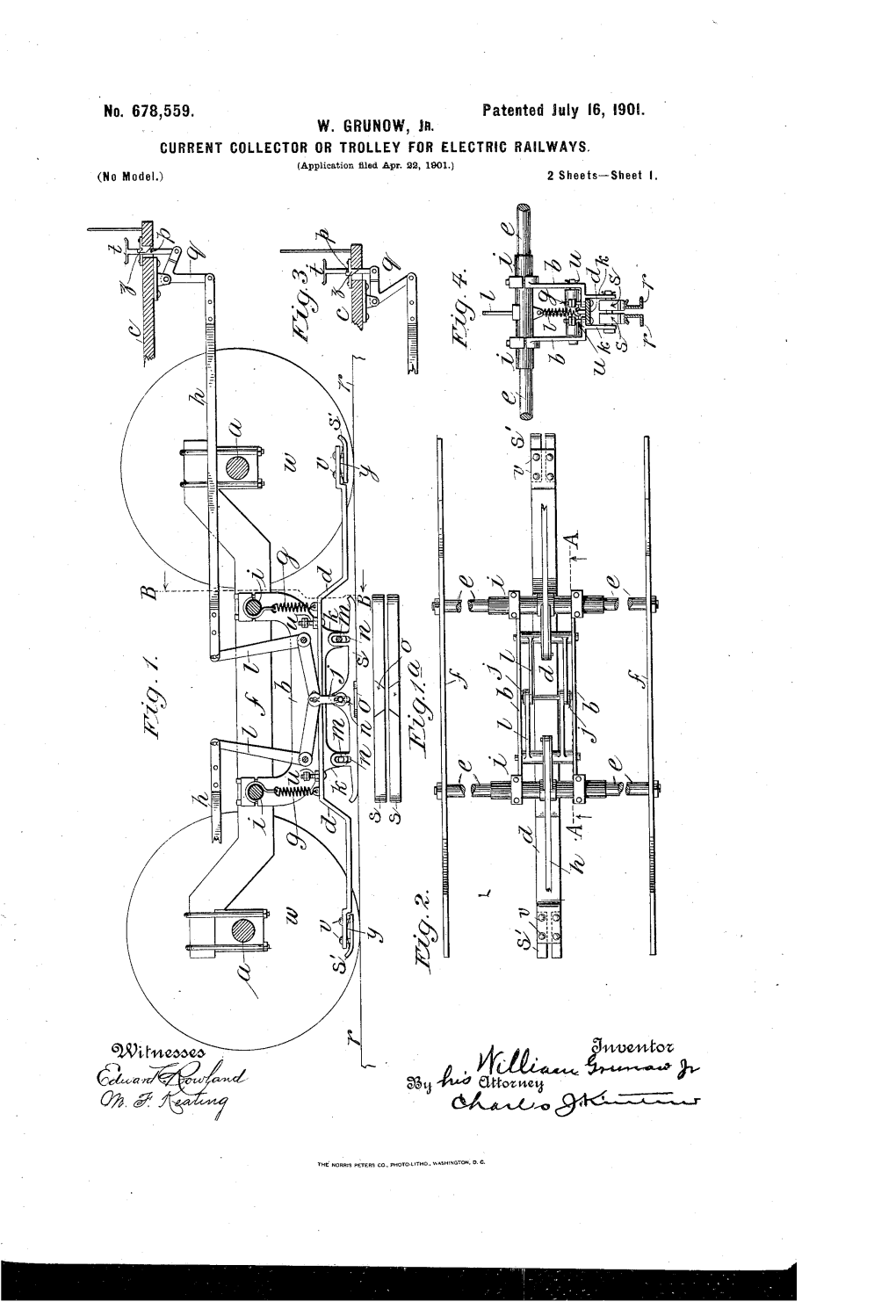

No. 678,559. Patented July 16, 1901. (2.A.Z/ 22-Ca. Lar 33 4-Y M.(?Ea

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Current Collector for Heavy Vehicles on Electrified Roads: Field Tests

