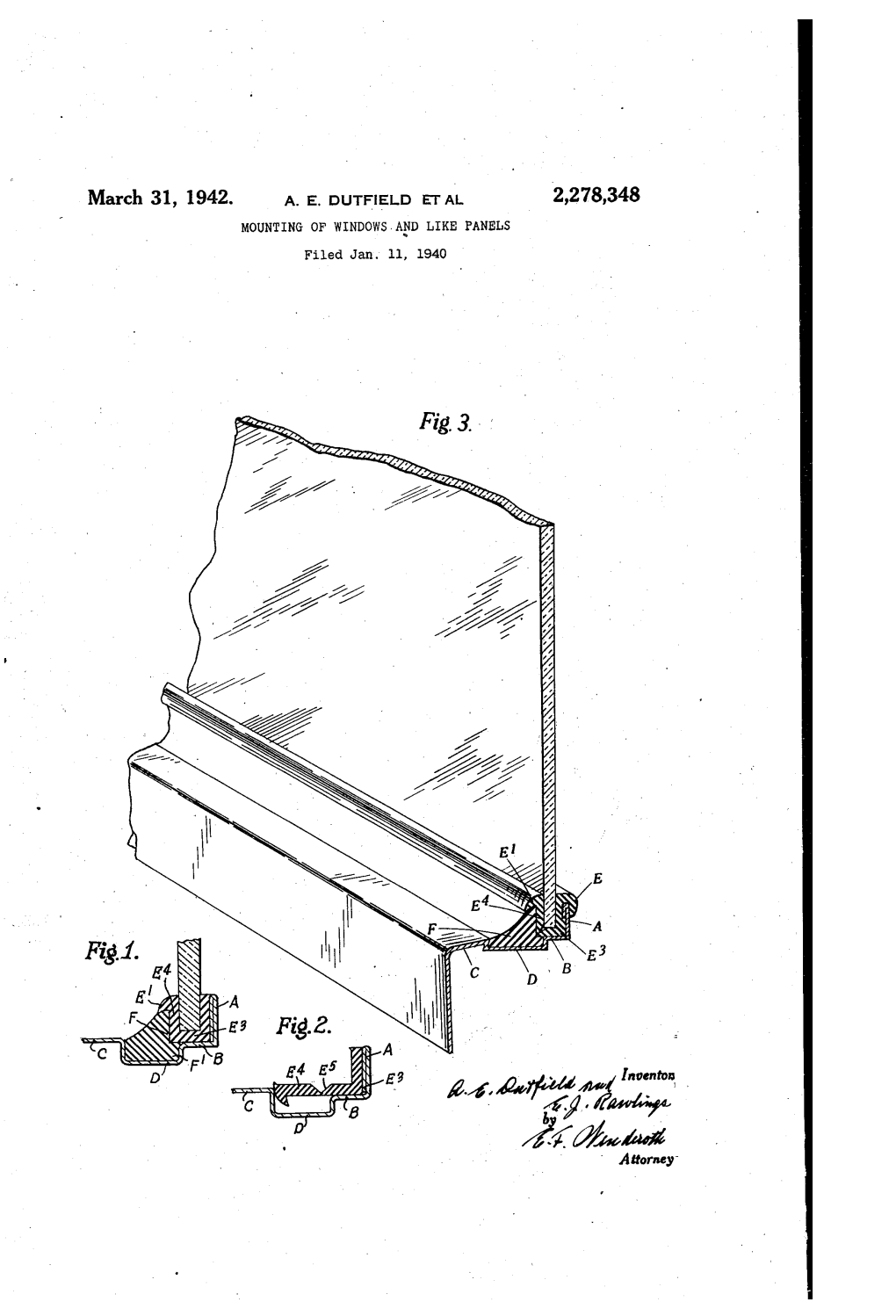

March 31, 1942. A, E, DUTFIELD ETA-L '2,278,348

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Tpo:06 Wandsworth Borough Council List of Properties Where Trees Are

