United States Patent Office Ratiented Sept

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Flexible Plasmonic Sensing Substrates and Their Application in Explosive Sensing Justin Bae Washington University in St Louis

Washington University in St. Louis Washington University Open Scholarship Engineering and Applied Science Theses & McKelvey School of Engineering Dissertations Spring 5-17-2017 Flexible Plasmonic Sensing Substrates and their application in Explosive Sensing Justin Bae Washington University in St Louis Srikanth Singamaneni Washington University in Saint Louis Follow this and additional works at: https://openscholarship.wustl.edu/eng_etds Part of the Engineering Commons Recommended Citation Bae, Justin and Singamaneni, Srikanth, "Flexible Plasmonic Sensing Substrates and their application in Explosive Sensing" (2017). Engineering and Applied Science Theses & Dissertations. 231. https://openscholarship.wustl.edu/eng_etds/231 This Thesis is brought to you for free and open access by the McKelvey School of Engineering at Washington University Open Scholarship. It has been accepted for inclusion in Engineering and Applied Science Theses & Dissertations by an authorized administrator of Washington University Open Scholarship. For more information, please contact [email protected]. WASHINGTON UNIVERSITY IN ST. LOUIS School of Engineering and Applied Science Department of Mechanical Engineering and Materials Science Thesis Examination Committee: Srikanth Singamaneni, Chair Guy Genin Jeremiah Morrissey Flexible Plasmonic Sensing Substrates and their application in Explosive Sensing by Sang hyun Justin Bae A thesis presented to the School of Engineering of Washington University in St. Louis in partial fulfillment of the requirements for the -

How to Take Your Phosphate Binders

How to take your phosphate binders Information for renal patients Oxford Kidney Unit Page 2 What are phosphate binders? To reduce the amount of phosphate you absorb from your food you may have been prescribed a medicine called a phosphate binder. Phosphate binders work by binding (attaching) to some of the phosphate in food. This will reduce the amount of phosphate being absorbed into your blood stream. A list of phosphate binders and how to take them is shown below. Phosphate binder How to take it Calcichew (calcium carbonate) Chew thoroughly 10-15 minutes before or immediately before food Renacet (calcium acetate) Phosex (calcium acetate) Osvaren (calcium acetate and magnesium carbonate) Swallow whole after the first Renagel 2-3 mouthfuls of food (sevelemer hydrochloride) Renvela tablets (sevelemer carbonate) Alucaps (aluminium hydroxide) Renvela powder Dissolve in 60ml of water and (sevelemer carbonate) take after the first 2-3 mouthfuls of food Fosrenol tablets Chew thoroughly towards the (lanthanum carbonate) end/immediately after each meal Fosrenol powder Mix with a small amount of (lanthanum carbonate) food and eat immediately Velphoro Chew thoroughly after the first (sucroferric oxyhydroxide) 2-3 mouthfuls The phosphate binder you have been prescribed is: ……………………………………………………………………………………………………………………………………………………….. Page 3 How many phosphate binders should I take? You should follow the dose that has been prescribed for you. Your renal dietitian can advise how best to match your phosphate binders to your meal pattern, as well as which snacks require a phosphate binder. What happens if I forget to take my phosphate binder? For best results, phosphate binders should be taken as instructed. -

Calcium Acetate Capsules

Calcium Acetate Capsules Type of Posting Revision Bulletin Posting Date 27–Dec–2019 Official Date 01–Jan–2020 Expert Committee Chemical Medicines Monographs 6 Reason for Revision Compliance In accordance with the Rules and Procedures of the 2015–2020 Council of Experts, the Chemical Medicines Monographs 6 Expert Committee has revised the Calcium Acetate Capsules monograph. The purpose for the revision is to add Dissolution Test 4 to accommodate FDA-approved drug products with different dissolution conditions and/or tolerances than the existing dissolution tests. • Dissolution Test 4 was validated using a YMC-Pack ODS-A C18 brand of L1 column. The typical retention time for calcium acetate is about 4.3 min. The Calcium Acetate Capsules Revision Bulletin supersedes the currently official monograph. Should you have any questions, please contact Michael Chang, Senior Scientific Liaison (301-230-3217 or [email protected]). C236679-M11403-CHM62015, rev. 00 20191227 Revision Bulletin Calcium 1 Official January 1, 2020 Calcium Acetate Capsules PERFORMANCE TESTS DEFINITION Change to read: Calcium Acetate Capsules contain NLT 90.0% and NMT · DISSOLUTION á711ñ 110.0% of the labeled amount of calcium acetate Test 1 (C4H6CaO4). Medium: Water; 900 mL IDENTIFICATION Apparatus 2: 50 rpm, with sinkers · A. The retention time of the calcium peak of the Sample Time: 10 min solution corresponds to that of the Standard solution, as Mobile phase, Standard solution, Chromatographic obtained in the Assay. system, and System suitability: Proceed as directed in · B. IDENTIFICATION TESTSÐGENERAL á191ñ, Chemical the Assay. Identification Tests, Acetate Sample solution: Pass a portion of the solution under test Sample solution: 67 mg/mL of calcium acetate from through a suitable filter of 0.45-µm pore size. -

