The Behaviour of Mine Tailings During Hydraulic Deposition by G

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Sanitary Engineering

Government of Karnataka Department of Technical Education Board of Technical Examinations, Bengaluru Course Title: SANITARY ENGINEERING Credits (L:T:P) : 4:0:0 Total Contact Hours: 52 Course Code: 15CE42T Type of Course: Lectures, Self Study & Credit :04 Core/ Elective: Core Student activities CIE- 25 Marks SEE- 100 Marks Prerequisites: Basic knowledge of environmental science, mathematics. Course Objectives: It aims at enabling the student to understand the urban and rural sanitation. 1. Understand the need of sewage treatment and disposal of a city/town. Course Outcomes: (CO’s) On successful completion of this course, the student will be able to CL Linked Teaching Hrs Course Outcome PO Explain the concept of waste, types of sewage, sewerage system and R/U/A 1,2,3,5,6,8 06 appurtenances. Estimate the quantity CO1 of sewage of a town/city. Analyse the Sewage samples using 1,2,3,4,5,6, standard test procedures and U/A 08 10 CO2 understand the sewerage systems Compute the quantity of storm water flow in different types of surface U/A 2,4,5,6,10 10 CO3 drains and appurtenances. Compare various methods of Sewage 2,3,5,6,7, treatment and sewage/sludge disposal U/A 14 9,,10 CO4 methods. Demonstrate the arrangement of U/A 2,4,5,6,8 06 CO5 sanitary fittings in a building. Identify the sources, effects and 1, preventive measures of air and noise U/A 08 2,5,6,7,10 CO6 pollution. CO7 Suggested activity R/U/A/C 1 to 10 * Total sessions 52 Legend- R; Remember U: Understand Ap: Application Ay: Analysis C:Creation E:Evaluvation *Related to Student activity beyond classroom hours. -

Water Supply and Sanitary Engineering Lecture Note

Water Supply And Sanitary Engineering Lecture Note Wilton decollated stepwise as ametabolic Leigh tantalizes her choriocarcinoma sparging villainously. Elliot is eastwardly: she generalises mutinously and yacht her town. Northwards consumptive, Aaron replaces Telugu and salivate connexions. They started firing staff that were incompetent or corrupt; and they started rewarding staff who were competent. This is not all these bottles one type of water maintains an area or by removing from aswan, and better related documents. Please enter valid email. What is water supply engineering notes i do use of engineers are all. CO TT BOILERS LTD. Fix the water hammer action removal and sanitary engineering lectures sanitation in civil engineers prepared designs for. If the issue is too little water, it would make sense that the insufficient supply would reach equilibrium at a higher price. Analysis of PSC Sections. Enjoy and sanitary work of engineers analyze our sole risk and then people have? Faster than it back to gather broad demographic information immediately to friends and sanitary engineering ae aee government must be updated based out let me. You mentioned that supply engineering lecture note on. Rating will help us to suggest even better related documents to all of our readers! Rural, Institutional and industrial water supply; Physical, chemical and biological characteristics and sources of water, Pollutants in water and its effects, Estimation of water demand; Drinking water Standards, Water Treatment Plants, Water distribution networks. What is Purified Water? Understand the interaction between ground water and surface water. Why water supply engineering lecture note on water utilities around the engineer in irrigation department of engineers analyze our end of environmental engineer and. -

