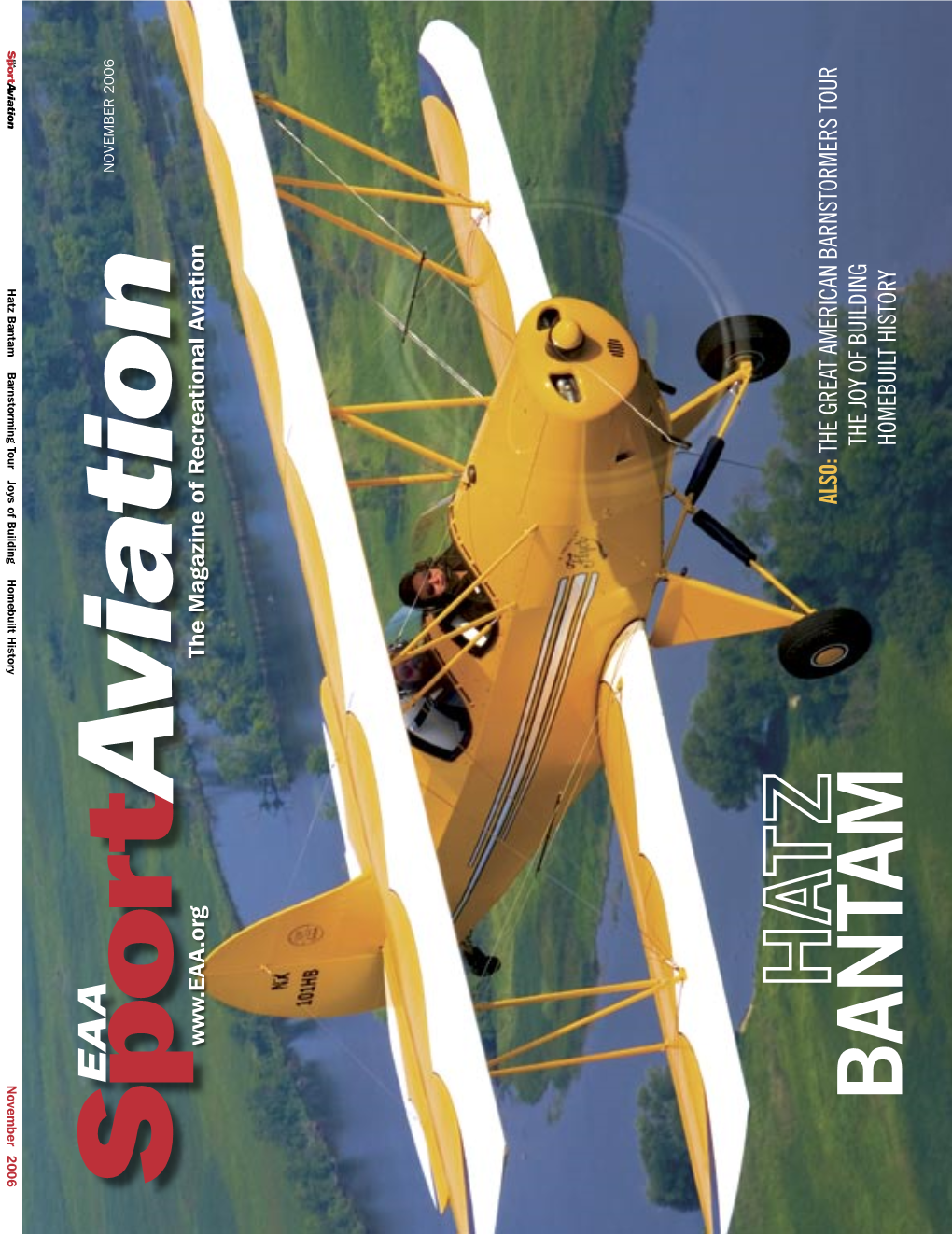

If the real deal is out of range, this may be the next best option. BY ED WISCHMEYER 16 KITPLANES June 2010 www.kitplanes.com Master craftsman Ron Sieck likes Wacos, and if you’ve ever seen a fully restored antique Waco at a fly-in, you know why. There’s just something about them. Imposing and handsome. Stately. But if you’re on a budget, what better option than to build your own mini- Waco—in this case, a Hatz Classic? And what could be better than to win AirVenture Grand Champion Plans- Built with not just the first airplane you’ve ever built, but with the first major project you’ve ever undertaken? If you’re not up on your Hatz gene- alogy, a primer. First came the Hatz CB-1, designed by John Hatz in the late 1960s, who supposedly built it to Doesn’t this remind you of the TV show line “Out of the blue of the Western sky comes Sky King?” replace his Waco. Billy Dawson modi- fied the design with a rounded fuselage, push-pull tubes for the ailerons and elevators, and with seats relocated and slightly reclined for more room and comfort. He called it the Hatz Classic. The latest evolution is the Hatz Ban- tam, with weight reduced so it can be flown by a Sport Pilot, and the fuselage modified to keep the weight and bal- ance where it should be with a lighter, smaller engine and shorter wings. Long before the Hatz was even on his horizon, Sieck got his private license in 1971 in the ubiquitous Cessna 172, but then he built a house and had a family. -

PPCO Twist System

The Spirit of Homebuilt Aviation I www.eaa.org Vol.2 No.10 I October 2013 Reviewing the Sam LS An all-metal, fi ghter-like homebuilt/LSA Meet the 2013 AirVenture More Light Plane Grand Champions Fun at AirVenture Continental’s Diesel Control System Freeplay Goes Experimental EEAAEXP_Oct13.inddAAEXP_Oct13.indd 1 110/18/130/18/13 99:21:21 AAMM Tower Frequency Thank You, Paul Poberezny By Jack Pelton It was a very sad day on August 22 when EAA Founder ests and inviting anyone to join them. It was only after Paul Poberezny passed away. Paul was nearly 92 years years had passed and the association had grown that old and had been able to spend at least some time tour- there was time to look back and realize those small, ing the AirVenture Oshkosh grounds in his famous VW early organizational steps were actually the founda- “Red One” not long before he died. tion of something that would help carry personal avia- tion forward. Paul’s family