Stock Solutions

STOCK SOLUTIONS 5 M NaCl (F.W. 58.44) 500 ml: 146.1 g NaCl ~350 ml H2O Dissolve, then bring up to volume with H2O Sterilize by autoclaving (15 minutes) 1 M Tris, pH 8 (F.W. 121.1) 500 ml: 60.55 g Trizma base ~400 ml H2O Approximately 21.1 ml concentrated HCl (Use pH meter) Bring up to volume with H2O Sterilize by autoclaving (15 minutes) 1 M Tris, pH 7.6 (F.W. 121.1) 500 ml: 60.55 g Trizma base ~400 ml H2O Approximately 28.5 ml concentrated HCl (Use pH meter) Bring up to volume with H2O Sterilize by autoclaving (15 minutes) 1 M MgCl2 (F.W. 203.30) 100 ml: 20.33 g MgCl2 ~70 ml H2O Dissolve, then bring up to volume with H2O Sterilize by autoclaving (15 minutes) 1 M CaCl2 (F.W. 147.02) 100 ml: 14.70 g CaCl2 ~90 ml H2O Dissolve, then bring up to volume with H2O Sterilization not required 1 M MgSO4 (F.W. 246.47) 100 ml: 24.65 g MgSO4 ~75 ml H2O Dissolve, then bring up to volume with H2O Sterilize by autoclaving (15 minutes) 0.1 M MgCl2 (F.W. 203.30) 100 ml: 2.03 g MgCl2 ~95 ml H2O Dissolve, then bring up to volume with H2O Sterilize by autoclaving (15 minutes) 3 M NaOH (F.W. 40.00) 100 ml: 12.0 g NaOH ~80 ml H2O Dissolve, then bring up to volume with H2O Sterilization not required 2 M Sorbitol (F.W. 182.2) 500 ml: 182.2 g Sorbitol ~300 ml H2O Dissolve, then bring up to volume with H2O Sterilization by filtration 5 M Potassium acetate (F.W. -

Production and Testing of Calcium Magnesium Acetate in Maine

77 Majesty's Stationery Office, London, England, River. Res. Note FPL-0229. Forest Service, U.S. 1948. Department of Agriculture, Madison, Wis., 1974. 14. M.S. Aggour and A. Ragab. Safety and Soundness 20. W.L. James. Effect of Temperature and Moisture of Submerged Timber Bridge PU.ing. FHWA/MD In Content on Internal Friction and Speed of Sound terim Report AW082-231-046. FHWA, U.S. Depart in Douglas Fir. Forest Product Journal, Vol. ment of Transportation, June 1982. 11, No. 9, 1961, pp. 383-390, 15. B.O. Orogbemi. Equipment for Determining the 21. A, Burmester. Relationship Between Sound Veloc Dynami c Modulus of Submerged Bridge Timber Pil ity and Morphological, Physical, and Mechani ·ing. Master's thesis. University of Maryland, cal Properties of Wood. Holz als Roh und Wer College Park, 1980. stoff, Vol. 23, No. 6, 1965, pp. 227-236 (in 16. T.L. Wilkinson. Strength Evaluation of Round German) • Timber Piles. Res. Note FPL-101. Forest Ser 22. c.c. Gerhards. Stress Wave Speed and MOE of vice, U.S. Department of Agriculture, Madison, Weetgum Ranging from 150 to 15 Percent MC. Wis., 1968. Forest Product Journal, Vol. 25, No. 4, 1975, 17. J, Bodig and B.A. Jayne. Mechanics of Wood and pp. 51-57. Wood Composites. Van Nostrand, New York, 1982. 18. R.M. Armstrong. Structural Properties of Timber Piles, Behavior of Deep Foundations. Report STP-670, ASTM, Philadelphia, 1979, pp. 118-152. 19. B.A, Bendtsen. Bending Strength and Stiffness Publication of this paper sponsored by Committee on of Bridge Piles After 85 Years in the Milwaukee Structures Maintenance. -

