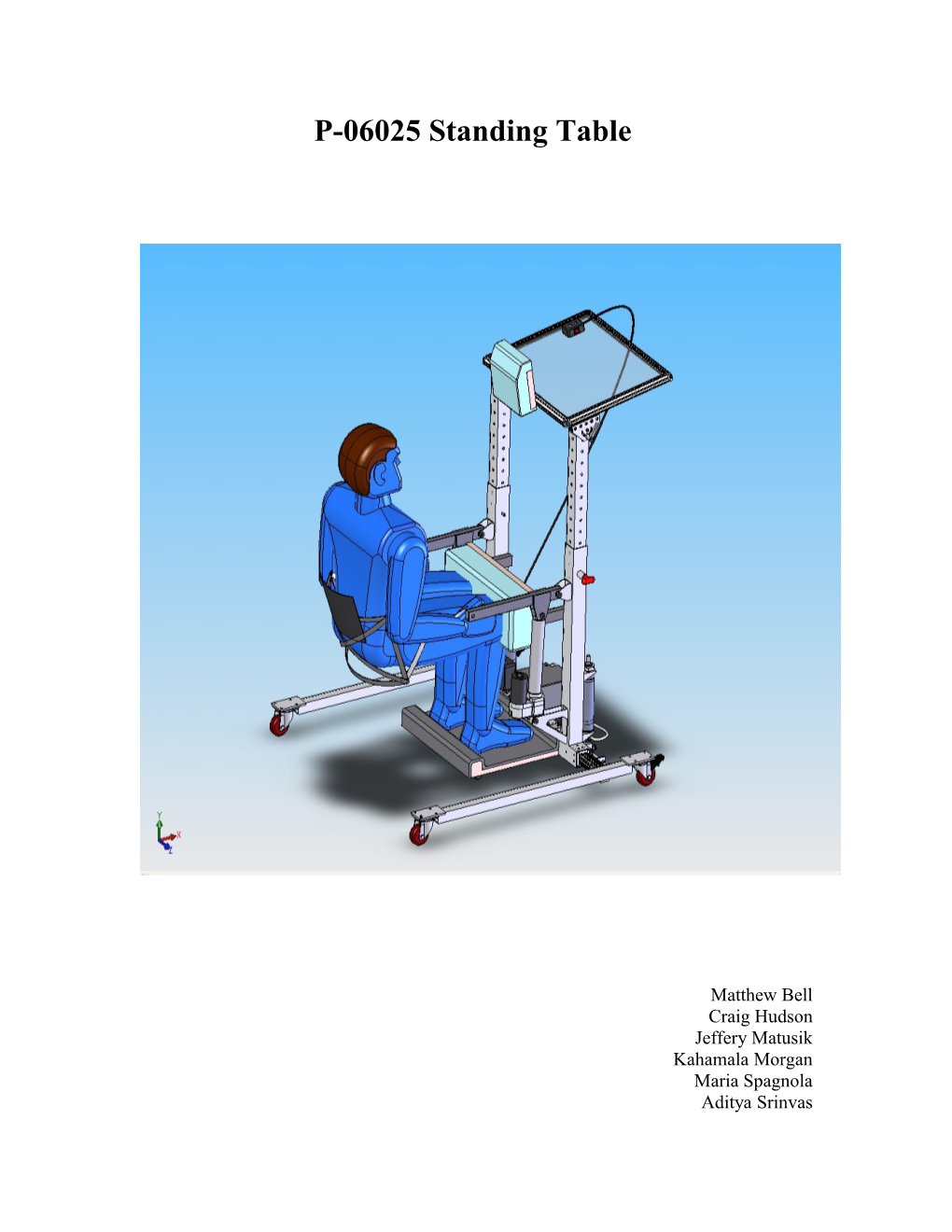

P-06025 Standing Table

Matthew Bell Craig Hudson Jeffery Matusik Kahamala Morgan Maria Spagnola Aditya Srinvas Senior Design Team P06205 Winter 2005-2006 Table of Contents 1 Project Introduction and Overview...... 5 1.1 Project Initiation...... 5 1.2 Project Beneficiary, the ARC...... 5 1.3 Definition of a Standing Table...... 6 1.4 Health Benefits of Standing...... 6 1.5 Project Projections...... 7 2 Team Mission Statements...... 9 2.1 Primary Goals...... 9 2.2 Primary Stakeholders...... 9 2.3 Key Business Goals...... 10 2.4 Primary and Secondary Markets...... 10 2.5 Success Winners and Qualifiers...... 11 3 Individual Roles and Responsibilities...... 13 3.1: Team Roles Tree...... 13 3.2 Project Manager, Craig A. Hudson...... 13 3.3 Report Organizer, Matthew Bell...... 13 3.4 Meeting Minutes, Jeff Matusik...... 14 3.5 Co-Lead Engineer, Maria Spagnola & Aditya Srinivas...... 14 3.6 Budget & Purchasing, Kahamala T. Morgan...... 14 4.1 Team Structure Tree...... 15 4.2 Power Team...... 16 4.3 Biomechanics & Ergonomics Team...... 16 4.4 Frame Design Team...... 17 5 Team Timeline...... 18 5.1 Winter Quarter...... 18 5.1.1 Needs Facet...... 18 5.1.2 Specifications Facet...... 18 5.1.3 Feasibility Assessment...... 19 5.1.4 Team Design...... 19 5.2 Spring Quarter, Future Plans...... 20 6 Ergonomics...... 21 6.1 Introduction to Ergonomics...... 21 6.2 Standing Risks and Benefits...... 22 6.3 Ergonomic Design Parameters...... 22 6.3.1 Height Thresholds...... 22 6.3.2 Weight Thresholds...... 24 6.3.3 Pad and Footplate Placement...... 24 6.3.4 Harness Design...... 25 6.3.5 Chest Pad and Table Parameters...... 25 7 Customer Needs and Specifications...... 27 7.1 Needs and Specifications Overview...... 27 7.2 Formal Needs Statements...... 27 8 Concept Development...... 32 8.1 General Concept Development...... 32 8.2 Detailed Concept Development...... 33 9 Project Feasibility...... 35 9.1 Feasibility overview...... 35 Page 2 of 150 Senior Design Team P06205 Winter 2005-2006

9.2 Non-weighted Pugh Analysis...... 35 9.3 Determination of Assessment Weights...... 36 9.4 Weighted Pugh Analysis...... 37 10 Base Design and Analysis...... 38 10.1 General Base Design...... 38 10.2 Fluid Drive System...... 39 11 Design of the Lifting Mechanism...... 41 11.1 Design Challenges...... 41 11.2 Solution Methods...... 42 12 Circuit Design and Analysis...... 44 12.1 Necessary Circuit Requirements...... 44 12.2 Circuit Components and Layout...... 44 13 Leg Design and Analysis...... 46 13.1 Free Body Diagram and Solutions...... 46 14 Table Top and Support Design and Analysis...... 48 14.1 Free Body Diagrams and Solutions...... 48 15 Product Strengths and Weaknesses...... 50 16 Method of Operation...... 52 16.1 Operating Instructions...... 52 16.2 Safeguards and Warnings...... 53

Appendices: Table of Contents...... 55 Appendix A – Project Proposal...... 57 Appendix A – Project Proposal...... 57 Appendix B – Mission Statement...... 60 Appendix C – Team Values and Norms...... 63 Appendix D – Gantt Chart...... 64 Appendix E – Feasibility...... 65 Section 1 – Pugh Analysis...... 65 Section 2 - QFD...... 66 Section 3 – Determination of Weights...... 68 Section 4 – Determination of Weights Results...... 69 Section 5 – Weighted Pugh Analysis...... 70 Appendix F – Ergonomics...... 71 Section 1 – Anthropometric Data Table (Height)...... 71 Section 2 – Relative Body Dimensions...... 71 Section 3 – Generic Body Weights...... 72 Section 4 – Segment Weights of 300lbs. Person...... 72 Section 5 – FEA Analysis of Footplate...... 73 Appendix G – The Five Whys...... 74 Appendix H – Concept Generation...... 78 Section 1 - Brainstorming...... 85 Section 2 – Requirements, Needs, and Guidelines...... 85 Section 3 – Design Parameters...... 86 Section 4 – Objective Trees...... 87 Section 5 – Morphological Charts...... 91 Section 6 – Individual Concepts...... 93 Section 7 – Team Preliminary Concepts...... 94

