1

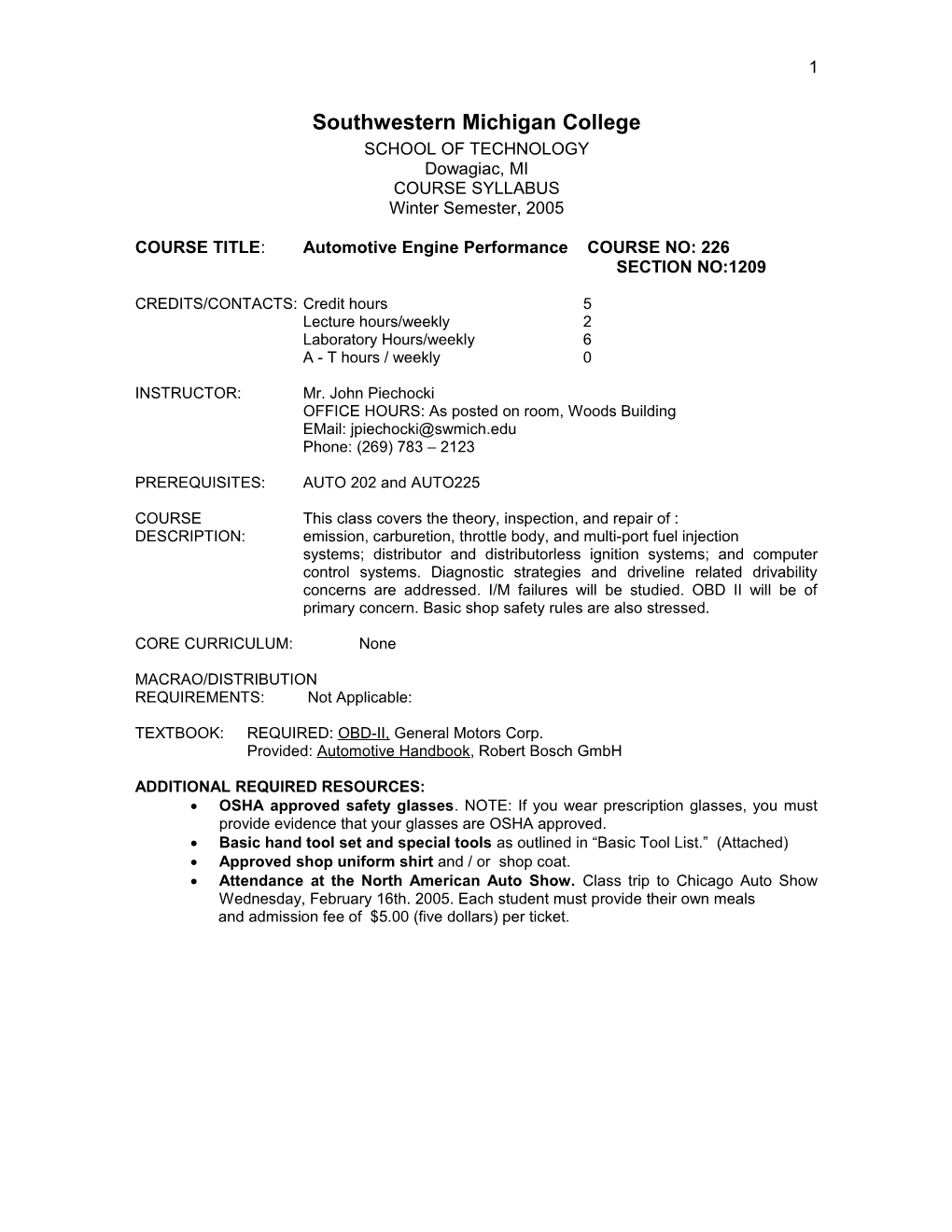

Southwestern Michigan College SCHOOL OF TECHNOLOGY Dowagiac, MI COURSE SYLLABUS Winter Semester, 2005

COURSE TITLE: Automotive Engine Performance COURSE NO: 226 SECTION NO:1209

CREDITS/CONTACTS: Credit hours 5 Lecture hours/weekly 2 Laboratory Hours/weekly 6 A - T hours / weekly 0

INSTRUCTOR: Mr. John Piechocki OFFICE HOURS: As posted on room, Woods Building EMail: [email protected] Phone: (269) 783 – 2123

PREREQUISITES: AUTO 202 and AUTO225

COURSE This class covers the theory, inspection, and repair of : DESCRIPTION: emission, carburetion, throttle body, and multi-port fuel injection systems; distributor and distributorless ignition systems; and computer control systems. Diagnostic strategies and driveline related drivability concerns are addressed. I/M failures will be studied. OBD II will be of primary concern. Basic shop safety rules are also stressed.

