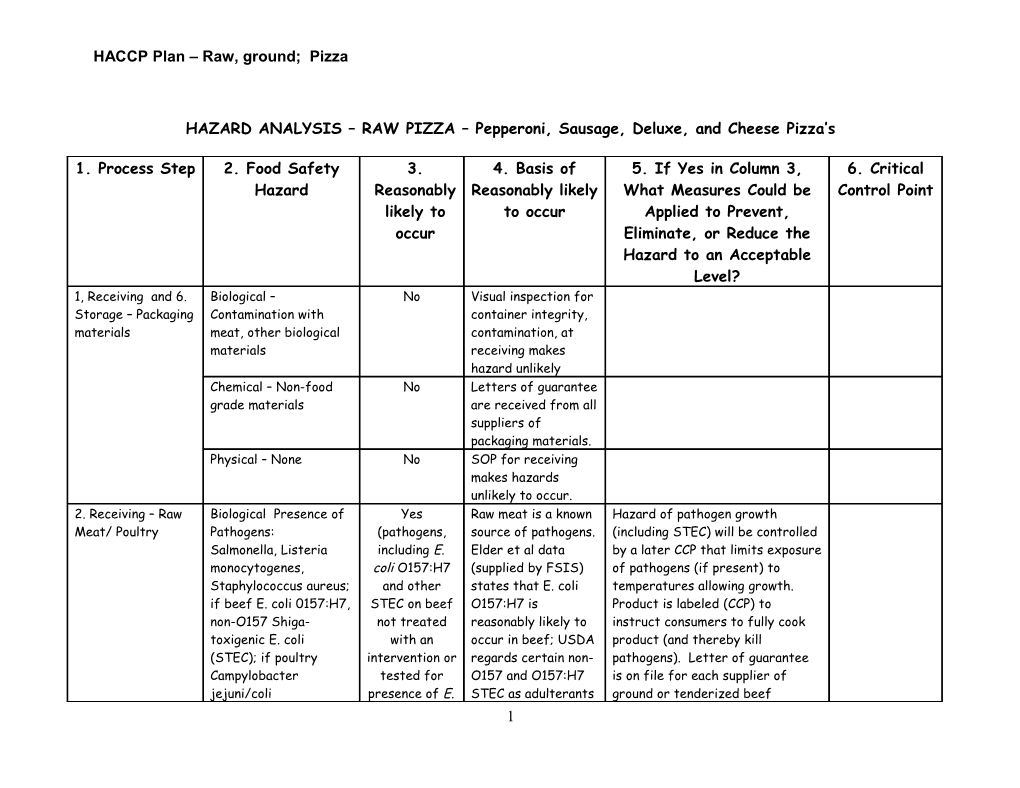

HACCP Plan – Raw, ground; Pizza

HAZARD ANALYSIS – RAW PIZZA – Pepperoni, Sausage, Deluxe, and Cheese Pizza’s

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical Hazard Reasonably Reasonably likely What Measures Could be Control Point likely to to occur Applied to Prevent, occur Eliminate, or Reduce the Hazard to an Acceptable Level? 1, Receiving and 6. Biological – No Visual inspection for Storage – Packaging Contamination with container integrity, materials meat, other biological contamination, at materials receiving makes hazard unlikely Chemical – Non-food No Letters of guarantee grade materials are received from all suppliers of packaging materials. Physical – None No SOP for receiving makes hazards unlikely to occur. 2. Receiving – Raw Biological Presence of Yes Raw meat is a known Hazard of pathogen growth Meat/ Poultry Pathogens: (pathogens, source of pathogens. (including STEC) will be controlled Salmonella, Listeria including E. Elder et al data by a later CCP that limits exposure monocytogenes, coli O157:H7 (supplied by FSIS) of pathogens (if present) to Staphylococcus aureus; and other states that E. coli temperatures allowing growth. if beef E. coli 0157:H7, STEC on beef O157:H7 is Product is labeled (CCP) to non-O157 Shiga- not treated reasonably likely to instruct consumers to fully cook toxigenic E. coli with an occur in beef; USDA product (and thereby kill (STEC); if poultry intervention or regards certain non- pathogens). Letter of guarantee Campylobacter tested for O157 and O157:H7 is on file for each supplier of jejuni/coli presence of E. STEC as adulterants ground or tenderized beef 1 HACCP Plan – Raw, ground; Pizza

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical Hazard Reasonably Reasonably likely What Measures Could be Control Point likely to to occur Applied to Prevent, occur Eliminate, or Reduce the Hazard to an Acceptable Level? coli O157:H7 in on-intact beef. documenting the application of at or other Adoption of least one intervention step against STEC.) intervention E. coli O157:H7 and other STEC. treatments and/or Alternately, supplier of beef has product testing by provided certificate of analysis suppliers prevents indicating that E. coli O157:H7 (or hazard of STEC STEC) were not detected by from occurring. testing of the shipped lot of beef. USDA has advised that interventions shown to be effective against E. coli O157:H7 are also considered effective against STEC. Chemical – None No SOP for Receiving and Storage makes hazards unlikely. Physical – None No SOP for Receiving and Storage makes hazards unlikely. 2a. Receiving –RTE Biological: No Letters of guarantee Meat/ Poultry Listeria indicating that each monocytogenes, product made by an 2 HACCP Plan – Raw, ground; Pizza

