ECE 477 Digital Systems Senior Design Project Rev 8/09

Homework 4: Packaging Specifications and Design

Team Code Name: Inebriation Station______Group No. _1_____ Team Member Completing This Homework: _Dan Carlo Mesina______E-mail Address of Team Member: dmesina__ @ purdue.edu

NOTE: This is the first in a series of four “design component” homework assignments, each of which is to be completed by one team member. The body of the report should be 3-5 pages, not including this cover page, references, attachments or appendices.

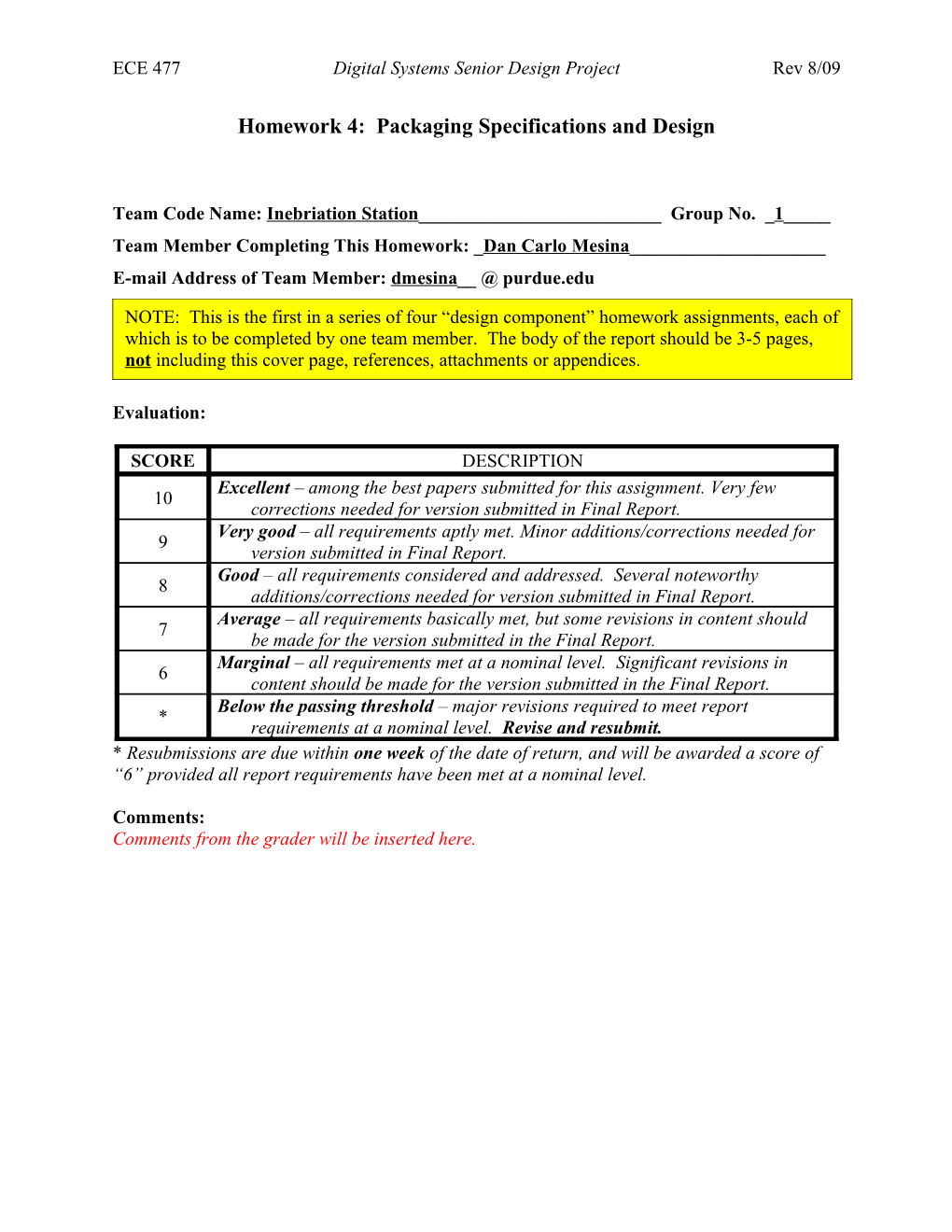

Evaluation:

