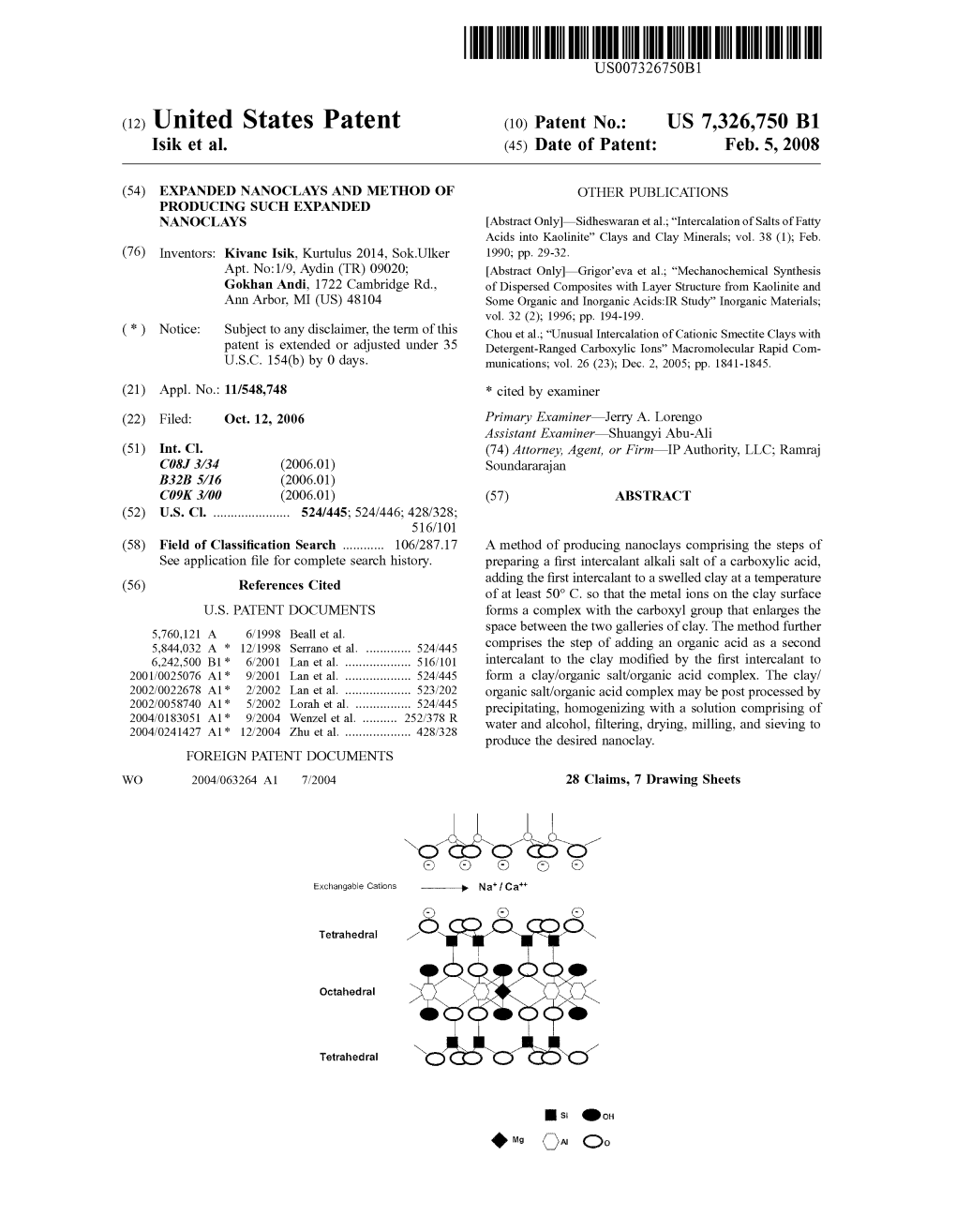

Occo to Exchangabe Cations -- Na Ca

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Chemical Names and CAS Numbers Final

