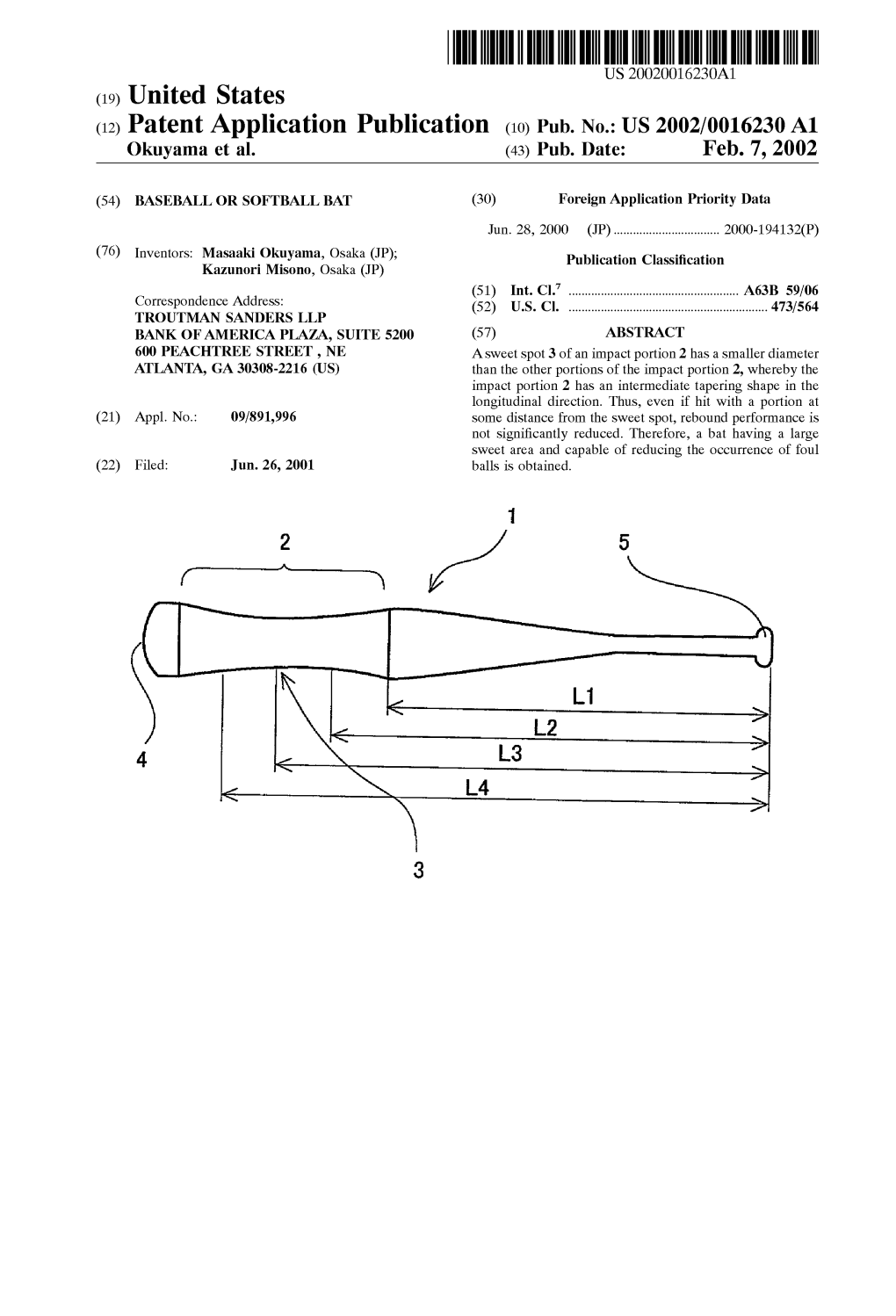

1 \ L4 : Patent Application Publication Feb

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Sabermetrics: the Past, the Present, and the Future

