Patented July 15, 1952 Dog +H:0 "..."

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Journal of Organic Chemistry, 9, 5291 (1944)

[CONTRIBUTIONFROM THE MEDICAL-RESEARCHDIVISION, SHARP AND DOHME,INC. ] STUDIES ON THE LEUCKART REACTION FRANK S. CROSSLEY AND MAURICE L. MOORE Received July 21, 194.4 In 1885, Leuckart (1) first described the conversion of certain aldehydes and ketones to the corresponding amines by heating with excess ammonium formate. Wallach (2) applied the method to a number of alicyclic and terpenoid ketones, as well as certain aldehydes, and showed its general application. Despite the excellent results reported by Wallach, the reaction had found little use by others until Ingersoll (3) and his co-workers published a review of the method and re- ported the synthesis of a series of substituted a-phenethylamines by an improved modification of the procedure. Since the appearance of this publication, other workers have been stimulated to use the reaction in the preparation of a number of amines with varying success. Although the exact mechanism has not been definitely established, the reaction has been studied by Wallach (2) and Ingersoll (4)and explained by the following steps: (a) The ammonium formate dissociates into ammonia and formic acid at the temperature of the reaction; and (b) ammonia adds to the carbonyl group or condenses to form the corresponding imine. (c) The formic acid then acts as a reducing agent to remove the hydroxyl or reduce the imino group; and (d) if in excess, may form the formyl derivative which is subsequently hydrolyzed to the free amine. HCOONH, HCOOH f NHj rR OH 7 R R \ + HCOOH + CHNHz + CO* / R’ H20 R’ R R \ \ CHNHz + HCOOH - CHNHCHO + HzO / / R R Formamide (90-9575) may be substituted for ammonium formate and prob- ably hydrolyzes in the reaction to undergo the same steps as above. -

Aromatic and Aliphatic Amines

Aromatic and Aliphatic Amines 1. Preparation: Amines are prepared by the alkylation of ammonia, Gabriel synthesis, reduction of amides, reduction of nitriles, reduction of nitro-compounds, and reductive amination of aldehydes and ketones. Alkylation of ammonia (Hoffmann,s method): Ethanolic solution of ammonia reacts with an alkyl halide to form primary amine which can further reacts with the alkyl halide to form a secondary amine that can further react to form a tri-substituted amine (i.e., 3o amine). Therefore a mixture of three classes of amines is obtained, alongwith some quaternary ammonium salts. The order of reactivity of halides is RI > RBr > RCl and follow the SN2 pathway. Reduction of alkylazides: A primary amine can be best prepared from alkyl azide by reduction with Na/alcohol or Zn/CH3COOH. Gabriel synthesis: In Gabriel synthesis, phthalimide is converted into its salt potassium phthalimide by the reaction of ethanolic KOH. That salt on heating with an alkyl halide Dr. Debsankar Das, Assistant Prof. P. K. College, Contai Page 1 produces N‐alkyl phthalimide. This can be hydrolyzed by aqueous acids or bases into the primary amine and phthalic acid. Reduction of nitriles: Nitriles can be reduced by lithium aluminum hydride (LiAIH4) or Na/ethanol to primary amines. Reduction of amides: Primary amines can be prepared from amides by reduction with lithium aluminum hydride, while N‐substituted and N, N‐disubstituted amides give secondary and tertiary amines, respectively. Dr. Debsankar Das, Assistant Prof. P. K. College, Contai Page 2 Reduction of nitrocompounds: Aromatic amines are normally prepared by reduction of the corresponding aromatic nitrocompounds with metal/acid or Ni/H2 or LAH. -