CORE CURRICULUM: None

MACRAO/DISTRIBUTION REQUIREMENTS: Not Applicable:

TEXTBOOK: REQUIRED: OBD-II, General Motors Corp. Provided: Automotive Handbook, Robert Bosch GmbH

ADDITIONAL REQUIRED RESOURCES: OSHA approved safety glasses. NOTE: If you wear prescription glasses, you must provide evidence that your glasses are OSHA approved. Basic hand tool set and special tools as outlined in “Basic Tool List.” (Attached) Approved shop uniform shirt and / or shop coat. Attendance at the North American Auto Show. Class trip to Chicago Auto Show Wednesday, February 16th. 2005. Each student must provide their own meals and admission fee of $5.00 (five dollars) per ticket. 2

NOTICE: Information in this syllabus was, to the best knowledge of the instructor, considered correct and complete when distributed for use at the beginning of the semester. The instructor, however, reserves the right, acting within the policies and procedures of Southwestern Michigan College, to make changes in course content or instructional techniques without notice or obligation.

HONESTY POLICY: Cheating or plagiarizing will absolutely NOT be tolerated at Southwestern Michigan College. Any student found cheating or plagiarizing material in any manner may be assigned a failing semester / session grade in this course. A second such incident while at SMC could result in suspension or expulsion from the institution. A student found in violation of this section of the syllabus will NOT be allowed to drop this course.

METHOD OF Instruction will be a combination of lecture, lab, audio- INSTRUCTION: video, and team learning. A written or demonstration special project will be assigned. Students will be assigned to a team and will work together on several lab projects; other lab projects will be done individually. Some computer simulation exercises will also be used.

EVALUATION: Students will be graded on a percentage scale with the following areas contributing to a final grade:

Attendance 20% Tests 20% Lab work 50% Final Exam 10% Total 100%

EVALUATION: Evaluation will be done on a point basis for each test, on a point basis based on specific criteria for lab work, and according to the attendance policy for attendance.

ASSIGNMENTS: Homework assignments are to be handed in on their appropriate due dates. NOTE: All assignments including lab sheets and other assignments must be handed into the instructor for final grade consideration before the start of the final exam. Any assignments received after the start of the final exam will not be accepted (unless prior arrangements were made with the instructor).

GRADING The following grading scale will be in effect for this course: SCALE: 3

ATTENDANCE Attendance will be recorded for each class period as per college POLICY: policy. Due to the cooperative and group leaning methods, as well as the extensive use of the laboratory used in this class, regular attendance is crucial to successful completion of this course. There is no differentiation between excused and unexcused absences. However, please see instructor about make-up assignments immediately. Absences will reduce your grade by the following percentages. SEE CHART BELOW.

Number of % of Grade Reduced: Sessions Absent 1 2.5% 2 5% 3 7.5% 4 10% 5 12.5% 6 15% 7 17.5% 8 Failing Grade

TARDINESS Tardiness of ¼ hour will count as one quarter absent POLICY: Tardiness of ½ hour will count as one half an absent. Tardiness of 1 hour will count as one absent

TESTING Quizzes will be given on an unscheduled basis. The goal of this POLICY: class is to develop your skills. To evaluate these skills, a combination of written and performance evaluations will be given. The schedule of test dates is shown in the attached course outline, but is subject to change. 4

ABSENCE FROM A TEST OR QUIZ: You are expected to be present in class to take all tests and quizzes. Students absent from a test or quiz must make them up within a week of when the test or quiz was given. Failure to make up a quiz or test within this time frame may result in a grade of “zero” for that particular exercise. However, the final exam must be taken no later than at the regularly scheduled time.