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical Hazard Reasonably Reasonably likely What Measures Could be Control Point likely to to occur Applied to Prevent, occur Eliminate, or Reduce the Hazard to an Acceptable Level? Staphylococcus aureus approved processor. (post-lethality Receiving SOP contaminants); minimizes risk of Clostridium perfringens accepting product and Clostridium that has been botulinum (spore- mishandled such that forming pathogens that spore-forming survive cooking) pathogens could germinate and grow. Chemical – None No SOP for Receiving and Storage makes hazards unlikely. Physical – None No SOP for Receiving and Storage makes hazards unlikely. 3. Receiving – Non- Biological: Pathogens No Letters of meat and Non- Salmonella, E. coli (Cheese, Guarantee are poultry Ingredients: 0157:H7, Listeria Crust, Sauce, received from all Crust, Cheese, monocytogenes, Spice) suppliers of food Vegetables, Sauce, Staphylococcus aureus, ingredients that Spice. Clostridium indicate the perfringens, ingredients are from Clostridium botulinum an approved source. Receiving SOP ensures that 3 HACCP Plan – Raw, ground; Pizza

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical Hazard Reasonably Reasonably likely What Measures Could be Control Point likely to to occur Applied to Prevent, occur Eliminate, or Reduce the Hazard to an Acceptable Level? ingredients are not accepted if they have been improperly handled. Yes Vegetables are stored separately (Vegetables) from other food components and washed prior to further processing. Hazard will be controlled by a later CCP that limits exposure of pathogens (if present) to temperatures allowing growth. Product is labeled (CCP) to instruct consumers to fully cook product (and thereby kill pathogens). Chemical – Ingredients No Approved not being added or formulations are used as intended. followed; letters of Ingredients containing guarantee are undesirable substances received from all suppliers of food additives, crust, sauce, cheese etc.. Physical – None No SOP for Receiving and Storage makes 4 HACCP Plan – Raw, ground; Pizza

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical Hazard Reasonably Reasonably likely What Measures Could be Control Point likely to to occur Applied to Prevent, occur Eliminate, or Reduce the Hazard to an Acceptable Level? hazards unlikely. 4. Storage (Cold – Biological: Presence or Yes (Presence) Raw meat is a known Hazard will be controlled by a Frozen/Refrigerate growth of pathogens source of pathogens. later CCP that limits exposure of d) – Raw (see list above) No Pathogens are pathogens (if present) to Meat/Poultry (Growth) unlikely to grow if temperatures allowing growth. raw meats are Product is labeled (CCP) to stored according to instruct consumers to fully cook the SOP for storage. product (and thereby kill pathogens). Chemical - None No SOP for Receiving and Storage makes hazards unlikely. Physical – None No SOP for Receiving and Storage makes hazards unlikely. 4a. Storage (Cold – Biological: Pathogens No Pathogens are Frozen/Refrigerate Listeria unlikely to grow if d) – RTE monocytogenes, the product is Meat/Poultry Staphylococcus aureus, maintained at proper Clostridium temperature (SOP perfringens, for storage). Clostridium botulinum Chemical – None No SOP for Receiving and Storage makes hazards unlikely. 5 HACCP Plan – Raw, ground; Pizza

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical Hazard Reasonably Reasonably likely What Measures Could be Control Point likely to to occur Applied to Prevent, occur Eliminate, or Reduce the Hazard to an Acceptable Level? Physical – None No SOP for Receiving and Storage makes hazards unlikely. 5. Storage – Food Biological - None No SOP for Receiving Ingredients, both and Storage makes refrigerated and hazards unlikely. non-refrigerated Chemical – None No SOP for Receiving and Storage makes hazards unlikely. Physical – None No SOP for Receiving and Storage makes hazards unlikely. 7. Tempering Biological – Presence or Yes Raw meat is a known Hazard will be controlled by a Frozen growth of pathogens (Presence) source of pathogens. later CCP that limits exposure of Meat/Poultry (see list above) No Tempering done pathogens (if present) to Ingredients (Growth) under conditions not temperatures allowing growth. conducive to growth. Product is labeled (CCP) to instruct consumers to fully cook product (and thereby kill pathogens). Chemical – None No SSOP makes hazard unlikely Physical - None No SSOP makes hazard unlikely 8. Make Sauce for Biological - None No SSOP makes hazard 6 HACCP Plan – Raw, ground; Pizza