TPO:06 WANDSWORTH BOROUGH COUNCIL LIST OF PROPERTIES WHERE TREES ARE COVERED BY TREE PRESERVATION ORDERS DECEMBER 2018 PROPERTIES WHERE TREES ARE COVERED BY TREE PRESERVATION ORDERS STREET NAME POSTAL PROPERTY NUMBER, NAME, TPO NO. DATE AREA SITE SERVED ABBERLEY MEWS SW11 Nos. 1 & 2 TPO 237/1998 26.11.98 ABBEY DRIVE SW17 Open space rear of nos. 17 & 20, TPO 99/1987 19.11.87 rear of 31-36 TPO 99/2003 28.03.03 See also Church Lane & Rectory Lane ABBOTSLEIGH SW16 1, 2, 3-9, 4-8, 12-14, 15, 17,18, 19, TPO 53/1984 21.11.84 ROAD 20-24, 25, 33-35 ABERCROMBIE SW11 Builders Yard (rear part of South TPO 37/1980 30.10.80 STREET Lodge, Latchmere Road) and adjacent to 88-90 Abercrombie Street. AKEHURST STREET SW15 Adj. End House Cottage TPO 202/1995 30.10.95 AKEHURST STREET SW15 8 TPO 423/2015 20.10.15 ALBERT BRIDGE RD SW11 2, 7, 41, 63, 65, TPO 10/1996 31.10.96 Albert Mansions, 67, 69, Ralph West Hall, 83, Albany Mansions, St Mary-le-Park Court, 111 ALBERT DRIVE SW19 No. 1 TPO 126/1990 12.09.90 ALBERT DRIVE SW19 R/O Mortimer Lodge TPO 85/1986 25.09.86 ALBERT DRIVE SW19 66 TPO 299/2003 03.04.03 ALDRINGTON ROAD SW16 2-16 (even incl.) see also TPO 53/1984 21.11.84 Fir Tree Close 11-13 (odd incl.) ALEXANDRA SW11 7 TPO 317/2005 20.07.05 AVENUE ALLFARTHING SW18 30, 31, 37, 43-45, 53-57 TPO 35/1979 LANE Superseded by TPO 35/2009 see Confirmed 02.09.80 below ALLFARTHING SW18 43, 57, 65, 85, TPO 35/2009 01.10.09 LANE 54, 56 ALTENBURG SW11 1-15 (St. -

Rydal Road Tooting Bec Common SW16

Rydal Road Tooting Bec Common SW16 FOR SALE This huge seven bedroom, five bathroom detached unjustified once youve lived here (I speak from and double-fronted Victorian house (3730 SQ.FT / experience!). Streatham mainline station is situated 346.5 SQ.M) offers outstanding living approximately a quarter of a mile away, which has accommodation for a family, a large garden, multiple excellent direct rail service to The City (Blackfriars, off-street parking and a garage. It sits on a London Bridge and Kings Cross), providing a quicker wonderfully wide and leafy street forming part of a journey than the tube. There are also excellent bus very sought-after conservation area nestling quietly services nearby serving the local areas as well as off the edge of Tooting Bec Common close to the Sloane Square, the West End and the City. Tooting famous Lido and excellent direct train services to The Bec Northern Line tube station is a mile away along City. the Common. The shopping facilities and wide choice of bars and restaurants of Streatham are House owners all pretty much long for the same nearby and it is approximately a mile to Balham things; a bigger garden, side access, play space for centre. the kids and an extra bedroom or two. This substantial and imposing Victorian property brings all of the above in spades plus the rare commodities of a garage and off-street parking. Naturally spacious, beautifully proportioned and well presented, this large family house has all the space youre ever likely to need. It has a light and airy feel, and is offered with no forward chain. -

Great Bus Journeys of the World No 11 from Streatham Hill to Selfridges: Mike Roden Takes a Ride on the 137 Bus

