US 2019 / 0027414 A1 Ramadas Et Al

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

UC Riverside UC Riverside Electronic Theses and Dissertations

UC Riverside UC Riverside Electronic Theses and Dissertations Title Designing New Structures of Magnetic Materials: Cases of Metal Borides and Metal Chalcogenides Permalink https://escholarship.org/uc/item/9ns4w70p Author Scheifers, Jan Phillip Publication Date 2020 License https://creativecommons.org/licenses/by-nc-sa/4.0/ 4.0 Peer reviewed|Thesis/dissertation eScholarship.org Powered by the California Digital Library University of California UNIVERSITY OF CALIFORNIA RIVERSIDE Designing New Structures of Magnetic Materials: Cases of Metal Borides and Metal Chalcogenides A Dissertation submitted in partial satisfaction of the requirements for the degree of Doctor of Philosophy in Chemistry by Jan Phillip Scheifers March 2020 Dissertation Committee: Dr. Boniface B. T. Fokwa, Chairperson Dr. Ming Lee Tang Dr.Yadong Yin Copyright by Jan Phillip Scheifers 2020 The Dissertation of Jan Phillip Scheifers is approved: Committee Chairperson University of California, Riverside Für Papa iv Acknowledgments Some of the research presented in here has previously been published as: Jan P. Scheifers, Boniface P. T. Fokwa: Unprecedented Selective Substitution of Si by Cu in the New Ternary Silicide Ir4-xCuSi2. Manuscript submitted to Z. Kristallogr. Cryst. Mater. Ryland Forsythe, Jan P. Scheifers, Yuemei Zhang, Boniface Tsinde Polequin Fokwa: HT‐ NbOsB: Experimental and Theoretical Investigations of a New Boride Structure Type Containing Boron Chains and Isolated Boron Atoms. European Journal of Inorganic Chemistry 02/2018; 2018(28)., DOI:10.1002/ejic.201800235 Jan P. Scheifers, Michael Küpers, Rashid Touzani, Fabian C. Gladisch, Rainer Poettgen, Boniface P. T. Fokwa: 1D iron chains in the complex metal-rich boride Ti5-xFe1- yOs6+x+yB6 (x = 0.66(1), y = 0.27(1)) representing an unprecedented structure type based on unit cell twinning. -

NON-HAZARDOUS CHEMICALS May Be Disposed of Via Sanitary Sewer Or Solid Waste

NON-HAZARDOUS CHEMICALS May Be Disposed Of Via Sanitary Sewer or Solid Waste (+)-A-TOCOPHEROL ACID SUCCINATE (+,-)-VERAPAMIL, HYDROCHLORIDE 1-AMINOANTHRAQUINONE 1-AMINO-1-CYCLOHEXANECARBOXYLIC ACID 1-BROMOOCTADECANE 1-CARBOXYNAPHTHALENE 1-DECENE 1-HYDROXYANTHRAQUINONE 1-METHYL-4-PHENYL-1,2,5,6-TETRAHYDROPYRIDINE HYDROCHLORIDE 1-NONENE 1-TETRADECENE 1-THIO-B-D-GLUCOSE 1-TRIDECENE 1-UNDECENE 2-ACETAMIDO-1-AZIDO-1,2-DIDEOXY-B-D-GLYCOPYRANOSE 2-ACETAMIDOACRYLIC ACID 2-AMINO-4-CHLOROBENZOTHIAZOLE 2-AMINO-2-(HYDROXY METHYL)-1,3-PROPONEDIOL 2-AMINOBENZOTHIAZOLE 2-AMINOIMIDAZOLE 2-AMINO-5-METHYLBENZENESULFONIC ACID 2-AMINOPURINE 2-ANILINOETHANOL 2-BUTENE-1,4-DIOL 2-CHLOROBENZYLALCOHOL 2-DEOXYCYTIDINE 5-MONOPHOSPHATE 2-DEOXY-D-GLUCOSE 2-DEOXY-D-RIBOSE 2'-DEOXYURIDINE 2'-DEOXYURIDINE 5'-MONOPHOSPHATE 2-HYDROETHYL ACETATE 2-HYDROXY-4-(METHYLTHIO)BUTYRIC ACID 2-METHYLFLUORENE 2-METHYL-2-THIOPSEUDOUREA SULFATE 2-MORPHOLINOETHANESULFONIC ACID 2-NAPHTHOIC ACID 2-OXYGLUTARIC ACID 2-PHENYLPROPIONIC ACID 2-PYRIDINEALDOXIME METHIODIDE 2-STEP CHEMISTRY STEP 1 PART D 2-STEP CHEMISTRY STEP 2 PART A 2-THIOLHISTIDINE 2-THIOPHENECARBOXYLIC ACID 2-THIOPHENECARBOXYLIC HYDRAZIDE 3-ACETYLINDOLE 3-AMINO-1,2,4-TRIAZINE 3-AMINO-L-TYROSINE DIHYDROCHLORIDE MONOHYDRATE 3-CARBETHOXY-2-PIPERIDONE 3-CHLOROCYCLOBUTANONE SOLUTION 3-CHLORO-2-NITROBENZOIC ACID 3-(DIETHYLAMINO)-7-[[P-(DIMETHYLAMINO)PHENYL]AZO]-5-PHENAZINIUM CHLORIDE 3-HYDROXYTROSINE 1 9/26/2005 NON-HAZARDOUS CHEMICALS May Be Disposed Of Via Sanitary Sewer or Solid Waste 3-HYDROXYTYRAMINE HYDROCHLORIDE 3-METHYL-1-PHENYL-2-PYRAZOLIN-5-ONE -

