惠 民 製 藥 股 份 有 限 公 司 WEI MING PHARMACEUTICAL MFG. CO., LTD. CYCLOCEL® Microcrystalline Cellulose

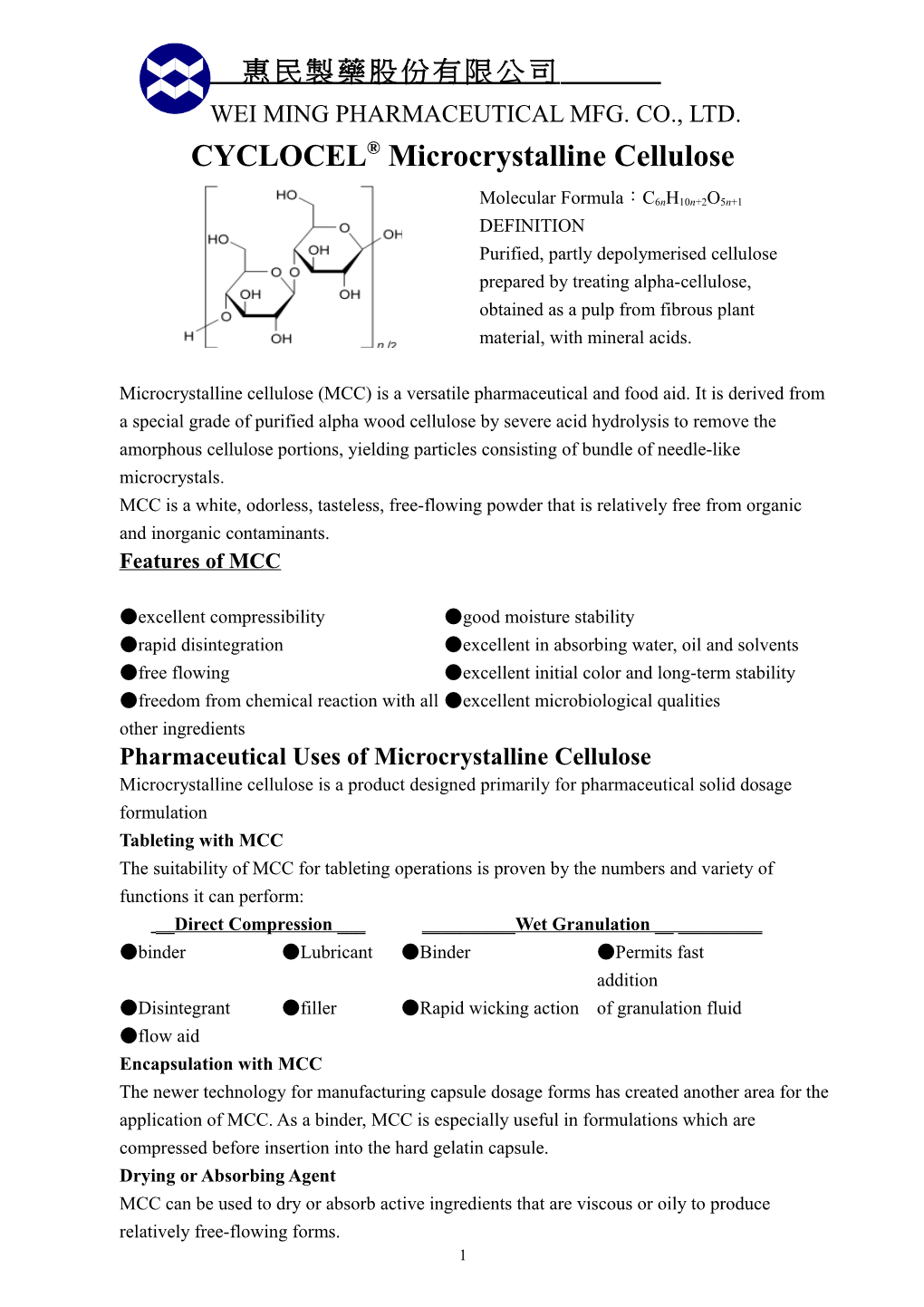

Molecular Formula:C6nH10n+2O5n+1 DEFINITION Purified, partly depolymerised cellulose prepared by treating alpha-cellulose, obtained as a pulp from fibrous plant material, with mineral acids.