SCORE DESCRIPTION Excellent – among the best papers submitted for this assignment. Very few 10 corrections needed for version submitted in Final Report. Very good – all requirements aptly met. Minor additions/corrections needed for 9 version submitted in Final Report. Good – all requirements considered and addressed. Several noteworthy 8 additions/corrections needed for version submitted in Final Report. Average – all requirements basically met, but some revisions in content should 7 be made for the version submitted in the Final Report. Marginal – all requirements met at a nominal level. Significant revisions in 6 content should be made for the version submitted in the Final Report. Below the passing threshold – major revisions required to meet report * requirements at a nominal level. Revise and resubmit. * Resubmissions are due within one week of the date of return, and will be awarded a score of “6” provided all report requirements have been met at a nominal level.

Comments: Comments from the grader will be inserted here. ECE 477 Digital Systems Senior Design Project Rev 8/09

1.0 Introduction The Inebriation Station is an automated beverage dispenser that also keeps track of the users’ account history with an RFID Reader communicating wirelessly via Wi-Fi to an onsite computer. In addition, the wireless module also transmits information about the unit (i.e. temperature and keg fill level). Our packaging is clean and simple, it will be a large unit with a single spout attached to the surface along with an LCD and keypad where the user can view their personal information, as well as make a beverage selection. 2.0 Commercial Product Packaging There are three commercial products that offer similar features that the Inebriation Station has. The three products are the “Draft Beer Counter” from Alcohol Controls [1], “TapAdvisor” from TapDynamics [2] and the “Inventory Control System” from US Beverage Net [3]. 2.1 Product #1 The Draft Beer Counter is a very small and simple device that runs on a 3V Lithium battery and is used to keep track of the amount of ounces that is dispensed from a keg. The installation is quick and easy. All that has to be done is replace the old beer tap with the Draft Beer Counter and it starts working immediately. The information on the website (AlcoholControls.com) had very limited information on the product and didn’t say how long the battery life of the product was. However, the lack of information shows that the product is very user friendly. I felt that this product was similar to the Inebriation Station because it offers the feature to inform the bartender how much alcohol is being dispensed in a given time. The only positive features to this product is that it is compact, easy to install, and is user friendly. However, the positive features are highly outweighed by the negatives, which show how obsolete this product is. For starters, the unit is powered by a battery. Since the battery is Lithium it may last a while, but there may be issues with the counter dying out in the middle of business hours without the user knowing, which throws off all the data. Another negative is that the bar attendant doesn’t have real-time information of how much is being dispensed. The counter is used to keep track of the number of ounces dispensed throughout the entire day and is then checked for the total amount after business hours. The data on the counter is then inputted to

-2- ECE 477 Digital Systems Senior Design Project Rev 8/09 a programmed excel sheet (provided by the company), which allows the user to compare the amount of ounces sold to the amount dispensed. Thus, instead of allowing the user to view the necessary information every moment on a user interface throughout the day, they can only see it at the end of the night and will have no idea what caused the data to be skewed. With the Inebriation Station, the bartender will have the capability to view real-time information on the kegerator unit, as well as be able to detect and correct any anomalies in the data right away. 2.2 Product #2

