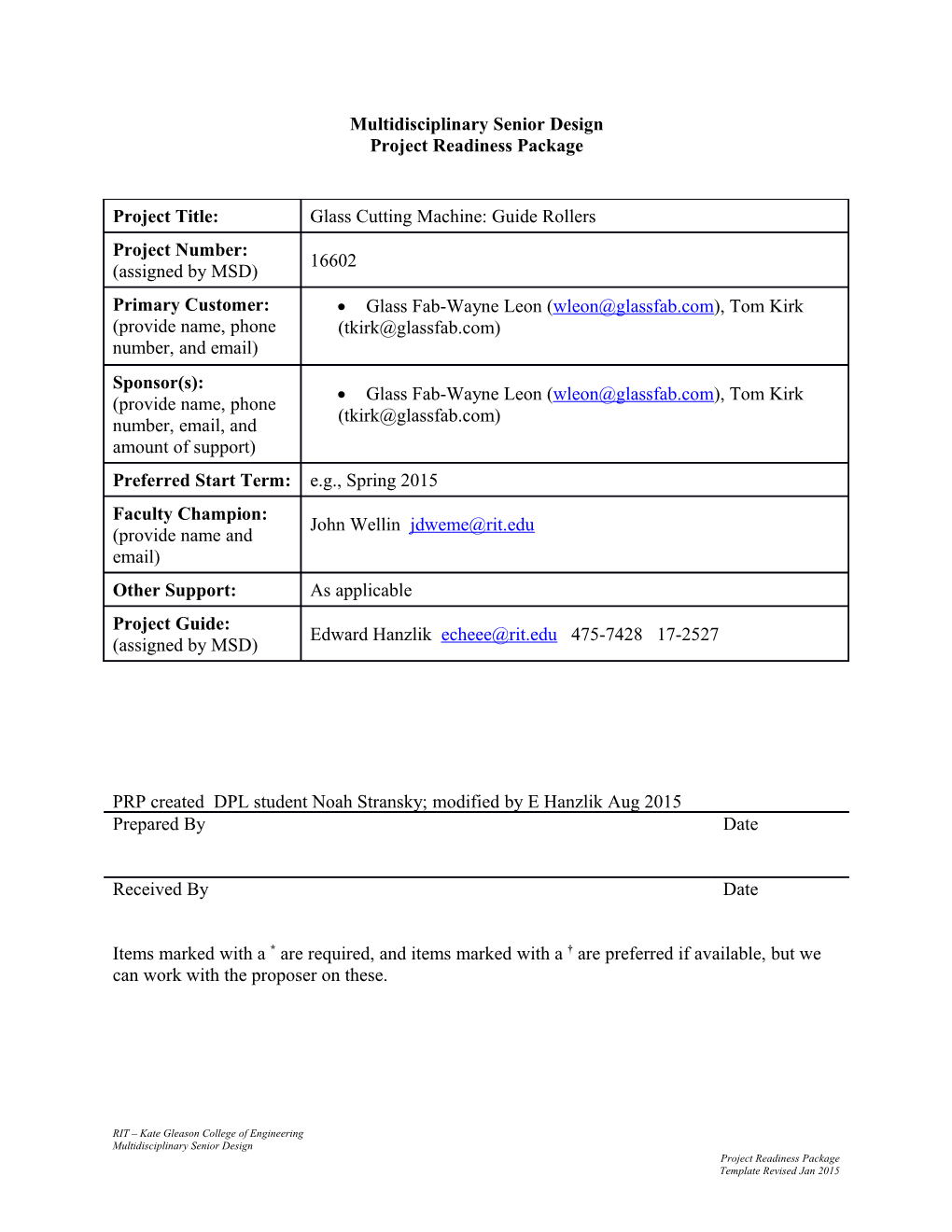

Multidisciplinary Senior Design Project Readiness Package

Project Title: Glass Cutting Machine: Guide Rollers Project Number: 16602 (assigned by MSD) Primary Customer: Glass Fab-Wayne Leon ([email protected]), Tom Kirk (provide name, phone ([email protected]) number, and email) Sponsor(s): Glass Fab-Wayne Leon ([email protected]), Tom Kirk (provide name, phone ([email protected]) number, email, and amount of support) Preferred Start Term: e.g., Spring 2015 Faculty Champion: John Wellin [email protected] (provide name and email) Other Support: As applicable Project Guide: Edward Hanzlik [email protected] 475-7428 17-2527 (assigned by MSD)

PRP created DPL student Noah Stransky; modified by E Hanzlik Aug 2015 Prepared By Date

Received By Date

Items marked with a * are required, and items marked with a † are preferred if available, but we can work with the proposer on these.