Journal of Asian Electric Vehicles, Volume 14, Number 1, June 2016 Current Collector for Heavy Vehicles on Electrified Roads: Field Tests Mohamad Aldammad 1, Anani Ananiev 2, and Ivan Kalaykov 3 1 Center for Applied Autonomous Sensor Systems, Örebro University, [email protected] 2 Center for Applied Autonomous Sensor Systems, Örebro University, [email protected] 3 Center for Applied Autonomous Sensor Systems, Örebro University, [email protected] Abstract We present the field tests and measurements performed on a novel current collector manipulator to be mounted beneath a heavy vehicle to collect electric power from road embedded power lines. We describe the concept of the Electric Road System (ERS) test track being used and give an overview of the test vehicle for testing the cur- rent collection. The emphasis is on the field tests and measurements to evaluate both the vertical accelerations that the manipulator’s end-effector is subject to during operation and the performance of the detection and tracking of the power line. Keywords current collector, electrified road, hybrid electric vehi- cle, electric road system, field test 1. INTRODUCTION The tendency to replace the fossil fuels used by vehi- cles with electrical energy nowadays is clearly identi- fied worldwide. While the solution of storing electrical energy in batteries for small vehicles seems to be rela- tively effective, large vehicles like trucks and buses require a non-realistic large amount of batteries when driving to distant destinations. Therefore, transfer- ring electricity continuously to vehicles while driving Fig. 1 The developed current collector prototype, seems to be the solution [Ranch, 2010] by equipping taken from Aldammad et al. -

High-Speed Rail Projects in the United States: Identifying the Elements of Success Part 2

San Jose State University SJSU ScholarWorks Faculty Publications, Urban and Regional Planning Urban and Regional Planning January 2007 High-Speed Rail Projects in the United States: Identifying the Elements of Success Part 2 Allison deCerreno Shishir Mathur San Jose State University, [email protected] Follow this and additional works at: https://scholarworks.sjsu.edu/urban_plan_pub Part of the Infrastructure Commons, Public Economics Commons, Public Policy Commons, Real Estate Commons, Transportation Commons, Urban, Community and Regional Planning Commons, Urban Studies Commons, and the Urban Studies and Planning Commons Recommended Citation Allison deCerreno and Shishir Mathur. "High-Speed Rail Projects in the United States: Identifying the Elements of Success Part 2" Faculty Publications, Urban and Regional Planning (2007). This Report is brought to you for free and open access by the Urban and Regional Planning at SJSU ScholarWorks. It has been accepted for inclusion in Faculty Publications, Urban and Regional Planning by an authorized administrator of SJSU ScholarWorks. For more information, please contact [email protected]. MTI Report 06-03 MTI HIGH-SPEED RAIL PROJECTS IN THE UNITED STATES: IDENTIFYING THE ELEMENTS OF SUCCESS-PART 2 IDENTIFYING THE ELEMENTS OF SUCCESS-PART HIGH-SPEED RAIL PROJECTS IN THE UNITED STATES: Funded by U.S. Department of HIGH-SPEED RAIL Transportation and California Department PROJECTS IN THE UNITED of Transportation STATES: IDENTIFYING THE ELEMENTS OF SUCCESS PART 2 Report 06-03 Mineta Transportation November Institute Created by 2006 Congress in 1991 MTI REPORT 06-03 HIGH-SPEED RAIL PROJECTS IN THE UNITED STATES: IDENTIFYING THE ELEMENTS OF SUCCESS PART 2 November 2006 Allison L. -

For Traction Current Collectors.Cdr

Morgan Advanced Materials For Traction Current Collectors TRANSPORTATION TRANSPORTATION Carbon exhibits many operational and financial advantages over metallic materials as a linear current collector, and the benefits to user Systems are becoming increasingly apparent as more of the world’s railway, third rail and tram/trolley bus systems change to carbon. Overhead current collection On pantograph systems, the advantages of carbon include: • Longer collector strip life, with lower maintenance costs and less frequent replacement • Longer wire life, giving significant reductions in cost of maintenance for the overhead system • Reduced mass for better current collection • Carbon’s inert qualities, which ensure that Carbon carbon will not weld to the conductor wire even after long periods of static current loading • The ability to operate at high speeds (300km/hour and more) • The virtual elimination of electrical interference Cooper to telecommunications and signal circuits • Negligible audible noise between rubbing surfaces. • Laboratory and field comparisons between carbon and copper, sintered bronze or Sintered metal aluminum pantograph collector strips show many examples of up to tenfold increase in collector and wire life and recent studies in Japan show a projected 25% saving in total system operating costs. Aluminium TRANSPORTATION Pantograph Strips Morgan offer a variety of collector strips to suit all your designs. Whatever your requirement Morgan Advanced Materials have the Pantograph strip for all applications. Morgan Advanced Materials supply:- • Full length metalized carbons • Fitted and Integral end horns • Kasperowski high current including auto drop in this design • Light weight bonded Aluminum designs • Auto-Drop collector strips • Arc protected collectors • Heated collectors • Ice breaker collectors • High current bonded collectors Integral end horn Whether it’s crimped, rolled, tinned, soldered, or bonded Morgan Advanced Materials offers the best solution for retaining the carbon in the sheath. -

