HEAT TREATING JUNE 2011

UNCONFIRMED MINUTES JUNE 20 – 23, 2011 GRAND CONNAUGHT ROOMS LONDON, ENGLAND

These minutes are not final until confirmed by the Task Group in writing or by vote at a subsequent meeting. Information herein does not constitute a communication or recommendation from the Task Group and shall not be considered as such by any agency.

MONDAY, JUNE 20, 2011 to THURSDAY, JUNE 23, 2011

1.0 OPENING COMMENTS/INTRODUCTIONS – OPEN

1.1 Call to Order / Quorum Check

The Heat Treat Task Group (HT) was called to order at 9:00 a.m. on 20-June-11. The HT Staff and Subscriber participants were introduced.

It was verified that only SUBSCRIBER MEMBERS were in attendance during the closed portion of the meeting.

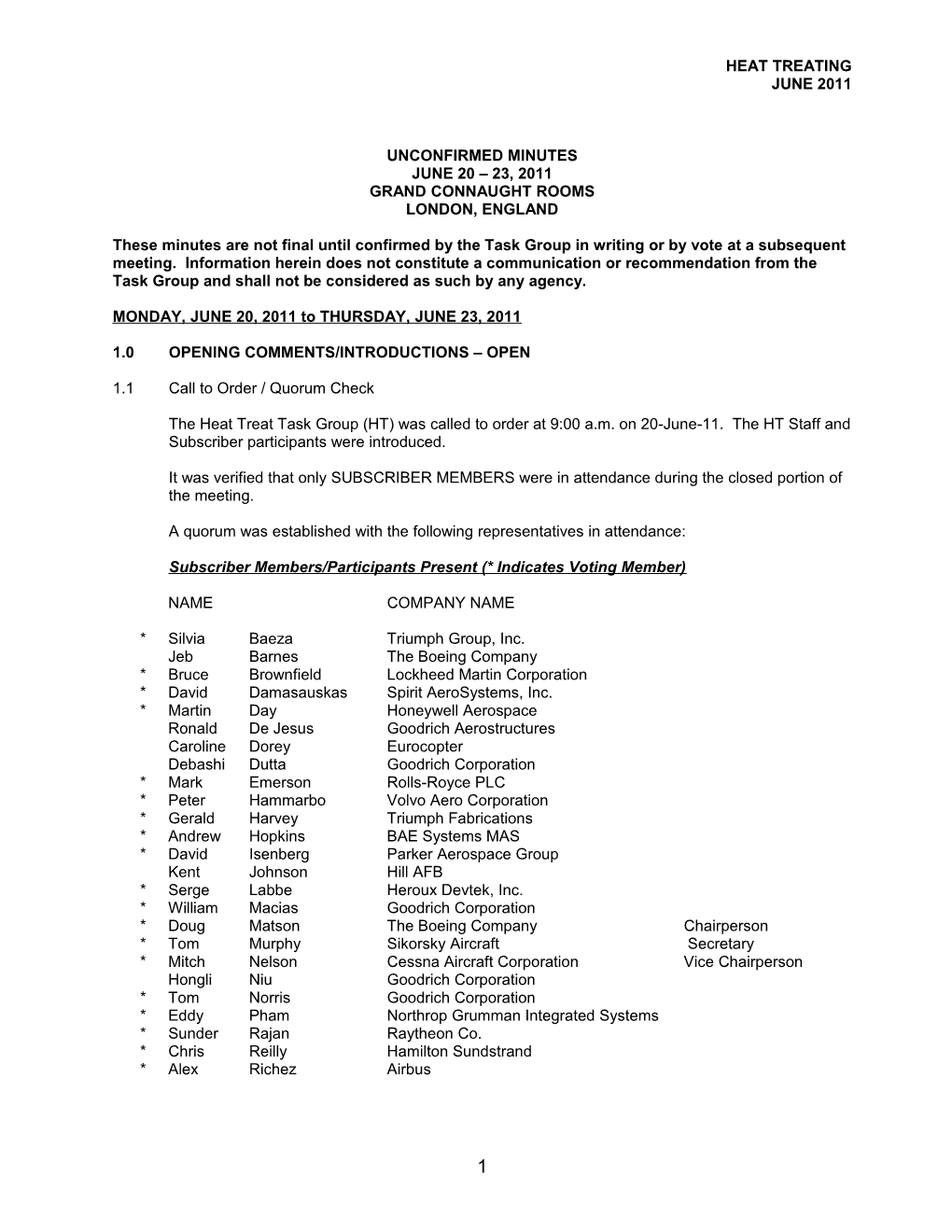

A quorum was established with the following representatives in attendance:

