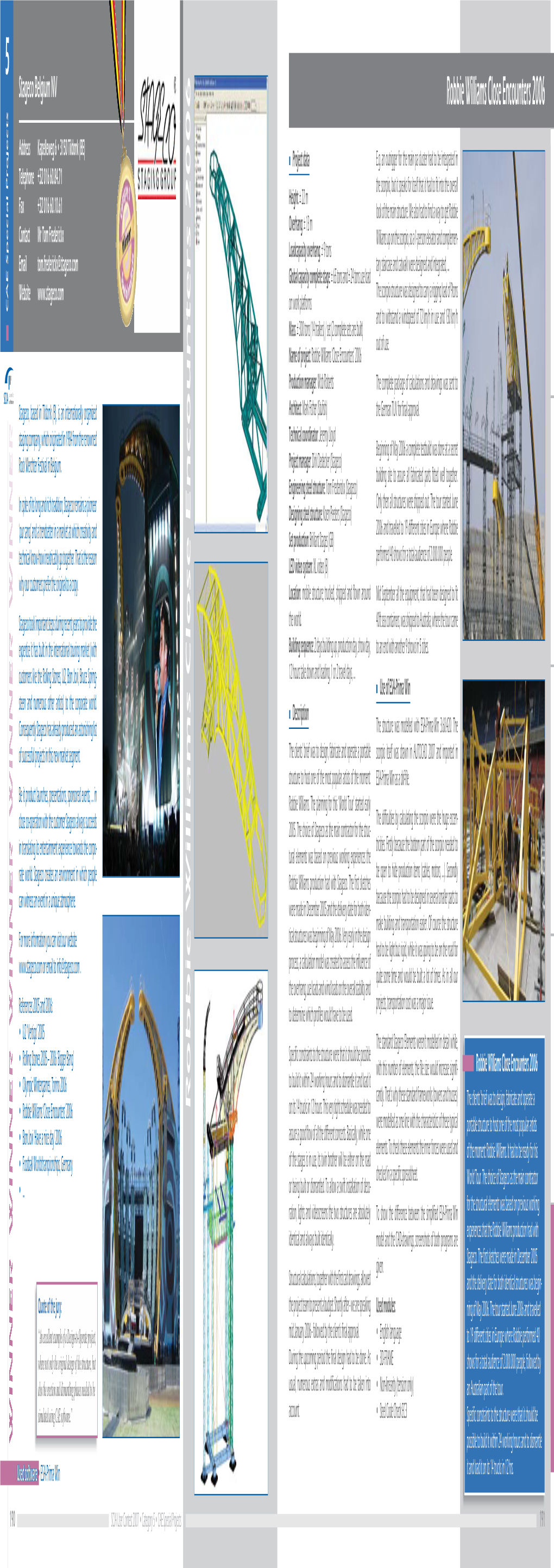

5 Robbie Williams Close Encounters 2006

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Belgian Technologies for International Sporting Events Sponsored by 611997:BOIC Boekje 26-07-2010 14:08 Pagina 2

611997:BOIC boekje 26-07-2010 14:08 Pagina 1 Would you like to benefit from the expertise that these Club member companies have to offer for your sportingevent? Are you looking for more information on the Club and its activities? Or are you thinking of becoming a member yourself? If so, please contact Mr Dimitri Huygen: Belgian Technologies for International Sporting Events Sponsored by 611997:BOIC boekje 26-07-2010 14:08 Pagina 2 STEERING COMMITTEE BELGIAN SPORTS TECHNOLOGY CLUB Johan Vanneste President of the Belgian Sports Technology Club CEO, CityJet John De Winter General Manager Automatic Systems Paul Anderson International Business Development Manager Sports Barco Piet Moons Marketing Director Belgian Olympic and Interfederal Committee Mark Beyst Commercial Director Besix Yves De Cocker International Sales Manager DESSO Sports Systems Ludo Ost Sales & Marketing Manager Veldeman Structure Solutions Peter Demuynck Director International Business Agoria Dimitri Huygen Project Manager 2 www.sportstechnology.be 611997:BOIC boekje 26-07-2010 14:08 Pagina 3 BELGIAN SPORTSTECHNOLOGY CLUB BELGIAN SPORTS TECHNOLOGY CLUB Belgian Technologies for International Sporting Events Belgium-based companies are trusted contributors to the success- ful organization of major international sporting events, such as the Olympic Games, the FIFA World Cup and the UEFA European Johan Vanneste Football Championship. The main reason? Their deep know-how and advanced technolo- gies have, in past decades, extensively proven their worth in numerous of sporting events the world over. The Belgian Sports Technology Club groups these strong players into a tight network that firmly puts Belgium-based know-how in sports technologies on the world stage. -

