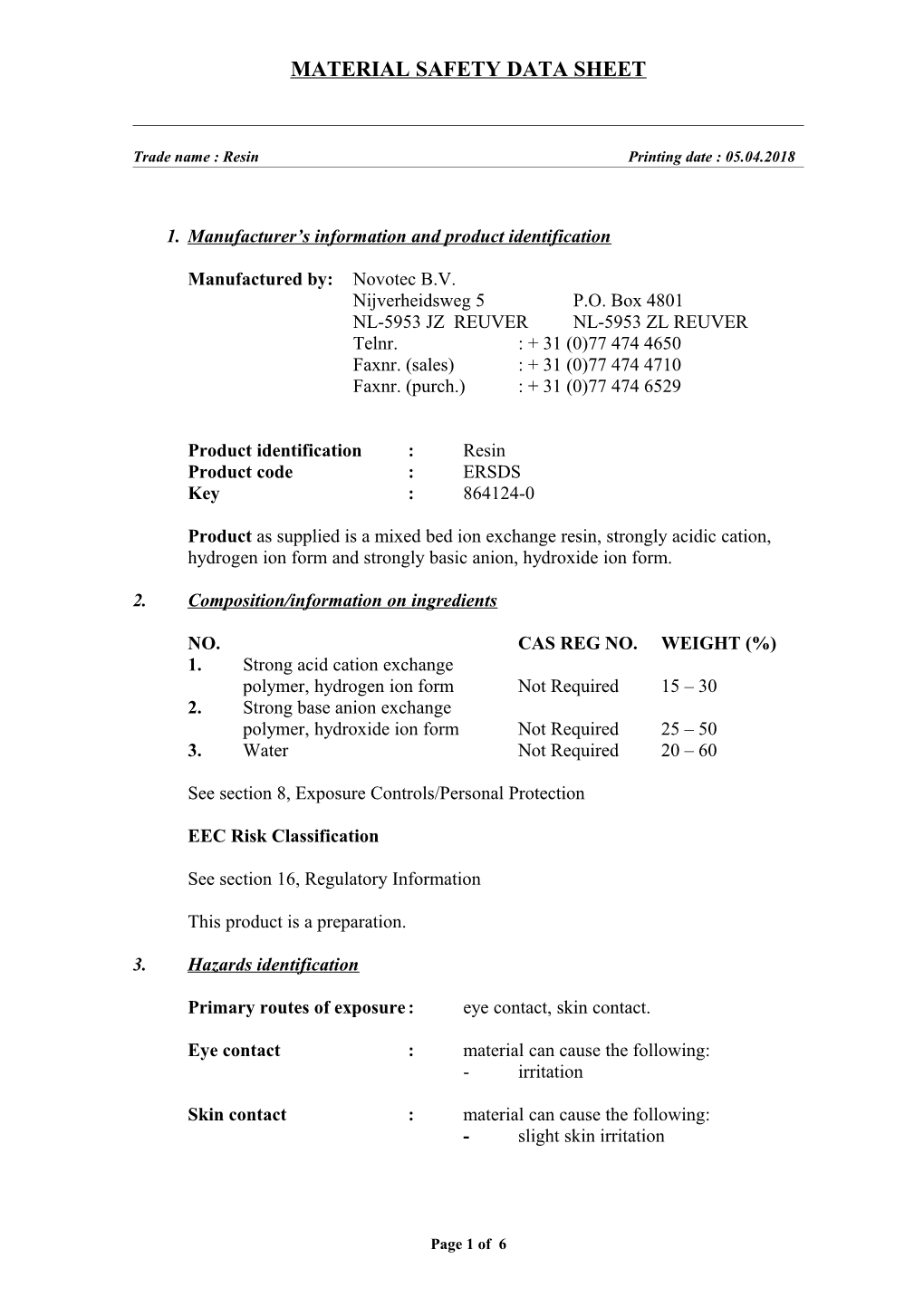

MATERIAL SAFETY DATA SHEET

Trade name : Resin Printing date : 05.04.2018

1. Manufacturer’s information and product identification

Manufactured by: Novotec B.V. Nijverheidsweg 5 P.O. Box 4801 NL-5953 JZ REUVER NL-5953 ZL REUVER Telnr. : + 31 (0)77 474 4650 Faxnr. (sales) : + 31 (0)77 474 4710 Faxnr. (purch.) : + 31 (0)77 474 6529

Product identification : Resin Product code : ERSDS Key : 864124-0

Product as supplied is a mixed bed ion exchange resin, strongly acidic cation, hydrogen ion form and strongly basic anion, hydroxide ion form.

2. Composition/information on ingredients

NO. CAS REG NO. WEIGHT (%) 1. Strong acid cation exchange polymer, hydrogen ion form Not Required 15 – 30 2. Strong base anion exchange polymer, hydroxide ion form Not Required 25 – 50 3. Water Not Required 20 – 60

See section 8, Exposure Controls/Personal Protection

EEC Risk Classification

See section 16, Regulatory Information

This product is a preparation.

3. Hazards identification

Primary routes of exposure : eye contact, skin contact.

Eye contact : material can cause the following: - irritation

Skin contact : material can cause the following: - slight skin irritation

Page 1 of 6 MATERIAL SAFETY DATA SHEET

Trade name : Resin Printing date : 05.04.2018

4. First aid measures

Eye contact : flush eyes with a large amount of water for at least 15 minutes. Consult a physician if irrititation persists.

Skin contact : wash affected skin areas thoroughly with soap and water.

5. Fire fighting measures

Flash point : not applicable. Auto-ignition temperature : 500ºC/932ºF estimate. Lower explosive limit : not applicable. Upper explosive limit : not applicable.