Conductix-Wampfler Conductor Rail System 0812

Insulated Conductor Rail www.conductix.com SinglePowerLine Program 0812 2 Table of Contents System Description 4 Technical Data 5 General Instructions 6 System Structure 7 Components and their use . 7 Insulated Conductor Rails . 8 Comparison of different Conductor Rail materials . 9 Clamps and Connectors 10 Hanger Clamps . 10 Compact Hanger Clamps . 11 Anchor Clamps . 11 Rail Connectors . 12 Power Feed Connectors . 12 End Caps . 13 Air Gaps . 13 Expansion Units 14 Expansion Units . 14 Pickup Guide for Intersections 16 Current Collectors 17 Current Collectors (Plastic Arm Type) . 17 Current Collectors (Parallel Arm Metal Type) . 18 Installation spacing for Current Collectors . 18 Dual Current Collectors (Parallel Arm Metal Type) . 19 Installation Instructions and Assembly Help for Current Collectors . 20 Dimensioning and Layout of Conductor Rail System 22 System Layout 25 Layout Schematic and Component Overview . 26 Example Material Overview / Example Order . 26 Mounting Accessories 27 Support Arms 30 × 32 × 2 mm - perforated . 27 Support Arms 40 × 40 × 2 .5 mm - perforated . 27 Permissible Load for Support Arms . 27 Holders for Support Arm 32 × 30 × 2 for Screw Mounting with 2-holed Connector Plate . 28 Holders for Support Arm 40 × 40 × 2 .5 for Screw Mounting with 2-holed Connector Plate . 28 Girder Clips, Clamping Thickness 4 - 20 mm . 29 Girder Clips, Clamping Thickness 18 - 36 mm . 29 Girder Clips, non-twistable, Clamping Thickness 6 - 25 mm . 29 Towing Arms . 30 End Caps . 30 Insulators . 30 Notch-type Cable Lugs for Power Feed Line . 31 Connector Cables for Current Collector Head 081209 . 31 Spring Assembly (lateral insertion) for Current Collector Head 081209 . -

Locomotive Operation Mode - the Basis for Developing the Requirements for the Energy Storage Device on Railway Transport

MATEC Web of Conferences 239, 01004 (2018) https://doi.org/10.1051/matecconf /201823901004 TransSiberia 2018 Locomotive operation mode - the basis for developing the requirements for the energy storage device on railway transport Andrey Shatokhin1,*, and Alexandr Galkin2 1Omsk State Transport University, Karl Marx Ave., 35, Omsk, 644046, Russia 2Ural State University of Railway Transport, Kolmogorova Street, 66, Yekaterinburg, 620034, Russia Abstract. Increasing the efficiency of cargo transportation by rail is not only one of the main directions of the company JSC “Russian Railways” but also one of the main tasks of our country in order to achieve sustainable economic growth. Electric rolling stock is the largest consumer of electric energy in the company, that’s why its effective and failure-free operation is the way to solve the set tasks. The paper deals with studies related to the operation modes of a freight electric rolling stock of direct current for the purpose of determining the requirements for electric energy storage device, since it is the electric rolling stock that determines the daily schedule of electric load. The order of the analysis of experimental trips of freight electric locomotives of a direct current on the basis of cartridges of recorders of traffic parameters installed on the locomotive is determined. On the basis of the analysis of conducted trips, the main requirements for the energy storage device were obtained with a single running of electric DC rolling stock, namely the average duration of the operation modes of the electric locomotive, the maximum, minimum, and average values of voltage and current, the average value of the electric energy returned to the contact network, time of charge/discharge, and the useful energy intensity of the electric energy storage device. -