Impact of Back Surface Field (BSF) Layers in Cadmium Telluride (Cdte) Solar Cells from Numerical Analysis

Impact of Back Surface Field (BSF) Layers in Cadmium Telluride (CdTe) Solar Cells from Numerical Analysis C. Doroody1,a), K.S. Rahman2,b), H.N. Rosly1, M.N. Harif1, Y. Yusoff2, S. Fazlili1, M.A. Matin3, S.K. Tiong2 and N. Amin2,c) 1College of Engineering, Universiti Tenaga Nasional (@The National Energy University), Jalan IKRAM- UNITEN, 43000 Kajang, Selangor, Malaysia 2Institute of Sustainable Energy, Universiti Tenaga Nasional (@The National Energy University), Jalan IKRAM-UNITEN, 43000 Kajang, Selangor, Malaysia 3Renewable Energy Laboratory, Chittagong University of Engineering and Technology, Chittagong 4349, Bangladesh a)Corresponding author: [email protected] b)[email protected] c)[email protected] Abstract. Numerical simulation has been executed using Solar Cell Capacitance Simulator (SCAPS-1D) to study the possibility of favourable efficiency and stable CdS/CdTe cell in various cell configurations. A basic structure of CdS/CdTe cell is studied in this work with 4 m CdTe absorber layer and 100 nm tin oxide (SnO2) as front contact, 25 nm cadmium sulfide (CdS) as buffer layer, zinc telluride (ZnTe) is used as back surface field (BSF) material compared with ZnTe:Cu, Cu2Te and MoTe2 in order to reduce the minority carrier recombination at back surface field (BSF). The cell structure of glass/SnO2/CdS/CdTe/MoTe2 has shown the highest conversion 2 efficiency of 17.04% (Voc=0.91V, Jsc=24.79 mA/cm , FF=75.41). These calculations have verified that SnO2 as buffer layer and MoTe2 as back contacts are suitable for an efficient CdS/CdTe cell. Also, it is found that a few nanometers (about 40 nm) of back surface layer is enough to achieve high conversion efficiency. -

Research of the Boundary of the Section of a Photo Receiver Based on Mos Pcdte / Cdo Structures