Great Bus Journeys of the World No 11 From Streatham Hill to Selfridges: Mike Roden takes a ride on the 137 bus And so it came to pass that a few any landmark worth noting, as we the beginning – focusing on symptom months ago I travelled from Sloane halt at every bus stop to take on more relief and enhancing a patient’s Square to Telford Avenue, Streatham, passengers. quality of life to the end. on the 319 bus, and was faced with As the bus heads along Clapham Cedars Road takes us to Lavender the choice of crossing the road and Park road and people get ready to Hill and then along Queenstown doing the whole journey backwards, disembark it’s clear that the main Road. The station here was opened or forging onward by waiting five destination of most of them is in 1877 and was known as Queens minutes for the 137 to Oxford Circus, Clapham Common Station. The Great Road until 1980. Its official name passing en route through Battersea Bus Journey to Peckham on the 345 is Queenstown Road (Battersea) (an essential component of one of took me this way, and I observed then though the important last word is these epic trips). I forged. that Clapham had changed since the usually missed off official signs One of the last services to days when Battersea’s main station and timetables. I expect the Love dispense with the old Routemaster had to be named after it to gain any Battersea campaign, are working bus, the 137 has had a rather credibility. -

Price List – Valid for All New Funerals Arranged from 6 July 2020 Onwards

Standard Funeral Service - £2,670 (or £2,765 including embalming) Professional Fee ............................................................................................................................................................ £1,050 • Taking all instructions and making the necessary arrangements for the funeral • Obtaining and preparing the necessary statutory documents • Liaising with cemetery/crematorium authorities • Liaising with hospitals, doctors, HM Coroner, clergy and other third parties • Providing advice on all aspects of the funeral arrangements Care of the Deceased ....................................................................................................................................................... £610 • Provision of private mortuary facilities prior to the funeral • Care of the deceased prior to the funeral • Provision of a standard white gown or dressing in clothes provided • Bereavement and aftercare assistance Vehicles and Funeral Staff ............................................................................................................................................ £1,010 • Closed hearse / private ambulance from place of death to our chapels (within a 10-mile radius of our premises) • Provision of a hearse and chauffeur on the day of the funeral • The provision of all necessary staff on the day of the funeral, including Funeral Conductor and four bearers • Provision of a limousine seating six people and chauffeur on the day of the funeral The Standard Funeral Service does not include -

Streatham and Streatham Hill Conservation Area Statement

Streatham High Road and Streatham Hill conservation area statement Location 1The Streatham High Road & Streatham Hill Conservation Area is in the southern part of the London Borough of Lambeth. The Conservation Area stretches from Telford Avenue to the Streatham United Reform Church encompassing buildings on Streatham Hill (not including those already within the Leigham Court Estate CA31) and those that line the length of Streatham High Road. The Conservation Area includes the impressive length of commercial and purpose built residential apartment blocks dating from the late Victorian, Edwardian and inter-war eras and includes the Free Tate Library, the Police Station, St. Leonard’s Church, the Odeon and ABC Cinemas and other public buildings, which form an important centre for shopping, recreation and commerce. Origins of development and settlement Streatham High Road is one of London’s major arterial roads. From Roman times, and perhaps earlier, it has been an important highway running between London and the 2Weald. Traces of pre Christian burials were discovered when St. Leonard’s was rebuilt in the 19th century and demonstrate that this was a burial place over 2000 years ago. Also discovered were Roman masonry, coins and a Roman ditch. It is probably that the Romans built a military station on the site of St. Leonard’s consisting of a small fort enclosing 2 or three acres surrounded by an earthwork and a ditch. The derivation of the name “Streatham” being from the Saxon “Strat” Street and “Ham” Settlement. Streatham probably evolved as scattered settlements of Saxon farms along the two Roman roads, which ran through the area. -

Planning Designations Desk Based Assessment Using Adopted UDP

Wandsworth Open Space Study APPENDIX A List of all Open Spaces 5028075 APPENDIX DIVIDER.doc Appendix A Space ID Name Ward Description Ownership Type ATK001 Arabella Drive Green Roehampton A green and other amenity areas associated within Arabella Drive housing estate on the north-western boundary of the Borough LB Wandsworth Park/Open Space Outdoors Sports Facilities/Playing Fields (Public) ATK003 Dowdeswell Close / Arabella Drive East Green Roehampton Amenity areas and some outdoor play provision around housing estate located to the north and west of the Priory Hospital LB Wandsworth Park/Open Space Amenity Green Space ATK005 The Priory Hospital Roehampton A mixture of wooded and lawn open space within the grounds of a private hospital Private Sector Owned and Managed Greenspaces within Grounds of Institutions ATK006 Bank of England Sports Ground Roehampton Private sports complex containing outdoor and indoor sports facilities of a high standard. New national tennis centre also under construction Private Sector Owned and Managed Outdoors Sports Facilities/Playing Fields (Private) ATK007 Rosslyn Park RFC Roehampton Rosslyn Park RFC Stadium/ground Private Sector Owned and Managed Outdoors Sports Facilities/Playing Fields (Private) ATK008 Roehampton Club Roehampton Private 18 hole golf course and sports complex including tennis courts Private Sector Owned and Managed Outdoors Sports Facilities/Playing Fields (Private) ATK010 Fairacres Gardens Roehampton Privately owned and maintained communal open space which flats face on to Private Sector -