RIT – Kate Gleason College of Engineering Multidisciplinary Senior Design Project Readiness Package Template Revised Jan 2015 Project Information

* Overview: Glass cutting is a process that can be done on both large and small scales with many different cutting tools. Some examples include using a saw blade, a diamond coated wire, or a brass coated wire in the presence of an abrasive slurry. Each of these methods will differently impact the way the glass is cut. The saw blade will cause a significant amount of movement and vibration of the glass. The diamond coated wire does not need any other tools to assist in cutting, but the wire can create chips in the surface of the glass during cutting. The brass coated wire with the slurry will give a finer cut than the diamond; however, temperature needs to be monitored.

Glass Fab Inc. currently uses a brass coated wire utilizing abrasive slurry for both large and small volume glass blanks. It is a Meyer Burger DS 264 glass cutting system that uses a wire wrapped around two guide rollers. These guides have grooves that the wire will sit in and can be adjusted to create various thickness cuts in the glass to get a range of different blanks. There is a control panel on the front as well to monitor the sensors and adjust the feed rate of the wire.

This machine works very well for Glass Fab, especially for high volume parts. However, the current Meyer Burger machine draws more power than every other machine Glass Fab owns put together. It takes a while to start up and because of the amount of power used, does not make sense to use for low volume parts. Glass Fab would like to look into creating a smaller machine, similar to the one that they currently have, that can be utilized only for low volume parts. There are existing smaller machines, but can only cut one blank at a time. The goal is to take elements of the bigger machine, essentially shrink it, and make a more energy efficient wire glass cutter.

This MSD project is part of a tightly coupled group of three projects that will run in the fall of 2015. The three projects are 16601, 16602 and 16603. Each of these project teams will develop, design and build a test fixture for their functional part of the overall system. In addition, members of this project team will actively participate on a “system engineering team”. The System engineering will define, develop and conceptually design a complete wire saw machine. The system engineering team will utilize CAD to convey the design. The system engineering team will work with the three project teams to array and manage all relevant project metrics at the system level. Some examples of these system metrics are weight, volume, power consumption, noise, heat emission. In addition, the system engineering team will be responsible for develop the necessary documentation to describe machine behavior and operation. Some examples of necessary documentation include a timing diagram for each of the possible use scenarios; this might include, cycle up, cycle down, and some diagnostic routines.

A key goal of P16602 is to design and build the spooling process. This includes specifying the spools and motors to be used, designing this portion of the wire path, mounting these components, and supplying power to these components. Of course, safety is paramount and should be considered in all aspects of the design and build of this industrial machine. In addition, this project team will be asked to consider and evaluate various methods of controlling and maintaining wire tension in the range of 10-40 newtons.

RIT – Kate Gleason College of Engineering Multidisciplinary Senior Design Project Readiness Package Template Revised Jan 2015

-example system

-

RIT – Kate Gleason College of Engineering Multidisciplinary Senior Design Project Readiness Package Template Revised Jan 2015 * Preliminary Customer Requirements (CR): What attributes does the customer seek in the final project? Each CR should map to one or more ER (see below). Glass Fab needs a new glass cutting machine with the capability to process small lot sizes without consuming much energy. Category Customer Request 1.1 Cost Cost effective for a low volume 1.2 Machine has a low power consumption 1.3 Cut produces minimum waste 1.4 Reduction of set up time 1.5 Machine cost is comparable to Glass Fab custom saw 1.6 Machine employs cost-effective cutting media 2.1 Project Scope This project takes about two years 2.2 Team size will be around five students 3.1 Operator safety Machine shuts down when the cutting wire breaks 3.2 Machine shuts down if overheating 3.3 Sufficient safety and protection provided to operator 3.4 Safe to run overnight 4.1 Cut quality Product is comparable to diamond cutting 4.2 Cutting operation reduces the need for additional finishing 5.1 Features Control panel that is easy to use for operator simplicity 5.2 Machine controls comparable to current wire saw for functionality 5.3 American parts are used 5.4 The machine indexs wire to provide optimal longevity 5.5 Machine uses one long wire so that is the only thing to replace 5.6 Machine makes multiple cuts at once to maintian productivity 5.7 Machine tracks wire in spool to prevent runnning out mid-cut 5.8 Complexity is reduced to allow one operator to set up 5.9 Running the machine requires only one operator for ease 5.10 Cutting machine footprint is comparable to Glass Fab custom saw 5.11 Machine is easy to load/ unload to maintain productivity 6.1 Cutting Requirements Lot sizes are from 10-20 cuts 6.2 Accommodates blank cross section comparable to current wire saw 6.3 Accommodates blank approximately 10" long 6.4 Throughput of machine is comparable to current wire saw Note: Cells Highlighted as this one is pertain to this project.