Chemical Abstract Chemical Formula Chemical Name Service (CAS) Number C3H8O 1‐propanol C4H7BrO2 2‐bromobutyric acid 80‐58‐0 GeH3COOH 2‐germaacetic acid C4H10 2‐methylpropane 75‐28‐5 C3H8O 2‐propanol 67‐63‐0 C6H10O3 4‐acetylbutyric acid 448671 C4H7BrO2 4‐bromobutyric acid 2623‐87‐2 CH3CHO acetaldehyde CH3CONH2 acetamide C8H9NO2 acetaminophen 103‐90‐2 − C2H3O2 acetate ion − CH3COO acetate ion C2H4O2 acetic acid 64‐19‐7 CH3COOH acetic acid (CH3)2CO acetone CH3COCl acetyl chloride C2H2 acetylene 74‐86‐2 HCCH acetylene C9H8O4 acetylsalicylic acid 50‐78‐2 H2C(CH)CN acrylonitrile C3H7NO2 Ala C3H7NO2 alanine 56‐41‐7 NaAlSi3O3 albite AlSb aluminium antimonide 25152‐52‐7 AlAs aluminium arsenide 22831‐42‐1 AlBO2 aluminium borate 61279‐70‐7 AlBO aluminium boron oxide 12041‐48‐4 AlBr3 aluminium bromide 7727‐15‐3 AlBr3•6H2O aluminium bromide hexahydrate 2149397 AlCl4Cs aluminium caesium tetrachloride 17992‐03‐9 AlCl3 aluminium chloride (anhydrous) 7446‐70‐0 AlCl3•6H2O aluminium chloride hexahydrate 7784‐13‐6 AlClO aluminium chloride oxide 13596‐11‐7 AlB2 aluminium diboride 12041‐50‐8 AlF2 aluminium difluoride 13569‐23‐8 AlF2O aluminium difluoride oxide 38344‐66‐0 AlB12 aluminium dodecaboride 12041‐54‐2 Al2F6 aluminium fluoride 17949‐86‐9 AlF3 aluminium fluoride 7784‐18‐1 Al(CHO2)3 aluminium formate 7360‐53‐4 1 of 75 Chemical Abstract Chemical Formula Chemical Name Service (CAS) Number Al(OH)3 aluminium hydroxide 21645‐51‐2 Al2I6 aluminium iodide 18898‐35‐6 AlI3 aluminium iodide 7784‐23‐8 AlBr aluminium monobromide 22359‐97‐3 AlCl aluminium monochloride -

(19) United States (12) Patent Application Publication (10) Pub

US 20140178624A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2014/0178624 A1 Tilford (43) Pub. Date: J 1111. 26, 2014 (54) BASE-MEDIATED HYDROPHOBING Publication Classi?cation COMPOSITIONS AND PROCESSES (5 1) Int. Cl. (71) Applicant: Georgia-Paci?c Gypsum LLC, Atlanta, C04B 11/00 (2006.01) GA (US) E04C 2/26 (2006.01) _ _ _ (52) US. Cl. (72) Inventorl Robert Wllllam Tllford, Stone CPC .. C04B 11/00 (2013.01); E04C 2/26 (2013.01) Mountaln, GA (US) USPC ............................ .. 428/67; 106/781; 106/678 (73) Assignee: Georgia-Paci?c Gypsum LLC, Atlanta, GA (US) (57) ABSTRACT (21) APP1~ NO-3 14/ 108,713 Water-resistant gypsum boards and compositions and meth _ _ ods for their manufacture are provided. The methods include (22) Flled' Dec“ 17’ 2013 forming a mixture of water, hydroxide, and siliconate, adding Related US. Application Data slloxane'to the mixture, adding calcmm sulfate hemi-hydrate to the mixture to form an aqueous slurry, cunng the aqueous (60) Provisional application No. 61/739,862, ?led on Dec. slurry under heat, drying the aqueous slurry, and forming a 20, 2012. water-resistant gypsum board. US 2014/0178624 A1 Jun. 26, 2014 BASE-MEDIATED HYDROPHOBING includes a gypsum core that is made of a mixture of calcium COMPOSITIONS AND PROCESSES sulfate hemi-hydrate, siloxane, hydroxide, and a ?brous mat at least partially penetrating a surface of the gypsum core. In CROSS-REFERENCE TO RELATED certain embodiments, the gypsum core also includes silicon APPLICATIONS ate. [0001] This application claims priority to US. Provisional [0009] In yet another aspect, a composition for the manu Application No. -