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical Hazard Reasonably Reasonably likely What Measures Could be Control Point likely to to occur Applied to Prevent, occur Eliminate, or Reduce the Hazard to an Acceptable Level? Pizzas unlikely; step is of short duration (pathogen growth is unlikely) Chemical – None No SSOP makes hazards unlikely. Physical - None No SSOP makes hazards unlikely. 9. Grind Cheese Biological – Pathogen No SSOP makes contamination via contamination via equipment and workers equipment and workers unlikely to occur. Chemical – Cheese is a No Application of potential allergen; correct label cleaning/sanitizing prevents inadvertent chemical residues consumption of allergen by consumer. Operational SSOP prevents cross- contamination of allergenic agents. Pre-op SSOP makes presence of chemical 7 HACCP Plan – Raw, ground; Pizza

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical Hazard Reasonably Reasonably likely What Measures Could be Control Point likely to to occur Applied to Prevent, occur Eliminate, or Reduce the Hazard to an Acceptable Level? residues unlikely to occur. Physical – Foreign No No history of materials problem. Visual observation for foreign materials during processing, inspection of equipment during cleaning make hazard unlikely. 10. Wash & Cut Biological - Pathogen No SSOP makes Vegetables contamination via (Contamina- contamination via equipment and workers. tion) equipment and workers unlikely to occur. Presence of pathogens Yes (Presence) Hazard will be controlled by a later CCP that limits exposure of pathogens (if present) to temperatures allowing growth. Product is labeled (CCP) to instruct consumers to fully cook product (and thereby kill pathogens). Chemical – None No SSOP makes hazard 8 HACCP Plan – Raw, ground; Pizza

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical Hazard Reasonably Reasonably likely What Measures Could be Control Point likely to to occur Applied to Prevent, occur Eliminate, or Reduce the Hazard to an Acceptable Level? unlikely. Physical – Foreign No No history of material problem. Visual observation for foreign materials during processing, inspection of equipment during cleaning make hazard unlikely. 11. Portioning Food Biological – Presence Yes Raw meat is a known Hazard will be controlled by Ingredients or growth of pathogens (Presence) source of pathogens. limiting exposure of pathogens (if (see list above); Yes Pathogens are present) to temperatures allowing Pathogen contamination (Growth) reasonably likely to growth during the portioning, via equipment and grow if temperature assembly, and packaging/labeling workers and time of exposure (CCP) steps. Product is labeled to unsafe (CCP) to instruct consumers to temperatures are fully cook product (and thereby not controlled. kill pathogens). No SSOP makes (Contamina- contamination via tion) equipment and workers unlikely to occur. Chemical – None No SSOP makes hazards 9 HACCP Plan – Raw, ground; Pizza

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical Hazard Reasonably Reasonably likely What Measures Could be Control Point likely to to occur Applied to Prevent, occur Eliminate, or Reduce the Hazard to an Acceptable Level? unlikely. Physical – None No SSOP makes hazards unlikely. 12. Combining Biological – Presence or Yes Raw meat is a known Hazard will be controlled by by Ingredients growth of pathogens (Presence) source of pathogens. limiting exposure of pathogens (if (Assemble Pizzas) (see list above); Yes Pathogens are present) to temperatures allowing Pathogen contamination (Growth) reasonably likely to growth during the portioning, via equipment and grow if temperature assembly, and packaging/labeling workers and time of exposure (CCP) steps. Product is labeled to unsafe (CCP) to instruct consumers to temperatures are fully cook product (and thereby not controlled. kill pathogens). No SSOP makes (Contamina- contamination via tion) equipment and workers unlikely to occur. Chemical – None No SSOP makes hazards unlikely. Physical - None No SSOP makes hazards unlikely. 13. Biological – Presence or Yes Raw meat is a known Hazard will be controlled by 1B Packaging/Labeling growth of pathogens (Presence) source of pathogens. limiting exposure of pathogens (if (see list above); Yes Pathogens are present) to temperatures allowing Pathogen contamination (Growth) reasonably likely to growth during the portioning, 10 HACCP Plan – Raw, ground; Pizza

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical Hazard Reasonably Reasonably likely What Measures Could be Control Point likely to to occur Applied to Prevent, occur Eliminate, or Reduce the Hazard to an Acceptable Level? via equipment and grow if temperature assembly, and packaging/labeling workers and time of exposure steps. to unsafe Product is labeled to indicate that temperatures are it is raw, not RTE, along with not controlled. validated cooking instructions, and No SSOP makes the safe food handling statement. (Contamina- contamination via tion) equipment and workers unlikely to occur. Chemical – improperly No Labeling SOP and labeled allergens SSOP make hazard unlikely to occur. Physical - None No SSOP makes hazards unlikely. 14. Finished Product Biological – Growth of No SOP for finished Storage pathogens (see list product storage above) makes this hazard unlikely to occur. Chemical – None No Product is handled according to SOP for Finished Product Storage Physical - None No Product is handled according to SOP for 11 HACCP Plan – Raw, ground; Pizza

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical Hazard Reasonably Reasonably likely What Measures Could be Control Point likely to to occur Applied to Prevent, occur Eliminate, or Reduce the Hazard to an Acceptable Level? Finished Product Storage 15. Shipping or Biological – None No Product is handled Retail according to SOP for Finished Product Storage Chemical – None No Product is handled according to SOP for Finished Product Storage Physical - None No Product is handled according to SOP for Finished Product Storage

12