Page 3 of 150 Senior Design Team P06205 Winter 2005-2006

Section 8 – Final Morphological Chart...... 95 Section 9 – Final Concepts...... 96 Appendix I – Pneumatic Fluid Drives...... 97 Section 1 – Solid Model: “Extend” Drive Cylinder...... 97 Section 2 – Solid Model: Fluid Drive/Leg Interface...... 98 Section 3 – Fluid Drive Ratio Formulas...... 100 Section 4 – Force and Travel Ratios for Cylinder Bore...... 101 Section 5 – Fluid Drive Schematic...... 102 Section 6 – FEA Analysis of Drive Cylinder Assembly...... 103 Section 7 – Stress Lift Curves of Base Assembly...... 104 Appendix J – Force Determination for Lifting...... 105 Section 1 – Body Segment Weights...... 105 Section 2 – Strap Forces...... 105 Section 3 – Angle and Force Determination...... 106 Section 4 – Torque Equation...... 107 Section 5 – Force and Torque Summary...... 107 Section 6 – Forces and Torques Graph...... 108 Section 7 – Torques Generated by Individuals...... 109 Section 8 – Force Required to Lift Individuals...... 110 Section 9 – Actuator Duty Cycles...... 111 Section 10 – Free Body Diagram of Lift Arms...... 111 Section 11 – FEA Analysis of Lifting Arm...... 112 Section 12 – Pin Shear Calculations...... 113 Section 13 – Stress Life Curves for Lifting Assembly...... 114 Appendix K – Table Electronic Systems...... 115 Section 1 – Circuit Schematic...... 115 Section 2 – Battery & Charger...... 116 Section 3 – Wiring Diagram for Circuit...... 120 Appendix M – Force in Main & Secondary Support...... 125 Appendix N – Stress in Table & Bolt...... 128 Appendix O – Bill of Materials (BOM)...... 129 Appendix P – Assembly Plans...... 131 Appendix Q – Business Plan Outline: Standing Table...... 134 Appendix R – Engineering Drawings...... 147

Page 4 of 150 Senior Design Team P06205 Winter 2005-2006

1 Project Introduction and Overview

1.1 Project Initiation Senior Design Project #P06205 was officially commissioned during the time that RIT received a grant from the National Science Foundation (NSF) and began to compile a list of projects that would meet the needs of the community, satisfy the objectives of

Rochester Institute of Technology’s (RIT) Senior Design program, and qualify for funding via the NSF grant. The grant was provided to RIT for the purpose of furthering the design and development of devices to improve the quality of life of disabled individuals. Work on the project first began during the fall quarter of 2005 during which,

Craig A. Hudson, the future project manager, began to compile preliminary documents detailing the needs, objectives, and design parameters that would need to be addressed by the team. The purpose of the project was to design, build, and test a standing table, also known as a powered standing lift, for use by the ARC of Monroe County in its residential program. A copy of the original project proposal, as presented to seniors entering the

Senior Design program in the Fall of 2005 can be found in Appendix A.

1.2 Project Beneficiary, the ARC The Arc of Monroe County is a non-profit (NP) foundation dedicated to providing services to individuals with physical or mental disabilities. The organization provides a warm enriching environment encouraging its members with physical or mental disabilities to celebrate their unique talents through recreation, community involvement and volunteerism. It provides a number a day, residential and vocational services which

Page 5 of 150 Senior Design Team P06205 Winter 2005-2006 aim to meet the different variety of care types, length, and scope that are needed by different individuals. More information can be found at the foundation’s website located at www.arcmonroe.org.

The standing table project is an attempt to provide help to this noble cause in the form of

Senior Design project (project #P06205) at RIT. As the ARC is an NP company, they do posses the necessary finances to purchase and use a commercially available standing table. The Standing Table Project is being designed by a team of six Rochester Institute of Technology students currently in their senior year.

1.3 Definition of a Standing Table A standing table is a device that allows individuals, unable to stand on their own, maintain a vertical standing position with either partial or full weight support. A table also allows the users to transfer from a seated position in a wheelchair or bed to another seating location, or to a standing position with some aid. A more detailed analysis and description of the method of operation can be found in the discussion of the methods of operation found in section 16.

1.4 Health Benefits of Standing Standing, in general, has a number of health benefits as it has been proven over the years by a number physicians and therapists. Standing facilitates the improvement of balance and strength of the upper body, as well as improving the range of motion of the spine, hips, knees, and ankles. Additionally, standing aids in good blood circulation throughout the body. Standing is also able to reduce pressure issues through changing positions,

Page 6 of 150 Senior Design Team P06205 Winter 2005-2006 improves systemic functions (digestive, bladder, respiratory, etc.). Standing also prevents the loss of bone density, alleviates pain caused by inappropriate positions and standing by itself also develops tolerance and endurance in the body. Another extremely important advantage of standing is the psychological benefits it provides to a person, as being reduced to spending your entire life from a seated position can be damaging to an individual’s self esteem. The standing table would provide its users a sense of independence and thus increase their self esteem. It can enhance social development and also interaction with peers. Thus, the standing table project is of immense importance for the ARC, and is a privilege for the team to design it. A more detailed analysis and description of the health benefits can be found in the discussion of the ergonomic factors found in section 6.

1.5 Project Projections As written above, a standing table provides a number of advantages that the ARC is currently unable to make use of. By designing a standing table that is able to support

95% of the entire population, the ARC will be able to utilize this device for the enjoyment, benefit, and health of its residents. While the table is currently planned to be left in a single residential home that provides service for only a handful of individuals, the design of the table is such that transporting it is a fairly easy process.

As stated previously, the project commenced at the beginning of the winter quarter of the

2005-2006 school year at RIT, and is currently scheduled to finish at the end of the spring quarter in May of 2006. The team involved in this project has been able to expand their knowledge on the biomechanics of people with different physical disabilities, and have

Page 7 of 150 Senior Design Team P06205 Winter 2005-2006 been able to gain experience in applying various engineering and design concepts in a multidisciplinary design environment. It is the team’s sincere desire that this project is going to be of great use to the ARC once it is finished, and would help to improve the quality living of all its members. Additionally, the team hopes that its final prototype is of a caliber that displays the quality of their hard work over the past five years, and would be able to compete in the market place if it was to be commercially produced.

Page 8 of 150 Senior Design Team P06205 Winter 2005-2006

2 Team Mission Statements

After defining a project, it is important for any group to formally state their mission. The intent of the team, within the next few pages, is to provide a brief overview of the team’s goals, priorities, and the limitations inherent to the project. For a comprehensive layout of the group’s mission statement, please see Appendix B.

2.1 Primary Goals The primary goal of the team, as defined by the customer, was to provide the ARC of

Monroe County with a complete working prototype of a standing table. The table is to be used on a daily, or near daily basis, so it is imperative that they are presented with a functioning, low maintenance design.

2.2 Primary Stakeholders The primary stakeholders for the standing table project are the team members, the ARC of Monroe county therapists and residents, and Dr. Elizabeth DeBartolo, the team mentor.

The stakeholders with the most vested into the project are the team members, and their mentor. For reasons that should be apparent for the interests of the team, successful completion of the Senior Design curriculum is a factor involved in determining their ability to graduate at the end of the current school year, and hence places the team as a primary stakeholder. However, the reasons for the team mentor’s stake in the project may not be quite as obvious. Due to the fact that funding for the project was provided by a grant from the National Science Foundation, Dr. Debartolo has been charged with being a good steward of a large sum of grant money. In order to ensure future funding of projects, it is important that currently funded teams utilize the available funds to the best Page 9 of 150 Senior Design Team P06205 Winter 2005-2006 of the school’s ability. The ARC affiliates themselves have the most potential to gain from this project, as they will be able to acquire a fully working, customized standing table, at no cost to them.

2.3 Key Business Goals Although Senior Design teams rarely evolve into anything more than a student led team, it is still important to conduct the team as though it is, or at the least has the potential, to be a business. Hence, the business goals of the team reflect a broad collection of ideals held by most of the business community. First and foremost, the design team is striving to build a better product, or minimally, a better valued product than currently exists on the commercial market. During the attempt to reach the first goal, there shouldn’t be any excessive, or undue, liability placed upon any of the stakeholders in any form. Please refer to Appendix B for a more in depth view of these liabilities, and how they are to be minimized.

2.4 Primary and Secondary Markets Again following the premise that a Senior Design project has the potential to be a working business prototype, a set of detailed primary and secondary markets were laid out. Listed as the primary market targets were the ARC residents and therapists, the engineering faculty at RIT, parents of students on the design team, and the students who could have been potential team members.