Phosphate Binders

Pharmacy Info Sheet Phosphate Binders calcium acetate, calcium carbonate (Tums, Calsan, Apocal, Ocal), calcium liquid, aluminum hydroxide (Basaljel, Amphojel), sevelamer (Renagel), lanthanum (Fosrenol) What it does: Phosphate binders are used to treat high Special considerations for lanthamum and blood phosphorus levels. sevelamer: Calcium acetate, calcium carbonate, calcium Lanthanum should be taken during or liquid, aluminum hydroxide, lanthanum and immediately after a meal. Taking a dose on an sevelamer bind dietary phosphate. When the empty stomach can cause nausea and kidneys fail, phosphorus builds up in the body vomiting. Chew the tablet completely before because the kidneys can no longer remove swallowing. DO NOT swallow tablets whole. much phosphorus. Phosphate binders are used to lower the amount of phosphorus Sevelamer should be taken just before eating. absorbed from food to limit development of Swallow the tablet whole – Renagel should not bone and blood vessel disease. be cut or chewed. The contents of sevelamer tablets expand in water and could cause Aluminum hydroxide and calcium carbonate choking if cut chewed or crushed. may also be prescribed as antacids. Calcium preparations may also be prescribed as Phosphate binders may interfere with the calcium supplements. Use them only as absorption of certain drugs such as iron prescribed. When these medications are supplements, antibiotics, digoxin, ranitidine, prescribed as calcium supplements or antiseizure, and antiarrhythmic medications. antacids, take between meals. If you are prescribed any of these drugs, take them at least 1 hour before or 3 hours after your How it works: phosphate binder. Kidney disease can cause phosphate to accumulate which results in bone and blood What to do if you miss a dose: vessel disease. -

NON-HAZARDOUS CHEMICALS May Be Disposed of Via Sanitary Sewer Or Solid Waste

NON-HAZARDOUS CHEMICALS May Be Disposed Of Via Sanitary Sewer or Solid Waste (+)-A-TOCOPHEROL ACID SUCCINATE (+,-)-VERAPAMIL, HYDROCHLORIDE 1-AMINOANTHRAQUINONE 1-AMINO-1-CYCLOHEXANECARBOXYLIC ACID 1-BROMOOCTADECANE 1-CARBOXYNAPHTHALENE 1-DECENE 1-HYDROXYANTHRAQUINONE 1-METHYL-4-PHENYL-1,2,5,6-TETRAHYDROPYRIDINE HYDROCHLORIDE 1-NONENE 1-TETRADECENE 1-THIO-B-D-GLUCOSE 1-TRIDECENE 1-UNDECENE 2-ACETAMIDO-1-AZIDO-1,2-DIDEOXY-B-D-GLYCOPYRANOSE 2-ACETAMIDOACRYLIC ACID 2-AMINO-4-CHLOROBENZOTHIAZOLE 2-AMINO-2-(HYDROXY METHYL)-1,3-PROPONEDIOL 2-AMINOBENZOTHIAZOLE 2-AMINOIMIDAZOLE 2-AMINO-5-METHYLBENZENESULFONIC ACID 2-AMINOPURINE 2-ANILINOETHANOL 2-BUTENE-1,4-DIOL 2-CHLOROBENZYLALCOHOL 2-DEOXYCYTIDINE 5-MONOPHOSPHATE 2-DEOXY-D-GLUCOSE 2-DEOXY-D-RIBOSE 2'-DEOXYURIDINE 2'-DEOXYURIDINE 5'-MONOPHOSPHATE 2-HYDROETHYL ACETATE 2-HYDROXY-4-(METHYLTHIO)BUTYRIC ACID 2-METHYLFLUORENE 2-METHYL-2-THIOPSEUDOUREA SULFATE 2-MORPHOLINOETHANESULFONIC ACID 2-NAPHTHOIC ACID 2-OXYGLUTARIC ACID 2-PHENYLPROPIONIC ACID 2-PYRIDINEALDOXIME METHIODIDE 2-STEP CHEMISTRY STEP 1 PART D 2-STEP CHEMISTRY STEP 2 PART A 2-THIOLHISTIDINE 2-THIOPHENECARBOXYLIC ACID 2-THIOPHENECARBOXYLIC HYDRAZIDE 3-ACETYLINDOLE 3-AMINO-1,2,4-TRIAZINE 3-AMINO-L-TYROSINE DIHYDROCHLORIDE MONOHYDRATE 3-CARBETHOXY-2-PIPERIDONE 3-CHLOROCYCLOBUTANONE SOLUTION 3-CHLORO-2-NITROBENZOIC ACID 3-(DIETHYLAMINO)-7-[[P-(DIMETHYLAMINO)PHENYL]AZO]-5-PHENAZINIUM CHLORIDE 3-HYDROXYTROSINE 1 9/26/2005 NON-HAZARDOUS CHEMICALS May Be Disposed Of Via Sanitary Sewer or Solid Waste 3-HYDROXYTYRAMINE HYDROCHLORIDE 3-METHYL-1-PHENYL-2-PYRAZOLIN-5-ONE -

