Novel Axial Flux Brushless Resolver Analysis and Optimization Using 3D Finite Element and d-q Model Method

F. Tootoonchian1, K. Abbaszadeh 2 and M. Ardebili 3 1Ph.D. Candidate of Electrical and Computer Engineering, K. N. Toosi University of Technology, Tehran, Iran, [email protected] 2Faculty of Electrical and Computer Engineering, K. N. Toosi University of Technology, Tehran, Iran, [email protected] 3Faculty of Electrical and Computer Engineering, K. N. Toosi University of Technology, Tehran, Iran, [email protected]

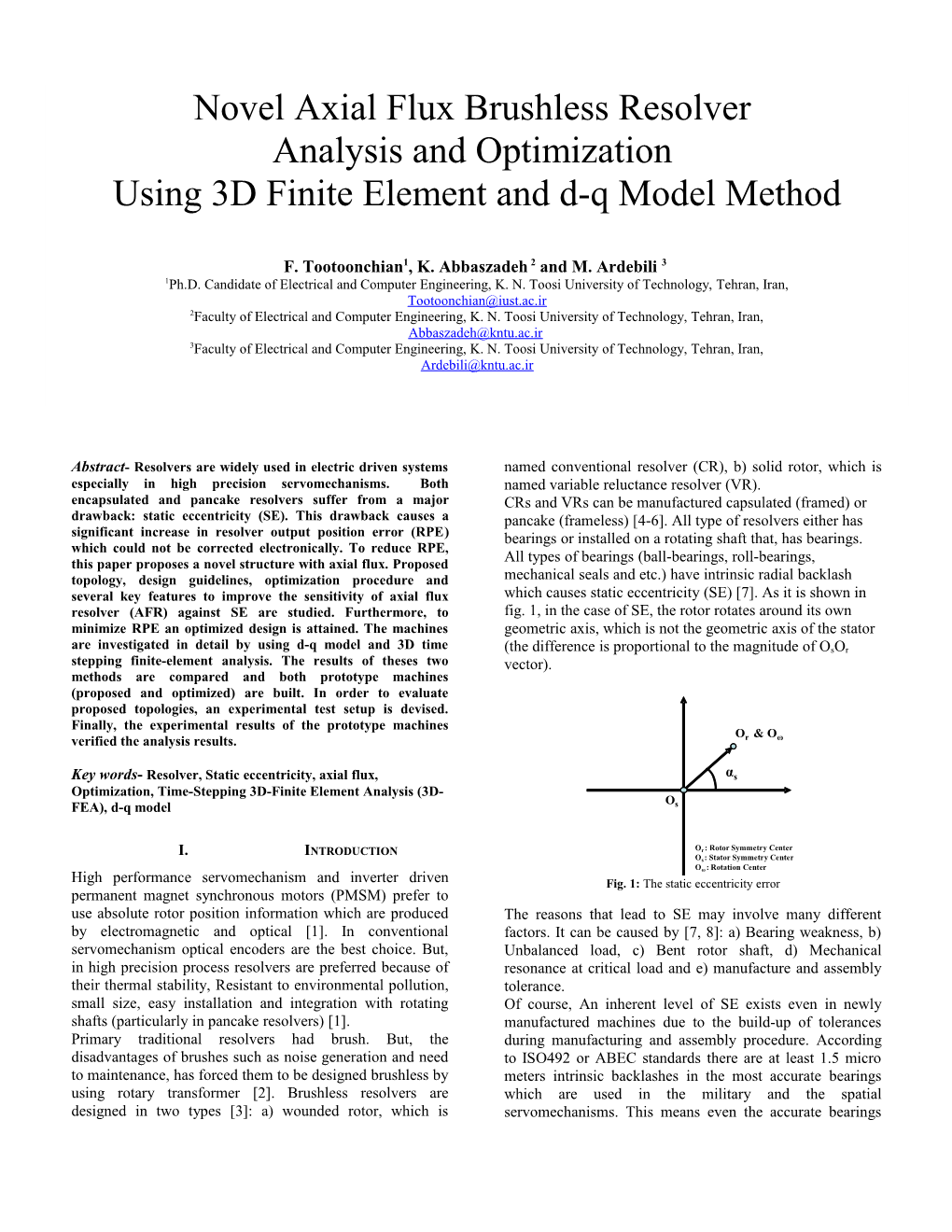

Abstract- Resolvers are widely used in electric driven systems named conventional resolver (CR), b) solid rotor, which is especially in high precision servomechanisms. Both named variable reluctance resolver (VR). encapsulated and pancake resolvers suffer from a major CRs and VRs can be manufactured capsulated (framed) or drawback: static eccentricity (SE). This drawback causes a pancake (frameless) [4-6]. All type of resolvers either has significant increase in resolver output position error (RPE) bearings or installed on a rotating shaft that, has bearings. which could not be corrected electronically. To reduce RPE, this paper proposes a novel structure with axial flux. Proposed All types of bearings (ball-bearings, roll-bearings, topology, design guidelines, optimization procedure and mechanical seals and etc.) have intrinsic radial backlash several key features to improve the sensitivity of axial flux which causes static eccentricity (SE) [7]. As it is shown in resolver (AFR) against SE are studied. Furthermore, to fig. 1, in the case of SE, the rotor rotates around its own minimize RPE an optimized design is attained. The machines geometric axis, which is not the geometric axis of the stator are investigated in detail by using d-q model and 3D time (the difference is proportional to the magnitude of OsOr stepping finite-element analysis. The results of theses two vector). methods are compared and both prototype machines (proposed and optimized) are built. In order to evaluate proposed topologies, an experimental test setup is devised. Finally, the experimental results of the prototype machines O & O verified the analysis results. r ω

Key words- Resolver, Static eccentricity, axial flux, αs Optimization, Time-Stepping 3D-Finite Element Analysis (3D- O FEA), d-q model s

I. INTRODUCTION Or : Rotor Symmetry Center Os : Stator Symmetry Center Oω : Rotation Center High performance servomechanism and inverter driven Fig. 1: The static eccentricity error permanent magnet synchronous motors (PMSM) prefer to use absolute rotor position information which are produced The reasons that lead to SE may involve many different by electromagnetic and optical [1]. In conventional factors. It can be caused by [7, 8]: a) Bearing weakness, b) servomechanism optical encoders are the best choice. But, Unbalanced load, c) Bent rotor shaft, d) Mechanical in high precision process resolvers are preferred because of resonance at critical load and e) manufacture and assembly their thermal stability, Resistant to environmental pollution, tolerance. small size, easy installation and integration with rotating Of course, An inherent level of SE exists even in newly shafts (particularly in pancake resolvers) [1]. manufactured machines due to the build-up of tolerances Primary traditional resolvers had brush. But, the during manufacturing