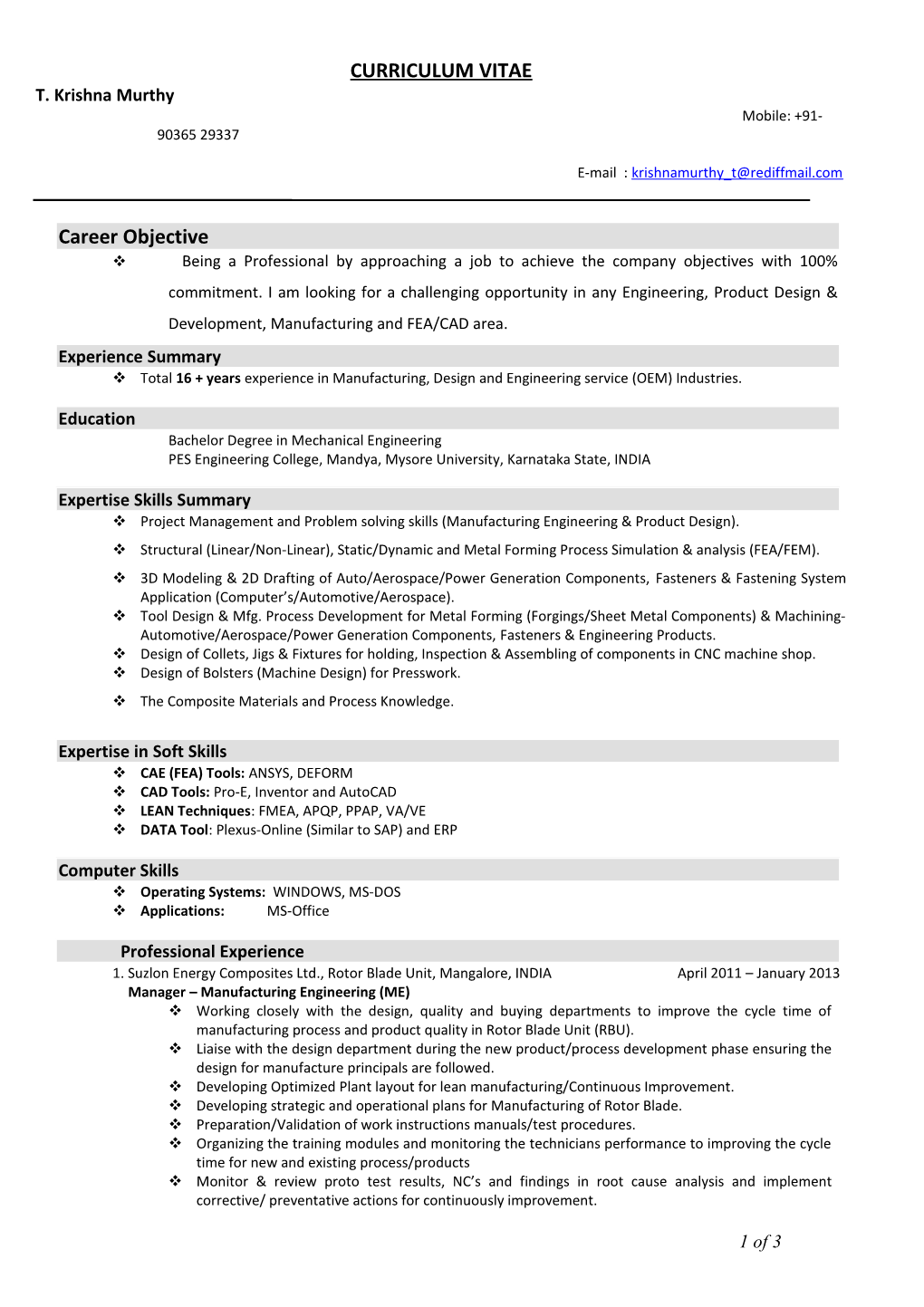

CURRICULUM VITAE T. Krishna Murthy Mobile: +91- 90365 29337

E-mail : [email protected]

Career Objective Being a Professional by approaching a job to achieve the company objectives with 100% commitment. I am looking for a challenging opportunity in any Engineering, Product Design & Development, Manufacturing and FEA/CAD area. Experience Summary Total 16 + years experience in Manufacturing, Design and Engineering service (OEM) Industries.