Comparison of Zinc Acetate and Propionate Addition on Gastrointestinal Tract Fermentation and Susceptibility of Laying Hens to S

ENVIRONMENT, HEALTH, AND BEHAVIOR Comparison of Zinc Acetate and Propionate Addition on Gastrointestinal Tract Fermentation and Susceptibility of Laying Hens to Salmonella enteritidis During Forced Molt R. W. Moore,*,†,1 S. Y. Park,†,2 L. F. Kubena,* J. A. Byrd,* J. L. McReynolds,* M. R. Burnham,*,3 M. E. Hume,* S. G. Birkhold,† D. J. Nisbet,* and S. C. Ricke†,4 *USDA-ARS, Southern Plains Agricultural Research Center, Food and Feed Safety Research Unit, College Station, Texas 77845; and †Department of Poultry Science, Texas A&M University, College Station, Texas 77843 ABSTRACT Feed deprivation is the most common Body weight losses were significantly higher in the M, method used to induce molting and stimulate multiple ZPR, and ZAC treatments than in the NM treatment. egg-laying cycles in laying hens for commercial egg pro- Crop lactic acid decreased more in M, ZPR, and ZAC duction. Unfortunately, an increased risk of Salmonella treatments than in NM hens in trial 2. Crop pH was < enteritidis (SE) colonization may result from the use of significantly (P 0.05) lower in NM hens than in M, ZAC, this method. Methods to stimulate multiple egg-laying and ZPR hens in trial 2. Although cecal individual or total volatile fatty acids (VFA), and lactic acid were not cycles without increasing the risk of SE are needed. In > each of 3 experiments, hens over 50 wk of age were di- significantly (P 0.05) different between NM hens and M, ZAC and ZPR hens in trial 1, lactic acid was signifi- vided into groups of 12 and placed in individual laying cantly (P < 0.05) higher in NM hens than in M, ZAC and cages. -

Potassium Acetate

OKI GROUNDWATER COMMITTEE June 3, 2009 - 10:00 A.M. OKI Board Room 720 East Pete Rose Way (at the corner of Eggleston Avenue)* AGENDA 1. Welcome/Introductions 2. Announcements 3. OKI Staff Updates 4. Update on Local Groundwater Management Efforts Frank Bell, Mike Heuer, Greg Stanley, Bruce Whitteberry, Tom Yeager 5. The St. Clair Township Comprehensive Plan: Protecting Source Water and Community Character Jane Wittke, OKI 6. The Groundwater Implications of Geothermal Systems: Geothermal Systems in Ohio Russell Smith, Ohio Department of Health and Geothermal System Construction Jacob Crabtree, Crabtree Drilling Company 7. Other Business ADJOURNMENT ** SEE the MAP and DIRECTIONS on the REVERSE HARD COPY (or in separate attachment to email) Mill Creek Headwaters Project Funding Federal Funds: $498,000 from Ohio EPA under Section 319 of the Clean Water Act Local Match: $472,600 from West Chester Township’s conservation easements and project partners’ in-kind services Mill Creek Headwaters Project Purposes 1. Educate public on how to reduce water pollution 2. Evaluate best management practices 3. Reduce nonpoint source pollution by installing: • 400 feet of stabilized streambank • 3,000 feet of restored riparian corridor • 18 acres of restored floodplain wetland Project Partners •West Chester Township • OKI Regional Council of Governments • Butler Soil and Water Conservation District • Mill Creek Watershed Council of Communities • Butler County Engineer’s Office • Butler County Water and Sewer Department • Greenacres Foundation • University -