OTHER COURSE Shop policies: EXPECTATIONS: All shop policies must be followed, using safe work practice rules. These include, but are not limited to:

1. All vehicles, including school owned cars, that enter the shop must have a filled out repair order. 2. Any vehicle that is run in the shop must have an exhaust system in functional condition, and it must be hooked to the shop’s ventilation system. 3. Students will not be allowed to work in the shop without safety glasses and appropriate safety equipment. 4. Steel toed shoes strongly recommended; leather shoes required (no tennis shoes). 5. Students with an Employer Sponsor are encouraged to wear the uniform of their sponsor. 6. Students must wear an instructor-approved uniform type work shirt or lab coat when in the lab. 7. Neat and safe dress and appearance is required at all times. No frayed or torn clothing is permitted. 8. Each vehicle in the shop must have at least one window down and the keys left in it at all times. 9. No student parking is permitted in, near, or around the shop without the expressed consent of your instructor. 10. Smoking is not allowed in the auto shop or within the fenced in area at the rear of the shop. 11. The time clock policy for lab attendance must be observed at all times. 12. Horseplay or unprofessional behavior is not allowed in the shop. 13. All students are to clean up after themselves and assist with the cleanliness of the shop. 14. College owned vehicles are not to be driven off of the college campus.

General: Profanity, ethnic or gender specific comments or jokes have no place in the shop, classroom, or workplace. Lack of respect for other students or personal or school property will be dealt with in an appropriate manner.

PERSONAL As a common courtesy to all students. It is expected that COMMUNICATION all students shall refrain from using cell phones, pagers, DEVICES: laptops, or similar personal electronic audio/visual devices during lecture periods. Therefore, all such devices are expected to be turned off before the start of class.

COURSE Upon completion of this course, the student will be able to OBJECTIVES: demonstrate a basic knowledge of the subject matter, as evidenced in testing, and have demonstrated competency in the 5

associated laboratory projects as assigned. The student should be prepared, upon course completion, to perform routine service and diagnosis on the types of assemblies covered in the lab and class topics.

SKILL OBJECTIVES:

Given: A vehicle, tools, specifications, manuals, and test equipment, the student will meet the following objectives:

1. Perform tests on the fuel delivery system 2. Perform tests and repairs to analog carburetors 3. Perform tests and repairs to computer controlled carburetors 4. Perform tests and repairs to the emission control system 5. Perform tests and repairs to the throttle body fuel injection system 6. Perform tests and repairs to the multi-port fuel injection system 7. Perform tests and repairs to the distributor ignition (DI) system 8. Perform tests and repairs to the distributorless (EI) ignition system 9. Perform tests and repairs to the engine mechanical systems 10. Test and diagnose driveline related driveability concerns 11. Perform a maintenance tune up procedure 12. Extract codes from a computer system using scan tools or other tools and interpret their meaning 13. Perform other tests using DMMs and other test equipment 14. Demonstrate proper use of analog and digital engine analyzers 15. Demonstrate proper use of exhaust gas analyzers 16. Demonstrate proper use of digital storage oscilloscopes 17. Analyze no-start vehicles

Criteria: The student will perform these skills at a minimum 93% accuracy, to specifications of the manufacturer, or standards set by the department. Time to do these tasks is determined by Mitchell Flat-Rate tables and students will be able to complete the task in no more than 1.5 times the listed time to receive an “A”.

KNOWLEDGE OBJECTIVES: Given: Necessary tools, manuals, specifications, and a vehicle, the student will demonstrate knowledge through written and / or oral tests to show competency in the following areas: 1. Describe safe procedures for testing fuel, emission, and computer systems 2. Describe the operation and design of fuel delivery system components. 3. Describe the operation and design of emission components. 4. Describe the operation and design of a carburetor and its component parts. 5. Describe the operation and design of computer controlled carburetors and their function in the emission control and driveability systems. 6

6. Describe the operation and design of throttle body injection systems and their component parts, and their function in the emission control and driveability systems. 7. Describe the operation and design of multi port fuel injection systems and their component parts, and their function in the emission control and driveability systems. 8. Describe the operation and design of both distributor and electronic ignition systems. 9. Explain the difference between maintenance tune up procedures and diagnostic procedures. 10. Explain strategy based diagnostics and other diagnostic approaches. 11. Describe On Board Diagnostics generations I and II and explain the differences between them. 12. Describe the OBD-II system and its operation. 13. Explain how the EPA and CAFE rules have impacted automobile design. 14. Describe the operation of automotive diagnostic test equipment.

Criteria: The student will pass at a minimum 93% accuracy to receive an “A”.

PRACTICAL APPLICATION OF THE KNOWLEDGE AND THINKING SKILLS

Given: A vehicle with a driveability problem. The student will: Make tests to accurately determine the cause of the specific condition, justify the diagnosis, and recommend needed repairs.

Criteria: The student will correct the problem.