As the ARC is the main material beneficiary of the project, it is important that they are satisfied with the features of the design, and the overall build quality. In order to develop

Page 10 of 150 Senior Design Team P06205 Winter 2005-2006 a product it is a bare necessity to have students that are not only well qualified, but also interested in the project. Thus, the engineering students of RIT also become a market as it is imperative to attract a broad knowledge base along with top notch skills. If the project does not appeal to students as much as other projects do, there is a risk of acquiring students that are here to pass the course, and are not interested in performing at the levels required.

The engineering faculty at RIT, and the parents of students at RIT, make up a primary market in that they have a vested interest in the success of their students and children. As is true of any investment, individuals desire to see their work and money used to its greatest potential. Thus, parents have invested a large amount of time and money in raising, teaching, and supporting current students, while the engineering faculty has invested a large amount of time in teaching and training their students. Therefore, it is not much to ask that the final capstone project would be able to showcase, to its utmost, the extent to which students have grown and acquired knowledge of engineering practices.

2.5 Success Winners and Qualifiers While the formal mission statement details the success qualifiers and winners, only a very brief overview will be given here. Essentially, the qualifiers are a list of the needs and goals that must be met in order for the team to reach minimal success. Success winners, on the other hand, are a list of what the team can do to meet and exceed any expectations placed upon the team and the design of the standing table. Again, as these qualifiers and winners are practically a formal written statement of customer needs, and a modified

Page 11 of 150 Senior Design Team P06205 Winter 2005-2006 formation of team goals, they will not be discussed here further. Please refer to

Appendix B, Sections 8 & 9 if more information is desired.

Page 12 of 150 Senior Design Team P06205 Winter 2005-2006 3 Individual Roles and Responsibilities

3.1: Team Roles Tree

Craig Hudson (Team Manager) ME

Maria Matthew Bell Jeff Matusik Kahamala Spagnola Aditya Srinivas (Report (Meeting Morgan (Co-Lead (Co-Lead Organizer) Minutes) (Budget) Engineer) Engineer) ME IE ME ME EE

Figure 1 Individual Jobs

3.2 Project Manager, Craig A. Hudson At the start of the first group meeting, the roles and responsibilities of the group members were assigned. The group leader, Craig Hudson, a mechanical engineer, was responsible for keeping the group on target and meeting the deliverables schedule as established by our customer and the RIT Senior Design Program. Craig facilitated the communication between the many disciplines involved and also served as a point of reference for the entire group.

3.3 Report Organizer, Matthew Bell Matthew Bell, a mechanical engineer, was designated as the main contact person for gathering together the pieces of the report. All individual work was to be given to him so

Page 13 of 150 Senior Design Team P06205 Winter 2005-2006 that he could provide some cohesion between the different written portions that were to be combined for the final report.

3.4 Meeting Minutes, Jeff Matusik Jeff Matusik, an industrial engineer, was responsible for recording any important information that was given or developed during the group meetings and distributed it to the team members via email. Jeff served as the reference point for our previous concepts and ideas throughout the project so that a linear timeline could easily be looked back upon.

3.5 Co-Lead Engineer, Maria Spagnola & Aditya Srinivas Maria Spagnola, a mechanical engineer, and Aditya Srinivas, an electrical engineer volunteered to both become Co-Lead Engineers. They were both responsible for proofreading and validating any paper work that was put into the group binder and report.

Maria and Aditya also served as secondary checks for any of the calculations that were performed.

3.6 Budget & Purchasing, Kahamala T. Morgan Kahamala Morgan was responsible for the team budget. Kahamala was not only in charge of putting together the final Bill of Materials, but also kept the group members aware of team spending in order to prevent the project from becoming over budget.

Page 14 of 150 Senior Design Team P06205 Winter 2005-2006 4 Team Structure

Due to the fairly large size of the team, and the many disciplines involved, it was determined that it would be best to divide the team into three subgroups. Each subgroup would be responsible for one of the three major components of the standing table:

Biomechanics/ergonomics, frame, and power/force generation. A copy of the “Team

Values and Norms”, a written contractual agreement of teamwork, can be found in

Appendix C.

4.1 Team Structure Tree

STANDING TABLE

BIOMECHANICS/ ERGONOMICS FRAME POWER Jeff and Maria Kahamala and Matt Aditya and Craig

ELECTRICAL Aditya

ACTUATOR & CYLINDERS Craig

Figure 2 Team Organizational Chart

Page 15 of 150 Senior Design Team P06205 Winter 2005-2006

4.2 Power Team Because of the somewhat wider scope of involved in powering the standing table, the

Power subgroup was divided into an electrical and actuators/cylinders subset. Aditya was responsible for the battery selection, designing a remote that would be used to operate the device, and for interfacing the electrical components with the mechanical components. Craig was responsible for selection of the actuators that would be used to lift the patients using the standing table. This was a challenging, yet exciting, responsibility because the actuators needed to be able to produce enough force to safely lift an individual, while at the same time fitting the limited space design of a standing table. A second important issue was also the development of expanding legs for the base of the frame. The legs had to be designed such that they were expandable to accommodate different chair styles, but at the same time must still be able to fit into the compact footprint area of the design.

4.3 Biomechanics & Ergonomics Team The Biomechanics/Ergonomics team was responsible for determining the relationship between the interaction of the human subject and the lifting mechanism, table surface, and pads/supports. Other responsibilities included determining the forces acting on the body, the range of comfort of the average adult, as well as the height and weight requirements necessary to ensure a safe and working design. The information provided by this team was invaluable in determining not only the position of the pads and supports which they designed, but also for generating the dimensions our overall design in order to provide a safe, stable, and comfortable environment for the user when using our product.

Page 16 of 150 Senior Design Team P06205 Winter 2005-2006

4.4 Frame Design Team Finally, the responsibilities of the Frame team were to design and analyze the primary and secondary supports of the system, determine the load requirements and forces acting on the system, and also identify the possible areas of maximum stress and fatigue. The frame team was also responsible for designing a table top that was not only height adjustable, but able to pivot to a location that was comfortable for the user.

While each of the three subgroups had specific assigned responsibilities, it was a group effort to ensure that all the different components interfaced well with each other.

Additionally, as needed, different teams would provide some concept development as well as technical support to other groups. The subgroups were, in no way, forced to adhere only to their assigned work, but were encouraged to network with, and work with, other groups on a weekly basis.

Page 17 of 150 Senior Design Team P06205 Winter 2005-2006 5 Team Timeline

5.1 Winter Quarter A complete Gantt chart detailing the proposed project schedule for the team can be found in Appendix D.

5.1.1 Needs Facet A majority of the preliminary information necessary for this project was completed prior to the start of Senior Design due to the project leader’s completion of Design Project

Management during the fall quarter. However, a group review and revision of these documents was performed after meeting with the Arc Representative to determine their customer needs. The initial documents had been created only with the input from a single individual. By reviewing all of the preliminary documents as a team, the unique input, as well as combined team input, was added to ensure much broader coverage and analysis of the project. The next task was to complete a needs assessment analysis. Extensive research was performed to ascertain any standards that pertained to the construction of a standing table and to also compare current models in the market. Simultaneously,

Functional and Why analyses were performed to determine which design functions and parameters would determine the success, or failure of a design, what environment the standing table would be used in, and the underlying reasons why the consumer needed this product. The needs assessment enabled the team to identify the customer’s needs and develop a plan of action that would satisfy those needs.

5.1.2 Specifications Facet The next phase in the product development was the specifications facet. During this phase, a requirements document was finalized, a verification and validation plan was Page 18 of 150 Senior Design Team P06205 Winter 2005-2006 created, and the QFD was reviewed and revised. The general dimensions and other specifications of the standing table were determined in order to begin the concept process. During the concept development period, there was a group brainstorming session in which a morphological chart was created. From these ideas, the six group members developed two individual concept ideas to present to the group. Through a non- weighted Pugh analysis, the best of these twelve ideas were decided upon and presented at the concept peer review. After this review, more concept research and development was performed and finally, the group decided upon a final concept. The results of this

Pugh analysis can be found in Appendix E, Section 1.

5.1.3 Feasibility Assessment As this section is oriented towards giving a general overview of the project schedule and series of events, no in depth look will be given here. For more information, please refer to the Feasibility Analysis, Section 9.