Review: Synthetic Methods for Amphetamine

Review: Synthetic Methods for Amphetamine A. Allen1 and R. Ely2 1Array BioPharma Inc., Boulder, Colorado 80503 2Drug Enforcement Administration, San Francisco, CA Abstract: This review focuses on synthesis of amphetamine. The chemistry of these methods will be discussed, referenced and precursors highlighted. This review covers the period 1985 to 2009 with emphasis on stereoselective synthesis, classical non-chiral synthesis and bio-enzymatic reactions. The review is directed to the Forensic Community and thus highlights precursors, reagents, stereochemistry, type and name reactions. The article attempts to present, as best as possible, a list of references covering amphetamine synthesis from 1900 -2009. Although this is the same fundamental ground as the recent publication by K. Norman; “Clandestine Laboratory Investigating Chemist Association” 19, 3(2009)2-39, this current review offers another perspective. Keywords: Review, Stereoselective, Amphetamine, Syntheses, references, Introduction: It has been 20 years since our last review of the synthetic literature for the manufacture of amphetamine and methamphetamine. Much has changed in the world of organic transformation in this time period. Chiral (stereoselective) synthetic reactions have moved to the forefront of organic transformations and these stereoselective reactions, as well as regio-reactions and biotransformations will be the focus of this review. Within the synthesis of amphetamine, these stereoselective transformations have taken the form of organometallic reactions, enzymatic reactions, ring openings, - aminooxylations, alkylations and amination reactions. The earlier review (J. Forensic Sci. Int. 42(1989)183-189) addressed for the most part, the ―reductive‖ synthetic methods leading to this drug of abuse. It could be said that the earlier review dealt with ―classical organic transformations,‖ roughly covering the period from 1900-1985. -

Simple Ruthenium-Catalyzed Reductive Amination Enables the Synthesis of a Broad Range of Primary Amines

ARTICLE DOI: 10.1038/s41467-018-06416-6 OPEN Simple ruthenium-catalyzed reductive amination enables the synthesis of a broad range of primary amines Thirusangumurugan Senthamarai1, Kathiravan Murugesan1, Jacob Schneidewind 1, Narayana V. Kalevaru1, Wolfgang Baumann1, Helfried Neumann1, Paul C.J. Kamer1, Matthias Beller 1 & Rajenahally V. Jagadeesh 1 1234567890():,; The production of primary benzylic and aliphatic amines, which represent essential feed- stocks and key intermediates for valuable chemicals, life science molecules and materials, is of central importance. Here, we report the synthesis of this class of amines starting from carbonyl compounds and ammonia by Ru-catalyzed reductive amination using H2. Key to success for this synthesis is the use of a simple RuCl2(PPh3)3 catalyst that empowers the synthesis of >90 various linear and branched benzylic, heterocyclic, and aliphatic amines under industrially viable and scalable conditions. Applying this catalyst, −NH2 moiety has been introduced in functionalized and structurally diverse compounds, steroid derivatives and pharmaceuticals. Noteworthy, the synthetic utility of this Ru-catalyzed amination protocol has been demonstrated by upscaling the reactions up to 10 gram-scale syntheses. Further- more, in situ NMR studies were performed for the identification of active catalytic species. Based on these studies a mechanism for Ru-catalyzed reductive amination is proposed. 1 Leibniz-Institut für Katalyse e. V. an der Universität Rostock, Albert-Einstein-Str. 29a, 18059 Rostock, Germany. Correspondence and requests for materials should be addressed to M.B. (email: [email protected]) or to R.V.J. (email: [email protected]) NATURE COMMUNICATIONS | (2018) 9:4123 | DOI: 10.1038/s41467-018-06416-6 | www.nature.com/naturecommunications 1 ARTICLE NATURE COMMUNICATIONS | DOI: 10.1038/s41467-018-06416-6 fi 25 he development of ef cient catalytic reactions for the Cl]2-BINAS catalysts were also applied . -

WASIMP Chemical Profiling of Waste from Clandestine Synthetic Drug Production

WASIMP Chemical Profiling of Waste from Clandestine Synthetic Drug Production. CATHOLIC UNIVERSITY OF LEUVEN LABORATORY OF TOXICOLOGY AND BROMATOLOGY The research is part of the "Research programme in support of the federal drugs policy document", commissioned and financed by the Belgian Science Policy Office 1 Introduction The large profits that can be realized by the trading of clandestine drugs have attracted the attention of organized crime and caused its proliferation in the domain. Both national and international judicial and police intelligence departments are confronted with this problem and are trying to find a fitting answer to the issue, sometimes with the assistance of science. More specific for the clandestine synthesis of so-called designer drugs, this is usually translated as the chemical profiling of confiscated drugs, synthetic precursors and chemical waste. Such analyses may assist law enforcement agencies to interconnect drugs sold on the street with manufacturing and dumping sites, and hence may result in the dismantlement of a criminal organization. Objective The WASIMP project attempted to find reliable chemical parameters that allow interconnection of chemical ditching sites, and/or permit to interlink dumping sites with underground drug laboratories. Research was focused on MDMA (XTC) and amphetamine (Speed), the two most popular clandestine designer drugs in Belgium. Most of the confiscated amphetamine has been manufactured via the Leuckart reductive amination, while MDMA is often synthesized using PtO2-catalyzed -