and assembly procedure. According disadvantages of brushes such as noise generation and need to ISO492 or ABEC standards there are at least 1.5 micro to maintenance, has forced them to be designed brushless by meters intrinsic backlashes in the most accurate bearings using rotary transformer [2]. Brushless resolvers are which are used in the military and the spatial designed in two types [3]: a) wounded rotor, which is servomechanisms. This means even the accurate bearings have intrinsic SE. These standards show that the intrinsic SE of the bearing which used in electrical machines is up to 35 II. PROPOSED STRUCTURE micro meters. If the eccentricity fault is occurred, it will be added with the intrinsic SE of the bearings. Resolver, as an angular position sensor, acts like a The eccentricity will disturb the flux distribution in the air synchronous generator with two phases. The field winding gap [9]. And, it will distort the output signals of the resolver of this generator is excited with high frequency alternative [10]. In this condition, the position error of the resolver can current (up to 20 kHz, Eq. 1) [14]. Obviously, supplying the be increased up to 500 Arc Minutes (more than eight field winding with AC produces two amplitude modulated degrees) [7]. It is mentioned in [11] that, these large position (AM) output voltages instead of sine and cosine voltages. errors occur with the less than 60 micro meters eccentricity Neglecting the coil resistance and motional e.m.f. terms, the level. Therefore, It can be concluded that, conventional output voltages can be expressed by Eqs. (2-3) and are resolvers with radial flux structure always suffer from a shown in fig. 2 [12, 14]. The ratio of the output voltages major drawback which is named SE [7]. gives the rotor rotation angle θm [11-12, 14]. Previous researches tried to show the effect of SE on the (1) accuracy of different type resolvers [7, 9, 11-13]. In [7] different kind of errors which are resulted from wrong installation process is classified. Also, [7] has used (2) experimental tests to show that, the SE may increase the resolver output position error up to 500 Arc Minutes (more (3) than 8 degrees). In [9] the effect of skewed rotor and eccentricity error on the accuracy of a brushless resolver is 1

studied using 2D finite element analysis. But, the authors of 0 . 5 e (4) g a t l

[9] have expressed that there is significant difference o V 0

t u p t between measured and calculated results. Finally, they have u

WhereO - 0 .K 5 is transformer ratio, p is pole number and θe is an justified that their model is not accurate enough. In [11] the electrical- 1 angle. 0 0 . 0 0 1 0 . 0 0 2 0 . 0 0 3 0 . 0 0 4 0 . 0 0 5 0 . 0 0 6 0 . 0 0 7 0 . 0 0 8 0 . 0 0 9 0 . 0 1 effect of eccentricity error and air gap length on the T i m e [ S e c ] accuracy of the detected angular position of a VR resolver is 1 e

g 0 . 5 a investigated using 2D FEM. In this research a relation t l o V

n 0 o between the harmonics of the detected position waveforms, i t a t i c

x - 0 . 5 air gap length and eccentricity error is determined using E

- 1 non-linear regression method. 3D FEM is used in [12] to 0 0 . 0 0 1 0 . 0 0 2 0 . 0 0 3 0 . 0 0 4 0 . 0 0 5 0 . 0 0 6 0 . 0 0 7 0 . 0 0 8 0 . 0 0 9 0 . 0 1 T i m e [ S e c ] evaluate the influence of the iron sheet permeability (a) dispersion and rotor eccentricity on the angular position 1