The Thrales of Streatham Park, II. the "Family Book": (I) 1764-1772

The Thrales of Streatham Park, II. The "Family book": (i) 1764-1772 The Harvard community has made this article openly available. Please share how this access benefits you. Your story matters Citation Hyde, Mary. 1976. The Thrales of Streatham Park, II. The "Family book": (i) 1764-1772. Harvard Library Bulletin XXIV (2), April 1976: 145-179. Citable link https://nrs.harvard.edu/URN-3:HUL.INSTREPOS:37364380 Terms of Use This article was downloaded from Harvard University’s DASH repository, and is made available under the terms and conditions applicable to Other Posted Material, as set forth at http:// nrs.harvard.edu/urn-3:HUL.InstRepos:dash.current.terms-of- use#LAA IL TI-IE~ FA.-l-1/LY UO(Jl( 1 (i) r764~1772 }lester .lfaria 1'hrale born on the 17: Sepf- 1764 at her F ather~sHouse, S out hu 1ark . 1"'bisis- to ser·i)e /JS a .1.lfe~norandum of ber ( 1 orpore.1l& J.fentnl Po""J)ers at t/Je Age of t~~o Years~ to ,w!: 1 She i.~.1rri·v\l tbis 17: Sept: 1766. Sb(;' ran •~:alk & run alone up & dorr;.Nlall s1nootb Places tbo' pretty stt::i!p,e,"" tbr/ the Hact.1strh1/4· is still l 1ept on it is -no lon.~er of [Jse. She is per f ectl.Y healt/Jy, of a lax Con stitu.tion & is .rfr(Jng enou_~·hto carry a _/H rJlrnd,/puppy two Al nntl.1s old quite aero.~·-~the l ...a... ti_:n at StreatbiVn~ ah'o to carry a Hori,.;.~J sucb as are used on bou,Jing Greens up tlJe .-llount to the Tubs. -

Planning Weekly List & Decisions

Planning Weekly List & Decisions Appeals (Received/Determined) and Planning Applications & Notifications (Validated/Determined) Week Ending 08/02/2019 The attached list contains Planning and related applications being considered by the Council, acting as the Local Planning Authority. Details have been entered on the Statutory Register of Applications. Online application details and associated documents can be viewed via Public Access from the Lambeth Planning Internet site, https://www.lambeth.gov.uk/planning-and-building- control/planning-applications/search-planning-applications. A facility is also provided to comment on applications pending consideration. We recommend that you submit comments online. You will be automatically provided with a receipt for your correspondence, be able to track and monitor the progress of each application and, check the 21 day consultation deadline. Under the Local Government (Access to Information) Act 1985, any comments made are open to inspection by the public and in the event of an Appeal will be referred to the Planning Inspectorate. Confidential comments cannot be taken into account in determining an application. Application Descriptions The letters at the end of each reference indicate the type of application being considered. ADV = Advertisement Application P3J = Prior Approval Retail/Betting/Payday Loan to C3 CON = Conservation Area Consent P3N = Prior Approval Specified Sui Generis uses to C3 CLLB = Certificate of Lawfulness Listed Building P3O = Prior Approval Office to Residential DET = Approval -