Zinc Acetate MSDS # 793.00

Material Safety Data Sheet Page 1 of 2 Zinc Acetate MSDS # 793.00 Section 1: Product and Company Identification Zinc Acetate Synonyms/General Names: Acetate Salt of Zinc; zinc acetate dihydrate Product Use: For educational use only Manufacturer: Columbus Chemical Industries, Inc., Columbus, WI 53925. 24 Hour Emergency Information Telephone Numbers CHEMTREC (USA): 800-424-9300 CANUTEC (Canada): 613-424-6666 ScholAR Chemistry; 5100 W. Henrietta Rd, Rochester, NY 14586; (866) 260-0501; www.Scholarchemistry.com Section 2: Hazards Identification White crystalline granules; slight acetic acid odor. HMIS (0 to 4) Health 2 WARNING! Severe body tissue irritant and moderately toxic by ingestion. Fire Hazard 0 Target organs: None known. Reactivity 0 This material is considered hazardous by the OSHA Hazard Communication Standard (29 CFR 1910.1200). Section 3: Composition / Information on Ingredients Zinc Acetate (5970-45-6), 100% Section 4: First Aid Measures Always seek professional medical attention after first aid measures are provided. Eyes: Immediately flush eyes with excess water for 15 minutes, lifting lower and upper eyelids occasionally. Skin: Immediately flush skin with excess water for 15 minutes while removing contaminated clothing. Ingestion: Call Poison Control immediately. Rinse mouth with cold water. Give victim 1-2 cups of water or milk to drink. Induce vomiting immediately. Inhalation: Remove to fresh air. If not breathing, give artificial respiration. Section 5: Fire Fighting Measures When heated to decomposition, emits acrid fumes. 0 Protective equipment and precautions for firefighters: Use foam or dry chemical to extinguish fire. 1 0 Firefighters should wear full fire fighting turn-out gear and respiratory protection (SCBA). -