February 2019

For The Technical And Production Professionals in Asia FEBRUARY 2019 Protec Reflects on 2018 and Expectations in 2019 Chameleon Welcome The New Year With Stagesmarts SNAPSHOT: Ron Schilling at the Guns N’ Roses Concert ALEX SCHLOESSER What is More Important - Gear or Ear? www.e-techasia.com WE LISTENED, NOW IT'S YOUR TURN Compatible Rigging System with all VTX-A Series Products New JBL Transducers for Best Sound Quality and Output Multiple Horizontal Coverage Options (90°|110°|120°) Best-in-Class Rigging System for Fast and Safe Deployment Compact, Truck-Friendly Dimensions Full-Range of Innovative Accessories Complete Solution Including Software and Amplification Small-Format Application Subwoofer Improved Linearity and Wider Dynamic Range Full Series Compatible Rigging (8” and 12” arrays) Reduced System Amplifier Requirements Learn more now at JBLpro.com. A12 A12 W A8 B18 NEW NEW For Product demos and enquiries write to us at [email protected] or contact your authorized country partner CONTENTS 3 February 2019 39 49 IN THIS ISSUE VOL 20 ISSUE 2 FEBRUARY 2019 04 FIRST WORDS 06 NEWS ALEX COLUMN 28 VIDEO FILES 44 What is More Important - Gear or Ear? LIVE 30 ENNOVATIONS 45 CHINA: HARMAN Professional Solutions at Traditional Chinese Theatre EXHIBITION PREVIEW 46 AUSTRALIA: Chameleon Welcome the New Year with StageSmarts 38 Prolight + Sound Guangzhou 2019 to Inculcate Full Solutions for the Entertainment Industry 48 CHINA: Jason Zhang Delivers Exceptional Performance 49 THAILAND: Cameo Fixtures Light Up Little Nemo in SNAPSHOT Slumberland Performance 39 Ron Schilling at the Guns N’ Roses Concert 50 ABU DHABI: Golden Disc Awards Celebrate K-Pop with Nexo SPOTLIGHT 51 EVENTS CALENDAR 40 Protec Reflects on 2018 and Gives Us an Insight Into What to Expect in 2019 56 MARKET PLACE ENTERTAINMENT TECHNOLOGY ASIA | www.e-techasia.com FIRST WORDS 4 RamFebruary Bhavanashi 2019 Editor, India And Middle East [email protected] The beginning of the year as always has started off with a buzz. -

Backstage Auctions, Inc. the Rock and Pop Fall 2020 Auction Reference Catalog

Backstage Auctions, Inc. The Rock and Pop Fall 2020 Auction Reference Catalog Lot # Lot Title Opening $ Artist 1 Artist 2 Type of Collectible 1001 Aerosmith 1989 'Pump' Album Sleeve Proof Signed to Manager Tim Collins $300.00 AEROSMITH - TIM COLLINS COLLECTION Artist / Musician Signed Items 1002 Aerosmith MTV Video Music Awards Band Signed Framed Color Photo $175.00 AEROSMITH - TIM COLLINS COLLECTION Artist / Musician Signed Items 1003 Aerosmith Brad Whitford Signed & Personalized Photo to Tim Collins $150.00 AEROSMITH - TIM COLLINS COLLECTION Artist / Musician Signed Items 1004 Aerosmith Joey Kramer Signed & Personalized Photo to Tim Collins $150.00 AEROSMITH - TIM COLLINS COLLECTION Artist / Musician Signed Items 1005 Aerosmith 1993 'Living' MTV Video Music Award Moonman Award Presented to Tim Collins $4,500.00 AEROSMITH - TIM COLLINS COLLECTION Awards, Plaques & Framed Items 1006 Aerosmith 1993 'Get A Grip' CRIA Diamond Award Issued to Tim Collins $500.00 AEROSMITH - TIM COLLINS COLLECTION Awards, Plaques & Framed Items 1007 Aerosmith 1990 'Janie's Got A Gun' Framed Grammy Award Confirmation Presented to Collins Management $300.00 AEROSMITH - TIM COLLINS COLLECTION Awards, Plaques & Framed Items 1008 Aerosmith 1993 'Livin' On The Edge' Original Grammy Award Certificate Presented to Tim Collins $500.00 AEROSMITH - TIM COLLINS COLLECTION Awards, Plaques & Framed Items 1009 Aerosmith 1994 'Crazy' Original Grammy Award Certificate Presented to Tim Collins $500.00 AEROSMITH - TIM COLLINS COLLECTION Awards, Plaques & Framed Items 1010 Aerosmith -