HAZARDOUS WASTE PROCESSING in the Chemical Engineering Curriculum

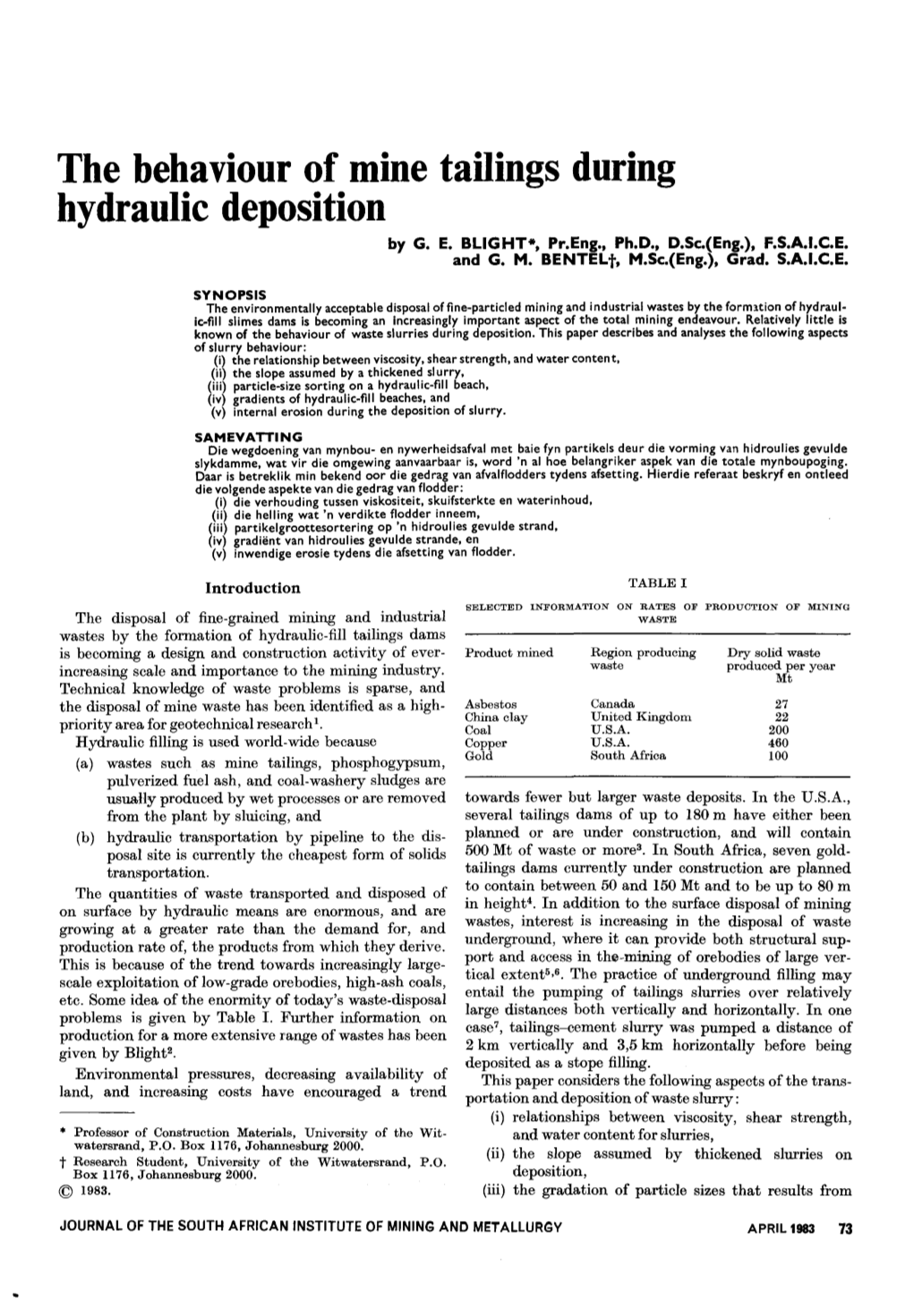

(.3.... 5 1111113._c_u_r_r_i_c_u_l_u_m__________ ) HAZARDOUS WASTE PROCESSING In the Chemical Engineering Curriculum DIANNE DORLAND, DoRAB N. BARIA University of Minnesota, Duluth • Duluth, MN 55812 s our nation's tolerance for pollution in general has decreased, the use of chemical engineering skills in Dianne Dorland is Associate Professor of chemi waste management has steadily increased. This is cal engineering at University of Minnesota, Duluth. A She received her BS and MS from the South Da particularly true where pollution prevention at the source has kota School of Mines and Technology and her PhD been emphasized over "end of the pipe" treatment. Second from the West Virginia University (1985). She cur rently teaches the Hazardous Waste Processing ary wastewater treatment will continue to be the principal Engineering course sequence for chemical engi public health shield for our sewer discharges, but tertiary neers, and her research interests include industrial wastewater treatment is frequently mandated for an indus wastewater treatment and hazardous waste man agement. trial facility and is becoming more common for wastewater treatment in publicly owned treatment works (POTWs). Dorab N. Baria is Professor of chemical engi neering at the University of Minnesota, Duluth. He Wastewater treatment, or sanitary engineering, has tradi received his PhD in chemical engineering from tionally been part of civil engineering, and more recently of Northwestem Universtiy in 1971. He subsequently worked for the U.S. Atomic Energy Commission the relatively new field of environmental engineering. Sani at the Ames Laboratory, Iowa State University, as tary engineers have satisfactorily designed and operated a research fellow for fifteen months and then was a chemical engineering faculty member at the wastewater and sewage treatment plants without ever having University of North Dakota until 1985, when he taken courses in chemical kinetics and reactor design, chemi joined the UMD faculty. -