5.1.4 Team Design During the latter half of the quarter the following goals were accomplished: development of component models and drawings, identification of suppliers and vendors, creation of assembly and production drawings, and a final cost analysis and Bill of Materials. The final phase was to review the QFD and needs assessment to ensure that we had met and exceeded the customer’s requirements. The remainder of the quarter was spent preparing for the PDR and preparing for senior design II.

Page 19 of 150 Senior Design Team P06205 Winter 2005-2006

5.2 Spring Quarter, Future Plans During the second ten weeks of the project, the group will continue to implement the ideas and concepts from Senior Design I into a working model. It is expected that most of the parts necessary will be delivered within the first or second week of spring quarter.

The primary focus of the quarter will be to finalize a build plan and create a finished prototype. Machining tasks will be assigned and executed based on skill level. If time permits, the prototype will be thoroughly tested, and preparation for the final design review will be completed.

The group will also decide upon an instruction manual for the utilization of the standing table, in order to ensure that any sources of failure and misuse are minimized. The manual will contain information about inspecting for structural damage, but it will also provide information about replacing batteries and other high wear parts, if necessary.

The manual will also be used as a safety manual; what to do in the case of the device getting stuck while in operation and explain the emergency override features.

Finally, the team will once again put together a detailed report based on our analysis from winter quarter and from our work and findings from spring quarter into a comprehensive report that will cover the conception of the design to its implementation as a working prototype.

Page 20 of 150 Senior Design Team P06205 Winter 2005-2006 6 Ergonomics

6.1 Introduction to Ergonomics Before any real design work or even any useful brainstorming could begin, it was vitally important for the team to research and understand the basic ergonomic factors relating to a standing table. Ergonomics is the science of designing a job or task to fit a worker, rather than the worker trying to adapt to the job. Modifying tasks, tools, and work stations can help reduce physical stress on a person’s body and eliminate potential musculoskeletal disorders (MSD). Musculoskeletal disorders are injuries to the soft tissues of the body (muscles, ligaments, tendons, etc.) and the nervous system. When equipment is designed without considering ergonomic principles, there is an increased risk of exposure to physical stress, strain, awkward postures, forceful exertion, repetitive motion, and heavy lifting. Health care facilities have been identified by OSHA as an environment where ergonomic stressors exist.

There are many residents/patients at care facilities that are wholly dependent on staff members for daily activities. Each activity involves an interaction with handling or transferring the resident which could result in employee injuries. Injuries to workers can increase costs to the employer and cause staffing shortages. To minimize injuries, OSHA recommends that “employers identify and address ergonomic stressors in their facility’s safety and health plan”. Six of the top 10 professions at greatest risk for back injury are: nurse’s aides, licensed practical nurses, registered nurses, health aides, radiology technicians and physical therapists (Nash, 2003).

Page 21 of 150 Senior Design Team P06205 Winter 2005-2006

6.2 Standing Risks and Benefits A patient or resident, who is dependent upon others, cannot be left sitting down for prolonged periods of time. Sitting is a static posture that increases stress in the neck, shoulders, back, arms, and legs. In particular, it can add large amounts of pressure to spinal disks and back muscles. In order to help alleviate these stressors, the resident should be allowed to stand up periodically. Standing helps increase blood flow and reduces fatigue.

A resident who is dependent upon others to transfer from a sitting to standing position would need the assistance of a staff member. The staff member, however, should not try to lift the patient themselves as it increases the risk of injury to themselves. Even if the injury is not acute, the repetition of such actions can lead to an MSD. Therefore, it is necessary to have a lifting device such as a standing table to help a staff member assist a resident or patient.

When lifting a person from a sitting position, it is important for the patient to feel secure and comfortable. An efficient and simple design will help make the device easy to use for the assisting staff member. Any part of the lifting device which the patient may come into contact with should be comfortable and safe.

6.3 Ergonomic Design Parameters

6.3.1 Height Thresholds To design a lifting device, one must consider the variable sizes of a potential user. In order to help determine the relative size of the device, anthropometric data is used to estimate the measurements of the user. When considering a mixed population (50% Page 22 of 150 Senior Design Team P06205 Winter 2005-2006 male, 50% female), the 95th percentile male and 5th percentile female are used as upper and lower limits. Using these percentiles, 95% of all users will be covered (because of the overlap between male and female body dimensions).

Research done by Drillis and Contini has suggested that the body is made up of mechanical links which are proportional to our total body height. The link-length diagram in Figure 3 shows the length of body segments as proportions to body height.

The height of a 95th percentile male is 73.6” and the stature of a 5th percentile female is

59.8” (see Appendix F, Section 1). Multiplying these heights by the ratios will give you the approximate length of the body segment (see Appendix F, Section 2).

Figure 3

Page 23 of 150 Senior Design Team P06205 Winter 2005-2006

6.3.2 Weight Thresholds The design parameters for this device require it to be able to lift a maximum of 300lbs.

To determine the relative weights of body segments, ratios of the total body weight can be calculated based on data from Drillis and Contini (see Appendix F, Section 3). For example, the relative weight of a 300lbs person’s thigh would be calculated by first determining the weight of the total leg (300lbs. X .157 = 47.1lbs.) and then taking 63.7% of the total leg (30.0lbs.). For the rest of the relevant body segment weights see

Appendix F, Section 4.

6.3.3 Pad and Footplate Placement In order to lift someone from a seated position, a moment is created about the knees. For this reason, it is important to keep the knees stationary, and in order to do so, a knee pad is required. Using the link-length diagram, the distance between a 95th percentile males’ knees can be calculated. This will help determine the maximum width of the knee pads.

The height of the knee pad is found using the link-length diagram as well, taking the ratio of the bottom of the foot to the knee for both the 5th percentile female and 95th percentile male. Making the pad large enough will allow the majority of the population to be able to use it, without having to adjust the kneepad.

To prevent the user’s feet from slipping while they are using the standing table, a foot plate is used. The surface of the plate is an anti-fatigue mat, which are designed to reduce fatigue from standing for long periods on hard surfaces. The mat also serves as traction for the user, to prevent them from slipping. A back stop is also used on the foot plate to prevent slipping, with a foam pad used for comfort and protection against the hard surface. Page 24 of 150 Senior Design Team P06205 Winter 2005-2006

6.3.4 Harness Design Lifting a patient from a seated position requires supporting the lower back/hip region. To do this safely, a padded harness is used which can slip under and behind the user before they are ready to be lifted. There are different settings of hoops along the straps of the harness which can be placed on the pegs of the lifting arms, which will allow users of different body types to be securely strapped in.

With the knees and feet set in place, and a harness lifting the user from the hips, a moment is created about the knees. This will not only lift the patient upwards, but also force them into the knee pads. Foam with an Indentation Load Deflection (ILD) of 80lbs. is used to help reduce the force placed upon the user’s knees. Calculating the moment created about the knees will determine what the maximum force will be on the system.

The harness used to lift the patient was designed to fit around a 95th percentile male, providing back and side support. Attached to the ends of the harness are straps with rings connected to them. The user can connect the rings to different pegs on the lifting arm

(depending on their size), which will then securely hold the patient before standing.

Within the harness is a back support, which is flexible but firm enough to provide support for the lower back of the user.

6.3.5 Chest Pad and Table Parameters When the user is lifted into a standing position, they will be brought into a chest pad.

This pad will provide support for the patient, to keep them in an upright position. The size and location of this pad can be determined by once again using the link-length Page 25 of 150 Senior Design Team P06205 Winter 2005-2006 diagram. The chest pad should be no higher than shoulders of a 5th percentile female, while at the same time, provide enough support for a 95th percentile male. The foam used is dense enough to provide firm support for the user, while also compressing to make it comfortable to use.

The height of the table top is adjustable on two supporting arms. The table should be located just below the elbows of the user, which would allow them to reach across the table without over extending their shoulders. The chest pad is attached to the edge of the table which will allow users to lean forward without creating a pressure point against the edge of the table.

This standing table is designed to fit 95% of the population, with a maximum weight limit of 300lbs. The proposed design will allow the nurse or aid to make minimal adjustments for specific residents, providing comfort and support for all users. Not only will the patient benefit from being able to stand periodically, but the employees will also reduce their risk of injury.

Page 26 of 150 Senior Design Team P06205 Winter 2005-2006

7 Customer Needs and Specifications

7.1 Needs and Specifications Overview As is true of any problem, it is imperative that the team or individual assigned to the task is able to fully comprehend the nature of the issue. Secondly, it is of equal importance that the task force is able to ascertain whether or not the problem, as defined by the customer, is truly the problem that needs to be solved, and not simply the customer’s solution to their real problem.