Impurity Profiling Amphetamine Made from Benzyl Cyanide and Phenylacetic Acid

School of Chemical Technology Degree Program of Chemical Technology Joel Ormala ONE MORE STEP BACK – IMPURITY PROFILING AMPHETAMINE MADE FROM BENZYL CYANIDE AND PHENYLACETIC ACID Master’s thesis for the degree of Master of Science in Technology, submitted for inspection in Espoo, 3rd of October, 2016. Supervisor Professor Ari Koskinen Instructor Dr. Pekka Joensuu Instructor M. Sc. Sami Huhtala Aalto University, P.O. BOX 11000, 00076 AALTO www.aalto.fi Abstract of master's thesis Author Joel Ormala Title of thesis ONE MORE STEP BACK – IMPURITY PROFILING AMPHETAMINE MADE FROM BENZYL CYANIDE AND PHENYLACETIC ACID Department Department of Chemistry Professorship Organic Chemistry Code of professorship Kem-4 Thesis supervisor Professor Ari Koskinen Thesis advisor(s) / Thesis examiner(s) Dr. Pekka Joensuu & M. Sc. Sami Huhtala Date 03.10.2016 Number of pages Language English 60 (+ 98) Abstract The aim of this theses was to employ a multi-disciplinary approach to chemical impurity profiling of illicitly produced amphetamine. Based on the literature on the illicit amphetamine market in Finland and Europe, the globally seized amphetamine pre- and pre-precursors, and the most commonly used illicit manufacturing methods, the synthetic routes to be studied in this research were determined. The role of chemical impurity profiling of drugs in intelligence-led policing strategies was explored, and the particular requirements of analytical methods employed in service of the forensic intelligence process were identified. Using this background knowledge, permission to conduct research on internationally controlled substances was applied and received from FIMEA. Amphetamine was synthesized from benzyl cyanide and phenylacetic acid, using the Leuckart re- action and reductive amination. -

January March 2014 67Kb

The Indian Police Journal The Indian Police Journal Vol LXI. No. 1 ISSN 0537-2429 Jan-March, 2014 IPJ Jan-March, 2014 Vol. LXI No. 1 EDITORIAL BOARD CONTENTS Editorial 2 Shri Rajan Gupta, IPS 1. The Commoner Goes Berserk: The Socio-Psychological DG, BPR&D Subset of a Rebel and a Terror Monger Dr. Manan Dwivedi 4 Chairman 2. “Maoist-Naxalite Problem : Threat Perception and Tackling Strategy through Responsive Governance” Dr. Krishna Kumar 19 Shri Radhakrishnan Kini, IPS 3. Terrorism and Human Rights: Critical Analysis Inderpreet Kaur 28 ADG, BPR&D 4. Human Rights-Obstacle for Police and Safety for Criminals Member Dr. Dalvir Singh Gahlawat 41 5. Intelligent Emergency Response System for Police Vehicles in India Smt. Nirmal Kaur, IPS Ishan Ganeshan 49 6. Clandestine Drug Laboratories: The Problem, IG/Director (SU) Dangers and Solution Member Ashok Juneja IPS 66 7. Digitalized Terrorism -The Technological Advancement of Crime Dr. Nidhi S & Dr. Priti Saxena 85 Shri Sunil Kapur 8. “Safe City – Surat”- Suraksha Setu DIG/DD (SU) Rakesh Asthana 103 9. Image Crisis of Indian Police Member Umesh Sharraf 121 10. Public Perception About Indian Police: An Empirical Analysis Bushara Bano & Dr. Parvaiz Talib 132 Editor 11. First Information Report and Criminal Justice Dr. Pradeep Singh 149 Gopal K.N. Chowdhary 12. Eleven Guidelines to be followed in all cases of Arrest and Detention Khush Kalra 182 13. Organisational Health, Leadership Effectiveness and Influence Tactics as Perceived by Police Personnel- Some Reflections of Vadodara Police Dhvani Patel & Urmi Nanda Biswas 192 14. Influence of Emotional Intelligence on Adjustment of Police Personnel Dr. -