Education Bachelor Degree in Mechanical Engineering PES Engineering College, Mandya, Mysore University, Karnataka State, INDIA

Expertise Skills Summary Project Management and Problem solving skills (Manufacturing Engineering & Product Design). Structural (Linear/Non-Linear), Static/Dynamic and Metal Forming Process Simulation & analysis (FEA/FEM). 3D Modeling & 2D Drafting of Auto/Aerospace/Power Generation Components, Fasteners & Fastening System Application (Computer’s/Automotive/Aerospace). Tool Design & Mfg. Process Development for Metal Forming (Forgings/Sheet Metal Components) & Machining- Automotive/Aerospace/Power Generation Components, Fasteners & Engineering Products. Design of Collets, Jigs & Fixtures for holding, Inspection & Assembling of components in CNC machine shop. Design of Bolsters (Machine Design) for Presswork. The Composite Materials and Process Knowledge.

Expertise in Soft Skills CAE (FEA) Tools: ANSYS, DEFORM CAD Tools: Pro-E, Inventor and AutoCAD LEAN Techniques: FMEA, APQP, PPAP, VA/VE DATA Tool: Plexus-Online (Similar to SAP) and ERP

Computer Skills Operating Systems: WINDOWS, MS-DOS Applications: MS-Office

Professional Experience 1. Suzlon Energy Composites Ltd., Rotor Blade Unit, Mangalore, INDIA April 2011 – January 2013 Manager – Manufacturing Engineering (ME) Working closely with the design, quality and buying departments to improve the cycle time of manufacturing process and product quality in Rotor Blade Unit (RBU). Liaise with the design department during the new product/process development phase ensuring the design for manufacture principals are followed. Developing Optimized Plant layout for lean manufacturing/Continuous Improvement. Developing strategic and operational plans for Manufacturing of Rotor Blade. Preparation/Validation of work instructions manuals/test procedures. Organizing the training modules and monitoring the technicians performance to improving the cycle time for new and existing process/products Monitor & review proto test results, NC’s and findings in root cause analysis and implement corrective/ preventative actions for continuously improvement.

1 of 3 Implement/execution/Optimize the Jigs & Fixtures for manufacturing process support tooling and Vendor Development for Tooling Development. Time motion study to optimize the process requirements and data documentation. ISO-9001:2008 Quality System of Department Documentation.

2. Milltec Machinery Pvt. Ltd., Bangalore, INDIA March 2010- March 2011 Manager - Design On new concept, reviewing with Director-Manufacturing and other dept. heads to freeze the design & process details of Machine Design and Develop the Jigs& Fixtures for Inspection and Assembling of Machine parts. Developing and preparing Assembly/Sub-assembly/process drawings on CAD software. Generating & updating the bill of materials (BOM), Tech spec’s., Material Spec’s. Design change notes on ERP system. Generating project documents like Gantt chart, design inputs/review, design/process feasibility, design output/review, check list, proto type testing report/review and final verification/validation report. Hand calculation for selection of Motor, Gear box, Pulleys, Bearings, etc. for a specified applications. Other Responsibilities – Vender Development - Attending Monthly dept. review meeting with Director-Mfg. along with Team. - Attending Monthly Technical Objective Review Meeting (TORM) with Management along with other dept. heads. - Attending Weekly Customer Complaints review meeting along with all other dept. HOD and lead by MR - Attending Weekly general co-ordination review meeting along with all other dept. HOD and lead by Manager-HR. The Machines Manufacturing in this company is Food processing machines, Bucket Elevators, Blowers and some Accessories. ISO-9001:2008 Quality System of Department Documentation.