IPM10 Delegates List for Web 170228.Xlsx

First Name Surname Company Country Phil Addyman Star Events Ltd UK Melanie Altbuerger The Maya Power GmbH Germany Sophie Amable A&E Visas USA UK Emma Andersson YouChip GmbH Germany Nigel Beaton GCC Events LLC UAE Tom Bilsen Stageco Belgium Belgium Danielle Bleazby AFL Australia David Bloch David Bloch International South Africa Boyan Boiadjiev Pan Harmony Bulgaria Alex Borger Mojo Barriers The Netherlands Neil Bracegirdle Audience Media Ltd UK Viktoria Breithecker GPS Global Germany Giovanni Broccu Sardinia Promotion Srl Italy Michael Brombacher MEGAFORCE GmbH Germany Kees Brouwer Pieter Smit The Netherlands Graham Brown Plaster Creative Communications UK Knute Brye eps america llc USA Titus Carole Electric Castle Festival Romania Jon Chapple IQ Magazine UK Lee Charteris Event Consultant Roberto Ciucci Vertigo Italy Jon Corbishley The Safety Officer Pty Ltd Australia Claire Cosgrave SSE Arena Belfast UK Dan Craig Loudsound UK Balint Cser Live Nation CEE Hungary Dirk De Decker Stageco Belgium Belgium Hedwig de Meyer Stageco Belgium Belgium Andreas Degen eps gmbh Germany Vanessa Denman MEGAFORCE GmbH Germany Steve Dixon Roadwerx Touring, LLC USA Martin Doetterl eps holding GmbH Germany Malcolm Louis Domingo esp Afrika Cape Town International Jazz Festival South Africa Ivana Dragila eps holding GmbH Germany Jon Drape Ground Control Production Ltd UK Martyn Drew 360° Show Production AG Switzerland Bells Driver Shure Distribution UK Heather Fitsell NEC Group UK Fiona Flynn Integro Insurance Brokers UK Andy Franks Music Support UK Kimberley -

Delegate List

First Name Surname Company Country Phil Addyman Star Events Ltd UK Sophie Amable A&E Visas USA UK Emma Andersson YouChip GmbH Germany Nigel Beaton GCC Events LLC UAE Tom Bilsen Stageco Belgium Belgium Danielle Bleazby AFL Australia David Bloch David Bloch International South Africa Boyan BoiadJiev Pan Harmony Bulgaria Alex Borger MoJo Barriers The Netherlands Neil Bracegirdle Audience Media Ltd UK Viktoria Breithecker GPS Global Germany Giovanni Broccu Sardinia Promotion Srl Italy Michael Brombacher MEGAFORCE GmbH Germany Kees Brouwer Pieter Smit The Netherlands Graham Brown Plaster Creative Communications UK Knute Brye eps america llc USA Titus Carole Electric Castle Festival Romania Jon Chapple IQ Magazine UK Lee Charteris Event Consultant UAE Roberto Ciucci Vertigo Italy Jon Corbishley The Safety Officer Pty Ltd Australia Claire Cosgrave SSE Arena Belfast UK Dan Craig Loudsound UK Balint Cser Live Nation CEE Hungary Dirk De Decker Stageco Belgium Belgium Hedwig de Meyer Stageco Belgium Belgium Andreas Degen eps gmbh Germany Vanessa Denman MEGAFORCE GmbH Germany Steve Dixon Roadwerx Touring, LLC USA Martin Doetterl eps holding GmbH Germany Malcolm Louis Domingo Cape Town International Jazz Festival South Africa Ivana Dragila eps holding GmbH Germany Jon Drape Ground Control Production Ltd UK Martyn Drew 360° Show Production AG Switzerland Bells Driver Shure Distribution UK Heather Fitsell NEC Group UK Fiona Flynn Integro Insurance Brokers UK Andy Franks Music Support UK Kimberley Fraser Live Nation - Indonesia Indonesia Oleg Gaidar Artist -