Unusual hazards : combustion generates toxic fumes of the following: - nitrogen oxides – sulfur oxides.

Extinguishing agents : use the following extinguishing media when fighting fires involving this material: - carbon dioxide – dry chemical – water spray.

Personal protective equipment: wear self-contained breathing apparatus (pressure demand MSHA/NIOSH approved or equivalent) and full protective gear.

6. Accidental release measures

Personal protection : wear gloves made of the following material: - butyl rubber additional personal protective equipment should include the following: - safety glasses (ANSI Z87.1 or approved equivalent).

Procedures : floor may be slippery; use care to avoid falling. Transfer spilled material to suitable containers for recovery or disposal.

7. Handling and storage

Storage conditions : the minimum recommended storage temperature for this material is 0C/32F.

Page 2 of 6 MATERIAL SAFETY DATA SHEET

Trade name : Resin Printing date : 05.04.2018

The maximum recommended storage temperature for this material is 60C/140F. Avoid repeated freeze-thaw cycles; beads may fracture.

Handling procedures : the maximum recommended operating temperature for this material is 60C/140F. Properly designed equipment is vital if these resins are to be used in conjunction with strong oxidizing agents such as nitric acid to prevent a rapid build up of pressure and possible explosion. Consult a source knowledgeable in the handling of these materials before proceeding. Do not pack column with dry ion exchange resins. Dry beads expand when wetted; this expansion can cause glass columns to shatter.

8. Exposure controls/personal protection

Exposure limit information

NO. CAS REG NO. WEIGHT (%) 1. Strong acid cation exchange polymer, hydrogen ion form Not Required 15 – 30 2. Strong base anion exchange polymer, hydroxide ion form Not Required 25 – 50 3. Water Not Required 20 – 60

NOVOTEC ACGIH MAK COMP NO. UNITS TWA STEL TWA STELL WERT KAT

1 None None None None 2 None None None None 3 None None None None

Respiratory protection : a respiratory protection program meeting OSHA 1910.134 and ANSI Z88.2 requirements must be followed whenever workplace conditions warrant a respiratory’s use. None required under normal operating conditions.

Eye protection : use safety glasses (ANSI Z87.1 or approved equivalent).

Hand protection : chemical resistant gloves should be worn whenever this material is handled.

Engineering controls : none required under normal operating (ventilation) conditions.

Page 3 of 6 MATERIAL SAFETY DATA SHEET

Trade name : Resin Printing date : 05.04.2018

Other protective equipment: facilities storing or utilizing this material should be equipped with an eyewash facility.

9. Colour

Golden

10. Physical and chemical properties

State : beads pH : 6 to 8 Aqueous slurry Viscosity : not applicable Specific gravity (water=1) : 1.05 to 1.20 g/cm3 Vapor density (air = 1) : < 1 Vapor pressure : 2266.4808 Pa @ 20ºC/68ºF water Melting point : 0ºC/32ºF water Boiling point : 100ºC/212ºF water Solubility in water : insoluble Percent volatility : 20 to 60 % water Evaporation rate (BAc = 1) : < 1

See section 5, Fire fighting measures.

11. Stability and reactivity

Instability : this material is considered stable under specified conditions of storage, shipment and/or use. See section 7, Handling and storage, for specified conditions. However, avoid temperatures above 200C/392F.

Hazardous decomposition products: thermal decomposition may yield the following: - monomer vapor - alkylamines - oxides of nitrogen - sulfur oxides.

Hazardous polymerization : product will not undergo polymerisation.

12. Toxicological information

Acute data : no toxicity data are available for this material.

13. Ecological information

no applicable data.

Page 4 of 6 MATERIAL SAFETY DATA SHEET

Trade name : Resin Printing date : 05.04.2018

14. Disposal considerations

Procedure : unused resin may be incinerated or landfilled in facilities meeting local, state and federal regulations. For contaminated resin, the user must determine the hazard and use an appropriate disposal method.

15. Transport information

Label : not regulated.

16. Regulatory information

United States : all components of this product are in compliance with the inventory listing requirements of the U.S. Toxic Substances Control Act (TSCA) Chemical Substance Inventory.

EEC : for information on latest EINECS status on this product, please contact your Novotec sales office.

EINECS information

NO. CAS REG NO. EINECS 1. Strong acid cation exchange polymer, hydrogen ion form Not Required 2. Strong base anion exchange polymer, hydroxide ion form Not Required 3. Water Not Required

Indication of danger : this product is not hazardous according to EEC Directives 67/548/EEC and 88/379/EEC.

17. Other information

NOVOTEC HAZARD RATING SCALE

Toxicity 1 4 = extreme Fire 1 3 = high Reactivity 0 2 = moderate Special - 1 = slight 0 = insignificant

Page 5 of 6 MATERIAL SAFETY DATA SHEET

Trade name : Resin Printing date : 05.04.2018

Ratings are based on Novotec guidelines, and are intended for internal use.

Abreviations

ACGIH = American Conference of Governmental Industrial Hygienistst. OSHA = Occupational Safety and Health Administration TLV = Threshold Limit Value PEL = Permissible Exposure Limit TWA = Time Weighted Average STEL = Short-Term Exposure Limit BAc = Butyl acetate

Additional information

The information contained herein relates only to the specific material indentified. Novotec B.V. believes such information is accurate and reliable as of the date of this material safety data sheet, but no representation, guarantee or warranty, expressed or implied, is made as to the accuracy, reliability, or completeness of the information. Novotec B.V. urges persons receiving this information to make their own determination as to the information’s suitability and completeness for their particular application.

Attention

This document is a Material Safety Data Sheet for European Region use only.

Page 6 of 6