The American Journal of Applied Sciences IMPACT FACTOR – (ISSN 2689-0992) 2020: 5. 276 Published: October 31, 2020 | Pages: 97-105 Doi: https://doi.org/10.37547/tajas/Volume02Issue10-14 OCLC - 1121105553 Research Of The Boundary Of The Section Of A Photo Receiver Based On Mos pCdTe / CdO Structures Sh.B.Utamuradova Research Institute Of Semiconductor Physics And Microelectronics At The National University Of Uzbekistan Named After Mirzo Ulugbek, Tashkent, Uzbekistan S.A.Muzafarova Journal Website: Research Institute Of Semiconductor Physics And Microelectronics At The National University http://usajournalshub.c Of Uzbekistan Named After Mirzo Ulugbek, Tashkent, Uzbekistan om/index,php/tajas Copyright: Original content from this work may be used under the terms of the creative commons attributes 4.0 licence. ABSTRACT In this work, we investigated an intermediate layer in the structure of a photosensitive MOS structure nCdO / pCdTe . X-ray phase analysis shows that the intermediate layer between Mo and pCdTe is rather complex in composition. It contains dichalcogenides - three oxide MoO3 and a thin layer of a composite material with the composition of ditelluride MoTe2 . According to X-ray diffraction measurements, the total thickness of the intermediate layer is no more than ~ 200Ǻ. It was shown that in the nCdO / pCdTe structure the base material CdTe mainly consists of a homogeneous cubic modification layer. KEYWORDS Intermediate layer, photosensitivity , gas transport, interfaces , dichalcogenides , X-ray diffraction analysis, structure. -

Synthesis and Characterization of Mote2 Thin Films for Photoelectro-Chemical Cell Applications

View metadata, citation and similar papers at core.ac.uk brought to you by CORE provided by Universiti Teknikal Malaysia Melaka (UTeM) Repository Synthesis and Characterization of MoTe2 Thin Films for Photoelectro-chemical Cell Applications Lim Mei Ying*, Nor Hamizah Bt. Mazlan and T. Joseph Sahaya Anand Department of Engineering Materials, Faculty of Manufacturing Engineering, University Technical Malaysia Melaka, Durian Tunggal Melaka 76100, Malaysia. Abstract - Thin films of transition metal chalcogenides, molybdenum ditelluride (MoTe2) have been electrodeposited cathodically on indium tin oxide-coated conducting glass substrates from ammonaical solution of H2MoO4 and TeO2. These MoTe2 thin films are useful as photovoltaic cell and photoelectro-chemical (PEC) solar cell. The electrode potential was varied while the bath temperature was maintained at 40±1 ºC and deposition time of 30 minutes. X-ray diffraction analysis showed the presence of highly textured MoTe2 films with polycrystalline nature. Compositional analysis by EDX gives their stoichiometric relationships. Scanning electron microscope (SEM) was used to study surface morphology and shows that the films are smooth, uniform and useful for device fabrication. The optical absorption spectra showed that the material has an indirect band- gap value of 1.91-2.04 eV with different electrode potential. Besides, the film exhibited p-type semiconductor behavior. Keywords: Molybdenum ditelluride; Thin films; Electrodepositon; Solar cell 1. INTRODUCTION using X-ray diffraction analysis, optical studies and SEM Recently there has been a growing interest in layered /EDX studies. semiconducting compounds consisting of group VI transition metal dichalcogenides MX2 (M = Mo, W, Cd, Ni etc. and X = 2. EXPERIMENTAL S, Se, Te) [1-3]. -