Identification of Impurities in Biological Material Remaining After Amphetamine Synthesis

IDENTIFICATION OF IMPURITIES IN BIOLOGICAL MATERIAL REMAINING AFTER AMPHETAMINE SYNTHESIS Agnieszka SIWIÑSKA-ZIÓ£KOWSKA1, Dariusz B£ACHUT2, Emilia WIDECKA-DEPTUCH2 1Chair and Department of Forensic Medicine, Medical Academy, Warsaw 2Department of Criminalistic and Special Chemistry, Internal Security Agency, Warsaw ABSTRACT: Toxicological analysis of biological material encompasses searching for different toxic substances, amongst which drugs are a very important group. Con- firmation of the presence of compounds in the amphetamine class is based on detec- tion of particular compounds in this class, for example: amphetamine (AMF), methamphetamine (MAMF), 3,4-methylenedioxymethamphetamine (MDMA), 3,4-methylenedioxyethylamphetamine (MDEA), p-methoxyamphetamine (PMA) and p-methoxymethamphetamine (PMMA), using instrumental methods. In this paper we show the possibility of identification of contaminations originating from the syn- thesis of amphetamine using Leuckart’s method in biological materials from two au- topsies performed in the Department of Forensic Medicine in Warsaw. In the first case we detected the presence of N-formylamphetamine, N,N-di-(b-phenylisopro- pyl)amine, N,N-di-(b-phenylisopropyl)methylamine, and derivatives of phenylmethyl- pyridine in stomach and blood samples. In the second case we found the same com- pounds only in the blood sample. Despite the lack of data about toxicity of these substances, it is possible that the toxicity may be comparable to that of amphetamine and its analogues. KEY WORDS: Amphetamine; Impurities; Toxicological analysis; Leuckart’s method; Fatal intoxication. Problems of Forensic Sciences, vol. LX, 2004, 130–148 Received 7 July 2005; accepted 1 September 2005 INTRODUCTION Analysis of toxicological results obtained at the Department of Forensic Medicine in Warsaw revealed that in several recent years fatal poisonings caused by drugs of abuse have occupied second position among all poisonings. -

Department of Chemistry, St. Paul's C. M. College

Lecture note for CC-4-8 (Organic Chemistry-4) Series: Nitrogen Compounds Aliphatic Amines-I Synthesis of aliphatic amines: Let us consider the synthesis of the primary amine R-NH2. Forming a C-N (carbon-heteroatom) bond is easier than forming a C-C bond. So we may consider the following type of disconnections. Thus a primary amine may be obtained by the treatment with ethanolic NH3 on an alkyl halide. But the reaction does not follow the above course absolutely. Over-alkylation is a serious problem: + and so on, i.e. after alkali treatment we get a mixture of RNH2, R2NH, R3N and R4N . But we do want the primary amine RNH2 exclusively. How may we do it? o Separation of primary amine from the above mixture – Hinsberg method. Department of Chemistry, St. Paul's C. M. College 1 Page Lecture note prepared by Kaushik Basu, St. Paul’s C. M. College, Kolkata o As evident from the above scheme, here NH3, RNH2, R2NH, and R3N are in competition to react with RX. If NH3 acts as the nucleophile in preference over the other nucleophilic species, we may get the primary amine. So we have to use a large excess of NH3. Thus we have the following ways to obtain amino acids: o We have to use a masked form of ammonia in which two valences of nitrogen are satisfied by easily removable groups, i.e. Thus we have the Gabriel’s phthalimide synthesis. But phthalimide cannot act as a nucleophile as shown:Department of Chemistry, St. Paul's C. -