Subscriber Members/Participants Present (* Indicates Voting Member)

NAME COMPANY NAME

* Silvia Baeza Triumph Group, Inc. Jeb Barnes The Boeing Company * Bruce Brownfield Lockheed Martin Corporation * David Damasauskas Spirit AeroSystems, Inc. * Martin Day Honeywell Aerospace Ronald De Jesus Goodrich Aerostructures Caroline Dorey Eurocopter Debashi Dutta Goodrich Corporation * Mark Emerson Rolls-Royce PLC * Peter Hammarbo Volvo Aero Corporation * Gerald Harvey Triumph Fabrications * Andrew Hopkins BAE Systems MAS * David Isenberg Parker Aerospace Group Kent Johnson Hill AFB * Serge Labbe Heroux Devtek, Inc. * William Macias Goodrich Corporation * Doug Matson The Boeing Company Chairperson * Tom Murphy Sikorsky Aircraft Secretary * Mitch Nelson Cessna Aircraft Corporation Vice Chairperson Hongli Niu Goodrich Corporation * Tom Norris Goodrich Corporation * Eddy Pham Northrop Grumman Integrated Systems * Sunder Rajan Raytheon Co. * Chris Reilly Hamilton Sundstrand * Alex Richez Airbus

1 Subscriber Members /Participants Present (* Indicates Voting Member)(Contd)

NAME COMPANY NAME

* Marc Taillandier Eurocopter * Jeffrey Thyssen GE Aviation * Cyril Vernault SAFRAN Group P. John Walsh Pratt & Whitney * Leevon Williams Sikorsky Aircraft Tom Wilson Bombardier Aerospace * Tomasz Wojtasik Honeywell Aerospace * Grzegorz Wryk Goodrich Corporation

Other Members/Participants Present (* Indicates Voting Member)

NAME COMPANY NAME

Bob Akin Quality Heat Treating Caroline Berquer-Muys Bodycote - Belgium Prabir Deb Peco Aerospace Fasteners Co. Inc. Ian Evans Timet UK Gorzegorz Gardynik Zaklad Kuznia Matrycowa sp. z o.o. Arshad Hafeez QuaLease Ltd. Jonathan Hebben Ducommen Aerostructures William Hewitt Bodycote UK Michael Kemp Maycast-Nokes Ltd. * Alexander Klyuch Blades Technology Ltd. Günter Krauss RUAG Switzerland Ltd, Division RUAG Technology Emmen * John Kunkle Howmet Castings Dover Casting Randy Lewis Wyman-Gordon Company * Johanna Lisa Continental and Quality Heat Treating Barry Martin S.S. White Technologies UK Ltd. Kevin McNee Firth Rixson plc Ken Morris Vector Aerospace International * Michael Niedzinski Alcan Rhenalu - Issorie Plant Toki Ogunkolati Vector Aerospace International * Nick Olpin Wallwork Heat 2 HEAT TREATING JUNE 2011

Treat Hefin Price Timet UK Elena Ritoli Metallurgical Processing Steve Roebuck Bodycote Heat Treatments Ltd. Graeme Rolfe SPS Technologies Ltd. Celine Savariau Bodycote - Belgium Stuart Sherman Metallurgical Processing Tony Solway Invensys Eurotherm Rudolf Sporer Bohler Edelstahl Gigi Streeter Barnes Aerospace Lansing Wilfried Weber PFW Aerospace AG Mark Willis Alcoa

PRI Staff Present

Jerry Aston Marcel Cuperman Rob Hoeth

3 2.0 HEATING TREATING TASK GROUP TUTORIAL – CLOSED

The meeting began with a reading of the Nadcap Code of Ethics and Conflict of Interest and Anti- Trust Policy.

The Chair reminded the Task Group of the following:

The feedback form for meeting facilitation will be done as a group at the end of the meeting. One microphone is available for anyone who would like to use it. Speak clearly, do not dismiss people’s opinions, emotional and off topics should be avoided.