† Functional Decomposition What functionality will be delivered in order to satisfy the customer requirements? This may be in the form of a list of functions, a function tree or a FAST diagram.

* Preliminary Engineering Requirements (ER): Include both metrics and specifications. Each ER should map to one or more CRs (see above). Metrics: what quantities will be measured in order to verify success? Specifications: what is the target value of the metric that the team should design to?

RIT – Kate Gleason College of Engineering Multidisciplinary Senior Design Project Readiness Package Template Revised Jan 2015 Project: R15601 Unit of Marginal Ideal rqmt. # Source Function Engr. Requirement (metric) Comments/Status Test (how are you going to verify satisfaction) Measure Value Value S1 Glass Fab. Requirements Adhere blank to top guide Force adhesive needs to sustain N 250 350 Estimated values further investigation needed measure force to see if marginal value is met S2 Glass Fab. Requirements Apply z-axis force Vertical force required to guide blank through wire N 150 200 Estimated values further investigation needed measure force to see if marginal value is met S3 Glass Fab. Requirements Maintain proper feed rate Velocity required ensure blank will be cut mm/min 0.3-2.5 0.35-2 Values from Customer measure velocity to see if marginal value is met S4 Glass Fab. Requirements Store wire Length of wire that can be stored before each job km 0.8 5 Estimated values further investigation needed measure length to see if marginal value is met S5 Glass Fab. Requirements Index wire Stroke length m 300 400 Estimated values further investigation needed measure length to see if marginal value is met S6 Glass Fab. Requirements Maintain proper wire speed Velocity of wire m/min 10 15 Estimated values further investigation needed measure velocity to see if marginal value is met S7 Glass Fab. Requirements Provide tension Force required to tension wire around guides N 20-30 N ~ 25 N Values from Customer measure force to see if marginal value is met (Y/N) when glass cutter is connected to power supply, all mechanical visual check to see if guide rollers and spools S8 Glass Fab. Requirements Convert electrical to mechanical power components operate (Y/N) Y Y Function needed for marginal and ideal cases move when machine is in use S9 Glass Fab. Requirements Accept standard voltage input Voltage required to power glass cutter V 440 220 Values from Customer measure voltage to see if marginal value is met

S10 Glass Fab. Requirements Controls interface accepts user inputs (Y/N) control panel prompts user to input values (Y/N) Y Y Function needed for marginal and ideal cases operators can easily input values on control panel measure input operations to ensure correct S11 Glass Fab. Requirements Machine runs off inputs (Y/N) machine changes initial conditions based on different user inputs (Y/N) Y Y Function needed for marginal and ideal cases values Notifications (red light?) appear on control panel and machine shuts test to see is machine shuts off based on sensor S12 Glass Fab. Requirements Controls monitor safety sensors off when machine operates outside safe conditions (Y/N) Y Y Function needed for marginal and ideal cases values S13 Glass Fab. Requirements Keep building safe (fire code) OSHA/Fire/Electrical safety standards are met (Y/N) Y Y Function needed for marginal and ideal cases OSHA and Glass Fab. standards are met OSHA/Fire/Electrical safety standards are met, internal components S14 Glass Fab. Requirements Keep machine components safe are housed while machine is in use (Y/N) Y Y Function needed for marginal and ideal cases OSHA and Glass Fab. standards are met S15 Glass Fab. Requirements keep operator safe OSHA safety standards are met and proper PPE is worn (Y/N) Y Y Function needed for marginal and ideal cases OSHA and Glass Fab. standards are met S16 Glass Fab. Requirements Machine consumes minimum power Amperage draw is minimum Amps 150 50 Estimated values further investigation needed measure total amperage draw S17 Glass Fab. Requirements Monitor components temperature Temperature of bearing, coolant, etc. °F 200 150 Estimated values further investigation needed measure temperature of items S18 Glass Fab. Requirements Wire break detection detects wire breaks (Y/N) Y Y Function needed for marginal and ideal cases visual check to see if wire stops after wire break S19 Glass Fab. Requirements Wire break detection time to detect wire breaks ms 400 0.1 Value should approach 0 measure time to shut down S20 Glass Fab. Requirements Housing allows for max blank size (Y/N) Housing allows for blank (L x W x H : 10in x 8in x 8in) (Y/N) Y Y Function needed for marginal and ideal cases Blank has clearance to be fully cut Note: Cells hightlighted as this one pertain to this project.

