TASX Bit 21 Troubleshooting Guide

This document will assist you in resolving a hall fault (TASX Bit 21). Several problems could cause such a hall fault. The following list will help you finding these problems. If you answer yes to any of the questions, the corresponding number could have caused your hall fault. See the following pages for what these causes are, as well as potential methods to correct them.

Checklist: Maybe caused by the problem #: 1. Does THALL report back either 0 or 7? 1, 2 2. Is there no change in THALL if you move the motor by hand? 2 3. THALL does not have six distinct hall states from 1 to 6? No 2 numerical order necessary. 4. Are there not n times 6 hall-states if the rotor turns one revolution? 2, 3 (For linear motor it is the pitch)? Where n is equal to the pole-pairs. 5. The hall state sequence isn’t [1, 5, 4, 6, 2, 3, 1 …] if the motor turns 4 clock wise (CW)? CW means TPE is increasing or CW is the direction of DMODE13. 6. The sequence is right but you still get a hall fault at every Drive1? 4 7. The hall fault is intermittent? Intermittent means: The fault does not 5 occur every revolution.

Cause 1: No hall states are available, or SHALL is set to 2. (Note: You have to move at least through one hall state)

Cause 2: Cable is not connected, or is incorrectly connected.

Cause 3: DPOLE or DMEPIT is not set correctly.

Cause 4: Either the halls wires or motor wires are connected incorrectly. To remedy this situation, use Procedure I if you want to change the motor wire. If you would rather change the hall wires use Procedure II. Cause 5: The hall wires or the encoder wires don’t have a solid connection and give intermittent faults.

Corrective Action - Procedure I:

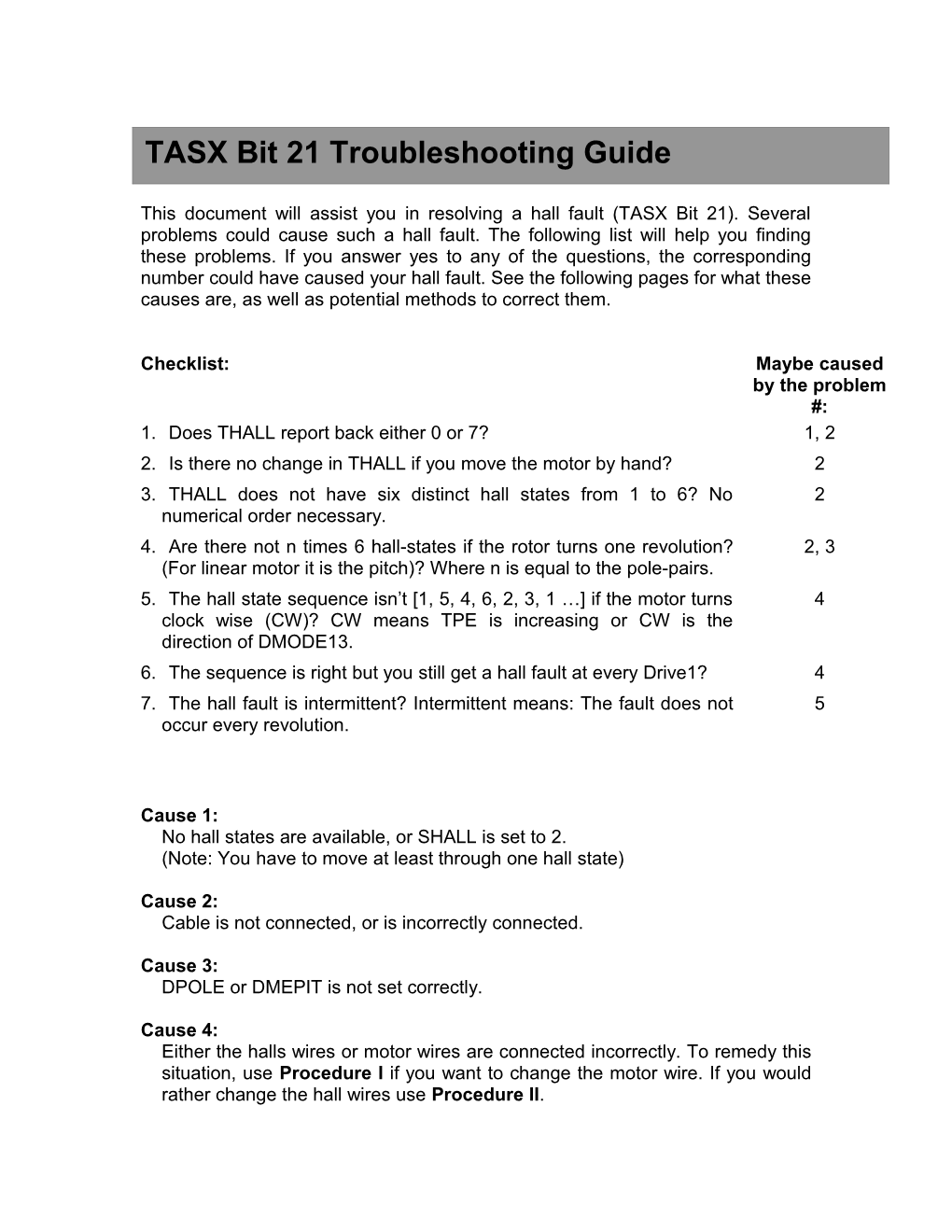

1. Randomly connect two motor wires and slowly apply a positive voltage with respect to the third. See Fig 1.

WARNING: This could damage the motor. Slowly increase the voltage until the motor moves. Don’t exceed the rated current.

2. If the THALL reports back a 1, 2 or 4, you have to change SHALL from either 0 to 1 or from 1 to 0. Do this and then reset the drive. 3. Repeat step 1 until you get THALL of 6. 4. The wire that is at negative voltage (or Ground) is motor wire W. The two at positive voltage are U and V. 5. Now there are two possibilities: 5.1. Connect the motor wire to the terminals. Run it in DMODE13. If the motor does not turn clock-wise, change motor wire U and V. 5.2. Put positive voltage on motor wire W together with either U or V and put negative voltage or ground on the remaining wire. If you get THALL3, the wire at the negative voltage is V. If you get THALL5, the wire at the negative voltage is U.

Corrective Action - Procedure II:

1. First you have to run DMODE13 and verify that the motor turns clock-wise. If not, you have to swap any two motor wires. 2. Connect motor wire U and V and slowly apply a positive voltage with respect to W. See Fig 1.

WARNING: This could damage the motor. Slowly increase the voltage until the motor moves. Don’t exceed the rated current.

3. If the THALL reports back a 1, 2 or 4, you have to change SHALL from either 0 to 1 or from 1 to 0. Do this and then reset the drive. 4. Change the hall wires until you get THALL of 6. 5. Connect motor wire U and W and slowly apply a positive voltage with respect to V. 6. IF THALL is not 3 change hall wire B and C. If not, you are connected correctly. W U

DC

V

Figure 1. Possible connection scheme

The following table is a summary of phase voltages and their corresponding hall states:

Phase Hall state CW U V W SHALL SHALL 0 1 - - + 1 6 - + + 5 2 - + - 4 3 + + - 6 1 + - - 2 5 + - + 3 4