A presentation was given on Task Group leadership, support staff, eAuditNet Process in detail regarding each step required, operational requirements list (Review of Operational Requirements)- NIP (Nadcap Internal Procedure), NTGOP (Nadcap Task Group Operating Procedure), NOP (Nadcap Operating Procedures), and Quality Manual AS7003, procedural hierarchy, procedure map, important procedures, group history, scope, mandates, NMC metrics (mandating Subscribers), group actions, current activities, meetings, and additional available information.

3.0 RAIL REVIEW - CLOSED

The RAIL and the progress on closing prior meeting action items was reviewed.

The RAIL document can be found at: www.eAuditNet.com under Documents / Public Documents / Heat Treating.

The Task Group was reminded that the RAIL is updated on www.eAuditNet.com on the 15th of every month.

4.0 AUDIT FAILURE ANALYSIS AND VCA REPORT OUT – CLOSED

The Staff Engineers presented to the Task Group the number of VCA audits being carried out per quarter.

The number of VCA audits for the previous quarter was 12 of which 4 audits failed. This was similar to the previous quarter when 10 VCA audits were conducted with 4 audits failing.

The Task Group confirmed that each audit is treated on its own merits regarding required follow up actions, and the VCA guidelines have been adhered to.

Further discussions were held by the Task Group regarding the number of VCA audits carried out and accepted that the number of VCA audits had increased even with the VCA guidelines being adhered to. The outcome of the discussions was to agree that mandating a VCA audit will be in line with failure policy of a 2/3rds majority. NTGOP-001, Appendix III will be modified to reflect this and balloted for approval.

ACTION ITEM: Staff Engineers to ballot the revised NTGOP-001, Appendix III. (DUE DATE: 31-Oct-11)

4 HEAT TREATING JUNE 2011

The Staff Engineer presented the results of an investigation that the Board of Directors had requested to determine if Suppliers who fail an audit could be identified prior to the audit taking place.

The non-conformances from failed audits were evaluated and the main reason for failure identified. The data was analyzed for trends that would indicate if audit failures could have been identified prior to the audit being conducted. Analysis of Heat Treating and other commodity audits showed that compliance to customer specifications was the main reason for failure and the Suppliers could not be identified before the audit took place.

One recommendation from the Task Group is that Suppliers should carry out a detailed self audit before their Nadcap audit.

5.0 SUPPLIER FEEDBACK – CLOSED

The Heat Treating Supplier Survey results were presented to the Task Group. The survey looks at the way an Auditor carried out the audit, and gives an indication that Auditors are showing correct auditing skills.

A review the results shows that good behaviors are demonstrated by the Auditors but in a very small number of audits the Auditors are allowing the Suppliers to select the job audits. This is not good practice. SE to determine if this is the same Auditor, and if so contact the Auditor to remind him of best practice.

ACTION ITEM: Staff Engineer to determine if it is an individual Auditor that is permitting the Suppliers to select the job audits and, if so, contact the Auditor to remind him of best practice. (DUE DATE: 31-OCT- 2011)

6.0 SE DELEGATION– CLOSED

Motion made by Jeff Thyssen & seconded by Tom Norris to continue to delegate Jerry Aston. Motion Passed

Motion made by Jeff Thyssen & seconded by Tom Murphy to continue to delegate Rob Hoeth. Motion Passed

Motion made by Bruce Brownfield & seconded by Tom Norris to continue to delegate Marcel Cuperman. Motion Passed

Motion made by Jeff Thyssen & seconded by Mark Emerson to continue to delegate Anne Allen. Motion Passed

7.0 AUDIT OBSERVERS REPORT OUT - CLOSED

When a Subscriber carries out an oversight audit of a Supplier, Nadcap is requesting that they complete the oversight form, and return it to John Barrett at PRI. This allows the forms to be reviewed and discussed at the Task Group meetings.

Since the last meeting, the oversight audit forms that have been returned and their summaries were reviewed by the Task Group. In general, the feedback on the Auditors was positive, but it does show areas that can be improved. These will be worked with those Auditors by the Staff Engineers.

Audit observation reports will be reviewed each subsequent meeting.

5 8.0 SYSTEMIC NON CONFORMANCE DEFINITION FOR NCRS – CLOSED

The Task Group was debriefed that there will be a change to the way non-conformances are graded as Major or Minor. The Auditors will no longer grade the non-conformances, but will check boxes in eAuditNet which will automatically assign Major or Minor to the non-conformance.