Wte2): an Atomic Layered Semimetal

The Pennsylvania State University The Graduate School Department of Materials Science and Engineering TUNGSTEN DITELLURIDE (WTE2): AN ATOMIC LAYERED SEMIMETAL A Thesis in Materials Science and Engineering by Chia-Hui Lee 2015 Chia-Hui Lee Submitted in Partial Fulfillment of the Requirements for the Degree of Master of Science December 2015 ii The thesis of Chia-Hui Lee was reviewed and approved* by the following: Joshua A. Robinson Professor of Materials Science and Engineering Thesis Advisor Thomas E. Mallouk Head of the Chemistry Department Evan Pugh University Professor of Chemistry, Physics, Biochemistry and Molecular Biology Mauricio Terrones Professor of Physics, Chemistry and Materials Science & Engineering Suzanne Mohney Professor of Materials Science and Engineering and Electrical Engineering Chair, Intercollege Graduate Degree Program in Materials Science and Engineering *Signatures are on file in the Graduate School iii ABSTRACT Tungsten ditelluride (WTe2) is a transition metal dichalcogenide (TMD) with physical and electronic properties that make it attractive for a variety of electronic applications. Although WTe2 has been studied for decades, its structure and electronic properties have only recently been correctly described. We explored WTe2 synthesis via chemical vapor transport (CVT) method for bulk crystal, and chemical vapor deposition (CVD) routes for thin film material. We employed both experimental and theoretical techniques to investigate its structural, physical and electronic properties of WTe2, and verify that WTe2 has its minimum energy configuration in a distorted 1T structure (Td structure), which results in metallic-like behavior. Our findings confirmed the metallic nature of WTe2, introduce new information about the Raman modes of Td-WTe2, and demonstrate that Td- WTe2 is readily oxidized via environmental exposure. -