During the meeting with the customer, it was necessary to clarify that the initial needs presented to the project manager during the fall quarter of 2005 were actually the basic needs of the client which need to be met, and not customer solutions. For a more detailed description of the meeting with the ARC, please refer to “The Five Whys” in

Appendix G. Following the meeting with the customer, the team met to write down and quantify the actual customer needs.

7.2 Formal Needs Statements The following is a list of these needs along with a brief description.

Adjustable Knee Pads: The knee pads for the table are used to support the knees

during the operation of the table. These knee pads should be made adjustable or

sized such that they accommodate 95% of the population variances.

Page 27 of 150 Senior Design Team P06205 Winter 2005-2006

Universal Design: The standing table needs to be universally adaptable in nature,

and should follow the general ADA regulations. Universality is, however, limited

to adult use.

Adult Use: The standing table is to be used only by adults and, thus, it does not

need to cover the heights and weights of children in its range of adjustability.

Lifting: The standing table is to aid in lifting the customer from their wheel chair

and then putting them back into the wheel chair as required.

Aided Use: Use of the standing table should not be a completely independent

operation as the individual using the table may only use it with the help of an

aide. Hence, functional use by a single individual should be impeded as this

would prevent misuse, or improper use, of the standing table.

Work Surface: The standing table should contain a table top or other equivalent

large, flat, work surface. The customer can use this table for basic activities such

as writing, arts, and crafts. Food use is to be prohibited while in the standing

table. The table surface should be made clear, if possible, to allow the user a

broader view of their surroundings. The table should be able tilt to an angle of 20

to 30 degrees, with respect to the ground, towards the user.

Page 28 of 150 Senior Design Team P06205 Winter 2005-2006

Trunk Support: Lateral supports of some type should be a part of the design.

This is necessary to prevent the user from falling sideways or backwards while in

a standing position.

Lower Body Support: The standing table design should have lower body support

for the individual using it.

Table Interface: The standing table should be operated by a remote control,

preferably corded to prevent loss of the remote.

Noise Generation: The standing table to should be reasonably quiet. Low motor

sounds or hummings are acceptable, but excessive noise and vibration should be

avoided.

Cycle Time: The time for one lifting cycle of the standing table should be

approximately 45 seconds.

Safety/Secure Access: The controls and buttons of the standing table should be

out of reach of the individual being lifted. This is a measure of safety to prevent

misuse of the standing table or unwanted motion by users fiddling with buttons.

Page 29 of 150 Senior Design Team P06205 Winter 2005-2006

Power: The table should be self powered with no need to plug the unit into the

wall during use. The power source which the standing table uses should be

renewable, easy to obtain, and inexpensive.

Human Interfacing: The table should use a sling to support the customer in the

hip area to facilitate lifting of the patient. The straps or the belt used in the

standing table should be made adjustable to fit everyone falling within the weight

and height ranges of the standing table.

Transport/Stability: The standing table should be able to move easily across

residential floors, carpets, and other surfaces. The table should also include a

locking mechanism so that when the table is not being transported, it can easily,

and quickly, be put into a stable, stationary state.

Force Generation: The standing table must be able to support the loads induced

while lifting and holding an individual. The table should cater to individual

weights between 115 lbs and 280 lbs. 280 Pounds is the official standing table

limit.

Height Ranges: The standing table should adjust to user heights between four feet

and eight inches, and six feet three inches.

Page 30 of 150 Senior Design Team P06205 Winter 2005-2006

Skin Contact: For safety, as well as legal purposes, skin contact must be

minimized (ideally zero) to reduce the risk of, and occurrence of, bruises, marks,

or discolorations that may occur from long term pressure points.

Foot Stand: The standing table should contain a place to support the feet of the

individual using it. The foot platform will also serve as a measure for safety due

to the fact that there is no possibility for relative motion between the table and the

user.

Design Dimensions: The standing table should be minimized in all of its height

dimensions. The legs should, ideally, be able to fit underneath larger furniture

that it can’t fully encompass within its legs. The maximum height of the table

should not exceed 6 feet, while the maximum width should be less than 36 inches

(width of a standard residential doorway).

Page 31 of 150 Senior Design Team P06205 Winter 2005-2006 8 Concept Development

One of the longest segments of the design process was the brainstorming and concept selection time frame. As could be expected, a written account of the entire process would be incredibly long. Even an abridged version of the proceedings of this section would take up several pages (as indeed it has) and is not monumentally essential to educating the reader about the final design that was chosen and developed. For this reason, only an excerpt from the complete “concept selection methods” write up is included here. For an in depth explanation of the actual feasibility methods employed, please see Project

Feasibility, Section 9. Additionally, a more concise version of the concept selection information is contained in a collection of easy to read charts are included in

Appendix H.

8.1 General Concept Development During the second week of the quarter, the team continued to discuss the general idea of what a standing table is, and began to form a list of questions for the meeting with the customer. The questions generally focused on the areas of how a standing table is supposed to work, and other basic requirements needed to successfully build and design a table. At this point, the team had not yet met with the ARC representative, so brainstorming was limited to general ideas for the project (see list in Appendix H,

Section 1). It was noted early on that one fundamental criteria for the design was that the weak link in the completed standing table should be a bit of a failsafe, in and of itself, which would not harm the resident, cause gross rupture, or fail abruptly in the event of a failure. In other words, the weak link should be purposefully designed to fail under certain conditions in order to prevent critical safety components from failing.

Page 32 of 150 Senior Design Team P06205 Winter 2005-2006

8.2 Detailed Concept Development By the middle of the following week, the team had spoken with the ARC representative,

Kristin Quinlan, on the phone and also met in person at an ARC residential house to clarify the ARC’s needs. While at the house, it was possible to analyze a Hoyer lift, which would later be compared against the initial concepts to determine which design would be better for our application. A list of our requirements and guidelines is included in Appendix H, Section 2. Based on the customer’s needs, design parameters began to be set which could be used to create some concepts based on different features.

Appendix H, Section 3 shows the initial list of design parameters generated by the team.

The design parameters and customer requirements were then combined to create an objective tree in order to organize different thought process during the initial stages of development. A copy of the objective tree is located in Appendix H, Section 4.

Page 33 of 150 Senior Design Team P06205 Winter 2005-2006

Below is a chart detailing the final concepts chosen for each design feature.

Feature Final Concept Power Batteries Force Generation Electromechanical Actuator Compact/Foldability Fluid Drive (cylinders) Main Frame Material Steel Main Frame Geometry Two Main Posts Ergonomics Lower Body Lifting Adaptable Multi-positional & Sliding supports Safety Use of Machine only by Aide Interface Remote Control (corded) Mobility Casters w/ brake Table Top Tilting Tabletop

Figure 4: Final Concept Design Features

Page 34 of 150 Senior Design Team P06205 Winter 2005-2006 9 Project Feasibility

9.1 Feasibility overview After the brainstorming and “weeding out” sessions, an in depth project feasibility analysis was completed to lend some methodical credibility to the concept selection process. One of the first analyses completed was a Quality Function Deployment, or

QFD, exercise. The QFD allowed the team to compare customer needs and their relations to actual design parameters or metrics that can be physically measured. As customer needs can often be lofty ideals or goals, it is important to have some method that allows a team to provide a concrete system of measuring. The completed QFD exercise is located in Appendix E, section 2.

In order to asses the feasibility of the various design created during the brainstorm sessions, two variations of the Pugh method were utilized, including a weighted and non weighted analysis. The first analysis conducted used a simple non-weighted Pugh chart that consisted of five separate concepts along the columns, and the features to be measured, or problems that needed to be solved, (customer needs) listed down the left hand side of the chart. Each customer need could also be grouped into one of four categories: Performance, Cost, Safety, and Aesthetics/Comfort.

9.2 Non-weighted Pugh Analysis As a team, each concept’s solution to a problem or method of implementing a certain feature was judged against a baseline. For the first analysis, the rating system was kept to a simple, yet effective, set of plus, minus, or zero. Coinciding with the plus, minus, zero scale, visual markers of green, red, and yellow, respectively, were used to facilitate quick Page 35 of 150 Senior Design Team P06205 Winter 2005-2006 comprehension of the chart. The baseline used as a standard was an overhead transfer lift currently in use by the ARC of Monroe County. While its operation, and the function, of the lift is fairly different than that of a standing table, it was the closest tool currently in use by the ARC that partially satisfies their needs.