6.2 Electron Configuration and the Periodic Table

CK-12 Chemistry - Intermediate Quizzes and Tests Donald Calbreath, Ph.D. Say Thanks to the Authors Click http://www.ck12.org/saythanks (No sign in required) www.ck12.org AUTHOR Donald Calbreath, Ph.D. To access a customizable version of this book, as well as other interactive content, visit www.ck12.org CK-12 Foundation is a non-profit organization with a mission to reduce the cost of textbook materials for the K-12 market both in the U.S. and worldwide. Using an open-source, collaborative, and web-based compilation model, CK-12 pioneers and promotes the creation and distribution of high-quality, adaptive online textbooks that can be mixed, modified and printed (i.e., the FlexBook® textbooks). Copyright © 2015 CK-12 Foundation, www.ck12.org The names “CK-12” and “CK12” and associated logos and the terms “FlexBook®” and “FlexBook Platform®” (collectively “CK-12 Marks”) are trademarks and service marks of CK-12 Foundation and are protected by federal, state, and international laws. Any form of reproduction of this book in any format or medium, in whole or in sections must include the referral attribution link http://www.ck12.org/saythanks (placed in a visible location) in addition to the following terms. Except as otherwise noted, all CK-12 Content (including CK-12 Curriculum Material) is made available to Users in accordance with the Creative Commons Attribution-Non-Commercial 3.0 Unported (CC BY-NC 3.0) License (http://creativecommons.org/ licenses/by-nc/3.0/), as amended and updated by Creative Com- mons from time to time (the “CC License”), which is incorporated herein by this reference. -

![United States Patent [191 [11] 3,807,956 Morin [45] Apr](https://docslib.b-cdn.net/cover/8711/united-states-patent-191-11-3-807-956-morin-45-apr-2558711.webp)

United States Patent [191 [11] 3,807,956 Morin [45] Apr

United States Patent [191 [11] 3,807,956 Morin [45] Apr. 30, 1974 [54] MODIFIED BIURET REAGENT FOR GLASS STORAGE AND METHOD Primary Examiner—Morris O. Wolk [75] Inventor: Leo G. Morin, Miami, Fla. Assistant Examiner—-R. E. Serwin Attorney, Agent, or Firm-Fisher, Christen & Sabol [73] Assignee: The First National Bank of Miami, Miami, Fla. [22] Filed: Aug. 30, 1972 [21} Appl. No.: 284,880 [57] CT [52] US. Cl. ......... .. 23/230 B, 23/230 R, 23/253 R, A modi?cation of the biuret reagent with zirconium 252/408 and reduced alkalinity to make the reagent suitable [51] Int. Cl. ......................................... .. G0ln 33/16 for storage in glass is disclosed. The performance of [58] Field of Search .................. .. 23/230 B; 252/408 the modi?ed reagent in measuring protein is not re duced. [56] References Cited UNITED STATES PATENTS 11 Claims, No Drawings 3,310,382 3/1967 Kingsley .......................... .. 23/230 B 3,807,956 , 1 2 MODIFIED BIURET REAGENT FOR GLASS Such biuret reagents often contain other non STORAGE AND METHOD essential ingredients, and this invention covers such bi— uret reagents. The biuret reagents often contain copper chelating agents,~such' as sodium potassium tartrate, ci BACKGROUND OF THIS INVENTION trates and ethylenediamine tetracetic acid, and ingredi 1. Field of 'this Invention ents, such as potassium iodide. The biuret reagent also This invention relates to a modi?cation of the biuret contains surfactants, such as the Tritons, e.g., Triton reagent so that it may be stored in glass. X-lOO and Triton X-l55, sodium salts of high molecu 2. -