Conductor Rail, 813 Series

Insulated Conductor Rail www.conductix.us SinglePowerLine Program 0813 2 Table of Contents System Description 5 Technical Data 6 General Instructions 7 System Structure 8 Components and their use . 8 Insulated Conductor Rails . 9 Comparison of different Conductor Rail materials . 10 Clamps and Connectors 11 Hanger Clamps . 11 Rail Connectors . 12 Power Feed Connectors . 12 Anchor Clamps . 13 End Caps . 13 Tubular Cable Lugs for Power Feed Line . 13 Air Gaps . 14 Expansion Units 15 Pickup Guides for Intersections 17 Current Collectors 18 Parallel Arm Type Current Collectors . 18 Parallel Arm Type Double Current Collectors . 19 Installation Instructions and Assembly Help for Current Collectors . 20 Dimensioning and Layout of Conductor Rail Systems 22 System Layout 25 Layout Examples 27 Mounting Accessories 28 Support Arms 40 × 40 × 2 .5 - perforated . .. 28 Permissible Load for Support Arms . 28 Holders for Support Arm 40 × 40 × 2 .5 for Screw Mounting with 2-holed Connector Plate . 29 Holders for Support Arm 40 × 40 × 2 .5 . 29 Girder Clips, Clamping Thickness 4 - 20 mm . .. 30 Girder Clips, Clamping Thickness 18 - 36 mm . 30 Girder Clips, non-twistable, Clamping Thickness 6 - 25 mm . 30 Towing Arms . 31 End Caps . 31 Insulators . 31 Terminal Boxes for Power Feed with Fittings, Glands and Accessories . 32 Terminal Boxes for Joints with Fittings, Glands and Accessories . 32 Tools and Accessories 32 Mounting Comb 081046 . 32 Grounding and Short-Circuiting Device . 33 Contact Grease for Connection Points . 33 Replacement Parts 34 Replacement Carbon Brushes for Current Collector Heads . 34 Replacement Parts for Current Collectors . 34 3 4 System Description The SinglePowerLine 0813 conduc- available, as well our special material accordance with general marking tor rail system is used as a standard CopperECO ||| . -

High-Speed Ground Transportation Noise and Vibration Impact Assessment

High-Speed Ground Transportation U.S. Department of Noise and Vibration Impact Assessment Transportation Federal Railroad Administration Office of Railroad Policy and Development Washington, DC 20590 Final Report DOT/FRA/ORD-12/15 September 2012 NOTICE This document is disseminated under the sponsorship of the Department of Transportation in the interest of information exchange. The United States Government assumes no liability for its contents or use thereof. Any opinions, findings and conclusions, or recommendations expressed in this material do not necessarily reflect the views or policies of the United States Government, nor does mention of trade names, commercial products, or organizations imply endorsement by the United States Government. The United States Government assumes no liability for the content or use of the material contained in this document. NOTICE The United States Government does not endorse products or manufacturers. Trade or manufacturers’ names appear herein solely because they are considered essential to the objective of this report. REPORT DOCUMENTATION PAGE Form Approved OMB No. 0704-0188 Public reporting burden for this collection of information is estimated to average 1 hour per response, including the time for reviewing instructions, searching existing data sources, gathering and maintaining the data needed, and completing and reviewing the collection of information. Send comments regarding this burden estimate or any other aspect of this collection of information, including suggestions for reducing this burden, to Washington Headquarters Services, Directorate for Information Operations and Reports, 1215 Jefferson Davis Highway, Suite 1204, Arlington, VA 22202-4302, and to the Office of Management and Budget, Paperwork Reduction Project (0704-0188), Washington, DC 20503. -