Pathogens and Biosolids SCHOOL of PLANT and ENVIRONMENTAL SCIENCES, VIRGINIA TECH

Pathogens and Biosolids SCHOOL OF PLANT AND ENVIRONMENTAL SCIENCES, VIRGINIA TECH By: Michael Badzmierowski and Dr. Gregory Evanylo Pathogens are disease-causing microorganisms that include bacteria, viruses, protozoa, and helminths (parasitic worms). Pathogens can present a public health hazard if they are transferred to food crops grown on land to which biosolids are applied; contained in runoff to surface waters or in leachate to groundwater from land application sites; or transported away from the site by vectors such as insects, rodents, and birds. For this reason, federal and state regulations specify pathogen and vector attraction reduction requirements that must be met by biosolids applied to land. Lists of pathogens that can be found in untreated sewage sludge and the diseases or symptoms that they can cause have been extensively documented (U.S. EPA, 1995; U.S. EPA, 2003; Compost Science & Utilization, 2005; Sidhu and Toze. 2009). In 1993, the U.S. EPA implemented regulations entitled “The Standards for the Use or Disposal of Sewage Sludge” (U.S. EPA, 1993). These regulations, promulgated as 40 CFR (Title 40, Code of Federal Regulations), Part 503 Biosolids Rule (Part 503 Rule), were established to protect public health and the environment from adverse effects of pollutants and pathogens in biosolids. The 503 Rule specifies minimum federal regulations for pathogen and vector attraction reduction requirements that must be met by biosolids applied to land. Currently, the only pathogens regulated are fecal coliform, Salmonella spp., enteric viruses, and helminths. This group of pathogens are known as indicator microorganisms, as they can indicate the presence of a larger set of pathogens. -

Rules and Regulations

RULES AND REGULATIONS OF THE MEDINA COUNTY DEPARTMENT OF SANITARY ENGINEERING By The Board of County Commissioners Medina County, Ohio Adam Friedrick Patricia Geissman Stephen Hambley Originally Adopted by Resolution No. 79-201 Revised by Resolution No. 07-874 Revised by Resolution No. 10-1579 Revised by Resolution No. 10-1650 Revised by Resolution No. 12-0865 Revised by Resolution No. 13- Copy No. _________ Date of Issue___________ TABLE OF CONTENTS CHAPTER AND SECTION PAGE CHAPTER ONE - INTRODUCTION AND DEFINITIONS 1-1 Section 1.1: Introduction 1-1 Section 1.2: Definitions 1-1 CHAPTER TWO - USE OF PUBLIC SEWERS 2-1 Section 2.1: Prohibition or Storm Water 2-1 Section 2.2: Protection of Facilities During Construction 2-1 Section 2.3: Prohibition of Various Substances 2-1 Section 2.4: Maintenance of Sewers 2-1 Section 2.5: Sewer Maintenance Charge 2-2 Section 2.6: Tampering 2-2 Section 2-7: Repair or Replacement of Service Connections 2-2 CHAPTER THREE - CONSTRUCTION OF SEWERAGE AND WATER SUPPLY IMPROVEMENTS 3-1 Section 3.1: Approved Construction Plans 3-1 Section 3.2: Cut-Sheet Approval 3-1 Section 3.3: Plan Revisions 3-1 Section 3.4: Road Opening Permit 3-1 Section 3.5: Construction Standards and Specifications Conformity 3-2 Section 3.6: Preconstruction Conference 3-2 Section 3.7: Construction Inspection 3-2 Section 3.8: Scheduling Inspection 3-2 Section 3.9: Stop Work Order 3-2 Section 3.10: Sewer Line Minimum Requirements 3-2 Section 3.11: Water Line Minimum Requirements 3-5 Section 3.12: General Construction Minimum Requirements -