After the first ranking of the initial concepts, the inferior design aspects of the concepts were rejected in favor of those that performed on a higher level. Using the colored chart, it was quite easy to understand which designs to insert into a second Pugh chart for further analysis. Before a second analysis was done, a pair wise comparison of the customer needs was done in order to provide better resolution to the second analysis. The results from this first Pugh analysis can be found in Appendix E, Section 1.

9.3 Determination of Assessment Weights By listing the customer needs on the ordinate and abscissa of a chart with all of the needs being repeated along the top and side of the chart, relative weights were determined. As a team, each need was rated as more important, equal to, or less important than the second need it was currently being measured against. Similar to the color scheme used for the Pugh analysis, a simple green, blue, and purple arrangement was selected in order to smooth the tallying process. Upon completion of the “Determination of Weights” exercise, the second Pugh analysis was performed in order to finalize a single concept. A chart detailing the process used to determine weights, as well as the results of the weight determination exercise can be found in Appendix E, Sections 3 and 4, respectively.

Page 36 of 150 Senior Design Team P06205 Winter 2005-2006

9.4 Weighted Pugh Analysis As with the first the Pugh analysis, five new concepts, different from the initial concepts used to weed out the various design features, were all measured against a baseline.

Instead of a simple plus, minus, zero scale, a more defined method consisting of rankings from one to five was employed. The scale had even divisions starting at the bottom with one for “much worse” up to five for “much better”. Three was the equivalent of a zero score with a rank of “equal”.

Unlike the first analysis that clearly differentiated between the brainstormed concepts, the second Pugh analysis simply revealed that the remaining two or three concepts developed were simply a matter of personal preference. The differences between the normalized weighted Pugh scores for all five concepts were only .04 from the best to worst concept.

After this point, concepts and designs were chosen purely upon team likes and preferences as all of the choices left equally satisfied the customer needs. Appendix E,

Section 5, details the final Pugh Assessment.

Page 37 of 150 Senior Design Team P06205 Winter 2005-2006

10 Base Design and Analysis

As one could surmise simply from the definition of the name of the part involved in the section, the base is the backbone of the standing table. Every part involved in the design of this senior design project either directly, or indirectly, interfaced with, or relied upon, the base for some means of positioning and support.

10.1 General Base Design As has been mentioned previously, the team had decided, upon review of the customer needs and the Pugh assessments that were completed, that an expandable base was needed. Borrowing from the linear bearing concept developed by 8020 inc., the expandable base consists of a square tube inside of which are mounted two different profile linear bearings. The bearings on the left and right faces of the base are simple rectangular cross sections, while the bearings on the top and bottom of the tube have a T profile. Both bearings are made from ultra high molecular weight polyethylene

(UHMWPE). UHMWPE is the same material used by 8020 for their bearing slides due to its low coefficient of friction, impact resistance, and high fatigue life. A standard 8020

1515-LITE slotted aluminum extrusion was chosen to ride on the bearing surfaces. The top and bottom T bearings would help maintain alignment of the 8020 extrusion as it moved in and out of the base. Appendix I, Sections 1 and 2 show the completed base design as well as a detail of the slide-bearing mechanism.

Page 38 of 150 Senior Design Team P06205 Winter 2005-2006

10.2 Fluid Drive System Now that a design for the actual legs themselves had been chosen and refined, a method of actually expanding the legs had to be devised. Again, borrowing concepts from previous group’s work, a modified pneumatic “fluid drive” was designed. For the 2004-

2005 moonbuggy, the human powered vehicle team has used a set of pneumatic cylinders filled with water to control the steering. By pushing on one cylinder, the driver was able to push water to two separate cylinders and control the rate and rotation of the front and back wheels simultaneously. Matthew Bell (Frame Design Team) was a member of the team that built the 2004-2005 moonbuggy.

As proof-of-concept was already readily available, and indeed field proven, all that remained was to derive a set of equations relating travel and force inputs to their respective outputs. Appendix I, Sections 3 and 4 detail the equations used to derive the ratios, and the travel and force ratios as a function of input to output cylinder bore ratios.

Ideally, a short stroke input coupled with a low force input is desired. However, as can be seen in charts, the travel and force ratios are inversely related. Thus, the travel ratio was constrained, and the resulting force ratio was checked for feasibility. A ratio of 3.54 was chosen in order to limit the input stroke to six inches, yet achieve an output of 10 inches of travel on the legs.

The two input cylinders (one to expand, one to retract) are mounted on the back of the main supports. The drive cylinders are mounted on the back side of the base.

Information detailing the cylinder drive schematic can be found in Appendix I, Section 5.

Assuming an input force of 50 lbs, the legs will extend outwards with a force of 14 pounds. If more output force is needed, the brackets holding the cylinders are designed

Page 39 of 150 Senior Design Team P06205 Winter 2005-2006 to completely support a 200 lb individual standing on the cylinder. This will give a maximum output force of 56 pounds. Appendix I, Section 6 details different input forces and the correlating output forces and accelerations.

Page 40 of 150 Senior Design Team P06205 Winter 2005-2006 11 Design of the Lifting Mechanism

The most important features of any device to interact with humans are the interfaces between man and machine. On top of that, components that will forcibly move or transport individuals are of utmost importance. For the standing table, the design, dimension, and loading of the lifting mechanism were the determining factors for the sizes and locations of all of the other subsystems.

11.1 Design Challenges The biggest challenge in creating the lifting mechanism was staying under budget, yet finding an electrically powered device (as chosen from the Pugh analyses) that was strong enough to lift and support a 300 pound individual. To further constrain the project, the mechanism had to comfortable attach to an individual while seated, support them through the entire length of the lift phase, and provide enough support while the user is standing. Additionally, it was desired to keep the mechanisms completely underneath the lower surface of the table throughout its travel.

The different variables that could be constrained, or determined through their association with other parts, included:

Actuator stroke Actuator force Mounting point for actuator on frame (X and Y position) Lift Arm dimensions o Overall length o Length of perpendicular arm “nub” o Mounting location of actuator (arm length ratios) o Mounting point for actuator on arm (X and Y position) Harness strap length Harness mounting point

Page 41 of 150 Senior Design Team P06205 Winter 2005-2006

11.2 Solution Methods

Originally, a mathematical modeling relating the torques, forces, lever arms, and leg angles was generated, but proved to be ineffective. Because only a limited number of equations could be developed, it would have been necessary to constrain several variables in order to determine the ones that remained. However, if the wrong constants were chosen, a solution could be derived mathematically, but it would not have physically satisfied all of the desired constraints. Due to the large number of variables involved, a simple two dimensional 4:1 scale paper model was developed to allow for quicker changing of variable dimensions. Using this method it was possible to, rather quickly and efficiently, determine the necessary dimensions for all of the variables. Only the force of the actuators was set as a constant prior to deriving the additional values needed.

Next, a simple link model was created in Solidworks to ensure that the measurements taken from the paper model were accurate. Indeed they were, with only the final model needing only one dimension to be shifted a half an inch upwards and to the right

Running parallel to the Solidworks and paper models was an Excel spreadsheet used to quickly and easily determine the induced strap tensions, torques on the moment arms, and the required arm dimensions needed, assuming the use of 2, 500 pound actuators.

Appendix J, Sections 1-4 provide details of the equations used to determine the strap forces and torques created. Sections 5-8 show example calculations for a 300 pound user, the corresponding Mechanism Mechanics chart, as well as the overall torque and force charts covering the entire weight range.

Finally, the flat mechanical models were transformed into a three dimensional model to which the free body diagram forces could be applied, and stresses and factors of safety

Page 42 of 150 Senior Design Team P06205 Winter 2005-2006 determined. Due to the fact that most of the components involved in the final lifting mechanism were fairly complex, no hand calculations were done, with the exception of the shoulder bolts, which were loaded in double shear. The rest of the components were tested using the Cosmoworks FEA program, embedded in Solidworks. Details of these analyses can be found in Appendix J, Sections 9-12 including insight into the duty cycle achieved, relevant free body diagrams for FEA analysis, as well as the FEA analyses themselves and hand calculations for pin shear.

Page 43 of 150 Senior Design Team P06205 Winter 2005-2006 12 Circuit Design and Analysis

12.1 Necessary Circuit Requirements As is true of any electromechanical system, the mechanics are left dead and lifeless without the addition of electrical power. As decided upon during the team concept selection deliberations, a rechargeable battery was chosen as the power source of choice.