and all of us in the EAA family can draw at least some comfort from the fact that he lived a very Even though he didn’t realize it at the time, Paul did long and remarkable life. Paul was vibrant and in- have the unique skills to found an organization, and he volved with the aviation people he loved almost to the had the essential ability to lay the groundwork to make very end. EAA last. Paul was our original leader, but what made him a founder was creating a structure that would allow I won’t dwell on the history of Paul’s life because the EAA to grow and attract new people to share our avia- highlights are covered later in this issue beginning tion passion long into the future. -

Paul H. Poberezny at Home in His Workshop

The Spirit of Homebuilt Aviation I www.eaa.org Vol.2 No.9 I September 2013 Hatz Trick AirVenture in Review Engines at AirVenture 2013 Fun Fly Zone Recap Paul H. Poberezny At home in his workshop EEAAEXP_Sept13.inddAAEXP_Sept13.indd 1 99/23/13/23/13 44:21:21 PMPM Tower Frequency The debut of Disney’s Planes was another Oshkosh fi rst Oshkosh and was wildly successful with an estimated 15,000 people fi lling every available spot to see the animated feature. Many challenges, much success We expanded our restroom facilities, had entertainment groups performing on stage throughout the week, not just By Jack Pelton on Monday evening, and expanded the tram service to make getting around easier. As the weeks counted down to AirVenture Oshkosh your board identifi ed many challenges facing EAA. When we Fifth, we needed expanded transparency in EAA gover- tightened the focus it became clear there were seven nance. We moved the annual meeting of the membership specifi c objectives that must be accomplished for Oshkosh to Wednesday morning from Saturday so more members and EAA to be successful. could attend. We presented a detailed fi nancial report. We listened to requests by members and eliminated fl ightline First, we had to deal with the FAA’s surprise charge of chalets. And your board listened and responded to com- nearly half a million dollars to provide air traffi c controller ments and questions from members at the meeting. service for the week. Without the controllers there could be no waivers, and without the waivers the special traffi c This year the compliments overwhelmed the complaints, procedures that allow 10,000 airplanes to come and go and EAA members showed their true colors by returning would not be possible. -