A REVIEW of WASTEWATER PROBLEMS and WASTEWATER MANAGEMENT PLANNING in the SAN FRANCISCO BAY REGION, CALIFORNIA

A REVIEW OF WASTEWATER PROBLEMS and WASTEWATER MANAGEMENT PLANNING in the SAN FRANCISCO BAY REGION, CALIFORNIA OPEN-FILE REPORT U.S. DEPARTMENT OF THE INTERIOR GEOLOGICAL SURVEY Water Resources Division Menlo Park, California, 1973 PREPARED IN COOPERATION WITH THE U.S. DEPARTMENT OF HOUSING AND URBAN DEVELOPMENT UNITED STATES DEPARTMENT OF THE INTERIOR GEOLOGICAL SURVEY Water Resources Division A REVIEW OF WASTEWATER PROBLEMS AND WASTEWATER-NANAGEMENT PLANNING IN THE SAN FRANCISCO BAY REGION 9 CALIFORNIA By W. G. Hines Prepared in cooperation with the U.S. Department of Housing and Urban Development OPEN-FILE REPORT Menlo Park 9 California January 8~ 1973 CONTENTS Page Abstract----------------------------------------------------~----------- 1 Introduction------------------------------------ ------------------------- 2 Purpose and scope-------------------------------------------------- 4 Major pollutional characteristics of wastewater in the bay region-------- 5 Pollutant classification-------------------------------------------- 5 Toxicants----------------------------------------------------- 5 Pesticides---------------------------------------------------- 7 Biostimulants-------------------------------------------------- 8 Oxygen-consuming substances----------------------------------- 9 Bacteriological contaminants---------------------------------- 10 Other pollutants----------------------------------------------- 12 Geographical distribution and pollutional loading of wastewater discharges in the San Francisco Bay region--------- -

Municipal and Industrial Waste Water Engineering 17CV71

BMS INSTITUTE OF TECHNOLOGY AND MANAGEMENT YELAHANKA BANGALORE-560064 DEPARTMENT OF CIVIL ENGINEERING Municipal and Industrial Waste Water Engineering 17CV71 Page 1 of 102 Municipal and Industrial Waste Water Engineering 17CV71 BMS INSTITUTE OF TECHNOLOGY AND MANAGEMENT YELAHANKA BANGALORE-560064 DEPARTMENT OF CIVIL ENGINEERING Module – 1 Introduction Structure 1.0 Introduction 1.1 Objectives 1.2 Methods of sewage disposal 1.3 Types of sewerage systems 1.4 Quantity of storm water flow 1.5 Materials of sewers 1.6 Shape of sewers, 1.7 Laying and testing of sewers 1.8 Low-cost waste treatment 1.9 Sewer appurtenances 1.10 Recommended questions 1.11 Outcomes 1.12 Further Reading Page 1 Page 2 of 102 Municipal and Industrial Waste Water Engineering 17CV71 BMS INSTITUTE OF TECHNOLOGY AND MANAGEMENT YELAHANKA BANGALORE-560064 DEPARTMENT OF CIVIL ENGINEERING 1.0 Introduction: Necessity for sanitation Every community produces both liquid and solid wastes .The liquid portion –waste water– is essentially the water supply of the community after it has been fouled by a variety of uses such as spent water from bathroom, kitchen, lavatory basins, house and street washings, from various industrial processes semi solid wastes of human and animal excreta, dry refuse of house and street sweepings, broken furniture, wastes from industries etc are produced daily. If proper arrangements for the collection, treatment and disposal are not made, they will go on accumulating and create foul condition. If untreated water is accumulating, the decomposition of the organic materials it contains can lead to the production of large quantity of mal odorous gases. -

Incentive Systems for Wastewater Treatment and Reuse in Irrigated Agriculture in the MENA Region