(12) United States Patent (10) Patent No.: US 7,892,351 B1 Kirkpatrick Et Al

US007892351B1 (12) United States Patent (10) Patent No.: US 7,892,351 B1 Kirkpatrick et al. (45) Date of Patent: Feb. 22, 2011 (54) COMPOSITION OF MATERIALS AND 6,554,894 B2 * 4/2003 Styronet al. ................ 106,705 PROCESSES FOR MAKING 6,932,344 B1 8/2005 Soto BORONCITRATES TO CREATE CEMENTS 7,125,944 B2 10/2006 Yamashita et al. WITH FIELD ADJUSTABLE SET TIMES 7,179,453 B1* 2/2007 Montgomery ..... ... 424/73 7,236,290 B1* 6/2007 Zhang et al. ................ 359,296 7,503.974 B2 3/2009 Mintz et al. (76) Inventors: William D. Kirkpatrick, 1431 S. Ocean 2008/0282938 A1 11/2008 Cifuentes et al. Blvd. #64, Lauderdale by the Sea, FL (US) 33062-7302: Carole W. FOREIGN PATENT DOCUMENTS Kirkpatrick, 1431 S. Ocean Blvd. #64, Lauderdale by the Sea, FL (US) WO WO 02/26458 A1 4/2002 33062-73O2 OTHER PUBLICATIONS JP 592 19377 Asahi Chemical Co. (Feb. 10, 1984) Machine transla (*) Notice: Subject to any disclaimer, the term of this tion into English.* patent is extended or adjusted under 35 JP 2005 179091 (Jul. 7, 2005) Kushihaashi et al., abstract only.* U.S.C. 154(b) by 0 days. JP 2005 179091 (Jul. 7, 2005) Kushihashi et al. Machine translation into English.* (21) Appl. No.: 12/504,192 JP 02051457 A (Feb. 21, 1990) Sasagawa et al., abstract only.* JP 02051457 A (Feb. 21, 1990) Sasagawa et al. Machine translation (22) Filed: Jul. 16, 2009 into English.* Note: All non-patent documents with asterisk were cited in related Related U.S. -

1 This Is a Generic Chemistry 134 Syllabus. Specific Dates and Times

This is a generic Chemistry 134 Syllabus. Specific dates and times will be given in a handout at the beginning of the term. Class Syllabus Summer II 2011 CHE 134 General Chemistry II Name: R.H. Langley Email: [email protected] Website: www.faculty.sfasu.edu/langleyricha Phone: (936) 468-3606 Office Hours: MW afternoons Class meeting time and place: 10:15-12:10 MTWR, NM132 Course Requirements: The student is expected to report to class on time, work homework problems in a timely basis, and take all quizzes and exams. Note: Chemistry 134L is a co-requisite for this course. You must enroll in Chemistry 134L, unless you already have credit for the course, and if you drop either co-requisite course, you must drop them both. This may have unforeseen consequences if dropping four hours drops you below the minimum of 12 hours required to be a full- time student. In addition, dropping both courses will count as two of your allowed course drops. The consequences may include loss of financial aid and student discounts on insurance. Note: Various announcements may be emailed to you throughout the term; it is your responsibility to check your email periodically. Attendance Policy: See SECTION V I. TEXT AND MATERIALS: N.J. Tro, Chemistry A Molecular Approach, Pearson/Prentice Hall, Upper Saddle River, NJ, 2008; additional material may be available on the instructor’s website. II. POINTS AVAILABLE: 4 Exams (1 hour long, 100 points each) 400 points 1 Final (2 hours long, 200 points) 200 points Unannounced Quizzes ??? points 600 points 1) The term "Final" refers only to the final exam. -