The TapAdvisor appears to be a more advanced product than the Draft Beer Counter. They have similar features except TapAdvisor provides the user with real-time data from the “TapAdvisor Web Portal”. The web portal can be accessed from any computer connected to the internet, which also includes smart phones. This gives the user much more flexibility in terms of having the ability to check on the dispensing units anytime, anywhere. The TapAdvisor is installed and setup by TapDynamics. The whole system consists of just two components: the TapAdvisor Appliance (Left) and Flow Meters. The Flow Meters are installed onto the faucets, which communicates with the TapAdvisor Appliance streaming information consisting of how much liquid is being dispensed. The TapAdvisor Appliance sends this information to TapAdvisor’s server and then views the data on the web portal on a “Daily Draught Beer Score Card”, which can only be accessed by subscription. Just like the Draft Beer Counter, it allows the user to compare the amount dispensed to the amount that has been sold. Moreover, the TapAdvisor also provides information on the temperature, line pressure and cleaning activity of the user’s inventory. The main positive for this product’s packaging is that the parts are compact and there aren’t many that need to be installed. In addition, the installation and system integration doesn’t have to be done by the consumer; it’s all done by TapDynamics. One aspect that really stands out is that the product can be implemented to any already existing dispensing unit, which makes the product more marketable. That would be a nice perk to have with the Inebriation Station, but it

-3- ECE 477 Digital Systems Senior Design Project Rev 8/09 involves having a unit that can be operated bartender free. In turn, if we were to make the Inebriation Station capable of being installed to any existing dispensing unit, there would be more parts to be installed and the integration process would be much more strenuous due to the additional features offered. Product #1 and #2 both need the bartender to serve the customers, which makes our project unique in comparison to them. From what’s documented on the website (TapDynamics.com) there aren’t any negatives to the product in terms of its’ capabilities. It provides most of the features our project does except it doesn’t automatically charge the customer for the beverage and pour a specified amount without the need of the bartender.

2.3 Product #3 US Beverage Net’s inventory control system is another monitoring system that operates similarly to the TapAdvisor. They both have Flow Meters that are connected to each of the beer lines and communicate to a unit that transmits the data to the company server. The unit that US Beverage Net uses is called the USBN bevBox and it works with the POS (Point-Of-Sale) system within the location to send real-time data to the USBN server where the user can access the information via computer or smart phone. However, there are some feature differences between this product and the TapAdvisor. USBN has a feature that allows the user to not just know the amount of draft poured vs. the amount sold, but keep track of the inventory also. The user can manage the inventory from a computer or smart phone and order more if needed. Then, after the order has been made, the user will be notified when it has been received. On the other hand, USBN doesn’t currently offer temperature, pressure and cleaning activity updates like the TapAdvisor does, but the website states that it will be implemented in the near future. Similar to the TapAdvisor, the major positives for USBN’s product are that it is compact and can be installed on any existing beverage dispensing units. Although, in comparison to the Inebriation Station, the product’s main user is the bartender. What makes the Inebriation Station unique is that the main users are the customers purchasing the beverage, which completely eliminates the need for the bartender altogether.

-4- ECE 477 Digital Systems Senior Design Project Rev 8/09

3.0 Project Packaging Specifications Due to the size of our project, we don’t have any constraints so it’s quite simple. All the solenoid valves and tubing will be place neatly within the freezer unit completely hidden from the user. The four tubes running from the kegs will come up and out a hole drilled in the freezer lid and be enclosed a single spout. The PCB and the other components have a large operation temperature range, making it possible to also mount the PCB within the freezer. A keg is typically kept cold between the temperatures 38 - 40º F [4]. Currently, the only components that we are planning to mount directly onto the PCB are the wireless module and the relay. The operating temperature of the wireless module is 0 - 70º C (32 - 158º F) [5] so it is capable of functioning in the freezer. We’re not sure what relay we are going to purchase, but by looking through the relay choices on Digikey, there are more than enough to choose from that are capable of operating in the freezer conditions. It should also be noted that we will be using a relay only if we are unable to figure out how to control the thermostat in the freezer by direct connection to the MCU. All the other components (LCD, Keypad, IR Sensor and RFID Reader) will have wires running from the PCB to the outside surface of the freezer, therefore there is no need for concern of their operating temperatures (assuming room temperature isn’t outside their operation range). Currently, our main concern with mounting the PCB in the freezer is having condensation occur and ruin the PCB whenever the lid is opened for some time to do maintenance on the unit. Our solution to this problem is having a plastic enclosure with small holes to cover the PCB and still have the capability to run wires. Although, if we feel that will not sufficiently protect the PCB, we are also considering placing the PCB on the outside of the freezer unit and keep it in an enclosure. Our next concern deals with the peripherals that will be mounted on the outside surface of the freezer. We are worried that with all the liquid that will be flowing along the surface, that there is a large possibility that the equipment will get wet and ruined. Before, we wanted to have the LCD/Keypad combo, although to prevent the equipment from being damaged we have to go with two separate units. Our plan right now is to have a rubber keypad that will be exposed for the user to punch in a selection and have the LCD screen protected by a piece of plexiglass placed evenly across the entire surface of the freezer. This will allow the user to input and view their selection while keeping the equipment protected from any damage. In addition to