One of the drivers for Major non-conformance will be systemic failure.

The Task Group requested that data be collected for the October meeting showing what effect these changes have made to the number of Major NCRs issued per audit. The data will be collected prior to the change, and after the change.

ACTION ITEM: Staff Engineer to collect data for the October meeting showing what effect the changes to Major and Minor non-conformance grading have made. The data will be collected prior to the change, and after the change. (DUE DATE: 31-OCT-2011)

9.0 ALWAYS QUESTION DEBRIEF – SUB-TEAM REPORT OUT – CLOSED

The Task Group had determined the ten checklist questions that should always be answered during an audit. A sub-team carried out a review of the last years audit data to see if a non- conformance was found on these questions during the following audit and if so, was this a problem with the Auditor not addressing this question or for other reasons. This data could then be used at the Auditor Conference and for Auditor consistency.

The Sub-team reported its analysis of the data and found that in most cases the non-conformance was raised due to a job audit finding, or when the procedure was not fully complete. Only in very few cases was it for a procedure not being there at all.

It was agreed that this was not an obvious audit consistency tool, but it was felt that further collection and review of data was required. A new Sub-team was created which would review the next set of data for the October meeting. At that time it will be decided if the Task Group should continue with the collection of data.

ACTION ITEM: Sub-team (Tom Murphy, Greg Wryk, Martin Day, Sunder Rajan) to analyze the always question data and present the findings at October meeting. (DUE DATE: 31-OCT-2011)

10.0 SUBSCRIBER PARTICIPATION - CLOSED

Balloting activity data was presented to the Task Group. The data showed that some Subscriber Voting Members and Supplier Voting Members have not attended meetings or voted on ballots during the last year which contradicts NTGOP-001 procedure.

A review of voting member activity against NTGOP-001 requirements was carried out and the Task Group’s decision was to continue to maintain all the voting members at this time. The Chairman will contact those members not meeting the procedural requirements.

ACTION ITEM: Task Group Chair to contact voting members not meeting NTGOP-001 procedural requirements. (DUE DATE 31-OCT-2011)

6 HEAT TREATING JUNE 2011

11.0 SUCCESSION PLANNING - CLOSED

The Heat Treat Task Group does not have any defined terms for the Task Group Chair and Vice Chair. In anticipation of the impending change of Chair in February 2012, a Sub-team was created to propose a definition for the length of the Heat Treating Task Group Chairperson’s term.

Proposal: - NTGOP-001, Appendix III, Para 3.1:

The initial term of the Task Group Chairperson shall be three years. Extension of one year to the initial term shall require affirmation of a simple majority of the Task Group Subscribing members with no limits to the number of extensions thereafter.

This was agreed by the Task Group

ACTION ITEM: Staff Engineer to ballot NTGOP-001, Appendix III. (DUE DATE: 31-OCT-11)

12.0 AUDITOR CONFERENCE – SUB-TEAM REPORT OUT – CLOSED

The Sub-team presented the plan and agenda for the Heating Treat Auditor Conference which will be held in October 2011. The plan was accepted by the Task Group.

An additional agenda item proposed was training the new Auditors in Torch Brazing. The Welding Task Group has committed to presenting this training. Upon discussion it was felt that there is insufficient time in the agenda to complete this training and it has been asked if this training could be presented by Web-ex outside of the October training.

Staff Engineer to review if this training could be completed outside of the October Auditor Conference.

All Task Group members preparing presentations for the October Auditor Conference are to send their presentation to Staff Engineer by 15th September 2011.

ACTION ITEM: Presentations for the October Auditor Conference are to be sent to Staff Engineer. (DUE DATE: 15-SEPT-11)

ACTION ITEM: Staff Engineer to discuss with the Welding Task Group if torch brazing can be presented by Web-ex. (DUE DATE 1-SEPT-11)

13.0 HEAT TREAT CHAT GROUP - CLOSED

The Task Group was updated on the Heat Treat Chat Groups usage. The Chat Group is open to Auditors and Subscribing member’s use.

It is recommended that all Heat Treat Task Group Subscriber members and Auditors join the Chat Group.