Also in This Issue:Tour Link Conference INFO

WINTER 2018 // ISSUE 1 Also in this issue: Tour LInk conference INFO Tour Link Magazine 1 Get the Tour LInk Pro Web Development Magazine app for exclusive Web Design interactive extras! Graphics SEO Hosting Available on Apple & Android App Stores Today!! 615.420.6153 www.warehousemultimedia.com Tour Link Magazine 2 Tour Link Magazine 3 CONTENTS Winter 2018 // Issue 1 LARRY SMITH PUBLISHER TOUR LINK CONFERENCE 6 // Tour Link Conference 2018 10 // Sponsors 17 // Lifetime Achievement Awards A new year is on us, so we decided that this would be a good time to reflect [email protected] 30 // Schedule on the U2 tour, one of the mega-shows of our time. This is always a treat for us 31 // Panels since we have so many good friends working this show. This is the time for planning new tours, checking inventories and reflecting on FEATURED ARTICLES the goals to set for this year. This is also time for the annual Tour Link Conference, so we thought it would make sense to turn this into the conference issue as well. 34 // U2 Joshua Tree Tour Every year, we gather to discuss issues, renew friendships and do some busi- 34 // U2 Joshua Tree Tour ness. Although the conference is structured with discussion topics and events, 49 // Silver & Gold, Thirty Years on, the goal as always is to promote person-to-person relationships. To this end, Stagco Tours the Joshua Tree with U2 we have been successful. To those of you who are attending, we welcome you. To those who are unable to join us, we will deliver a recap of the conference in a future issue and we hope you can join us in the future. -

3D TV XXL Voor Robbie Williams “Take the Crown Tour”

3D TV XXL voor Robbie Williams “take the crown tour” van idee tot 19e staalbouw in amper 7 maanden Robbie Williams Take the crown tour 2013 Robbie Williams Take the crown tour 2013 Stageco • Temporary structures for events (official start 1984) • Worldwide activities : – Concert stages : tours, festivals, indoor events – Temporary buildings – Grandstands, platforms, scaffold, … • Where : – Belgium – USA – Deutschland + Austria – France – Netherlands Take the crown tour 2013 : spec • Initial design spec : – Set : 47 m wide x 25 m high – Screen 32 x 23 m (710 m²) – Moving show objects up to 7 t • Schedule : – Start development jan 2013 – Start test build brussels 9/05 – 26 shows in 18 cities between 14/06 (Dublin) and 26/08 (Stavanger) : 3 days build / 1 day tear down per city Take the crown tour 2013 Take the crown tour 2013 Additional specs • Outdoor temporary structures (EN 13814 and EN 1991) : wind loads • Transport by regular trucks / trailers (max 40 t each) • Builds with 3 cranes and 6 fork lifts • Easy installation of production items (screen / sound / moving objects) • Stadium access and limitations • Cost effective • Minimal depth How ? • Initial concept making use of (standard) stageco elements • Collection of characteristics of all production items • Initial structural calc of this concept (SCIA) + optimalisation • Definition of missing parts, tools, … • Price offer taking into account the above + schedule Loads • Video : 30 t + 2 x 3 t • Sound : 6 t per side • Wind 25 m/s - 35 m/s • Floor loads : 500 kg/m² • Objects up till 7 t Special Manufacturing Facts • 2 sets steel / 1 set production • Per steel set : – 385 t gear (including scaffold and floor) – 85 % standard parts / 15 % specials : all s355 except base frames (s235) – Main towers : 2x2 m section. -

U2’S Latest Touring Extravaganza € 5.00 on Tour: Preview • MA U2 • PLASA09 Lighting • TF: LED Tools & Toys