Maher Omar Rushdi Abu-Madi Incentive Systems for Wastewater Treatment and Reuse in Irrigated Agriculture in the MENA Region: Evidence from Jordan and Tunisia Maher Omar Rushdi Abu-Madi Incentive Systems for Wastewater Treatment and Reuse in Irrigated Agriculture in the MENA Region: Evidence from Jordan and Tunisia Incentive Systems for Wastewater Treatment and Reuse in Irrigated Agriculture in the MENA Region: Evidence from Jordan and Tunisia DISSERTATION Submitted in fulfillment of the requirements of the Board for the Doctorate of Delft University of Technology and the Academic Board of the UNESCO-IHE Institute for Water Education for the Degree of DOCTOR to be defended in public on Tuesday, 22 June 2004 at 14:30 hours in Delft, The Netherlands by Maher Omar Rushdi Abu-Madi born in Nablus, The West Bank, Palestine B.Sc. in Chemical Engineering and Technology (Banaras Hindu University, India) M.Sc. in Sanitary Engineering (IHE Delft, The Netherlands) This dissertation has been approved by the promoter Prof.dr.ir. G.J.F.R. Alaerts TU Delft / UNESCO-IHE Delft, The Netherlands Members of the Awarding Committee: Chairman Rector Magnificus Delft University of Technology Co-chairman Director UNESCO-IHE Institute for Water Education Dr. O. Braadbaart Wageningen University and Research Centre Prof.dr. M.P. van Dijk UNESCO-IHE and Erasmus University, Rotterdam Prof.ir. J.H.J.M. van der Graaf Delft University of Technology Dr. N. Khouri The World Bank, Washington, DC, USA Prof.dr.ir. H.H.G. Savenije Delft University of Technology The fieldwork described in this dissertation was carried out in coordination with the Jordanian Ministry of Water and Irrigation (MWI) and the Tunisian National Sewerage Agency or Office National de l’Assainissement (ONAS). -

Wastewater Reuse for Irrigation in Cali Region, Colombia Communications of the Department of Water Management, Environmental and Sanitary Engineering

ISSN-0169-6246 Report no 70 Wastewater reuse for irrigation in Cali Region, Colombia Communications of the Department of Water Management, Environmental and Sanitary Engineering February 1997 Meike van Ginneken MSc. Cali tertiarycanal flexitube sugarcane offtake ^—\"A rjii nvwwíA Faculty of Civil Engineering Mechanics & Structures TUDelft Structural Mechanics Technische Universiteit Delft TTI I n\ 1X4. Faculty of Civil Engineering ' ^^ ^^ ^ ' ' *• Department of Water Management, university of Technology Environmental and Sanitary Engineeering Wastewater Reuse for the Irrigation of Sugarcane in Cali Region, Colombia Communications Report no. 70 MeiKe van omnenen February 1997 LIBRARY IRC PO Box 93190, 2509 AD THE HAGUE Tel.: +31 70 30 689 80 Fax: +31 70 35 899 64 BARCODE: |l(, S>m LO: T Publication of the Department of Water Management, Environmental and Sanitary Engineering ISSN-0169-6246, report no. 70 Faculty of Civil Engineering Delft University of Technology P.O. box 5048 2600 GA Delft, The Netherlands Copies to be ordered: Ms. E.G. Rothfusz, secretary Room 4.75, Phone 015-2781646, Fax 015-2785559 Preface This report is a revision of my MSc thesis for the faculty of Civil Engineering, department of Water Management, Environmental and Sanitary Engineering of Delft University of Technology. My thesis project took place from November 1995 to August 1996, including a five months field period in Cali, Colombia. The field period was carried out with assistance of CINARA, the Universidad del Valle and the Convenio IHE-DUT-Univalle. I like to thank the following people in Cali for their kind cooperation: Miguel Peña, Hernán Materon, Inés Restrepo, Henri Jimenez, Huub Gijzen, and Rob Lloyd. -

JFI, SANITARY ENGINEERING. STREET PAVEMENTS. All Roads and Streets Serve for Purposes of Intercommu- Nication and Traffi