(12) United States Patent (10) Patent No.: US 9.222,913 B2 Deschamps Et Al

US009222913B2 (12) United States Patent (10) Patent No.: US 9.222,913 B2 Deschamps et al. (45) Date of Patent: Dec. 29, 2015 (54) ANALYSIS AND ASSAY OF GLYCATED FOREIGN PATENT DOCUMENTS HAEMOGLOBINS BY CAPILLARY ELECTROPHORESIS, BUFFER EP 1659 398 A1 5, 2006 COMPOSITIONS AND KITS FOR JP 6-5O2244 3, 1994 CAPLLARY ELECTROPHORESS (Continued) (75) Inventors: Gérald Deschamps, Ury (FR); Frédéric OTHER PUBLICATIONS Robert, Mennecy (FR); Denis Simonin, Evry (FR) Margo P. Cohen, Rex S. Clements, Measuring Glycated Proteins: Clinical and Methodological Aspects, Diabetes Technology & Thera (73) Assignee: SEBIA, Lisses (FR) peutics, vol. 1, No. 1, pp. 57-70 (1996).* (*) Notice: Subject to any disclaimer, the term of this (Continued) patent is extended or adjusted under 35 U.S.C. 154(b) by 199 days. Primary Examiner — J. Christopher Ball (21) Appl. No.: 12/827,795 Assistant Examiner — Maris R. Kessel (74) Attorney, Agent, or Firm — Birch, Stewart, Kolasch & (22) Filed: Jun. 30, 2010 Birch, LLP (65) Prior Publication Data US 2011 FOOOO788A1 Jan. 6, 2011 (57) ABSTRACT The invention relates to a method for analysis by capillary (30) Foreign Application Priority Data electrophoresis of glycated haemoglobins comprising at least Jul. 1, 2009 (FR) ...................................... O9 O322O one globin chain comprising a glucose residue bound to the amino acid in the N-terminal position, contained in a biologi (51) Int. Cl. cal sample, said method comprising using a buffer composi G0IN 27/447 (2006.01) tion comprising at least one compound which is capable of (52) U.S. Cl. specifically complexing glucose residues of one or several CPC ................................ G0IN 2744747 (2013.01) glycated haemoglobin(s) and of providing said glycated hae moglobin(s)with several negative electric charges at an alka (58) Field of Classification Search line pH. -

EDEXCEL INTERNATIONAL GCSE (9 –1) Change to Subject CHEMISTRY Student Book Content All Jim Clark, Steve Owen, Rachel Yu Proof

2017 ©Pearson part. in or whole Jim Clark, Steve Owen, Rachel Yu Rachel Owen, Jim Clark, Steve Student Book CHEMISTRY GCSE(9 INTERNATIONAL EDEXCEL in included eBook distribution or circulation resale, for Not discretion. publisher at change to subject content all –1) proof, Uncorrected 2017 ©Pearson part. in or Student Book CHEMISTRY GCSE(9 INTERNATIONAL EDEXCEL whole Rachel Yu Rachel Steve Owen Jim Clark in distribution or circulation resale, for Not discretion. publisher at change to subject content all –1) proof, Uncorrected CONTENTS 2017 ©Pearson part. in or INDEX GLOSSARY APPENDICES CHEMISTRY ORGANIC UNIT 4: ENERGETICS UNIT 3: CHEMISTRY INORGANIC UNIT 2: PRINCIPLESOFCHEMISTRY UNIT 1: INTRODUCTION whole in distribution or circulation resale, for Not discretion. publisher at change to subject content all proof, 334 327 319 254 206 140 Uncorrected 02 VI v 2017 ©Pearson part. in or in trains thatlevitate abovethetracks. in trains used thatare superconductors development ofthesenewmaterials, forinstancehigh-temperature involvedinthe chemistsare Inorganic properties. fornewmaterials withexciting searching always scientistsare of themostimportant materials thatweuseineveryday life.However, some metalsandtheseare are Table and theircompounds.MostoftheelementsinPeriodic chemistsasaguideto understandingthebehaviourofelements principle usedbyinorganic unifying Table isthegreat Periodic andtheyformahugevarietyofcompounds.The different very oftheseelementsare compoundsformedbycarbon.Theproperties organic form, except andthecompoundsthey Table -