-5- ECE 477 Digital Systems Senior Design Project Rev 8/09 the LCD screen, the RFID reader will also be kept safe under the plexiglass by the spout where the user will place the cup. The cup will contain the user’s RFID tag. The cups we will be using have an exposed RFID tag pasted to the bottom of a cup. However, if we were to market the Inebriation Station, the RFID tag would be melted into reusable plastic cups. When considering these packaging ideas, we thought since the wireless module and RFID Reader had solid surfaces all around them, that their signal may be weakened. However, we found that RFID Readers can read tags through skin [7] so we assumed that it would be perfectly fine under plexiglass. Also, the wireless module’s signal will not be affected because it has 802.11b wireless networking, which has signals fully capable of operating through walls and floors. [6] Note: The CAD drawing was made assuming we used the minimum size requirements of a internal dimensions of the freezer (19 inches wide, 19 inches deep, 31 inches tall) to fit 4 sixth- barrel kegs and solenoid valves. 4.0 PCB Footprint Layout The components that will be surface mounted onto the PCB are the PIC24FJ128GB108 MCU, the ZG20101M wireless module, voltage regulators, level translators, keypad controller, capacitors, resistors, inductors, two female socket for 12V power supplies, and different size headers. The headers will be used to connect to the LCD, keypad, RFID Reader, IR sensor and solenoids. In addition, for expansion purposes, there will also be a large header connection for the I/O pins that we won’t be using.. The reason we have two female sockets are for the 12V power supply going directly to the solenoids sand the 12V power supply that will be regulated to 3.3V and 5V. Originally we were going to use one, but we were told that the large amount of current being drawn by the solenoids may cause noise in the signals being regulated. The solenoids will be powered only one at a time for a short period. In turn, we had to add components to switch them on and off. The power switching circuitry for the solenoids will consist of optically isolated transistors as mentioned in lecture Since there won’t be many large components on our PCB, we won’t have to use the given area of 60 square inches. Instead, we will use a 6 x 6 inch PCB as shown in Appendix C, which gives us more than enough space for all the necessary components. It can be seen in Appendix C that the relay and the solenoid circuitry are isolated from the other components. The relay and solenoid circuitry is isolated because they will be drawing large amounts of current, which can

-6- ECE 477 Digital Systems Senior Design Project Rev 8/09 create noise that will affect the digital logic devices. Originally, the wireless module was positioned with the antenna off of the PCB because we were going with a module with an integrated PCB antenna. In turn, we had to follow module layout guidelines provided by the datasheet, which defines the areas of the module where there shouldn’t be any planes or traces underneath. If these guidelines weren’t followed, the signal of the antenna could be compromised. However, we recently decided to use an external antenna to increase the range of the signal by 10 times more. This also allowed us to make our PCB smaller since we weren’t limited by the guidelines. 5.0 Summary It can be seen that there is no commercial product quite like the Inebriation Station. It offers similar features in comparison to the top-of-the-line products, but has more to eliminate the need for a bartender. Though our packaging is large, it is user friendly and makes the beverage distribution business faster, easier, and more enjoyable.