Sabermetrics: The Past, the Present, and the Future Jim Albert February 12, 2010 Abstract This article provides an overview of sabermetrics, the science of learn- ing about baseball through objective evidence. Statistics and baseball have always had a strong kinship, as many famous players are known by their famous statistical accomplishments such as Joe Dimaggio’s 56-game hitting streak and Ted Williams’ .406 batting average in the 1941 baseball season. We give an overview of how one measures performance in batting, pitching, and fielding. In baseball, the traditional measures are batting av- erage, slugging percentage, and on-base percentage, but modern measures such as OPS (on-base percentage plus slugging percentage) are better in predicting the number of runs a team will score in a game. Pitching is a harder aspect of performance to measure, since traditional measures such as winning percentage and earned run average are confounded by the abilities of the pitcher teammates. Modern measures of pitching such as DIPS (defense independent pitching statistics) are helpful in isolating the contributions of a pitcher that do not involve his teammates. It is also challenging to measure the quality of a player’s fielding ability, since the standard measure of fielding, the fielding percentage, is not helpful in understanding the range of a player in moving towards a batted ball. New measures of fielding have been developed that are useful in measuring a player’s fielding range. Major League Baseball is measuring the game in new ways, and sabermetrics is using this new data to find better mea- sures of player performance. -

Physics of Knuckleballs

Home Search Collections Journals About Contact us My IOPscience Physics of knuckleballs This content has been downloaded from IOPscience. Please scroll down to see the full text. 2016 New J. Phys. 18 073027 (http://iopscience.iop.org/1367-2630/18/7/073027) View the table of contents for this issue, or go to the journal homepage for more Download details: IP Address: 129.104.29.1 This content was downloaded on 03/08/2016 at 09:50 Please note that terms and conditions apply. New J. Phys. 18 (2016) 073027 doi:10.1088/1367-2630/18/7/073027 PAPER Physics of knuckleballs OPEN ACCESS Baptiste Darbois Texier1, Caroline Cohen1, David Quéré2 and Christophe Clanet1,3 RECEIVED 1 LadHyX, UMR 7646 du CNRS, Ecole Polytechnique, 91128 Palaiseau Cedex, France 18 December 2015 2 PMMH, UMR 7636 du CNRS, ESPCI, 75005 Paris, France REVISED 3 Author to whom any correspondence should be addressed. 6 June 2016 ACCEPTED FOR PUBLICATION E-mail: [email protected] 20 June 2016 Keywords: sport ballistics, zigzag trajectory, path instability, drag crisis, symmetry breaking PUBLISHED 13 July 2016 Original content from this Abstract work may be used under Zigzag paths in sports ball trajectories are exceptional events. They have been reported in baseball the terms of the Creative Commons Attribution 3.0 (from where the word knuckleball comes from), in volleyball and in soccer. Such trajectories are licence. associated with intermittent breaking of the lateral symmetry in the surrounding flow. The different Any further distribution of this work must maintain scenarios proposed in the literature (such as the effect of seams in baseball) are first discussed and attribution to the author(s) and the title of compared to existing data. -

Role of Materials & Design on Performance of Baseball Bats

Copyright Warning & Restrictions The copyright law of the United States (Title 17, United States Code) governs the making of photocopies or other reproductions of copyrighted material. Under certain conditions specified in the law, libraries and archives are authorized to furnish a photocopy or other reproduction. One of these specified conditions is that the photocopy or reproduction is not to be “used for any purpose other than private study, scholarship, or research.” If a, user makes a request for, or later uses, a photocopy or reproduction for purposes in excess of “fair use” that user may be liable for copyright infringement, This institution reserves the right to refuse to accept a copying order if, in its judgment, fulfillment of the order would involve violation of copyright law. Please Note: The author retains the copyright while the New Jersey Institute of Technology reserves the right to distribute this thesis or dissertation Printing note: If you do not wish to print this page, then select “Pages from: first page # to: last page #” on the print dialog screen The Van Houten library has removed some of the personal information and all signatures from the approval page and biographical sketches of theses and dissertations in order to protect the identity of NJIT graduates and faculty. ABSTRACT ROLE OF MATERIAL & DESIGN ON PERFORMANCE OF BASEBALL BATS by Kim Benson-Worth Baseball bat safety has become an increasing area of interest with more than 19 million people in the United States alone participating in this sport. An increase in injuries resulting from bat injuries has brought the performance of the bats into question. -