RIT – Kate Gleason College of Engineering Multidisciplinary Senior Design Project Readiness Package Template Revised Jan 2015 * Constraints: List any external factors that limit the selection of alternatives, e.g., allowable footprint, budget, required use of legacy hardware/software.

To be determined.

† Potential Concepts: Generate a short list of potential solutions, along with the disciplines that may be required to realize each. This helps to ensure that projects are feasible.

* Project Deliverables: Minimum requirements: Wire movement fixture is completely operational; wire can be unwound from the supply spool and wound up on the takeup spool. System can operate between 0 m/s and 20 m/s . System can unwind from 0-1000m of wire and windbackup 0-1000m. Fixture can simulate several real world job scenarios supplied by GlassFab. Fixture can control and maintain tension between 10n and 40n. Fixture is properly instrumented to evaluate performance of th wire supply and takeup system. Team has actively participated in the development and delivery of a CAD based final wire cutting saw. Design that incorporates all of the key functional elements for P16601, 16602, and 16603. The design will be captured in CAD as a proposed wire saw system. Additionally, appropriate system level documentation such as timing diagrams, operational details and use cases will be created. A comprehensive rollup of key parameters such as cost, weight, power consumption etc.. will be created and managed to minimize running costs/ cut. All design documents (e.g., concepts, analysis, detailed drawings/schematics, BOM, test results) Technical paper per course standards. Presentation poster per course standards.

RIT – Kate Gleason College of Engineering Multidisciplinary Senior Design Project Readiness Package Template Revised Jan 2015 Team will demonstrate working prototype at ImagineRIT.

Additional required deliverables: List here, if applicable

† Budget Information: List major cost items anticipated, and any special purchasing requirements from the sponsor(s). Budget is being finalized by client at this time.

* Intellectual Property: Describe any IP concerns or limitations. Is there patent potential? Will confidentiality of any data or information be required? IP is possible.

RIT – Kate Gleason College of Engineering Multidisciplinary Senior Design Project Readiness Package Template Revised Jan 2015 Project Resources

† Required Resources (besides student staffing): Describe the resources necessary for successful project completion. When the resource is secured, the responsible person should initial and date to acknowledge that they have agreed to provide this support. We assume that all teams with ME/ISE students will have access to the ME Machine Shop and all teams with EE students will have access to the EE Senior Design Lab, so it is not necessary to list these! Limit this list to specialized expertise, space, equipment, and materials.

Faculty list individuals and their area of expertise (people who can provide specialized knowledge unique to your project, e.g., faculty you will need to consult for Initial/ more than a basic technical question during office hours) date Professor Wellin; technical consultant on projects 16601 16602 and 16603 Environment (e.g., a specific lab with specialized equipment/facilities, space for very large or oily/greasy projects, space for projects that generate airborne debris or Initial/ hazardous gases, specific electrical requirements such as 3-phase power) date Will need significant floor space for fixtures for 16601 16602 16603 Equipment (specific computing, test, measurement, or construction equipment that Initial/ the team will need to borrow, e.g., CMM, SEM, ) date

Materials (materials that will be consumed during the course of the project, e.g., test samples from customer, specialized raw material for construction, chemicals that must Initial/ be purchased and stored) date

Initial/ Other date

† Anticipated Staffing By Discipline: Indicate the requested staffing for each discipline, along with a brief explanation of the associated activities. “Other” includes students from any department on campus besides those explicitly listed. For example, we have done projects with students from Industrial Design, Business, Software Engineering, Civil Engineering Technology, and Information Technology. If you have recruited students to work on this project (including student-initiated projects), include their names here, as well!