The Workings of Maglev: a New Way to Travel

THE WORKINGS OF MAGLEV: A NEW WAY TO TRAVEL Scott Dona Amarjit Singh Research Report UHM/CE/2017-01 April 2017 The Workings of Maglev: A New Way to Travel Page Left Blank ii Scott Dona and Amarjit Singh EXECUTIVE SUMMARY Maglev is a relatively new form of transportation and the term is derived from magnetic levitation. This report describes what maglev is, how it works, and will prove that maglev can be successfully constructed and provide many fully operational advantages. The different types of maglev technology were analyzed. Several case studies were examined to understand the different maglev projects whether operational, still in construction, or proposed. This report presents a plan to construct a maglev network using Maglev 2000 vehicles in the United States. A maglev system provides energy, environmental, economic, and quality of life benefits. An energy and cost analysis was performed to determine whether maglev provides value worth pursuing. Maglev has both a lower energy requirement and lower energy costs than other modes of transportation. Maglev trains have about one-third of the energy requirement and about one- third of energy cost of Amtrak trains. Compared to other maglev projects, the U.S. Maglev Network would be cheaper by a weighted average construction cost of $36 million per mile. Maglev could also be applied to convert the Honolulu Rail project in Hawaii from an elevated steel wheel on steel rail system into a maglev system. Due to the many benefits that Maglev offers and the proof that maglev can be implemented successfully, maglev could be the future of transportation not just in the United States but in the world. -

(12) United States Patent (10) Patent No.: US 9,376,023 B2 Messerschmidt (45) Date of Patent: Jun

US0093.76023B2 (12) United States Patent (10) Patent No.: US 9,376,023 B2 Messerschmidt (45) Date of Patent: Jun. 28, 2016 (54) SYSTEM FOR AUTOMATICALLY (56) References Cited CONNECTING AND A DISCONNECTING CATENARY VEHICLE TO AND FROM THE U.S. PATENT DOCUMENTS OVERHEAD LINE DURING TRAVEL 6,557.476 B2 * 5/2003 Batisse ......................... 104,289 8.324,858 B2 * 12/2012 Hill et al. ...................... 320,109 (75) Inventor: Jan Messerschmidt, Saarbrücken (DE) (Continued) (73) Assignee: DaLOGIKa Gesellschaft fir angewandte Informatik mbH, FOREIGN PATENT DOCUMENTS Saarbrücken (DE) CH 596O11 A5 2, 1978 CN 101746284 6, 2010 (*) Notice: Subject to any disclaimer, the term of this patent is extended or adjusted under 35 (Continued) U.S.C. 154(b) by 0 days. OTHER PUBLICATIONS (21) Appl. No.: 13/990,422 Written Opinion of the International Searching Authority dated Nov. (22) PCT Filed: Nov. 24, 2011 26, 2012 for corresponding PCT/DE2011/002058. (Continued) (86). PCT No.: PCT/DE2O11AOO2O58 S371 (c)(1), Primary Examiner — Hussein A. Elchanti (2), (4) Date: May 29, 2013 (74) Attorney, Agent, or Firm — Lempia Summerfield Katz (87) PCT Pub. No.: WO2012/072067 LLC PCT Pub. Date: Jun. 7, 2012 (57) ABSTRACT (65) Prior Publication Data A method and device for automatically connecting and dis US 2013/0245876A1 Sep. 19, 2013 connecting a current collector of a vehicle which is designed for operating with an overheadline. The invention specifies a (30) Foreign Application Priority Data device and a method for automatically connecting and dis connecting at least one current collector (3) of a vehicle which Nov.30, 2010 (DE) ........................ -

Development of a Third Rail Type Current Collecting Shoegear for the Rubber-Tired AGT System

Development of a Third Rail Type Current Collecting Shoegear for the Rubber-tired AGT System Yeon-Su Kim Rag-Gyo Jeong Byung-Song Lee Sung-Hyuk Park Woo-Dong Lee [email protected] [email protected] [email protected] [email protected] [email protected] junior researcher senior researcher chief researcher senior researcher senior researcher Light Railway Team, Urban Transit Engineering Department, Korea Railway Research Institute, Kyounggi-Do, Korea Abstract The employment of a third rail type current collecting shoe gear is prescribed in Korean standard specifications for the rubber tired AGT system. Based on the Korean rubber tired AGT specifications, a third type shoe gear was developed. It has a simple link mechanism and spring action so that interruption with conductor rails is minimized and the life cycle of shoe is lengthened. As the rolling stock gauge and the requirements for the rubber-tired AGT R&D project, the prototype is designed and manufactured. With a rotary disk type equivalent testing equipment, the wearing of shoes and interruption with conductor rails are evaluated. Keywords: Rubber-tired AGT(automated guideway transit), Korean standard specification, Third rail, Current collecting shoe gear, Interruption, Shoe wearing, Contact force. 1. Introduction There are two electrification systems in the urban railway, one is third rail type and another is overhead catenary type. In general a third rail type current collecting shoe gear is the most common type of practical use in the rubber-tired AGT system, since it is more efficient and economical than an overhead catenary/pantograph in conventional electric railways and subway systems[1-4]. -