14.0 CHECKLIST VISION – CLOSED

NMC representatives gave a presentation on Checklist Vision and updated the Task Group on what other Task Groups are doing, and how they have approached reviewing their checklists against the Vision.

The Heat Treating Task Group does not believe that the Heat Treating checklist has been written to add requirements above specification requirements. The Heat Treating Task Group highlighted the very good relationship it has with the AMEC committee who writes the AMS specifications. 7 It was agreed that a Sub-team would be created to review the checklists against the Vision requirements and report back their findings at the October meeting.

ACTION ITEN: Sub-team of Jeff Thyssen, Doug Matson, Tom Murphy, Mitch Nelson, Mark Emerson, Greg Wryk to review checklists against the Vision requirements. (DUE DATE 31-OCT-11)

15.0 AUDIT HANDBOOK REVIEW – CLOSED

No changes planned.

16.0 PROCESS CONTROL SYSTEM – CLOSED

The Process Control System is now being audited during Supplier audits and there is still some confusion amongst the Auditor base as to what is required. It was agreed that further training would be given at the Auditor Conference.

17.0 AUDITOR CONSISTENCY - CLOSED

Doug Matson gave a debrief on what the NMC Sub-team is doing with regards to monitoring and improving Auditor consistency.

One of the actions is to test the Auditors on their Heat Treating knowledge and use this data to improve Auditor training. Heat Treating has written 60 Heat Treating questions and plans to test all Auditors at the October conference.

The Sub-team has also highlighted nine different types of metrics that can be used to monitor Auditor consistency. It is planned that Task Groups will select from these to monitor Auditor consistency within their Task Group. The NMC Sub-team will provide further information.

18.00 +/-5 NCRs - CLOSED

SE provided data on audits where there had been +/- 5 NCR swing between audits. This information is provided to allow ‘weak’ Auditors to be highlighted, allowing the Task Group to follow up with these Auditors.

ACTION ITEM: Staff Engineer to send the list of +/- 5 NCR audits to the Task Group(DUE DATE 1-SEPT- 11)

19.0 AVERAGE NCR VARIATION FOR AUDITORS - CLOSE

Doug Matson presented the data of average number of NCRs found per Auditor which highlights Auditors who are not finding, on average, many NCRs. The Auditors performance will be monitored to see if further training is needed.

8 HEAT TREATING JUNE 2011

20.0 APPEALS ANALYSIS – CLOSED

Marcel Cuperman gave a presentation showing the number of Supplier appeals between May 2010 and May 2011.

It was noted that there were 6 appeals in 2010 and 5 appeals in 2011.

The Task Group asked for the following information:

Reasons for appeals How many of the appeals were successful.

ACTION ITEM: Staff Engineer to provide data on appeals. (DUE DATE 31-OCT-11)

21.0 AUDIT ALLOCATIONS – CLOSED

Audit reviews were allocated to the Subscribers

22.0 OPENING COMMENTS, APPROVAL OF FEBRUARY 2011 MINUTES – OPEN

The Nadcap Heat Treating minutes were read in the open meeting and approved as read.

23.0 CLOSED MEETING DEBRIEF – OPEN

The Heat Treat Chairman debriefed the closed meeting discussions to the Suppliers in the open meeting.

24.0 NMC METRICS - OPEN

The NMC metrics for the Heat Treating Task Group were presented. The NMC metrics show that the Heat Treating metrics are green.

25.0 SUPPLIERS PARTICIPATION - OPEN

Balloting activity data was presented to the Task Group. The data showed that some Subscriber Voting Members and Supplier Voting Members have not attended meetings or voted on ballots during the last year which contradicts NTGOP-001 procedure.

It was agreed that a review of the voting members would take place at the next Nadcap meeting and decisions made as to their continued voting status.

26.0 AMEC COMMITTEE DEBRIEF – OPEN

Doug Matson gave a summary of the topic being worked on by the AMEC committee. For additional information, please refer to the AMEC web site at:

http://www.sae.org/servlets/works/committeeHome.do?comtID=TEAAMSAMEC

9 27.0 HT-STSTG REPORT OUT – OPEN

Joanna Lisa debriefed the discussion held by the Suppliers during the HTSTSTG meeting.

The Suppliers would like the Subscribers to help with the definitions of start of soak and end of soak. The Task Group did not accept this action as there is too much variation between Subscribers. Each Supplier will need to understand their customer’s needs.