Dept. # Req. Expected Activities BME CE EE 1.Drive roll motor selection and implementation, 2. Sensors for operation and test activities ISE Very Active participation on systems engineering team; define and implement work processes where necessary for system integration

RIT – Kate Gleason College of Engineering Multidisciplinary Senior Design Project Readiness Package Template Revised Jan 2015 ME 4 1. Active participation on systems engineering team includes CAD; DME , 2. Lead design activities on guide roller sizing, DME 3. CAD design for test fixture; extensive DME, 4. CAD design for fixture; extensive DME Other

* Skills Checklist: Indicate the sills or knowledge that will be needed by students working on this project. Please use the following scale of importance: 1=must have 2=helpful, but not essential 3=either a very small part of the project, or relates to a “bonus” feature blank = not applicable to this project

Mechanical Engineering ME Core Knowledge ME Elective Knowledge 1 3D CAD 1 Finite element analysis Matlab programming Heat transfer 1 Basic machining Modeling of electromechanical & fluid systems 1 2D stress analysis 1 Fatigue and static failure criteria 1 2D static/dynamic analysis 1 Machine elements Thermodynamics Aerodynamics Fluid dynamics (CV) Computational fluid dynamics LabView Biomaterials Statistics Vibrations 1 Materials selection IC Engines 1 GD&T 1 Linear Controls Composites Robotics Other (specify)

Electrical Engineering EE Core Knowledge EE Elective Knowledge Circuit Design (AC/DC converters, regulators, amplifies, analog filter design, FPGA logic design, Digital filter design and implementation sensor bias/support circuitry) 1 Power systems: selection, analysis, power budget Digital signal processing 1 System analysis: frequency analysis (Fourier, Laplace), stability, PID controllers, modulation Microcontroller selection/application schemes, VCO’s & mixers, ADC selection Circuit build, test, debug (scope, DMM, function Wireless: communication protocol, component generator selection Board layout Antenna selection (simple design) Matlab Communication system front end design PSpice 1 Algorithm design/simulation Programming: C, Assembly Embedded software design/implementation Electromagnetics: shielding, interference Other (specify)

RIT – Kate Gleason College of Engineering Multidisciplinary Senior Design Project Readiness Package Template Revised Jan 2015 Industrial & Systems Engineering ISE Core Knowledge ISE Elective Knowledge Statistical analysis of data: regression 2 Design of Experiment Materials science 1 Systems design – product/process design Materials processing, machining lab Data analysis, data mining Facilities planning: layout, mat’l handling 1 Manufacturing engineering 1 Production systems design: cycle time, throughput, DFx: manufacturing, assembly, environment, assembly line design, manufacturing process 1 sustainability design Ergonomics: interface of people and equipment 1 Rapid prototyping (procedures, training, maintenance) Math modeling: OR (linear programming, Safety engineering simulation) Project management Other (specify) Engineering economy: Return on Investment Quality tools: SPC Production control: scheduling Shop floor IE: methods, time studies Computer tools: Excel, Access, AutoCAD Programming (C++)

Biomedical Engineering BME Core Knowledge BME Elective Knowledge Matlab Medical image processing Aseptic lab techniques COMSOL software modeling Gel electrophoresis Medical visualization software Linear signal analysis and processing Biomaterial testing/evaluation Fluid mechanics Tissue culture Biomaterials Advanced microscopy Labview Microfluidic device fabrication and measurement Simulation (Simulink) Other (specify) System physiology Biosystems process analysis (mass, energy balance) Cell culture Computer-based data acquisition Probability & statistics Numerical & statistical analysis Biomechanics Design of biomedical devices

Computer Engineering CE Core Knowledge CE Elective Knowledge Digital design (including HDL and FPGA) Networking & network protocols Software for microcontrollers (including Linux Wireless networks and Windows) Robotics (guidance, navigation, vision, machine Device programming (Assembly, C) learning, control) Programming: Python, Java, C++ Concurrent and embedded software Basic analog design Embedded and real-time systems Scientific computing (including C and Matlab) Digital image processing

RIT – Kate Gleason College of Engineering Multidisciplinary Senior Design Project Readiness Package Template Revised Jan 2015 CE Core Knowledge CE Elective Knowledge Signal processing Computer vision Interfacing transducers and actuators to Network security microcontrollers Other (specify)

RIT – Kate Gleason College of Engineering Multidisciplinary Senior Design Project Readiness Package Template Revised Jan 2015