2021Tournament Preparation

Tournament 20212021Preparation Kit #SoMuchMoreThanBaseball 3-Day Experience PLEASE READ IN FULL The information contained in this kit is up to date as of the time of publication. From time to time updates may occur. Please check our web site [ballparksofamerica.com] for latest updates. 2021 Tournament Preparation Kit #SoMuchMoreThanBaseball TABLE OF CONTENTS Page 3 ...................................... Welcome Letter Page 4 ........................................... Campus Map Page 5 ..................................... Team Dashboard Page 6 ...................................... Team Insurance Page 7 .......................................... What to Bring Page 8 ................................... BJs Trophy (Pins) Page 9 ........................................... Photography Page 10 ............................. Tournament Itinerary Page 11 .......................................... Official Rules Page 12 ............................................. Game Rules Page 16 .......................................... Ground Rules Page 17 ................. Scheduling & Weather Policy Page 18 .......................................... Facility Rules Page 20 ........................... Home Run Derby Rules Page 21 ........................ Things to Do on Campus Page 22 ........................................... Our Partners Page 2 of 25 2021 Tournament Preparation Kit #SoMuchMoreThanBaseball Welcome Dear Coach, Baseball is a great game. It is a game that is symbolic of life itself - one hit, one catch, one pitch - any of these can change -

Room Service Menu Sugar Mill & Sweet Spot Sports

Room Service Menu Sugar Mill & Sweet Spot Sports Bar About the Sugar Mill In 1912, the Santa Ana Sugar Co-Operative, founded by Mr. James Irvine, used the Embassy Suites Hotel’s parcel of land to construct a sugar beet factory. Bought out by the Holly Sugar Corporation in 1918, the factory continued to operate and at one point produced one fifth of the United States’ refined sugar, until 1983 when the Holly Sugar Corporation closed the factory. Soon following, in 1984, the Embassy Suites Hotel was constructed with thoughts of its predecessor in mind. In keeping with the history of the land use, we welcome you to the Sugar Mill ! We hope you find our classic American and regional Orange County cuisine enjoyable; but, be sure to leave room for our special Sugar Mill desserts as they will surely satisfy your sweet spot. Hours of Operation Sugar Mill Sweet Spot Sports Bar Lunch Sunday – Thursday 11:00am – 2:00pm 11:00am – 11:00pm Dinner Friday & Saturday 5:00pm – 10:00pm 11:00am – 12:30am Sweet Spot Sports Bar The Sweet Spot Sports Bar , Embassy Suites Hotel’s newest sports bar, is the ideal place to catch the big game or shed the stress of the day. Complete with flat panel televisions, surround sound, delicious finger foods and full menu, plus today’s favorite drinks, we are sure you’ll be able to make yourself right at home amongst our friends and family. Banquet and Catering Services The seasoned professionals of the Embassy Suites’ are eager and ready to meet the needs of your special social or corporate event. -

THE SWEET SPOT of a BAT OR RACQUET Rod Cross Physics Department, University of Sydney, Sydney, NSW 2006 Australia the Sweet Spot

THE SWEET SPOT OF A BAT OR RACQUET Rod Cross Physics Department, University of Sydney, Sydney, NSW 2006 Australia The sweet spot of a bat or racquet is sometimes identified as a vibration node, sometimes as the centre of percussion (COP) and sometimes as the impad point where the ball rebounds with maximum speed. The batter or player is more likely to identify the sweet spot as the impact point that results in minimum shock and vibration, and therefore as the point that feels best. Theoretical and experimental results described in this paper indicate that the sweet spot is a narrow zone, located between the fundamental vibration node and the COP, where the energy transferred to the handle is minimised. KEY WORDS: sweet spot, bat, racquet, centre of percussion, vibration node INTRODUCTION: The sweet spot of a baseball bat or a tennis racquet is rewgnised by most players as the point that feels best when the ball is struck. The player feels almost no shock or vibration for an impact at the sweet spot. Conversely, the impact can be moderately painful for an impact well removed from the sweet spot. Various studies (eg Brody, 1986) have indicated that the sweet spot might coincide with the fundamental vibration node of the bat or racquet, or it might coincide with the centre of percussion (COP). Many authors assume that the sweet spot also coincides with the point at which the ball rebounds with the maximum possible speed. The latter assumption is clearly incorrect. If a tennis ball is incident on a stationary racquet, it bounces best near the throat of the racquet and worst near the tip. -