The Thrales of Streatham Park, I. Hester Lynch Salusbury and Henry Thrale

The Thrales of Streatham Park, I. Hester Lynch Salusbury and Henry Thrale The Harvard community has made this article openly available. Please share how this access benefits you. Your story matters Citation Hyde, Mary. 1976. The Thrales of Streatham Park, I. Hester Lynch Salusbury and Henry Thrale. Harvard Library Bulletin XXIV (2), April 1976: 130-144. Citable link https://nrs.harvard.edu/URN-3:HUL.INSTREPOS:37364300 Terms of Use This article was downloaded from Harvard University’s DASH repository, and is made available under the terms and conditions applicable to Other Posted Material, as set forth at http:// nrs.harvard.edu/urn-3:HUL.InstRepos:dash.current.terms-of- use#LAA I. HESl~Ell LY~CH Si\l~LTSBCllY J.\;\D HENRY THlZALE I+ In ()ctohcr t 763., three years before the journal began, Hester Lynch Salusbury, an attraclivc young ,von1an of rwenty-t~.vu, \l'as given in 1narriagc L_vher uncle, Sir Thomas Salusbury 1 to Henry Thralc., n1orc than ten years her senior~ an Oxford rnan, h~ndsome., \vorldlv-. 1 and rich, o,vncr of the 1 'hrale Bre,vtrv in Southwark and the ad Joining rt:sjdcncc; o,vncr of a pack of fox hounds and a hunting box near (~roydon; o,vncr of Cro\vn1arsh ~atde, a far1n in Oxfordshire; and o\vner of Strcatha1n Park, a country house and property of nearly a hundred acres in Surrcv,~· ahont six n1ilcs f ron1 I.... ondon. Sir Tl101nas S::11usbury,a judge of the i\.dmiralty Court, and a Ilert- fordshire country squire~ had been fnrtheri't1g the n1atch for son1etin1e. -

Former Tooting Police Station & Section House, 251 Mitcham Road

Former Tooting Police Station & Section House, 251 Mitcham Road, Tooting SW17 Development opportunity. Main building fronting Mitcham Road The opportunity. Former Tooting Police Station & Section House, 251 Mitcham Road, Tooting SW17 The former Tooting Police Station provides a development opportunity in the heart of Tooting, South West London. • The site is well located close to the amenities of Tooting Broadway • The property comprises two connected buildings – the former Police Station and Section House • The former Police Station was constructed in 1939 with Section House added shortly afterwards • The buildings are arranged over lower ground, ground and four upper floors and constructed of concrete frame with brick elevations • The property provides convenient access into Central London with train station Tooting and underground stations Tooting Broadway and Tooting Bec within walking distance • The existing accommodation extends to approximately 6,603 sq m (71,074 sq ft) GIA • The site measures approximately 0.847 acres (0.343 hectares) • The property is available with vacant possession • Unconditional offers are being sought for the freehold interest Tooting is one of South West London’s vibrant hubs offering a wide selection of shops, restaurants and cafes. Tooting’s popularity is ever growing thanks to its lively high street and convenient access into Central London. Local area Tooting is well known for its eating and drinking establishments to the subject property. The station is within Zone 3 between plus vibrant indoor markets including Tooting Market and Tooting Bec and Colliers Wood. Broadway Market. The main retail and restaurant offering is Tooting provides convenient access to a variety of green open located on Tooting High Street and Mitcham Road which is spaces for its residents including Tooting Bec Common with its home to a mix of both independent and national occupiers. -