Kitplanes Feature

HATZ CB-1 CLASSIC It took 10 years for Hansueli and Samuel Gautschi to complete the ultimate do-it-yourself project, and the result is an absolute gem. BY ERNST BICKMEIER I look up against the morning sun, machine is built. The sound of the nine- leather aviator helmet, and flying gog- barely able to contain myself. It’s still cylinder radial engine rings through my gles. He then helps his passenger out of early at Langenthal Airfield in Swit- entire body. The aural and visual sensa- the front seat. This time, it’s his mother zerland, and I have an appointment to tions bring me to a sense of euphoria. Therese who is the lucky one to enjoy the meet someone. Then I see and hear the There it finally stands before me—a flight, surely a good feeling, since she biplane I’ve been waiting for. Just the masterpiece that I have been following knows it took 10 years for her husband faraway silhouette and light hum of the since its inception. It has a certain radi- and son to build the airplane. engine make my heart beat a little faster. ance from the last century, the glory days Samuel greets me enthusiastically; we After an impressive flyover, the of the American radial-engine biplane. haven’t seen each other in a few years. machine enters the pattern and lands. The airplane parks, and for a moment My wife and I first met Samuel and his As it slowly motors over to the parking everything is still. Then the pilot, Sam- father Hansueli at the Frankfurt Air- area, all eyes turn toward the plane. -

Kit Buyer's Guide

313 AIRPLANES YOU CAN BUILD! ®® CELEBRATING 25 YEARS AS YOUR HOMEBUILT AIR C RAFT AUT H ORITY The Wicked Cool World of Experimental Aircraft—BE A Part OF IT! 2010 Kit Buyer’s Guide December 2009 From Russia With Love Grand Designs: A Preview of the E-7 Bush Hog 1984 25 2009 Installing & Flying Third Time’s the Charm? GRT’s Synthetic Ben Haas’ Ford V-8 Conversion Vision EFIS Go Fly.TM Electronic Flight Information Autopilot Engine Monitoring Systems Systems Systems The Avionics Leader for Experimental Aircraft. Quality - Usability - Affordability www.DynonAvionics.com 425-402-0433 [email protected] Seattle,Washington December 2009 | Volume 26, Number 12 On the cover: Art Director Suzanne Stackle designed the photo montage that amply demon- strates the wide range of Experimental possibilities. Photos by Paul Bertorelli, Kevin Wing, Richard VanderMeulen, Dick Starks and courtesy Belite and Sonex. 2010 Kit Aircraft Buyer’s Guide 36 Here’s your opportunity to peruse a current and comprehensive listing of the 313 kit aircraft available today; compiled by Cory Emberson. Flight Preview 36 8 BUSH HOG This improbably named Russian export could be a viable kit some day; by Ed Wischmeyer. Builder Spotlight 12 AVIONICS SPECIAL: SURFING THE RAPIDS Installing and flying with Grand Rapids Technologies’ Horizon HX synthetic vision EFIS in the Glastar Sportsman... easier done than said; by Marc Cook. 18 BUILD A BEAR: PUT THE FABRIC IN FABRICATION The Texas Sport Cub project proves that even the uninitiated can iron out covering problems; by Dave Prizio. 26 THE INDEPENDENCE PROJECT: THE FINISH KIT Little systems that are part of the finish kit on the RV-12 8 mean big projects; by Dave Martin. -

Super Hatz Classic #1

EAA CHAPTER 25 MINNEAPOLIS / ST PAUL, MN SEPTEMBER 2003 Super Hatz Classic #1 By Dennis Simmons see page 4 Frank Hanish & young eagles Young Eagles at Airlake by Mike Dolan A mini Young Eagle rally can be just as much fun for all who are in- volved as the larger ones. The smiles on the new Young Eagles are all the same size anyhow, HUGE! Saturday, August 30th brought the best of the best as far as VFR flying is concerned. Mark Kolesar arrived at the Chapter hangar in his A36 Bonanza raring to start flying Young Eagles and he ex- claimed "Something must be wrong today. I didn't hit a bump all the way down here." It was that nice. Soon after (Continued on page 7) Cleared for Takeoff Pat Halligan P2 IO-470 Hot Start Procedure Frank Hanish p6 September Meeting/Announcements P3 Safety Wire Tool Don Sektnan p6 1903 Flyer at Mall of America Pete Gavin p5 Events/Fly-ins, Stuff for Sale/Wanted p7 Cleared for Takeoff by Pat Halligan The night of Sept. 17th is shaping up to be another excit- ing night at our hanger. We have Dennis Simmons lined up to bring his award winning Hatz (Reserve Grand Champion plans-built) aircraft to the hanger for a static display and presentation. It is also the monthly meeting at which we will draw the winner of the Ford pickup lease that Mark Gul- brandson has donated. If you have tickets and money to turn in, make sure you make it to the hanger as early as possible on the 17th.