The battery has a capacity of 12 volts and 26 amp hours. The actuators require a maximum input of 20amps at 12 volts DC. One important aspect of the actuator operation is simultaneous operation of both actuator DC motors. In light of this fact, the motors of the actuators are also going to be connected in parallel to maintain balance in the lifting mechanism. The circuit schematic for this system is given below in figure #, as well as Appendix K, Section 1. A brief description of the batteries and a data sheet may be found in Appendix K, Section 2.

12.2 Circuit Components and Layout The main components used in the circuit are two double pole double throw (DPDT) relays, a single pole single throw (SPST) lighted switch, two momentary SPST switches, a double pole single throw (DPST) switch, an ABS project box, and of course, black and red 18 gauge wires. The main purpose of the circuit is to provide 20 amps of power to the actuators through a corded remote control. The use of the two relays allows the user to switch power to the actuators, using the momentary SPST switches, without passing 20 amps through the hand piece. The lighted SPST switch is a safety device that allows the user to lock out the remote when not in use, or for emergency purposes, kill power to the remote during operation, if needed. The DPST switch is used to disconnect both the hot

Page 44 of 150 Senior Design Team P06205 Winter 2005-2006 and ground wires attached to the battery to effectively disconnect the batteries from everything when not in use.

As per regulations regarding the design of a powered standing lift, an emergency switch has been inserted which is separate from the emergency button on the remote. This switch has the capacity to handle 20 amperes of current and will be used to disconnect the batteries from all connections in a hurry.

The surge currents of the actuator motors were taken into account as there is the possibility of a power spike during the initial start up of the system. Thus batteries were chosen to be able provide a maximum capacity of 24 amp hours rather than the specified

20 amp hours.

A wiring schematic for these parts can be found in Appendix K, Section 3.

Page 45 of 150 Senior Design Team P06205 Winter 2005-2006 13 Leg Design and Analysis

In order to translate the conceptual standing table model into a working model, a design analysis was completed. These analyses would either add credibility to the design or negate it in the case of failure. A force analysis was performed in order to determine the dimension of the main and secondary frame support, the legs and the casters.

13.1 Free Body Diagram and Solutions To determine the size of the front and rear casters needed to support the standing table, the following beam was analyzed.

y L

F a b

x B

R1 M3 R2

The force applied is equal to the weight of the standing table and the force exerted by a

300 pound person. The moment is generated as the individual leans against the chest pad support (assumed leaning angle of 5 degrees). From this, the reactions (R1 and R2) were found to be 184.741b and 15.28lb respectively. Casters were sized at 3” diameters in order to support these forces, as listed by the manufacturer's specifications.

Page 46 of 150 Senior Design Team P06205 Winter 2005-2006

The dimension of the legs the casters would be attached to was determined mainly by the size of the interface to the leg attachment for the legs inside the base. Because the design would implement a T-slotted aluminum extrusion expandable leg, the caster legs would need to connect to this leg. Therefore, the outer dimensions of the legs were chosen to be equal to those of the T-slotted leg (1.5inx1.5in). The thickness of the cross section was chosen by investigating what standard profiles were commercially available. A stress analysis was completed to verify if a leg of this dimension would actually sustain the loading applied to it, and was determined to be safe.

The complete analysis, including moment and shear diagrams can be found in

Appendix L.

Page 47 of 150 Senior Design Team P06205 Winter 2005-2006 14 Table Top and Support Design and Analysis

14.1 Free Body Diagrams and Solutions The main and secondary supports were designed to be space efficient, yet also be able to support the loading from the actuator and the loads applied to the pads. The following loading scenario was analyzed (assumes a 300 pound individual and worse case loading).

40lb 228 lb R1 10 lb 5472 lb-in 3725 lb-in A

500 lb 383 lb R2 478.75lb-in M1

From this it was determined that the moment and reactions( R1 and R2) were –8718.25lb- in and 278lb and –117lb respectively. The total stress is –10,281 psi. The part will not fail under this loading as the yield stress of the steel being used is 39,000 psi.

The main support and secondary support were designed to be telescoping and interface through a set of pins. To test the stability of this arrangement, it was necessary to determine the shear stress in the pins which are in single shear. The shear stress on the pins is 407.4psi. This value is less than the manufacturer specified maximum of 42,600 psi. The complete FBD, as well as the solutions can be found in Appendix M.

Page 48 of 150 Senior Design Team P06205 Winter 2005-2006

Finally, it was important to determine the stress on the tabletop support to ensure that the loads induced would not cause failure. The main force exerted on the tabletop comes from the chest pad mounted to the front of the quarter-round 8020 extrusion surrounding the Lexan table top. The stress generated is approximately 3.3 psi, which is considerably less than the maximum stress of 35, 000psi that the table material is capable of withstanding. For more detailed information and FEA analysis results, please see

Appendix N.

Page 49 of 150 Senior Design Team P06205 Winter 2005-2006 15 Product Strengths and Weaknesses

As is true with any product, choices must be made due to time, group abilities, the current state of technology, and of course, cost. Senior design teams are certainly not exempt from any of the above. Therefore, the following will provide the reader with a sense of where the standing table excels, and where it may not be as notable as other commercial designs, or even other aspects of the team’s own design.

Product Strengths:

Semi-Automatic Operation (minimal user input required)

Renewable Power Source

Ability to expand legs from 30” to 50” to encompass chairs

“One Step” leg expansion

Clear impact, scratch, and UV resistant table top

Smooth table top protective frame

Quick Adjust table height and tilt angle

Easy setup and teardown for travel

Lifting capacity up to 300 pound individual

Accommodates users from 59.8” to 73.6”

Quick locking casters

High factor of safety on all parts

Ergonomic pad and sling system

Intuitive design and user interface

Page 50 of 150 Senior Design Team P06205 Winter 2005-2006

Product Weaknesses:

Cannot support bariatric patients

Won’t fit around or underneath large, low slung couches (competitor’s designs

can not fit around small couches either)

Not appropriate for child/junior patients

Limited, large-scale upper body support

Battery is reasonably heavy (18 lbs)

Doesn’t completely fold up (problem affects competitor’s designs as well)

Limited chest pad adjustability

Actuator DC motor surfaces may become hot if overused (operator instructions

discourage use exceeding a 15% duty cycle)

Risk of electric shock if table is misused (operator instructions detail correct and

proper usage and charging procedures)

Page 51 of 150 Senior Design Team P06205 Winter 2005-2006 16 Method of Operation

16.1 Operating Instructions As is true with any device, a machine will only function as well as the user knows how to operate it. No matter how well conceived, designed, and manufactured a product might be, customer education is the key to successful use, and a satisfied customer. Below is a linear list of the steps that should be enacted in order to obtain the best results from the standing table.

First, make sure the battery has been fully charged. The battery can then be

inserted into the designated holder in the standing table if it was removed for

charging.

Manually move the table to where the patient is sitting.

Press the cylinder that is currently in the up position (the cylinder marked extend)

downward in order to extend the legs such that it can fit around the patients

current chair.

Wheel the table closer to the patient until their knees are touching the knee pad

and their feet can be firmly planted on the footrest.

Lock the two back wheels to ensure the standing table is steady for lifting.

Slide the lifting harness behind and underneath the patient. Make sure that the

patient is comfortable and aware of the actions that occur during the lift phase.

Attach each strap of the harness to the lifting arms by placing a ring on the

harness onto a peg on the lifting arm. The size of the patient will determine

which ring and peg should be used, to ensure a secure harness fit.

Page 52 of 150 Senior Design Team P06205 Winter 2005-2006

Flip the main power cutoff switch, if it has not already been, to the one position to

connect the battery to the circuit.

Using the red button on the side of the remote, power up the remote and prepare

for use.

Using the switches on the remote, red for up and black for down, activate the

actuator arms to lift the patient into a standing position. Pressing down at any

time will lower the patient, and releasing the button will leave the patient in their

current position.

Once the patient is standing, adjust the height of the table, using the quick release

pins, so that it best suits the patient (table should be between elbow and waist

height). If the patient would prefer to use a titled table, the aid can adjust the

angle of the table by loosening both locking handles.

Then tighten both handles to secure table at desired angle.

To reseat the patient, follow the same procedure of ensuring a tight harness fit,

power up the system, and using the same remote, lower the patient into a chair.

Unhook and remove the harness.