The HTSTSTG had been asked by the Task Group to complete the work on the Top 5 Heat Treating checklist questions where non-conformances are found, and to create guidance for these questions.

The HTSTSTG present the guidance raised for these questions, and it was in the format of Question, Intent, Objective Evidence, and Common Non-Compliance issues.

It was agreed that the Task Group Sub-team would now review these questions and put them into a standard format. The HTSTSG was thanked for their work..

ACTION ITEM: Task Group Sub-team (Jeff Thyssen, Tom Murphy, Mitch Nelson, Mark Emerson) to review Top questions from the HTSTSTG, send for comments then publish on www.eAuditNet.com. (DUE DATE: 31-OCT-11)

28.0 AC7102/7 – INDUCTION HEAT TREATMENT- OPEN

A checklist for Induction Heating and Tempering based on AMS2745A was presented to the Task Group to review. After discussion it was agreed that the Task Group would be polled as to if this checklist is needed.

It was agreed that the Staff Engineer would provide a copy of the checklist to the Task Group to gauge the interest in making this a Heat Treating Task Group checklist.

ACTION ITEM: Staff Engineer to send a copy of the draft checklist for Induction Heating and Tempering to the Task Group for comment. (DUE DATE 31-OCT-11)

29.0 AC7102/5 CHECKLIST SUB-TEAM REPORT OUT - OPEN

Mitch Nelson reported that no progress has been made on updating this checklist, but a revision will be presented at the October meeting.

30.0 NTGOP-001, Appendix III, COMMENTS – OPEN

The ballot comments were reviewed, and it was agreed that further modifications were required. The NTGOP-001, Appendix III will be re-balloted.

ACTION ITEM: Staff Engineer to re-ballot NTGOP-001, Appendix III. (DUE DATE 1-SEPT-11)

31.0 QML DISCLAIMER - OPEN

The Task Group requested that the Staff Engineers review the wording of the disclaimer given in the Supplier audit scope on the On-Line QML to ensure that it is clear what the Nadcap approval has been given for.

The disclaimer was reviewed with the Chemical Processing Staff Engineer and it is believed that the wording is clear. After further discussion within the Task Group it was agreed that PRI would have the disclaimer statement reviewed by PRI legal, and get their input on the wording.

10 HEAT TREATING JUNE 2011

ACTION ITEM: Staff Engineer to have a disclaimer statement reviewed by legal and bring the revised wording to the October meeting. (DUE DATE 31-OCT-11)

32.0 SSC REPORT – OPEN

Johanna Lisa reported on the SSC meeting, which was well attended, and covered the following items.

Supplier Mentoring Metrics Supplier Survey Communication Education Activities New Supplier Initiatives SSC Meetings Flow Down issues

The flow down issue topic led to an open discussion on the possibility of establishing links to gain access to specifications for Suppliers several tiers down, who do not typically have direct access to customer specifications.

33.0 AQS LIAISON REPORT – OPEN

No report was provided

34.0 VOC SURVEY – OPEN

Mitch Nelson presented the Voice of the Customer Survey results.

Please refer to eAuditNet for the presentation

Key topics from the presentation were as follows

The perception of the intent for Nadcap to reduce the number of Prime audits has not been realized The mitigation of risk has been realized It does not appear the Heat Treating Task Group is getting the full intent of the audit from the checklists. Overall there is a sense of satisfaction with the Nadcap process

Open discussion topics from the presentation are as follows

What was discussed in Barcelona was not fully seen in this survey as it only focused on the checklists. The checklist is used to determine how the audit is performed by some while others use it as a guidance tool or complete it just because it is required. Auditors do not have access to all specifications prior to the audit causing other time issues as well as forcing the focus of the audit on specifications the Auditor is already familiar with.

35.0 AUDITOR ADVISORIES – OPEN 11 All the Auditor Advisories created since the beginning of the year were presented and reviewed during the open meeting.

Auditor Advisories are found on eAuditNet in Documents, Heat Treating.

36.0 AC7102/6 HIP - COMMENTS – OPEN

Ballot comments were reviewed and addressed. AC7102/6 is now in NMC ballot.

37.0 AC7102 CHECKLIST JOB AUDITS – OPEN

An open discussion was requested by the VOC Survey Team if the scope of the audit should determine the number of required job audits.

The following were the key points of the discussion.

