Hadron Calorimeter – Introduction

The Hadron Calorimeter (HCal) is a sandwich of absorber plates with gaps instrumented with active detector elements. To satisfy the stringent imaging requirements of the PFA algorithm transverse segmentation is required to be small of order a few cm2 and each layer is read out separately. This in principle allows an analog or digital treatment of the signals.

The current baseline uses steel for the absorber and resistive plate chambers as the detector. Alternative detector possibilities, consisting of Gas Electron Multipliers (GEMs), Micromegas or scintillator are also under study. One of the design criteria for the HCal is to minimize the size of the active gap, because an increase in the gap size has a large impact on the overall detector cost. The current gap size is 12mm. The absorber consists of steel plates with a thickness of 20 mm or approximately 1.1 X0. The cell structure, which is identical for the barrel and the endcaps, is repeated 34 times, leading to an overall depth of the HCal corresponding to four interaction lengths. Tungsten has been and will also be considered as a absorber, but is currently not the baseline.

The inner radius of the HCal is 138 cm, the outer radius of the barrel is 233.7 cm and its length is 554.0 cm. The endcaps start at a distance of 179.65 cm from the interaction point. The SiD baseline design uses steel as absorber material in the HCAL. Steel with a radiation length Xo = 1.8 cm and an interaction λI = 16.8 cm offers the smallest X0/λI of all commonly used absorber materials. A small ratio permits a one radiation sampling, while keeping the number of active layers manageable for a hadron calorimeter with a depth equivalent to four interaction lengths at 90o to the beam pipe.

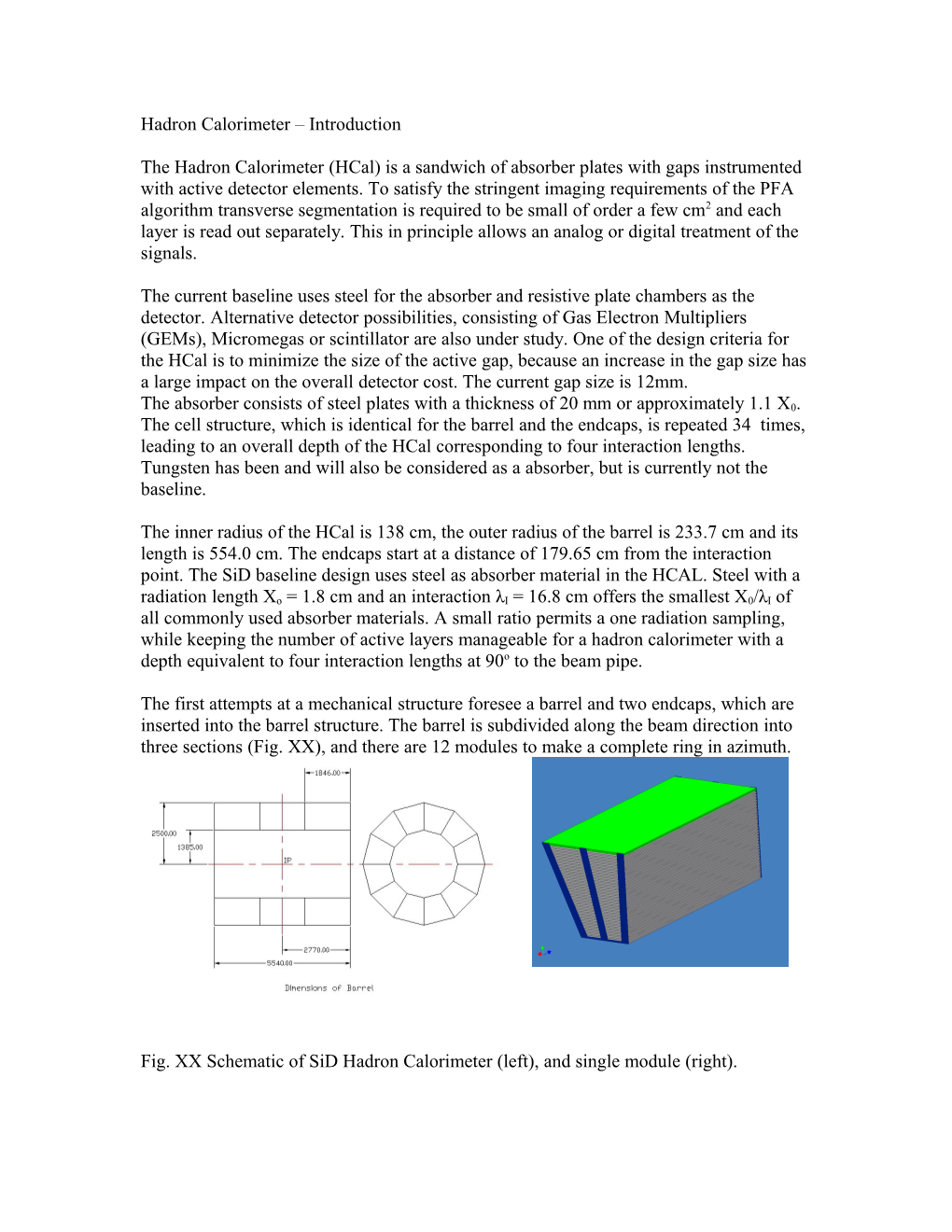

The first attempts at a mechanical structure foresee a barrel and two endcaps, which are inserted into the barrel structure. The barrel is subdivided along the beam direction into three sections (Fig. XX), and there are 12 modules to make a complete ring in azimuth.

Fig. XX Schematic of SiD Hadron Calorimeter (left), and single module (right). The steel plates are held in place by a set of picture frames located at each end (Fig. XX). Readout cables, high voltage cables and the gas lines are routed to the outer radius of the barrel structure through the openings in the picture frames. In azimuth the barrel structure is subdivided into twelve modules. Each module weighs approximately ten tons and will be held in place through supports in the cryostat of the solenoid. Deflections have been calculated and do not exceed 0.5 mm at any point of the structure.

Prototyping and testing of active gap technology options has been ongoing for several years. The basic characteristics and initial viability of each option have been established through a series of cosmic ray and beam tests. For the gas-based technologies the next stage will involve a “slice test” of a number of RPC and GEM chambers with absorber layers. The scintillator based medium has been validated with test beam studies and focus has moved to production issues. Beyond this we plan to build one or more ILC prototypes of approximately 1m3 size to contain hadron showers, and read out using these technologies. This scale of testing, involving up to 400,000 channels is presently limited by funding in the US.

We have defined a set of criteria and requirements for the selection of the final active medium. We have established a time schedule for the convergence of the hardware tests and the PFA results. We anticipate making a selection on the timescale of the SiD CDR – around middle to late 2008.