16.2 Safeguards and Warnings CAUTION! For safety purposes, both the battery disconnect switch and the remote power switch should be left in the OFF position while not in use. Failure to adhere to this safety procedure could result in undesired lift operation or battery discharge. Always disconnect power before attempting to clean or service the standing table. Battery is capable of delivering more than 20 amps of power during operation. Under no circumstances, should anyone attempt to alter or modify the existing circuit layout as

Page 53 of 150 Senior Design Team P06205 Winter 2005-2006 improper modification may result in compromising of built in safety features or electrical shock. Actuator DC motor surfaces may become hot during extended or repeated use. A built in thermal trip sensor will shut off the actuators for 15 minutes during an overheat to prevent damage to the system. Actuator should not be run continuously, but should be restricted to complete up and down cycles when needed.

Any injuries resulting from negligent use or failure to adhere to the above listed procedures and cautions are not the liability of the design team. The user is responsible for making themselves familiar with all procedures and cautions. Any questions may be directed to the design team through the Mechanical Engineering Department at Rochester

Institute of Technology.

Page 54 of 150 Senior Design Team P06205 Winter 2005-2006 Appendices: Table of Contents

Appendices: Table of Contents...... 55 Appendix A – Project Proposal...... 57 Appendix B – Mission Statement...... 60 Appendix C – Team Values and Norms...... 63 Appendix D – Gantt Chart...... 64 Appendix E – Feasibility...... 65 Section 1 – Pugh Analysis...... 65 Section 2 - QFD...... 66 Section 3 – Determination of Weights...... 68 Section 4 – Determination of Weights Results...... 69 Section 5 – Weighted Pugh Analysis...... 70 Appendix F – Ergonomics...... 71 Section 1 – Anthropometric Data Table (Height)...... 71 Section 2 – Relative Body Dimensions...... 71 Section 3 – Generic Body Weights...... 72 Section 4 – Segment Weights of 300lbs. Person...... 72 Section 5 – FEA Analysis of Footplate...... 73 Appendix G – The Five Whys...... 74 Appendix H – Concept Generation...... 78 Section 1 - Brainstorming...... 85 Section 2 – Requirements, Needs, and Guidelines...... 85 Section 3 – Design Parameters...... 86 Section 4 – Objective Trees...... 87 Section 5 – Morphological Charts...... 91 Section 6 – Individual Concepts...... 93 Section 7 – Team Preliminary Concepts...... 94 Section 8 – Final Morphological Chart...... 95 Section 9 – Final Concepts...... 96 Appendix I – Pneumatic Fluid Drives...... 97 Section 1 – Solid Model: “Extend” Drive Cylinder...... 97 Section 2 – Solid Model: Fluid Drive/Leg Interface...... 98 Section 3 – Fluid Drive Ratio Formulas...... 100 Section 4 – Force and Travel Ratios for Cylinder Bore...... 101 Section 5 – Fluid Drive Schematic...... 102 Section 6 – FEA Analysis of Drive Cylinder Assembly...... 103 Section 7 – Stress Lift Curves of Base Assembly...... 104 Appendix J – Force Determination for Lifting...... 105 Section 1 – Body Segment Weights...... 105 Section 2 – Strap Forces...... 105 Section 3 – Angle and Force Determination...... 106 Section 4 – Torque Equation...... 107 Section 5 – Force and Torque Summary...... 107 Section 6 – Forces and Torques Graph...... 108 Section 7 – Torques Generated by Individuals...... 109 Section 8 – Force Required to Lift Individuals...... 110

Page 55 of 150 Senior Design Team P06205 Winter 2005-2006

Section 9 – Actuator Duty Cycles...... 111 Section 10 – Free Body Diagram of Lift Arms...... 111 Section 11 – FEA Analysis of Lifting Arm...... 112 Section 12 – Pin Shear Calculations...... 113 Section 13 – Stress Life Curves for Lifting Assembly...... 114 Appendix K – Table Electronic Systems...... 115 Section 1 – Circuit Schematic...... 115 Section 2 – Battery & Charger...... 116 Section 3 – Wiring Diagram for Circuit...... 120 Appendix M – Force in Main & Secondary Support...... 125 Appendix N – Stress in Table & Bolt...... 128 Appendix O – Bill of Materials (BOM)...... 129 Appendix P – Assembly Plans...... 131 Appendix Q – Business Plan Outline: Standing Table...... 134 Appendix R – Engineering Drawings...... 147

Page 56 of 150 Senior Design Team P06205 Winter 2005-2006 Appendix A – Project Proposal

2005/2006 RIT Multidisciplinary Senior Design Project Proposal Project Name and Number Updated 06205 Standing Table 12-15-05 Sponsor Arc of Monroe County Sponsor Contact Phone Email

RIT Contact Phone Email DeBartolo 475-2152 [email protected] Project Start Quarter 052 (Winter 05-06) Finish Quarter 053 (Spring 06)

Project Overview (please provide a brief background and description of the project)

A standing table is a device that allows individuals unable to bear weight alone to stand with partial or full weight support. A standing table also allows users to independently transfer from a seated position in a wheelchair or bed to transfer to another seating location, or a standing position. Such a device would greatly improve the self esteem and independence level of these consumers as they are no longer fully reliant on others to stand up or move about. Additionally, a standing table is able to improve poor muscle tone and increase the range of motion of certain joints that are not normally used. A table that is capable of folding or collapsing would be innovative as existing standing tables are quite large, require a great deal of space, and are more suited to commercial living centers rather than standard homes. Some existing designs for standing tables are as simple as a sturdy walker with a wide base and gripping handles, while other more flexible designs utilize actuators to assist the individual who is not capable of pulling themselves out of a chair. The senior design team will meet with the members of the ARC home and the ARC physical therapist. The team will also customize the design of the standing table to the specific needs and sizes of the individuals currently living in the home. As part of the learning process, students will expand their knowledge of the biomechanics of people with different physical disabilities and apply basic manufacturing procedures.

Project Success Factor Checklist

(x) The project is important to the sponsor, but is Comments not on the critical path. The standing table would lessen the strain on ARC workers and improve the condition of ARC community members.

(x) There is an advocate in the sponsor’s Advocate Contact Information organization committed to the project success. Kristen Quinlan, ARC Representative 585-747-7509 (Cell) (x) There are no intellectual property or other legal IP Status concerns that will interfere with the student’s ( ) a non-disclosure agreement will be required course commitments (reports, presentations, web ( ) a provisional patent application has been files site, poster) ( ) a full patent application has been filed ( ) a patent has been issues

Page 57 of 150 Senior Design Team P06205 Winter 2005-2006

(X) students may retain their IP rights as individuals ( ) students will be required to assign IP rights to sponsor (x) The success of the project requires the skills of Estimated Number of Students Needed at least two engineering disciplines Computer Engineering ______Electrical Engineering___1____ Mechanical Engineering__4___ Industrial & Systems Engineering ___1____ Industrial Design ______Business ______Other ______

Proposed Team Members Major Email Has this individual agreed to join the team? 1. Craig A. Hudson (Manager) ME [email protected] Y 2. Matthew Bell ME [email protected] Y 3. Jeff Matusik ISE [email protected] Y 4. Kahamala Morgan ME [email protected] Y 5. Maria Spagnola ME [email protected] Y 6. Aditya Srinivas EE [email protected] Y

The improvement team will be provided with the following :

(x) Background Information: Comments ( ) data, Team will meet personally with the ARC physical ( ) drawings, therapist to go over critical design factors and ( ) reports, patient needs. Team will be supplied with Project (x) other: See comments Readiness Package from Design Project Management. ( ) Requirements Document, including Comments qualitative performance goals Specific requirements will be determined by the quantitative performance goals Project Manager during scheduled meetings with operating environment the ARC therapist. human interfaces interfaces with other systems physical & aesthetic requirements design constraints

(x) Security Clearance: See comments Comments Team must complete IRB form to receive institute permission to work with human subjects

( ) Lab or Office Space: Comments

( ) Computers & Software: Comments

( ) Equipment: Comments

( ) Other Essentials: Comments

Page 58 of 150 Senior Design Team P06205 Winter 2005-2006

Desired Outcomes:

( ) concept sketches Comments ( ) prototype drawings Purpose of project is to provide the ARC with a ( ) production grade drawings usable product after 20 weeks ( ) prototype (x) fully functional, ready to use model

Funding Considerations & Budget (note: Sponsors are responsible for purchasing, and out-of-pocket expenses, such as project materials, equipment, and external fabrication costs.)

The standing table project is part of the “Design Projects to Aid People with Disabilities” program. These projects are sponsored by an umbrella grant from the National Science Foundation. Design teams are required to track their individual expenses as the NSF grant is being managed under a single account.

Page 59 of 150 Senior Design Team P06205 Winter 2005-2006 Appendix B – Mission Statement

P06205 - Standing Table