Magnesium Hydroxide - Wikipedia, the Free Encyclopedia

Magnesium hydroxide - Wikipedia, the free encyclopedia http://en.wikipedia.org/wiki/Magnesium_hydroxide Magnesium hydroxide From Wikipedia, the free encyclopedia Magnesium hydroxide is an inorganic compound with Magnesium hydroxide the chemical formula Mg(OH)2. As a suspension in water, it is often called milk of magnesia because of its milk-like appearance. The solid mineral form of IUPAC name magnesium hydroxide is known as brucite. Magnesium hydroxide Other names Magnesium hydroxide is a common component of Milk of Magnesia antacids and laxatives; it interferes with the absorption Identifiers [2] of folic acid and iron. Magnesium hydroxide has low CAS number 1309-42-8 solubility in water, with a K of 1.5×10−11; all of PubChem 14791 sp RTECS OM3570000 magnesium hydroxide that does dissolve does number dissociate. Since the dissociation of this small amount Properties of dissolved magnesium hydroxide is complete, Molecular Mg(OH) 2 magnesium hydroxide is considered a strong formula electrolyte. Its low solubility makes it a weak base. Molar mass 58.3197 g/mol Appearance White solid Density 2.3446 g/cm3 Melting point Contents 350 °C (decomp.) Solubility in 1.2 mg/100 mL 1 History water 2 Preparation Solubility 1.5×10-11 3 Uses product, K sp 4 Biological metabolism Refractive 1.559[1] index (n ) 5 References D Thermochemistry Std enthalpy –925 kJ/mol of History formation Δ Ho In 1829, Sir James Murray used a fluid magnesia f 298 Standard 63 J K–1 mol–1 preparation of his own design to treat the Lord molar Lieutenant of Ireland, the Marquis of Anglesey. -

SCIENCE 10 a TEACHING RESOURCE Iii Activity 38: Matching Data, Graphs, and Words

Qu D es i s I n ti c ves o o n , tig v e a S t r e, ! CIE N CE 1 0 AA TTEEAACCHINHINGG RRESESOOURURCCEE SCIENCE 10 Website References Website references contained within this document are provided solely as a convenience and do not constitute an endorsement by the Department of Education of the content, policies, or products of the referenced website. The department does not control the referenced websites and is not responsible for the accuracy, legality, or content of the referenced websites or for that of subsequent links. Referenced website content may change without notice. School boards and educators are required under the department’s Public School Network Access and Use Policy to preview and evaluate sites before recommending them for student use. If an outdated or inappropriate site is found, please report it to [email protected]. Science 10: A Teaching Resource © Crown copyright, Province of Nova Scotia, 2012 Prepared by the Department of Education The contents of this publication may be reproduced in part provided the intended use is for non-commercial purposes and full acknowledgment is given to the Nova Scotia Department of Education. Where this document indicates a specific copyright holder, permission to reproduce the material must be obtained directly from that copyright holder. Photographs and student text and artwork may not be extracted or reused. Cataloguing-in-Publication Data Main entry under title. Science 10 / Nova Scotia. Department of Education. English Program Services. ISBN: 978-1-55457-459-9 1. Science—Study and teaching—Handbooks manuals, etc. I.