Aug-Sept Cover:Cover 27/08/2009 13:32 Page 1 Lighting & Sound AUGUST-SEPTEMBER 2009 AUGUST-SEPTEMBER Aug-Sept 2009 entertainment, presentation, communication www.lsionline.co.uk 360% for 360° UK £3.50 US $6.00 Steve Moles reports on U2’s latest touring extravaganza € 5.00 On Tour: U2 • PLASA09 Preview • MA Lighting • TF: LED Tools & Toys LED Tools Lighting • TF: U2 • PLASA09 Preview • MA On Tour: PLUS: K1 at Hyde Park; Vibes from the Vines; Women in Lighting; Who’s Who in an install?; Manchester International Festival; Sound for photo: Andy Brining photo: Chris Toulmin Latitude; Jazz à Vienne; Audio File; Crew Cuts; Tour Talk; Green Room TF: LED Tools & Toys MA Lighting PLASA09 in Preview Get creative with LED grandMA knows best . All that’s to come . & more . L&SI has gone digital! Register online FREE at www.lsionline.co.uk/digital On Tour - U2:On tour.qxd 27/08/2009 08:23 Page 60 All photography: Steve Moles On Tour - U2:On tour.qxd 27/08/2009 08:23 Page 61 “The mind boggles. You might carry 120,000lb of equipment for a major show - we’ve got four times that. That’s the commitment to 360, and it takes 360% from everyone to make it work.” Jake Berry, production director Continued >>> On Tour - U2:On tour.qxd 27/08/2009 08:24 Page 62 Steve Moles reports from the tour Stade de France, Paris . on The U2 360° tour lays down a gauntlet for the industry. This show, just three gigs in when I saw it in Paris, displays absolute maturity of design, thought through in every detail. -

IPM10 Delegates List for Web 170131.Xlsx

First Name Surname Company Country Phil Addyman Star Events Ltd UK Melanie Altbuerger The Maya Power GmbH Germany Emma Andersson YouChip GmbH Germany Tom Bilsen StageCo Belgium Belgium Alex Borger Mojo Barriers The Netherlands Neil Bracegirdle AudienCe Media Ltd UK MiChael Brombacher MEGAFORCE GmbH Germany Graham Brown Plaster Creative CommuniCations UK Knute Brye eps ameriCa llC USA Titus Carole EleCtriC Castle Festival Romania Roberto Ciucci Vertigo Italy Jon Corbishley The Safety OffiCer Pty Ltd Australia Dan Craig Loudsound UK Balint Cser Live Nation CEE Hungary Dirk De Decker StageCo Belgium Belgium Hedwig de Meyer StageCo Belgium Belgium Andreas Degen eps gmbh Germany Vanessa Denman MEGAFORCE GmbH Germany Steve Dixon Roadwerx Touring, LLC USA Martin Doetterl eps holding GmbH Germany MalColm Louis Domingo esp Afrika Cape Town Internaional Jazz Festival South AfriCa Ivana Dragila eps holding GmbH Germany Martyn Drew 360° Show ProduCtion AG Switzerland Bells Driver Shure Distribution UK Matt Earle EFM Event LogistiCs UK Fiona Flynn Integro InsuranCe Brokers UK Martin Goebbels Integro InsuranCe Brokers UK Anna Golden AEG Live UK Alan Goodman BarClayCard Arena UK Randell Greenlee VPLT - The German Entertainment TeChnology AssoCiationGermany Ian Greenway LarMac Live UK David Grindle Loudsound UK Georg Hartmann CTS Eventim Austria GmbH Austria Octavia Harwood The O2 UK Adam Hatton Global Motion Ltd UK Tony Hayes BarClayCard Arena UK Andreas Henkel Maya Event AG LieChtenstein MiChael Herbst StageCo DeutsChland GmbH Germany Stephanie Higginson -