For Peer Review Journal: Drug Testing and Analysis

View metadata, citation and similar papers at core.ac.uk brought to you by CORE Drug Testing and Analysis provided by LJMU Research Online ‘APAAN in the neck’ - A reflection on some novel impurities found in seized materials containing amphetamine in Ireland during routine forensic analysis. For Peer Review Journal: Drug Testing and Analysis Manuscript ID DTA-17-0070.R1 Wiley - Manuscript type: Perspective Date Submitted by the Author: 18-Mar-2017 Complete List of Authors: Power, John; Trinity College Dublin, Pharmacology Kavanagh, Pierce; Trinity College Dublin, Department of Pharmacology and Therapeutics, School of Medicine, Trinity Centre for Health Sciences, St. Jame’s Hospital, Jame’s Street, Dublin 8, D08W9RT, Ireland. McLaughlin, Gavin; University of Dublin Trinity College, Pharmacology & Therapeutics; Athlone Institute of Technology, Life & Physical Sciences Barry, Michael; School of Medicine, Trinity Centre for Health Sciences, St. Jame’s Hospital, Jame’s Street, Dublin 8, D08W9RT, Ireland., Department of Pharmacology and Therapeutics Dowling, Geraldine; Dublin Institute of Technology, School of Chemical and Pharmaceutical Sciences, College of Sciences and Health, Dublin Institute of Technology, Kevin Street, Dublin 8, D08NF82, Ireland. Brandt, Simon; School of Pharmacy & Biomolecular Sciences , Liverpool John Moores University Keywords: amphetamine, APAAN, synthesis, by-products, importations, adulturants Abstract: none, as this is a perspective article. http://mc.manuscriptcentral.com/dta Page 1 of 26 Drug Testing and Analysis -

(12) United States Patent (10) Patent No.: US 8,710,268 B2 Bobylev (45) Date of Patent: *Apr

US008710268B2 (12) United States Patent (10) Patent No.: US 8,710,268 B2 Bobylev (45) Date of Patent: *Apr. 29, 2014 (54) METHOD FOR THE HYDROLYSIS OF (58) Field of Classification Search SUBSTITUTED FORMYLAMINES INTO USPC .................................................. 564/336,386 SUBSTITUTEDAMINES See application file for complete search history. (71) Applicant: Mikhail Bobylev, Minot, ND (US) (56) References Cited (72) Inventor: Mikhail Bobylev, Minot, ND (US) U.S. PATENT DOCUMENTS (*) Notice: Subject to any disclaimer, the term of this 8.329,948 B2 * 12/2012 Bobylev ........................ 564,215 patent is extended or adjusted under 35 FOREIGN PATENT DOCUMENTS U.S.C. 154(b) by 0 days. This patent is Subject to a terminal dis EP O 518414 * 12/1992 claimer. * cited by examiner (21) Appl. No.: 13/657,505 Primary Examiner — Shailendra Kumar (74) Attorney, Agent, or Firm — James K Petell (22) Filed: Oct. 22, 2012 (57) ABSTRACT (65) Prior Publication Data An improved method for the synthesis of substituted formy US 2013/OO46111A1 Feb. 21, 2013 lamines and Substituted amines via an accelerated Leuckart reaction. The Leuckart reaction is accelerated by reacting formamide or N-alkylformamide and formic acid with an Related U.S. Application Data aldehyde or aketoneata preferred molar ratio that accelerates (63) Continuation of application No. 12/182,451, filed on the reaction. The improved method is applicable to various Jul. 30, 2008, now Pat. No. 8,329,948. Substituted aldehydes and ketones, including Substituted ben Zaldehydes. An accelerated method for the hydrolysis of sub (60) Provisional application No. 60/962,739, filed on Jul. stituted formylamines into Substituted amines using acid or 31, 2007. -