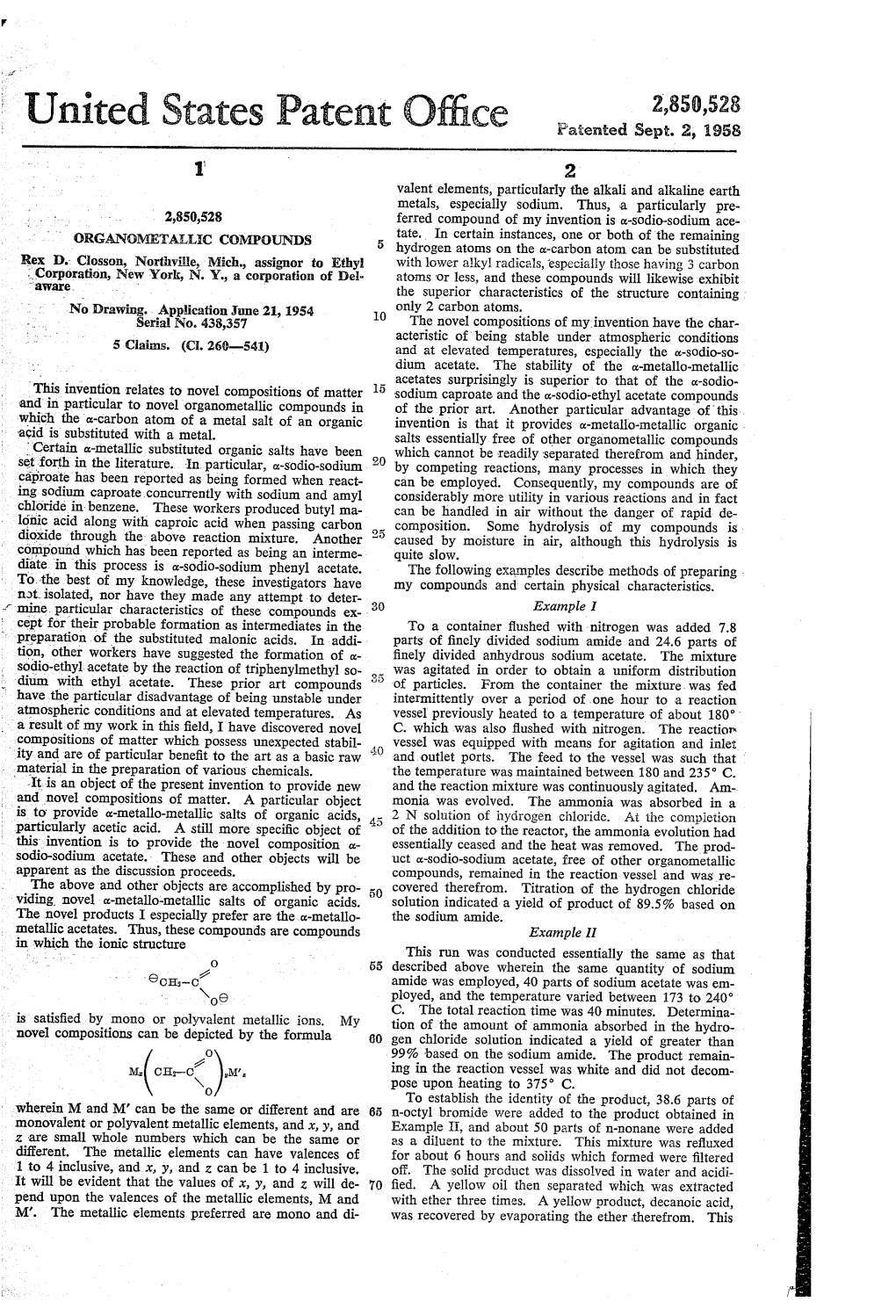

UNITED STATES PATENT Office

Patented Mar. 7, 1950 2499,924 UNITED STATES PATENT office 2,499,924 HIGH VIscosiTY PoLYVINYL Alcohol Edward Lavin, Springfield, Mass, assigner to Shawinigan Resins Corporation, Springfield, Mass, a corporation of Massachusetts No Drawing. Appliention November 20, 1946, Serial No. 711,207 4 Claims. (CL 260-91s), 2 This invention relates to a process for pre The process employed in preparing the prod paring polyvinyl alcohols having high viscosities. lucts set forth in the examples in Tables A and B Hydrolyzed polyvinyl acetates are useful for comprises dissolving the polyvinyl acetate in the many purposes. However, for some uses e. g., toluene and then adding the methanol containing as thickening agents, protective colloids and the the sulfuric acid (98% HaSO4) dissolved therein. like, it is desirable that such materials possess The charge is prepared in a suitable apparatus materially higher viscosities. provided with an agitator and a water-cooled It is an object of this invention to provide a return condenser. The hydrolysis is carried out process for preparing partially hydrolyzed poly by heating the charge at its reflux temperature vinyl acetates having an unusually high viscosity. O and continuing the heating under these condi A particular object of this invention is to pro tions until the desired degree of hydrolysis is vide a process for preparing high viscosity poly effected. The reaction mixture is then cooled vinyl alcohols having an acetate content of 15-40 and the hydrolyzed product which is in the form per cent by weight, calculated as polyvinyl of...a precipitate is allowed to settle. Thereafter acetate. -

Protective Effects of Zinc-L-Carnosine /Vitamin E on Aspirin- Induced Gastroduodenal Injury in Dogs

PROTECTIVE EFFECTS OF ZINC-L-CARNOSINE /VITAMIN E ON ASPIRIN- INDUCED GASTRODUODENAL INJURY IN DOGS MASTER’S THESIS Presented in Partial Fulfillment of the Requirements for the Master of Science Degree in the Graduate School of the Ohio State University By Mieke Baan, DVM, MVR ***** The Ohio State University 2009 Master’s Examination Committee: Professor Robert G. Sherding, Adviser Professor Stephen P. DiBartola Associate Professore Susan E. Johnson Approved by Adviser Veterinary Clinical Sciences Graduate Program ! Copyright by Mieke Baan 2009 ABSTRACT Zinc plays a role in many biochemical functions, including DNA, RNA, and protein synthesis. The dipeptide carnosine forms a stable complex with zinc, which has a protective effect against gastric epithelial injury in-vitro and in-vivo. This randomized double-blinded placebo-controlled study investigated the protective effects of zinc-L-carnosine in combination with alpha-tocopheryl acetate (vitamin E) on the development of aspirin-induced gastrointestinal (GI) lesions in dogs. Eighteen mixed-breed dogs (mean 20.6 kg) were negative for parasites, and had normal blood work evaluations, and gastroduodenoscopic exams. On days 0 – 35, dogs were treated with 1 tablet (n=6) or 2 tablets (n=6) of 30 mg zinc-L-carnosine/ 30 IU vitamin E q12h PO, or a placebo (n=6). On days 7 – 35, all dogs were given 25 mg/kg buffered aspirin q8h PO. Endoscopy was performed on Days -1, 14, 21, and 35, and GI lesions (hemorrhages, erosions, or ulcers) were scored using a 12-point grading scale. Repeated measures ANOVA was used for statistical evaluation. The significance level was set at p ! 0.05.