Making Friends Courtney Barnett Gets Festivals Thinking

For the International contemporary Live Music Industry ISSUE 199 AUGUST 2016 UK £6.25 EUROPE €9.40 ROW $12.25 Making friends Courtney Barnett gets festivals thinking SFX founder faces court threat Snoop fans injured at concert Wacken steps up security These days it is all about getting people to talk about your event, rather than talking to them about it Peer Osmundsvaag of Norway’s Atomic Soul’s Always the supporting star Brilliant Stages The international staging sector has had a tough few years including stage collapses, festival cancellations, new regulations, aggressive competition and shrinking budgets, but on the up side, everyone needs a stage and for many major artistes and events, the bigger and more impressive, the better. Brooke Nolan reports. t was in the mid-1970s that rock promoters resulting in deaths and injuries, which have Rugby World Cup 2019 and the 2020 Olympics.” began to need more than a stage built from made staging companies even more aware of Hornbuckle has noticed a closer collabora- scafolding and wooden boards (or worse). their challenges and responsibilities. tion with clients regarding the Construction Structures needed proper roofs to protect Meanwhile, staging – especially for festivals Design and Management Regulations (CDM), Ithe increasing amount of electrical equipment – has become a multi-million-dollar global in- which came into force in April 2015 in the UK. from the elements and US artistes, in particular, dustry, with a variety of regional leaders and as- “We pride ourselves on quality product with were used to a higher level of production than sociations that can provide a major artiste with no compromise on safe delivery and it’s good they often found in Europe, let alone elsewhere. -

Trans-Siberian Orchestra

volume 2 issue 12 2009 BROWN BURNOIWTEND UNITED www.B r o w n U n i t e d .com B 1-800-442-7696 [email protected] BB 1-800-44-BROWN Int’l 1-626-357-1161 BLEACHERS . STAGING . SEATING . SCAFFOLDING mobilePRODUCTION monthly con volume 2 issue 11 2009tents FEATURES 6 Video Video Scenic Convergence: Tait Technologies Takes the Mantra to Reality 8 Transportation Spirit of America Tours /Corporate Transport The New Transportation Specialists 10 Sound Meyer Sound JM-1P Makes Africa’s Gospel “Experience” Uplifting Everywhere 12 Trans-Siberian Orchestra Bigger, Better, Brighter 14 TSO Tour Personnel 18 TSO Tour/Business Credits 24 U2 360° Tour The Largest Tour to Ever Go Out 32 Jan Paulsen - An Amazing Story of Loyalty, Friendship and Perseverance 24 33 U2 Tour Personnel/Offices 34 Clair U2 360° Redefines Live Production 36 Upstaging Upstaging U2 200 Trucks. No, Really. 38 Sound Moves Moving U2 From There to Here and Back! 40 Stageco The Bigger the Better 6 12 34 48 Advertiser's Index MobileProductionPro.com Mobile Production Pro features the world's most comprehensive searchable database of music and entertainment touring contacts includ- ing equipment rental and sales (sound, lighting, staging, video, etc.), hotels, production, talent, transportation, ven- ues, services and more. Create a FREE Account Today 36 38 40 mobile production monthly 3 FROM THE Publisher With this issue we wrap up our coverage of the industry in 2009, and we felt that U2 would be the appropriate tour to feature. After such a difficult year for many of us, we wanted to feature the outstanding show of the year – U2. -

The Magic Behind

Volume 7 Issue 6 The Magic Behind mobile production monthly 1 2 mobile production monthly CONTENTS Volume 7 Issue 6 On The Cover pg 6 The Magic Behind TomorrowWorld Behind the Magic of 13 Rutger Jansen & Backbone International Making EDM 6 TomorrowWorld Explode in North America 14 Tech Smart Touring: Attendee Charging Options at TomorrowWorld 19 Stageco Belgium Moves Mountains for TomorrowWorld 20 Mojo Barriers is TomorrowWorld’s Choice for Safety 23 Mojo Barriers New High Fence Design 24 Pyrotecnico FX Lights Up the Sky of TomorrowWorld 27 Comfort Zone: Your World-Wide Sanitation Solution for Events of any Size 28 The Skill of Skrillex’s Sets 31 ESA 33 Renaissance Atlanta Midtown & Renaissance Hotels, All Your Tomorrow Needs Today and Worldwide 34 Beauty, Mate! Tri-Point Rigging Services and StageCo in Australia 37 Powerful K System Chosen by NoizBoyz for top EDM Festival in Belgium 38 Nobel Worthy LED’s mobile production monthly 3 Notes from the Publisher After 35 years in this part of the business and 47 years since my first professional gig, I admit to being an “Old Dog” in this Industry and pretty set in my ways. I also mobileproductionpro.com admit to having a certain musical bias and a structural PUBLISHED BY perception that may be dated. This was never made Anvil Productions, LLC more obvious to than when, for the past year, members 740 Cowan Street, Nashville, TN 37207 of my staff and family have been trying to get me to ph: 615.256.7006 • f: 615.256.7004 take a serious look at the new EDM and festival mar- ket.