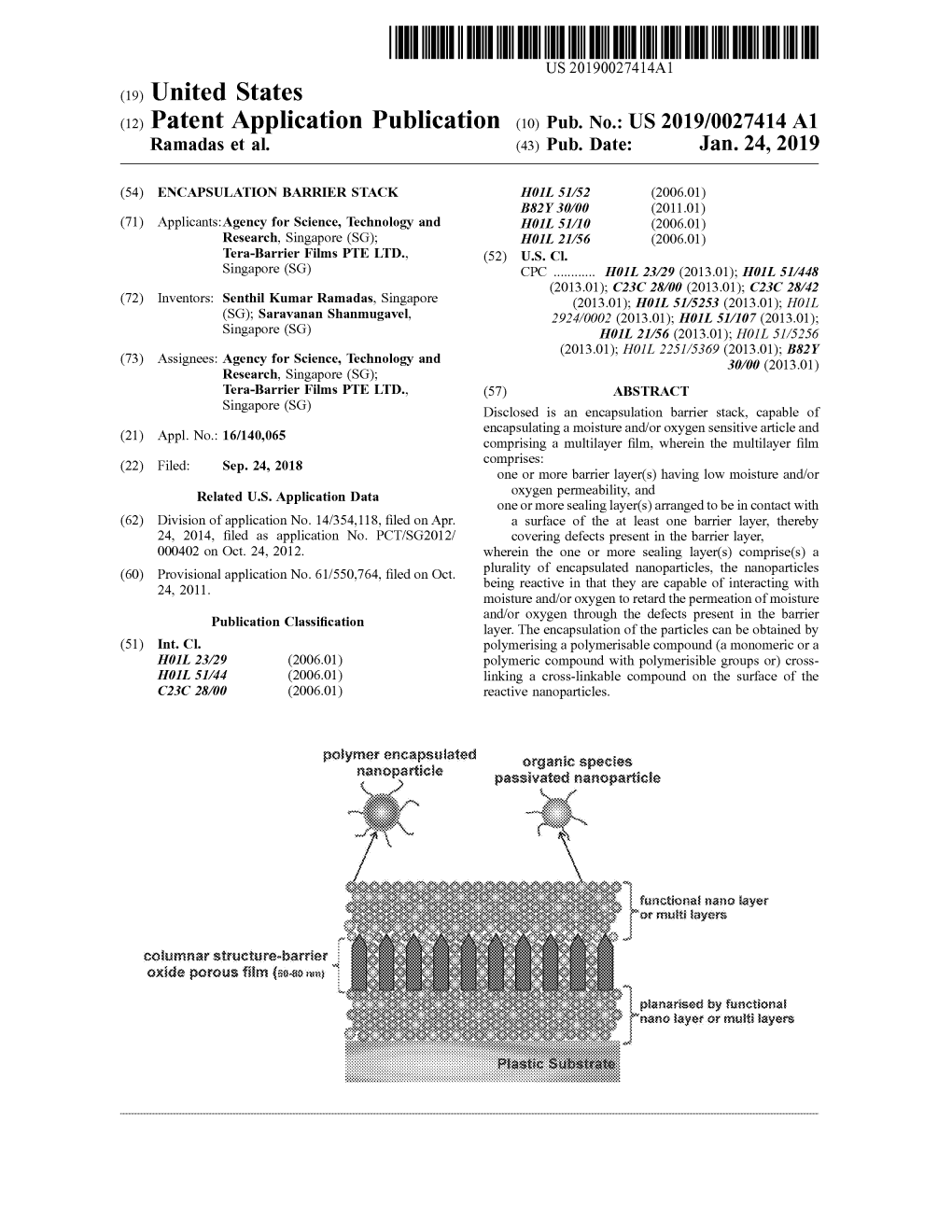

WO 2014/062135 Al 24 April 2014 (24.04.2014) P O P C T

(12) INTERNATIONAL APPLICATION PUBLISHED UNDER THE PATENT COOPERATION TREATY (PCT) (19) World Intellectual Property Organization International Bureau (10) International Publication Number (43) International Publication Date WO 2014/062135 Al 24 April 2014 (24.04.2014) P O P C T (51) International Patent Classification: AO, AT, AU, AZ, BA, BB, BG, BH, BN, BR, BW, BY, B32B 5/16 (2006.01) H01L 23/29 (2006.01) BZ, CA, CH, CL, CN, CO, CR, CU, CZ, DE, DK, DM, B32B 27/04 (2006.01) H01L 51/52 (2006.01) DO, DZ, EC, EE, EG, ES, FI, GB, GD, GE, GH, GM, GT, B32B 19/02 (2006.01) HN, HR, HU, ID, IL, IN, IR, IS, JP, KE, KG, KN, KP, KR, KZ, LA, LC, LK, LR, LS, LT, LU, LY, MA, MD, ME, (21) International Application Number: MG, MK, MN, MW, MX, MY, MZ, NA, NG, NI, NO, NZ, PCT/SG201 3/000448 OM, PA, PE, PG, PH, PL, PT, QA, RO, RS, RU, RW, SA, (22) International Filing Date: SC, SD, SE, SG, SK, SL, SM, ST, SV, SY, TH, TJ, TM, 18 October 2013 (18.10.201 3) TN, TR, TT, TZ, UA, UG, US, UZ, VC, VN, ZA, ZM, ZW. (25) Filing Language: English (84) Designated States (unless otherwise indicated, for every (26) Publication Language: English kind of regional protection available): ARIPO (BW, GH, (30) Priority Data: GM, KE, LR, LS, MW, MZ, NA, RW, SD, SL, SZ, TZ, 61/715,420 18 October 2012 (18. 10.2012) US UG, ZM, ZW), Eurasian (AM, AZ, BY, KG, KZ, RU, TJ, TM), European (AL, AT, BE, BG, CH, CY, CZ, DE, DK, (71) Applicant: TERA-BARRIER FILMS PTE LTD EE, ES, FI, FR, GB, GR, HR, HU, IE, IS, IT, LT, LU, LV, [SG/SG]; 3, Research Link, Singapore 117602 (SG). -