The Physics of Baseball Bats

Get In The Swing of Physics The Physics of Baseball Bats David Kagan Department of Physics California State University, Chico [email protected] Physics and Baseball Web Site: phys.csuchico.edu/baseball The Physics of Baseball Bats Sorry, but I was watching the MLB playoffs and….… The Physics of Baseball Bats Conservation of Momentum The Physics of Baseball Bats Conservation of Momentum The Physics of Baseball Bats To understand the images produced by the camera we need to investigate two key ideas: • Center of Percussion (CP) • Vibrational Nodes (VN) The Physics of Baseball Bats Center of Percussion (CP) We locate the CP by finding where we can hit the stick so that there is no jerk at the top. In other words, the bat goes into pure rotation. For the simple stick the CP is 2/3 of the way down the bat. This is where you want to hit the ball so you don’t get thrown around by the motion of the bat handle. The Physics of Baseball Bats Vibrational Nodes (VN) You can demonstrate vibrational nodes with a flexible stick. The Physics of Baseball Bats If you wrap a paper megaphone around the top of the stick you can hear the vibrations. The place where the sound is minimum is the VN. For the simple stick, the node is ¾ of the way down the bat. At the node, little energy will go into bat vibrations, leaving more energy in the ball. The Physics of Baseball Bats The CP and the VN are in different spots for a simple stick. -

Basics of the Two Man Umpiring System

NHBUA Field Mechanics 1 TWO MAN MECHANICS Conventions used to designate players or locations UIC = Plate Umpire BU = Base Umpire F# = Number designating a fielder position (F1 = Pitcher) #B = base (1B = first base) HP = home plate Pos A/B/C = Position A/B/C R# = Runner and base B = batter BR = batter-runner IF = Infield OF = Outfield AB = At Bat Definitions The Box • An imaginary area in the IF that is a 45 foot square with one corner at HP and the opposite corner at the mound. Working lane • The area on the IF grass running parallel with the baselines between first and second and second and third in which the BU moves while the defensive is playing a batted ball. Sweet spot • The area behind the mound that allows for excellent angles on all plays made at the bases. Secondary sweet spots are designated on each side of the mound. A Play • The course of action in which the defense attempts to put out a runner. Two things are required; the ball and a runner. The “V” • The area on the field between F7 and F9 in which the BU has catch/no catch responsibility. This area is specified on Page 5. Rotation • A specific change in position made by each umpire in response to the ball put in play. Pressure • This term derives from the movement of F3 or F4 while making a play on a batted ball which forces the BU to clear the area around POS A so as not to impede play. Time Play • The situation in which the possibility exists that a run may cross the plate close to or at the same time the third out of an inning is made on the bases. -

The Physics of Baseball

Washington University in St. Louis Baseball Lab Introductory Physics Lab Fall 2015 The Physics of Baseball Pre-Lab: America’s National Pastime A Bit of History Filled with men, myths, and legends, the history of baseball is much too long to be described in any Bit of History. If you’re interested in A Lot of History, check out the excellent documentary titled Baseball – A Film by Ken Burns. But be warned: it is 18.5 hours long. For our purposes, it is sufficient to know that sometime in the late 1860s, the first professional baseball teams formed in the U.S. (our very own St. Louis Cardinals made their debut in 1882) and since that time the sport has become intertwined with American culture. No place is this truer than here in America’s greatest baseball town! What Is This Lab About? By the end of this lab you should see the tremendous number of physics topics that show up in the game of baseball. You’ll get to revisit topics such as momentum, impulse, projectile motion, the drag force, moment of inertia, cross-products, constant acceleration equations, energy, center of mass, and spherical cows. You will also be introduced to the Magnus force, waves, and the center of percussion. Whew! If you are already familiar with baseball, you can skip to the section titled “The Pitcher” at the top of page 3. The next couple sections attempt to explain some of the game to newcomers. The Game A game of baseball is played between two teams, each using nine players. -