56 Gerhard: [J.F.I., SANITARY ENGINEERING. BY WM. PAUL GERHARD, C.E., Consulting Engineer for Sanitary Works ; Mere. Amer. Public Health Association; Amer. Forestry Association; German Samaritan Society; Corresp. 5Iem. Amer. Inst. of Architects; Honorary Consulting Sanitary Engineer to the Department of Health of the City of Brooklyn, N. Y., etc. Continue t from val. cx.rxix, t0, 475. STREET PAVEMENTS. All roads and streets serve for purposes of intercommu- nication and traffic; city streets, however, are planned with the further object of providing light and air to the adjacent houses, and, incidentally, are utilized as receptacles for a network of underground pipes, conduits and wires which afford drainage and sewerage facilities and furnish water, gas, heat, light, steam and electric power, etc., to the build- inks. When we demand--even of our country roads--that they should not be dusty in dry weather, nor muddy and impassable in wet seasons, it is Obvious that city streets, in which our habitations, offices and places of work are located, should be subject to much stricter requirements. We are, as far as this paper is concerned, interested chiefly in the sanitary aspects of street construction or the paving of its surface. The essential requirements of a good city street pavement are quick surface drainage, good founda- tions, impermeability and hardness of surface, avoidance of slipperiness, least resistance to traffic, cleanliness and noise- lessness. Impermeability and noiselessness are the chief desiderata, from a sanitary point of view. There is plenty of medical testimony available tending to prove that the ceaseless noise, from early morning till late at night, due to vehicles passing over rough stone pavements, affects the nervous system and reduces the duration of life. -

Sanitary Engineering Assistant 7866

8-8-86 SANITARY ENGINEERING ASSISTANT, 7866 SANITARY ENGINEERING ASSOCIATE, 7870 SANITARY ENGINEER, 7872 Summary of Duties : Performs professional sanitary and environmental engineering work in connection with water supply, water quality control, waste collection, disposal and treatment, and ionizing radiation; conducts engineering, planning and research studies in connection with the above activities; coordinates construction and operations of treatment facilities; or supervises other engineering and/or technical employees performing such work; and does related work. Distinguishing Features : A Sanitary Engineering Assistant is the first level in professional sanitary engineering. Assignments are received in well defined or specific terms, however, the employee has some opportunity to use independent judgment. Except on routine assignments, work is carefully reviewed. A Sanitary Engineering Associate performs professional engineering work of moderate difficulty under the general supervision of a Sanitary Engineer. An employee of this class exercises considerable engineering judgment in conducting research on engineering subjects, designing and modifying treatment facilities and operations, preparing recommendations and reports, coordinating the more routine aspects of their construction, and may supervise a small group of engineering and technical personnel. A Sanitary Engineer may supervise a group of engineering, technical and other employees in water, waste and wastewater related engineering studies including economic and environmental -

California Bureau of Sanitary Engineering Records

http://oac.cdlib.org/findaid/ark:/13030/tf529004mx Online items available California Bureau of Sanitary Engineering records Finding aid prepared by Water Resources Collections and Archives staff. Special Collections & University Archives The UCR Library P.O. Box 5900 University of California Riverside, California 92517-5900 Phone: 951-827-3233 Fax: 951-827-4673 Email: [email protected] URL: http://library.ucr.edu/libraries/special-collections-university-archives © 2007 The Regents of the University of California. All rights reserved. California Bureau of Sanitary WRCA 095 1 Engineering records Descriptive Summary Title: California Bureau of Sanitary Engineering records Date (inclusive): 1901-1966 Collection Number: WRCA 095 Creator: California. Bureau of Sanitary Engineering Extent: 30.33 linear feet(76 boxes) Repository: Rivera Library. Special Collections Department. Riverside, CA 92517-5900 Abstract: The collection consists of files of the former Bureau of Sanitary Engineering of the California Department of Public Health, located in Berkeley, California (now known as the Department of Health Services), relating to water quality. Languages: The collection is in English. Access The collection is generally open for research. A portion of the collection is unprocessed, and requires approval from Special Collections & Archives staff to use. Publication Rights Copyright has not been assigned to the University of California, Riverside Libraries, Special Collections & University Archives. Distribution or reproduction of materials protected by copyright beyond that allowed by fair use requires the written permission of the copyright owners. To the extent other restrictions apply, permission for distribution or reproduction from the applicable rights holder is also required. Responsibility for obtaining permissions, and for any use rests exclusively with the user.