Microcrystalline cellulose (MCC) is a versatile pharmaceutical and food aid. It is derived from a special grade of purified alpha wood cellulose by severe acid hydrolysis to remove the amorphous cellulose portions, yielding particles consisting of bundle of needle-like microcrystals. MCC is a white, odorless, tasteless, free-flowing powder that is relatively free from organic and inorganic contaminants. Features of MCC

●excellent compressibility ●good moisture stability ●rapid disintegration ●excellent in absorbing water, oil and solvents ●free flowing ●excellent initial color and long-term stability ●freedom from chemical reaction with all ●excellent microbiological qualities other ingredients Pharmaceutical Uses of Microcrystalline Cellulose Microcrystalline cellulose is a product designed primarily for pharmaceutical solid dosage formulation Tableting with MCC The suitability of MCC for tableting operations is proven by the numbers and variety of functions it can perform: __Direct Compression ______Wet Granulation ______●binder ●Lubricant ●Binder ●Permits fast addition ●Disintegrant ●filler ●Rapid wicking action of granulation fluid ●flow aid Encapsulation with MCC The newer technology for manufacturing capsule dosage forms has created another area for the application of MCC. As a binder, MCC is especially useful in formulations which are compressed before insertion into the hard gelatin capsule. Drying or Absorbing Agent MCC can be used to dry or absorb active ingredients that are viscous or oily to produce relatively free-flowing forms. 1 惠 民 製 藥 股 份 有 限 公 司 WEI MING PHARMACEUTICAL MFG. CO., LTD.

Tableting Uses of Microcrystalline Cellulose

IN DIRECT COMPRESSION Microcrystalline cellulose can be used in all methods of tableting, it is most effectively used in direct compression.

Performance of MCC in direct compression: Dry Binder High hardness level, low friability, excellent compression Disintegrant Promotes rapid disintegration and dissolution. Co-lubricant Aid to dry lubrication Free Flowing Efficient dry blending of ingredients, enable direct compression of many formulations Whiteness Tablets of superior whiteness and color stability.

The amount of MCC used in direct compression tableting depends on the flow and compression characteristics of the other formulation’s ingredients. Normally, about 20 percent of the formulation is MCC, but the range is from 10 to 50 percent.

IN WET GRANULATION

MCC often added to both the dried granulation before compression and to the wet mass. MCC is used by the amount of 10~30% of the formulations.

IN SLUGGING METHOD

Generally, 20 percent or less of MCC is used. It is normally added into dried granulation before compression, but in some formulation it is beneficial to add a small percentage.

REMARK: The information contained in this bulletin is correct to the best of our knowledge. The recommendations or suggestions herein are made without guarantee or representation as to result, since the conditions of use are beyond our control. We suggest that you evaluate the recommendations contained in this bulletin in your own laboratory prior to use. No statement is to be construed as violating any copyright or patent. They are intended only as a source of information.

2 惠民製藥股份有限公司 WEI MING PHARMACEUTICAL MFG. CO., LTD.

Grades of Microcrystalline Cellulose

ALL GRADES of MCC have good compressibility and disintegration. The detailed application as below: 101 – standard grade and most widely used, especially for wet granulation. 102 – better flowability than 101, good for direct compression. 200 – bigger particle size than 102, better flowability than 102, good for direct compression. 301 – same particle size as 101, but better flowability and higher bulk density. 302 – same particle size as 102, but better flowability and higher bulk density. 112 – same particle size as 102, but less moisture, suited for tableting of water sensitive ingredients. L-101 – very low bulk density, super compactible dry binder, excellent loading capacity. 100H – suit for Chinese herbal medicine manufacture, absorb the extraction of herbal. 105 – smaller particle size, carrier for herbal extracts, very good absorption of oily substance.

Average Particle Particle Size Bulk Density Grade Size (μm) Specification (g/ml) ______101 50μm + 60 mesh ≦1.0% 0.26~0.31 + 200 mesh≦30.0% 102 90μm + 60 mesh ≦8.0% 0.28~0.33 + 200 mesh≧45.0% 200 180μm +60 mesh≧ 10.0% 0.29~0.36 +100mesh≧ 50.0% 301 50μm + 60 mesh ≦1.0% 0.34~0.45 + 200 mesh≦30.0% 302 90μm + 60 mesh ≦8.0% 0.35~0.46 + 200 mesh≧45.0% L-101 50μm + 60 mesh ≦0.5% 0.13~0.23 + 100 mesh≦5.0% +200 mesh 5-30% 100H 50μm +200 mesh≦ 20.0% 0.26~0.40 105 25μm + 400 mesh≦1.0% 0.20~0.30 112 90μm + 60 mesh ≦8.0% 0.28~0.40 + 200 mesh≧45.0%

3