COURSE OUTLINE AND COURSE ASSIGNMENTS: Can be found on the outline at the back of this syllabus. 7 Southwestern Michigan College Automotive Training Program

The following tools are REQUIRED for all students:

Basic Tool Set A toolbox capable of holding and organizing the following tools. Lower cabinet (cart) strongly suggested, as carts will be unavailable.

3/8 drive deep or shallow six point socket set, US: 3/8, 7/16, 1/2, 9/16, 5/8, 11/16, 3/4, Hammers: 13/16, 7/8 Ball peen : 8 oz and 20 oz 3/8 drive deep or shallow six point metric Plastic tip or dead blow socket set: 8, 9, 10, 11, 12, 13, 14, 15, 17, Pry bar: 16” 18, 19 mm Brass drift 3/8 drive spark plug sockets, 5/8 and 13/16 Tire Gauge, 0 - 50 psi (best to get the new deep design) HEI Spark Tester 1/4 drive socket set, US: 1/4, 5/16, 3/8, Ramp type Spark Plug Gap Gauge 7/16, 1/2 Tire Valve Core Remover Tool 1/4 drive socket set, metric: 5, 5.5, 6, 7, 8, Ratchet, 3/8” 9, 10, 11, 12 mm Ratchet, 1/4” Set of Torx bits: 1/4” Drive T8, T10, T15, Drive adapter, 1/2” female to 3/8” male T20, T25, and 3/8” drive T25, T27, T30, T40, Drive adapter, 3/8 female to 1/4” male T45, T50, and T55 Drive extension sets: 1/4” and 3/8” Impact sockets: 1/2” drive x 3/4” and 13/16” Brake return spring installer/remover Socket rails to organize above sockets Allen sockets, 3/8” x 3/8” and 8mm x 3/8” Combination wrench set, US: 1/4 to 7/8 by Spark plug boot removing pliers 1/16 Pocket Thermometer (analog or digital) Combination wrench set, metric: 7 to 21 Non-powered test light mm Tape measure, 25 foot Screwdriver set: Standard, Phillips, and Brake Spring hold down tool PosiDrive Brake adjusting spoon Pliers: Inspection Mirror Slip joint Magnetic Pick-up Tool Needle nose (recommend long neck with Small flashlight bent nose) Feeler gauge set Diagonal cutter Punch and Chisel set 9” channel lock type External and internal snap ring pliers set 6” and/or 10” Locking (vice grip type) Wire stripper / crimper pliers 5/16 insulated battery terminal box ratchet Hook and Pick set 8

Southwestern Michigan College Automotive Training Program Tool List: Continued

The following tools are recommended but optional. You will need these tools to be successful as a technician.

Self powered test light Digital Multimeter Torque Wrenches: 10-300 lb./in and 30 - 300 lb./ft Utility knife Drill bit set Oil filter wrenches (3 sizes) Steering wheel puller set Tilt steering pivot pin puller Steering wheel lock plate depressor/remover Flare nut wrench set, US Flare nut wrench set, Metric Gasket scraper Remote starter switch Tubing cutter 36 mm drive axle nut socket Swivel / universal spark plug sockets 3/8 or 1/2 hand impact drive Adjustable wrench set (“crescent” wrench) Bolt extractor set Spark plug wire pliers File set 3/8” air ratchet 1/2” air impact wrench 9 COURSE OUTLINE AND SCHEDULE Date Subject Text: Read BEFORE class: Be prepared to discuss!!! Week 1 Introduction; Tool overview; Syllabus Review Bosch review handbook Week 2 Auto Emissions Study Tape Series OBD II-Book

Week 3 Auto Emissions Study Test I Tape Series OBD II book Week 4 OBDII OBDII Book System Overview Handout

Week 5 Scan Tool OBDII Book Diagnosis Handout Week 6 Sensor OBDII Book Test 2 Diagnosis Handout Week 7 HO2S and OBDII Catalyst Diagnosis Handout Week 8 Misfire Detection OBDII Book Diagnosis Handout Week 9 Control System OBDII Book Test 3 Diagnosis Handout Week 10 Evap System OBDII Book Diagnosis Handout Week 11 Reprogramming Handout Week 12 Emission control systems Handout SPECIAL Exhaust systems PROJECT DUE Week 13 Exhaust Gas Analysis Handout Test 4 I/M 240; BAR87, BAR 90 tests Week 14 Review Final Exam

This schedule is subject to change as the class progresses.