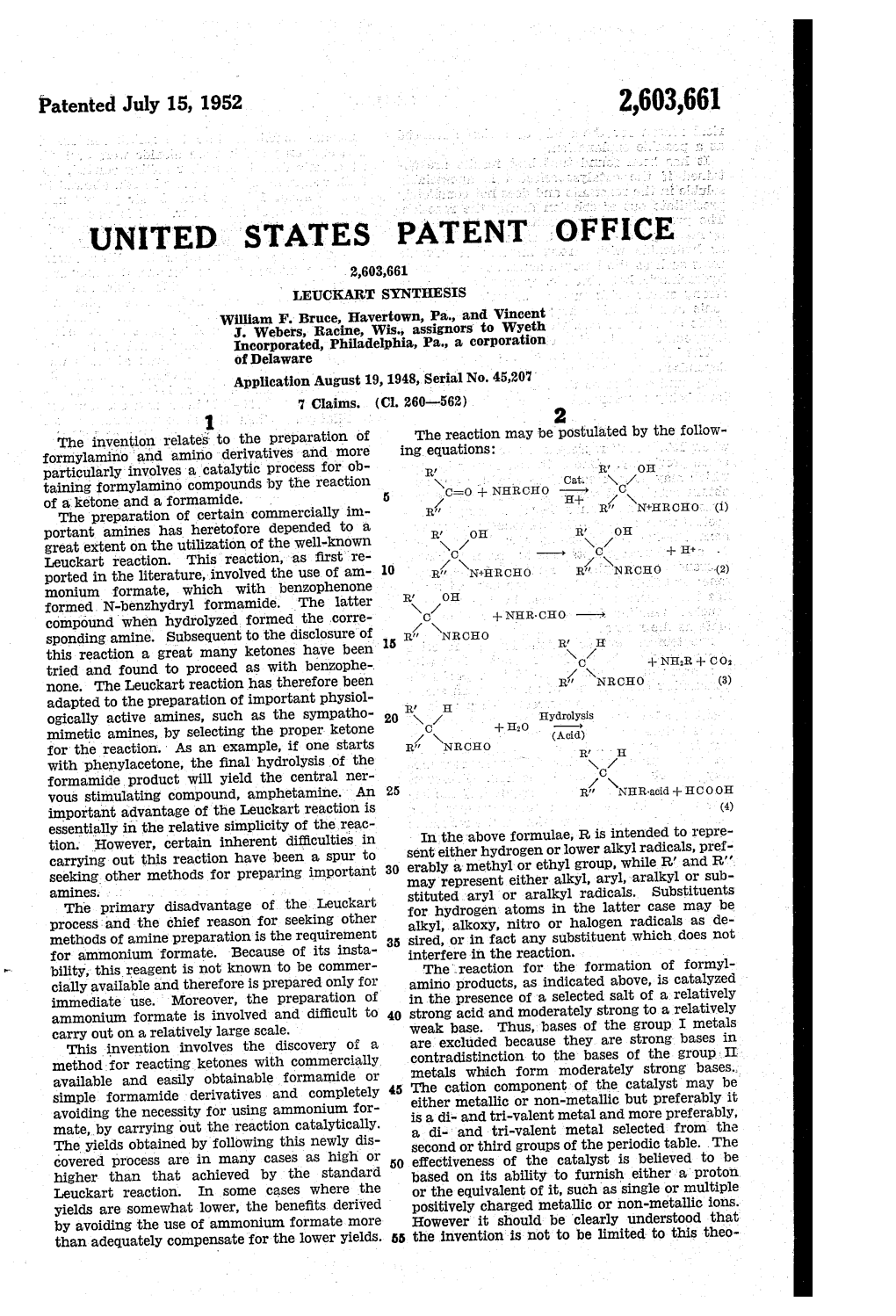

The Leuckart Reaction: a Study of the Mechanism Vincent J

Subscriber access provided by University of Sydney Library The Leuckart Reaction: A Study of the Mechanism Vincent J. Webers, and William F. Bruce J. Am. Chem. Soc., 1948, 70 (4), 1422-1424 • DOI: 10.1021/ja01184a038 Downloaded from http://pubs.acs.org on December 28, 2008 More About This Article The permalink http://dx.doi.org/10.1021/ja01184a038 provides access to: • Links to articles and content related to this article • Copyright permission to reproduce figures and/or text from this article Journal of the American Chemical Society is published by the American Chemical Society. 1155 Sixteenth Street N.W., Washington, DC 20036 1422 VINCENTJ. WEBERSWITH WILLIAMF. BRUCE Vol. 70 [CONTRIBUTION FROM THE WYETK INSTITUTE OF APPLIEDBIOCHEMISTRY] The Leuckart Reaction: A Study of the Mechanism BY VINCENTJ. WEBERS~WITH WILLIAMF. BRUCE The preparation of N-benzhydryl formamide with this, the use of six moles of formamide gave from benzophenone by the Leuckart reaction has less than 50% conversion (Runs 3-A and 4-A). been reported by Leuckart and Bach2 using am- In testing the effect of the addition of various monium formate. The compound has been pre- substances to the reaction mixture, all the runs pared in this la&oratory by the general procedure numbered 3 were made in the same oil-bath at the of Ingersoll” with good results. Since Ingersol14 same time and likewise for the runs numbered 4 stated that somewhat higher yields might be ex- in order to secure reaction conditions as compar- pected in the Leuckart reaction if formzmide it- able as possible. Runs 3-A and 4-A, with the self were used rather than ammonium formate, same reagents, served as controls so that a com- benzophenone was refluxed with 99% formamide; parison might be made between the two sets.