3. Stokes Forgings Ltd., Walsall, WS2 8BH, UK March 2008 - January 2009 Design/Process Development Engineer Identifying & Optimize the design and process for new/current running parts to reduce the rejection percentage and to improve the production rate/product quality. Design and Develop the Collets, Jigs& Fixtures for holding, Inspection and assembling purposes in CNC machining process of automotive components. Developing and preparing process drawings, tooling drawings on CAD software. Generating & Updating bill of materials (BOM), Drawings spec’s., Material Spec’s. First of inspection methods and control plan etc. for new products on plexus-online software data tool (similar to SAP). Perform the forging process simulation/analysis (FEA/FEM) on DEFORM simulation software and making presentation to explain the results to the customer about design and process feasibility. TS 16949 Quality System of Department Documentation. Split Bolster design for undercut Forging Products is an end to end designed project i.e. concept generation, detailed design, prototyping, Testing, pilot batch production, optimization & project hand over.

4. Textron (India) Pvt. Ltd., Bangalore, INDIA October 2004- November 2007 Product Design Engineer After receiving new (concept) project details as per export compliance check list, we will have discussion thru teleconference meeting about concept design and process with R & D team those who are sitting at manufacturing plant around the globe. Developing and preparing product analysis documentation, Tool Design & Process drawings with respect to concept design and specifications. Perform the process simulation/analysis (FEA/FEM) on DEFORM Software and with respect to FEA results if necessary need to be modifying the design until to obtain optimized design. Generating project detailed report and oral presentation of the results. Generating & Updating Project Progress Report & Standard NPD Technique Documents and uploading on FTP server. By Every quarterly Sharing (Best Practice) the Projects FEA report with Engineering, Manufacturing and Marketing/sales managers through WebEx Meeting .

2 of 3 Micro Miniature Screw (M1.0X15MM Length) is an end to end designed project i.e. concept generation, detailed design, prototyping, Testing, pilot batch production, optimization & project hand over.

5. Advanced Forming Technology Center, Bangalore, INDIA August 2003 – September 2004 Sr. Engineer-Design & Development Providing process modeling & simulation services. Support to the various Forging industries, Engineering Analysis Groups, automotive, manufacturer's (Tier1 &Tier2 OEM'S), and Aeronautical industries. Providing FEA/FEM forging process simulation on DEFORM software, Tool Design, Jigs & Fixture design on CAD software and Process Development for automotive & aerospace Industries. Generating project detailed report and oral presentation of the results. Conducting Training to the Fresh Engineers on Projects & to the Customers on Software (DeForm). Conducting seminars & presenting on latest/advanced techniques in metal forming simulation concepts to optimize the design & process prior to the proto type sample. It can be save development cost and time.

6. Apten Forgings Ltd., (LGB Group), Bangalore, INDIA March 2000 - July 2003 Tool Room Engineer Planning and executing work, Coordinating with Design, purchase and PPC Engineers, Vender Development, Optimizing Tools manufacturing process, Involving in new product development, Collets Design for CNC machines, Jigs & Fixture Design, Maintaining Quality documents like job cards, inspection report, test reports, etc., Estimating for tools raw material, ISO 9001:2008 Quality System.

7. Centura Watch Cases Pvt. Ltd., Tumkur, Karnataka, INDIA January 1995 - February 2000 Tool Room Engineer Planning and executing work, Coordinating with Design, purchase and PPC Engineers, Vender Development, Optimizing Tools manufacturing process, Involving in new product development, Collets Design for CNC machines, Jigs & Fixture Design, Maintaining Quality documents like job cards, inspection report, test reports, etc., Estimating for tools raw material, ISO 9002 Quality System.

Training Undergone GD & T – To control the dimensioning process for improving the productivity SIX SIGMA - To execute the project in a systematic way to find the solutions My Prospects – To engage with time management for effectiveness Leading Edge – To Improve the leadership skills

Hobbies Playing Cricket, Swimming and Trekking. Watching Movies and Listening to Music.

Personal Profile

Name : T.Krishna Murthy Gender : Male Date of Birth : 01st June 1971 Marital Status : Married Languages Known : English, Kannada and Telugu Nationality : Indian Passport Details : F1231518 Visa Status : B1/B2 (USA) Visa & Valid till end of 2016.

3 of 3