United States Patent 0 "Ice Patented May 28, 1968

3,385,667 United States Patent 0 "ice Patented May 28, 1968 1 2 3,385,667 given the designation ASTM 15-658. Calculated lattice MULYBDENUM DITELLURIDE AND HIGH parameters were (123.5182 A., and 0:13.9736 A., the TEMPERATURE, HIGH - PRESSURE SYN calculated density was 7.784 g./cc. THESES METHOD OF PREPARING SAME L. H. Brixner, Journal Inorganic Nuclear Chemistry, ieyer Shea Siiverman, Norristown, Pa., assigncr to Penn vol. 24, pp. 257—-65, (1962), prepared MoTe2 in single salt Chemicals Corporation, Philadelphia, Pa, a cor crystal form by means of transport reactions using bro poration of Pennsylvania mine as the transport agent. Crystallographic data was No Drawing. Filed Feb. 11, 1966, Ser. No. 526,702 taken on the basis of single crystal patterns using K a 4 Claims. (Cl. 23-204) radiation of Cu()t=1.5418 A). Lattice parameters were 10 (1:3.517 A. and 0:13.949 A., which constants were in ABSTRACT OF THE DISCLOSURE good agreement with those of Puotinen and Newnham, and Knop and MacDonald, supra. The MoTe2 exhibited A new form of molybdenum ditelluride having a rhom good semi-conducting properties having an electrical bohedral crystal structure is prepared by subjecting a mix resistivity measured at 25° C. and at —-196° C. of 8.5 ture of molybdenum and tellurium to a temperature of at and 1.34>< l03 ohm-cm, respectively. least about 1700° C. and a pressure of at least about 15 It is also reported by the US. Department of Com kilobars. merce, Ot?ce of Technical Service, Bulletin AD 265,121 (1961) that small single crystals of MoTe2 were obtained This invention relates to a new form of molybdenum by chemical transport reaction with bromine as the trans ditelluride and to a method of preparing molybdenum 20 port agent. -

Polymorphism Control of Layered Mote2 Through Two-Dimensional

www.nature.com/scientificreports OPEN Polymorphism Control of Layered MoTe2 through Two-Dimensional Solid-Phase Crystallization Received: 20 March 2019 Jyun-Hong Huang1, Hao-Hua Hsu1, Ding Wang2, Wei-Ting Lin2, Chun-Cheng Cheng2, Accepted: 29 May 2019 Yao-Jen Lee3,4 & Tuo-Hung Hou 1 Published: xx xx xxxx Two-dimensional (2D) molybdenum ditelluride (MoTe2) exhibits an intriguing polymorphic nature, showing stable semiconducting 2H and metallic 1T′ phases at room temperature. Polymorphism in MoTe2 presents new opportunities in developing phase-change memory, high- performance transistors, and spintronic devices. However, it also poses challenges in synthesizing homogeneous MoTe2 with a precisely controlled phase. Recently, a new yet simple method using sputtering and 2D solid-phase crystallization (SPC) is proposed for synthesizing high-quality and large-area MoTe2. This study investigates the polymorphism control of MoTe2 synthesis using 2D SPC. The Te/Mo ratio and oxygen content in the as-sputtered flms correlate strongly with the fnal phase and electrical properties of SPC MoTe2. Furthermore, the SPC thermal budget may be exploited for stabilizing a deterministic phase. The comprehensive experiments presented in this work demonstrate the versatile and precise controllability on the MoTe2 phase by using the simple 2D SPC technique. 1 Two-dimensional (2D) molybdenum ditelluride (MoTe2) shows a moderate bandgap close to that of Si , high carrier mobility2,3, and a large spin-orbit coupling splitting in the valence band4. Tese unique properties are being explored for various electronics5–7, optoelectronics8, and spintronics9,10 applications. In contrast to most 2D transition metal dichalcogenides (TMDs) with only one monotonous phase stable at room temperature, 2D 11 MoTe 2 exhibits intriguing polymorphism with a low phase transition barrier , and it can be directly synthesized into either a semiconducting or metallic phase5,12–14. -

Material Safety Data Sheet

LTS Research Laboratories, Inc. Safety Data Sheet Molybdenum Telluride ––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– 1. Product and Company Identification ––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– Trade Name: Molybdenum Telluride Chemical Formula: MoTe2 Recommended Use: Scientific research and development Manufacturer/Supplier: LTS Research Laboratories, Inc. Street: 37 Ramland Road City: Orangeburg State: New York Zip Code: 10962 Country: USA Tel #: 855-587-2436 / 855-lts-chem 24-Hour Emergency Contact: 800-424-9300 (US & Canada) +1-703-527-3887 (International) ––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– 2. Hazards Identification ––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– Signal Word: Danger Hazard Statements: H301 Toxic if swallowed H332 Harmful if inhaled Precautionary Statements: P261 Avoid breathing dust/ fume/ gas/ mist/ vapors/ spray. P264 Wash skin thoroughly after handling. P270 Do not eat, drink or smoke when using this product. P271 Use only outdoors or in a well-ventilated area. P301 + P310 + P330 IF SWALLOWED: Immediately call a POISON CENTER or doctor/physician. Rinse mouth. P304 + P340 + P312 IF INHALED: Remove person to fresh air and keep comfortable for breathing. Call a POISON CENTER or doctor/ physician if you feel unwell. P405 Store locked up. P501 Dispose of contents/ container to an approved waste disposal plant. HMIS -