Selecting a Baseball & Softball

Selecting a Baseball & Softball Bat Baseball is one of the most popular and competitive sports in the world. With this status, comes the need for the right equipment and training for that skillful edge. Selecting a baseball bat is an individual choice, but it doesn't have to be complicated. There are a few factors to consider for finding the perfect bat. Whichever one you choose, make sure it adheres to league requirements for your division. Check with your coach or local league association for details. The true athlete is the prepared athlete and Dick's Sporting Goods is dedicated to winning with all levels of athletes. Even the pros understand the importance of superior equipment. This tool will help with an understanding of bat construction, bat materials and establish which league you are in to find bats for your level of play. Links to Bat Information by Player Youth Adult Fastpitch Slow Pitch Bat Materials Bat Materials Bat Materials Bat Materials Regulations Regulations Regulations Regulations Frequently Asked Questions Covering the Basics Understanding Bat Construction Even in America's oldest pastime, enhanced craftsmanship is vital. Dick's Sporting Goods, is constantly doing research to find the perfect blend between improved features and technologies, while staying true to sports traditions and rich histories. Barrel Size The measurement of the diameter around the bat. Generally, the longer the barrel the larger the "sweet spot" for making substantial contact. Many players prefer a smaller barrel diameter that lightens the weight and provides more swing speed. Barrel size varies by league. Grip The grip is simply the covering that bat manufacturers use on the handle of aluminum, wood and composite bats. -

Example Practice Plan

Practice schedule 6PM Stretching a. This warm-up should include cardiovascular and stretching activities All exercises will be done for a 10 count. Feet together toe touch Feet together reach for the sky Feet apart reach for the middle Feet apart reach to the right foot Feet apart reach for the left foot Stand on left leg, pull right leg back with heel touching hamstring or backside Stand on right leg, pull left leg back with heel touching hamstring or backside Right arm across the chest with the left hand pulling in arm to the body Left arm across the chest with the right hand pulling in the arm to the body Arms outs small circles rotating forward Arms out small circles rotating backward Arms out big circles rotating forward Arms out big circles rotating backward Sitting on ground, Butterfly technique 2 Laps around the outside of the bases Warm-ups These exercises are done at each practice. The exercises are to emphasis throwing but also work on catching as well. Throw ball up in air to self low to medium height complete 10 tries, throw ball up in air high height complete 10 tries./ glove positioning –“hello” position/ belly position Wrist flicks/glove positioning Elbow throws/glove positioning 90 degree L throws with proper foot movement/glove out, hand in “hello” position, give thrower target, ready body stance Underhand throws from the side-arm straight down/ glove out, hand in “hello” position, give thrower target, ready body stance, emphasis on transfer of ball out of glove and into throwing hand. -

Finding the Sweet Spot of a Baseball Bat

Thaksha Kulahan, Bob Tian, Kai Yang Page 1 of 16 Mathematical Model: Finding the Sweet Spot of a Baseball Bat Thaksha Kulahan Bob Tian Kai Yang University of Toronto Our approach to the problem is the conservation of energy. The sweet spot should be the location where maximum energy is transferred to the ball so that the ball attains best performance. Although hitting at the end gives you the greatest torque that gives you greatest force and greatest acceleration but high torque also means high rotational force on the handle which causes the handle to shake. Since hitters are human, their arms cannot be perfectly rigid when the ball hits at the end of the bat, so there will be some energy loss due to the movement of the bat because the ball does not hit on the center of percussion of the bat. Also the end of the bat is an anti-node of the bat which means hitting on the end of bat causes the greatest vibration, which is another place you lose energy. Given a math model, our goal is to find the center of percussion where the movement of the bat is minimized and a point near the node of fundamental mode of the bat where the vibration of the bat is minimized. And hence, the sweet spot should be in between the center of percussion and the point to minimize vibration so that the total energy loss it minimized. We will find the sweet spot first in terms of different models and then we will discuss what corking would do to our model and the impact of different material of the bat.