Third Rail Current Collection Equipment Periodic Inspection and Maintenance

APTA STANDARDS DEVELOPMENT PROGRAM APTA RT-VIM-S-001-02 Rev 1 RAIL STANDARD First Published: Feb. 2, 2002 American Public Transportation Association First Revision: June 28, 2013 1666 K Street, NW, Washington, DC, 20006-1215 APTA Rail Transit Standards Vehicle Inspection and Maintenance Working Group Third Rail Current Collection Equipment Periodic Inspection and Maintenance Abstract: This Rail Standard covers basic procedures for periodic inspection and maintenance of third rail current collection equipment on rail transit vehicles, with emphasis on maintenance of high-voltage current collection devices. Keywords: periodic inspection and maintenance, third rail current collection equipment Summary: This document establishes a standard for the inspection and maintenance of third rail current collection equipment. Individual rail transit systems should tailor these standards to accommodate their specific equipment and mode of operation. Scope and purpose: This standard includes all essential periodic inspection and maintenance requirements for third rail current collection equipment used on rail transit vehicles. This standard is intended for use by rail transit equipment maintenance organizations. It establishes procedures for periodic inspection and maintenance of third rail current collection equipment used on rail transit vehicles. This Rail Standard represents a common viewpoint of those parties concerned with its provisions, namely, transit operating/planning agencies, manufacturers, consultants, engineers and general interest groups. The application of any standards, practices or guidelines contained herein is voluntary. In some cases, federal and/or state regulations govern portions of a transit system’s operations. In those cases, the government regulations take precedence over this standard. APTA recognizes that for certain applications, the standards or practices, as implemented by individual transit agencies, may be either more or less restrictive than those given in this document. -

United States Patent (19) 11 Patent Number: 5,788,033 Licking Et Al

USOO5788033A United States Patent (19) 11 Patent Number: 5,788,033 Licking et al. 45) Date of Patent: Aug. 4, 1998 54 ARRANGEMENT FOR SUPPLYING POWER 204387 9/1907 Germany. TO AN ELECTRIC LOCOMOTIVE 214565 5/1908 Germany. 25856 5/908 Germany. 75) Inventors: Manfred Licking; Dieter Zimek, both 462902 7/1928 Germany. of Essen, Germany 4233.007 4/1994 Germany. 86366 8/1955 Norway ................................... 191/11 73) Assignee: Krupp Fordertechnik GmbH. Essen, Germany Primary Examiner-S. Joseph Morano (21 Appl. No.: 897,141 Attorney, Agent, or Firm-Spencer & Frank (22 Filed: Jul. 21, 1997 57 ABSTRACT 30 Foreign Application Priority Data An arrangement for supplying power to an electric locomo Jul. 19, 1996 DEl Germany ........................ 19629 126.7 tive (1) while the locomotive is passing through a section (51) Int. Cl. ... B60L 9/00 which is not spanned by a contact wire, for example, while 52) U.S. Cl. .......................... 191/33 R; 191/1 R; 191/11; passing through a transshipment facility. To supply power to 191/22 R the locomotive (1) which has a current collector (2), a 58) Field of Search ........................... 191/1 R, 11, 22 R. movable supply car (3) is provided, with the movable supply 191133 R, 40 car (3) having an arm (4) on which a current collector bow (5), which simulates a contact wire, is mounted. The loco 56) References Cited motive (1) and the supply car (3) are coupled to a path U.S. PATENT DOCUMENTS measuring system which orients the position of the current collector bow (5) toward the respective position of the 5,609,460 3/1997 Abel et al.