SWLP Courier Runs Listing for Welcome Packs

SWLP Courier Runs Listing for Welcome Packs - November 2016 SWLP - Listing of Courier Journey SWLP - Listing of Courier Journey ERS Run Name Target CALLNAME ERS Run Name Target CALLNAME SWLP 1 09:25 SWL ERS Base SWLP 2 09:15 SWL ERS Base SWLP 1 Farley Road Medical Practice SWLP 2 Mitcham Medical Centre SWLP 1 Queenhill Medical Practice SWLP 2 Tooting Bec Surgery SWLP 1 Fieldway Medical Centre SWLP 2 Trinity Medical Centre SWLP 1 Headley Drive Surgery SWLP 2 Balham Park Surgery SWLP 1 Castle Hill Surgery SWLP 2 Balham Health Centre / Bedford Hill Family SWLP 1 Parkway Health Centre (Pathology) SWLP 2 Open Door Surgery SWLP 1 Selsdon Park Medical Centre SWLP 2 Thurleigh Road Practice SWLP 1 Purley Interception Van - Drop Off SWLP 2 Balham Hill Medical Practice SWLP 1 Mitchley Avenue Surgery SWLP 2 Macmillan Surgery SWLP 1 Sanderstead Clinic SWLP 2 Streatham Park Surgery (Franciscan Road) SWLP 1 Gravel Hill Surgery (Dr J Salerno) SWLP 2 Tooting Health Centre SWLP 1 Violet Lane Medical Practice SWLP 2 Streatham Park Surgery (Mitcham Lane) SWLP 1 Haling Park Medical Practice SWLP 2 The Greyswood Practice SWLP 1 Parkside Group Practice SWLP 2 The Practice Furzedown SWLP 1 Farley Road Medical Practice SWLP 2 Tooting South Medical Centre SWLP 1 Queenhill Medical Practice SWLP 2 Bec Family Practice SWLP 1 Selsdon Park Medical Centre SWLP 2 Upper Tooting Road Medical Centre SWLP 1 Fieldway Medical Centre SWLP 2 Trevelyan House SWLP 1 Headley Drive Surgery SWLP 2 12:25 SGH Hub Lab - Drop Off SWLP 1 Parkway Health Centre (Pathology) SWLP 2 13:10 -

Open Spaces 0 - 2Ha ATK154 ATK207 2Ha - 20Ha ATK221 ATK208 20Ha >

ATK054 ± Legend Wandsworth Wards ATK152 Open Spaces 0 - 2ha ATK154 ATK207 2ha - 20ha ATK221 ATK208 20ha > 300m Catchment Area (>2ha) ATK112 ATK206 2000m Catchment Area (>20ha) ATK116 ATK068 Ackroyden Estate ATK050 ATK069 Inner Park Road ATK113A ATK158 ATK070 Wimbledon Parkside (former Southlands College) ATK072 Argyle Estate ATK114 ATK073 Wimbledon Park Housing Estate ATK074 Linden Lodge School ATK075 Wimbledon Park ATK076 Coronation Gardens ATK219 ATK077 Morris Gardens Estate ATK220 ATK078 "Wimbledon Common / Putney Heath" ATK048 ATK080 Putney Vale Playing Fields and Stag Lane ATK222 ATK080 Putney Vale Playing Fields and Stag Lane ATK001 ATK082 Riverside Quarter ATK084 River Wandle ATK085 Osiers Road Embankment ATK082 ATK086 St Josephs RC Primary School ATK097 ATK108 ATK087 King George's Park ATK215 ATK094 Hughenot Burial Ground ATK216 ATK095 Trinity Road North Open Space ATK097 Jews Row (Bemco Ousts') ATK003 ATK029 ATK192 ATK100 ATK100 Wandsworth Common ATK121 ATK103 Fitzhugh Grove Estate ATK010 ATK056 ATK095 ATK105 Earlsfield ATK005 ATK033A ATK085 ATK106 Battersea Rise Cemetery ATK214 ATK108 "Central Open Space, Clapham Junction Estate" ATK033B ATK047 ATK094 ATK112 Fred Wells Gardens ATK008 ATK086 ATK106 ATK113A Falcon Park ATK114 Sacred Heart R.C School ATK032 ATK042 ATK116 Sheepcote Lane Rough ATK043 ATK058 ATK120 St Thomas Preparatory School ATK012 ATK039 ATK120 ATK121 Clapham Common ATK034 ATK123 Heathfield Road ATK124 St George's Square ATK127 Beatrix Potter Primary School ATK128 Open View Sports Field/Battersea Ironsides Sports Fi ATK028 ATK023 ATK059 ATK130 Burntwood School ATK211 ATK132 Central London Golf Centre ATK024 ATK044 ATK100 ATK100 ATK139 Trinity Crescent ATK014 ATK142 "Chesnut Grove School / ATK013 ATK021 ATK027 Hearnville Junior" ATK038 ATK144 Mayford Close Estate Green ATK025 ATK145 "Hospital ATK035 ATK040 ATK105 (Nightingale House)" ATK212 ATK145 ATK146 Oak Lodge School ATK017 ATK016 ATK041 ATK064 ATK077 ATK149 Balham Hill and Estate (West) ATK213 ATK123 ATK146 ATK152 Battersea Park ATK149 ATK154 St.