-7- ECE 477 Digital Systems Senior Design Project Rev 8/09

List of References

[1] Alcohol Controls, “Draft Beer Counter”, [Online Document], unknown publication date, [Accessed: 2010 Feb 2], Available HTTP: http://www.alcoholcontrols.com/drafbeercoun.html? gclid=CNfvweG61J8CFQEMDQodn2VScQ

[2] TapDynamics, “TapAdvisor Service Overview”, [Online Document], unknown publication date, [Accessed: 2010 Feb 2], Available HTTP: http://www.tapdynamics.com/service.html

[3] US Beverage Net, “Company Profile”, [Online Document], unknown publication date, [Accessed: 2010 Feb 2], Available HTTP: http://www.usbeveragenet.com/Docs/USBN %20Profile%20Mar08.pdf

[4] KegWorks, “Draft Beer Systems”, [Online Document], unknown publication date, [Accessed: 2010 Feb 3], Available HTTP: http://www.kegworks.com/company/draft- beer-systems#DB4

[5] “ZG2100M/ZG2102M Wi-Fi Module Datsheet”, [Online Document], unknown publication date, Available HTTP: http://www.zerogwireless.com/technology/techmicrochip.html

[6] WLAN Antennas, “Comparing Wireless Standards: 802.11a vs. 802.11b vs. 802.11g”, [Online Document], unknown publication date, [Accessed: 2010 Feb 3], Available HTTP: http://www.wlanantennas.com/wireless_standard_comparison.php

[7] Technovelgy, “How RFIDs Work”, [Online Document], unknown publication date, [Accessed: 2010 Feb 3], Available HTTP: http://www.technovelgy.com/ct/Technology- Article.asp?ArtNum=2

IMPORTANT: Use standard IEEE format for references, and CITE ALL REFERENCES listed in the body of your report.

-8- ECE 477 Digital Systems Senior Design Project Rev 8/09

LCD Appendix A: Project Packaging Illustrations

Keypad PCB

“Beer Me” Button

RFID Solenoid Reader Valves (x4)

Sixth-Barrel Kegs (x4)

-9- ECE 477 Digital Systems Senior Design Project Rev 8/09

Appendix B: Project Packaging Specifications

-10- Materials Tool Requirements Weight Cost Microchip Solder/Soldering Negligible $0.00 PIC24FJ128GB108 Iron ECE 477 Digital Systems Senior Design Project Rev 8/09 ZG2101M Wireless Solder/Soldering Negligible $29.40 + shipping Module Iron Parallax RFID Reader Screwdriver NA $39.99 + shipping Appendix C: PCB Footprint Serial Layout Crystalfontz CFA634- Screwdriver 80 g $65.00 + shipping TMC-KS MM74C923WM Solder/Soldering Negligible $7.75 + shipping Keypad Encoder Iron Figure 2: Preliminary PCB Grayhill Series 88 Screwdriver 350 g $30.03 + shipping Keypad Footprint Solenoid Valves (x4) Solder/Soldering 2.4 lbs $228.00 + shipping Iron, Pliers, Screwdriver Various Headers (male Solder/Soldering Negligible $0.00 & female) Iron, Crimping tools Voltage Regulators (5V Solder/Soldering Negligible $14.00 and 3.3V) Iron Relay Solder/Soldering Negligible $20.00 Iron Solenoid Power Solder/Soldering Negligible $2.00 Switching Circuitry Iron Freezer None ~275 lbs $175.00 Kegs (x4) None ~232 lbs NA None NA $ 26.40 + shipping 5 ft 3/16 inch beerline (x4) Keg Coupler (x4) None NA $106.20 + shipping 5/16 inch CO2 Cross- None NA $ 37.80 + shipping Fitting (x4) 5/16 inch CO2 “T” None NA $7.55 + shipping Fitting CO2 Tank Pliers 5 lbs $0.00 ¾ inch thick plywood Screwdriver, Drill NA NA (to cover the surface of the freezer lid) Plexiglass(to cover the Screwdriver, Drill NA NA surface of the freezer lid) Spout w/ 1inch diameter Screwdriver NA NA Total: ~525 lbs > $789.12 ECE 477 Digital Systems Senior Design Project Rev 8/09