Other commodities have job audits in the applicable non-core checklists to apply this logic The amount of variance within a non-core checklist might not make this possible How would the Heat Treat Task Group address this variation with the number of processes? A series of minimums for different scopes and number of customers was discussed. If the processes are not performed the particular minimum could be dropped.

ACTION ITEM: Sub-team (Tom Norris, Bruce Brownfield, Martin Day, Doug Matson, Marc Taillandier, Johanna Lisa, Cyril Vernault) formed to investigate the feasibility of the scope of the audit defining the required job audits. (DUE DATE: 17-OCT-11)

38.0 AC7102/3 – CARBURIZING COMMENTS – OPEN

It was agreed that one job audit is enough for all equipment in section 10.1 AC7102/3 ballot comments were reviewed and updated on the presented file.

Motion made by Jeff Thyssen & seconded by Sunder Rajan to accept one job audit per each processing method. Motion Passed

ACTION ITEM: Staff Engineer to ballot AC7102/3 to NMC. (DUE DATE: 17-OCT-11)

39.0 MEETING FEEDBACK – OPEN

Meeting feedback form was completed

40.0 PLANNING AND OPS DEBRIEF

Doug Matson debrief the Task Group on the Planning and Ops meeting. The following were the main points covered. Nadcap are introducing electronic ballots. Checklist on demand sub-team gave a debrief; full scope of project not yet defined, the name of Sub-team will change. Prime identification in e-Auditnet was proposed by J Satchwell Chemical Processing. This is to record all Subscribers the Suppliers work for.

41.0 OCTOBER 2011 AGENDA – CLOSED The Heat Treat Task Group discussed and created the agenda for the October meeting.

42.0 MERIT – MAXIMUM NCRS FOR 18 MONTHS – CLOSED 12 HEAT TREATING JUNE 2011

At the February 2011 Nadcap meeting NMC Standardization chartered a sub-team to assess the effect of introducing a limit on the number of NCRs in order for 18 month merit to be granted. It was noted that the standardization team had chosen 50% of the NOP 011 failure thresholds on total NCRs. Applying the same percentage on the major NCR limit was found to be problematic for those commodities having low NCR failure thresholds and hence to maintain standardization across all commodities a 60 % of Major NCRs was recommended.

43.0 PYROMETRY AS A SEPARATE SLASH SHEET – CLOSED

A proposal was made to separate the Pyrometry questions out of the AC7102 checklist. The advantages to doing this would be to aid sub-contract service providers, and also allow its use by other Task Groups who use Heat Treatment as part of their process.

Before the Task Group make any changes, it was agreed that the Staff Engineer would ask the other Task Groups if they would find this useful.

A Sub-Team was also set up to evaluate the need for having separate checklists for Pyrometry, Steels and titanium.

ACTION ITEM: Sub-Team of Mitch Nelson, Sunder Rajan, Dave Damasaukas, and Andy Hopkins, to evaluate the need for having separate checklists for Pyrometry, Steels and titanium. (DUE DATE: 17-OCT- 11)

ACTION ITEM: Staff Engineer to review will other Task Groups if having a separated Pyrometry Checklist would be useful (DUE DATE: 17-OCT-11)

44.0 NEW BUSINESS – CLOSED

DEVIATION

NUCAP deviation 000016, review not completed as the Task Group needs to know who raised the deviation.

ACTION ITEM: Staff Engineer supply who raised deviation 000016, (DUE DATE: 17-OCT-11)

NEW TECHNOLOGY

Nadcap have canvassed all Nadcap Suppliers and Subscribing Primes, to get feedback on New Technology proposals. The Task Group reviewed the feedback, and made decisions on these as to if further actions are needed.

45.0 RAIL / ACTIONS REVIEW – CLOSED

See RAIL posted on www.eAuditNet.com/Documents/Heat Treat.

ADJOURNMENT – (23rd June 11) – Meeting was adjourned at 2:00 p.m.

Minutes Prepared by: Jerry Aston - [email protected] Rob Hoeth – [email protected]

See RAIL posted on www.eAuditNet.com/Documents/Heat Treat.

13 ***** For PRI Staff use only: ******

Are procedural/form changes required based on changes/actions approved during this meeting? (select one)

YES* NO

*If yes, the following information is required:

Documents requiring Who is responsible: Due date: revision:

14