CMB Protocol

Protocol for Applying and Validating the CMB Model for PM2.5 and VOC EPA-451/R-04-001 December 2004 Protocol for Applying and Validating the CMB Model for PM2.5 and VOC By: John G. Watson et al. Desert Research Institute University and Community College System of Nevada Reno, NV 89512 Prepared for: C. Thomas Coulter and Charles W. Lewis, Project Officers U.S. Environmental Protection Agency Research Triangle Park, NC 27711 Contract No. 5D1808NAEX US. Environmental Protection Agency Office of Air Quality Planning & Standards Emissions, Monitoring & Analysis Division Air Quality Modeling Group i ACKNOWLEDGMENTS This revised protocol for applying and validating the Chemical Mass Balance Model (CMB) was originally developed by Desert Research Institute (DRI) of trhe University and Community College System of Nevada under Contract 5D1808NAEX with EPA’s Office of Air Quality Planning & Standards. The Project Officers were C. Thomas Coulter1 and Charles W. Lewis.2 Substantial contributions to the initial draft of this protocol were made by DRI staff members John G. Watson, Judith C. Chow, and Eric M. Fujita. Tom Coulter spent considerable time reviewing and reformatting the protocol, and harmonizing it with the latest version of CMB: EPA-CMB8.2. He also developed and produced its Appendixes A, B and G. DISCLAIMER This protocol was reviewed by EPA for publication. The information presented here does not necessarily express the views or policies of the U.S. Environmental Protection Agency or the State of Nevada. The mention of commercial hardware and software in this document does not constitute endorsement of these products. No explicit or implied warranties are given for the software and data sets described in this document. -

Formation of an Mote2 Based Schottky Junction Employing Ultra-Low and High Resistive Metal Cite This: RSC Adv.,2019,9, 10017 Contacts†

RSC Advances View Article Online PAPER View Journal | View Issue Formation of an MoTe2 based Schottky junction employing ultra-low and high resistive metal Cite this: RSC Adv.,2019,9, 10017 contacts† Sikandar Aftab,a Muhammad Waqas Iqbal, *b Amir Muhammad Afzal,a M. Farooq Khan,a Ghulam Hussain,b Hafiza Sumaira Waheedb and Muhammad Arshad Kamran c Schottky-barrier diodes have great importance in power management and mobile communication because of their informal device technology, fast response and small capacitance. In this research, a p-type molybdenum ditelluride (p-MoTe2) based Schottky barrier diode was fabricated using asymmetric metal contacts. The MoTe2 nano-flakes were mechanically exfoliated using adhesive tape and with the help of dry transfer techniques, the flakes were transferred onto silicon/silicon dioxide (Si/SiO2) substrates to form the device. The Schottky-barrier was formed as a result of using ultra-low palladium/gold (Pd/Au) Creative Commons Attribution-NonCommercial 3.0 Unported Licence. and high resistive chromium/gold (Cr/Au) metal electrodes. The Schottky diode exhibited a clear rectifying behavior with an on/off ratio of 103 and an ideality factor of 1.4 at zero gate voltage. In order to check the photovoltaic response, a green laser light was illuminated, which resulted in Received 23rd November 2018 À a responsivity of 3.8 Â 103 AW 1. These values are higher than the previously reported results that Accepted 18th March 2019 were obtained using conventional semiconducting materials. Furthermore, the barrier heights for Pd and DOI: 10.1039/c8ra09656b Cr with a MoTe2 junction were calculated to be 90 meV and 300 meV, respectively.