0 . 5 e accuracy of the VR resolver. This paper presents that g a t l o

V 0

100μm SE increases position error upto 90 Arcmin. Finally, t u p t u [13] regards the nonlinearity characteristics of eccentricity O - 0 . 5

- 1 on the angular position error of a VR resolver. 0 0 . 0 0 1 0 . 0 0 2 0 . 0 0 3 0 . 0 0 4 0 . 0 0 5 0 . 0 0 6 0 . 0 0 7 0 . 0 0 8 0 . 0 0 9 0 . 0 1 Almost all literatures have studied just the effect of T i m e [ S e c ] 1 (b) eccentricity on the resolver's position error and they have Fig. 2: Resolver signals (a) Exciting voltage (b) Output voltages e

g 0 . 5 a t l not suggested any solution to decrease the eccentricity error. o V

n 0 o i t a t

In order to reduce the effect of SE two novel structures are In the i conventional resolvers with radial flux the static c

x - 0 . 5 proposed in this paper. The first one has an axial flux eccentricityE even in the range of some micro-meters causes - 1 0 0 . 0 0 1 0 . 0 0 2 0 . 0 0 3 0 . 0 0 4 0 . 0 0 5 0 . 0 0 6 0 . 0 0 7 0 . 0 0 8 0 . 0 0 9 0 . 0 1 geometry which can reduce the eccentricity error. This the strong variation in the linkageT i m e [ S e c ] and leakage inductances structure is optimized to the second one who can minimize of rotor and stator windings [9]. this error. The performances of both topologies are These inductance variations are the main factor witch calculated using time stepping 3D FEM and frequency increase the resolver detected position error [9, 11-12]. analysis of output signals. Then, they are constructed and Using magnetic circuit concepts, the inductance of one their test setup is devised. Practical testes carried out by phase of the resolver can be written as [15]: applying assignable eccentricities and investigating the (5) sensitivity of proposed structures to these variations. Where, K: is a constant which depends on the physical The following points are resulted from this study: a) the SE parameters involved (e.g. the number of turns per phase, the has the minimum effect on the accuracy of proposed number of teeth per stator pole, etc.), P(θ) is the permeance structures, b) there is acceptable accordance between time between one stator and rotor tooth as a function of position, stepping 3D FE results and experimental ones, c) using time μ0: is permeability of air, dA: is differential crosssectional stepping 3D FEM to study this sensor was very time area between the rotor and stator teeth and z: is length of the consuming process (witch will be resolved in an up coming flux path between the rotor and stator. paper).

2 According to Eq. (5), in proposed structure the inductances must have the minimum sensitivity from the SE. This A.1. Dynamic Model requires a uniform air gap length and a constant effective The voltage equations in machine variables can be iron surface between stator and rotor. expressed as following: The unique structure whose air gap length and effective iron surface are not changed with the SE is axial flux topology ( (as shown in Fig. 3). This paper proposes and studies this 6 topology as a novel resolver structure which is robust ) against SE. Proposed resolvers with axial flux structures have distinct ( advantages over radial flux ones. Some of these advantages 7 are their planar and adjustable air gap, compact ) construction, better ventilation and cooling. Furthermore, their rotors are integrated easily with the rotating parts. On ( the other hand, this type of resolvers, because of their short 8 axial length, can easily be adopted into the construction of ) various devices and has advantages in terms of size, In the above equations the s and r subscripts denote appearance, and function. Finally, in mass production, according to Polard’s theoretical considerations the AF variables and parameters associated with the stator and rotor machine needs 12-13 percent less copper and 21.5-32.5 circuits, respectively. Vas, Vbs are the stator voltages, Vr is percent less iron than similar traditional one [16-17]. the excitation signal of the resolver (), ias, ibs are the stator currents, ir is the rotor current, rs is the resistance of stator

circuit, Lℓs, Lms are the leakage and magnetizing inductances Resolver Rotor Yoke Rotary Transformer Rotor Core of the stator winding, respectively, rr, Lrr are the resistance

and self inductance of rotor circuit, Lsr is the mutual Resolver Stator Yoke inductance between the rotor and stator circuits, ωr is the

rotor angular velocity and θr is electrical angular displacement. The inductances of AFR can be calculated as

Resolver [18-19]: Rotor Slot (9 )

Resolver Rotor Tooth (1 Resolver Stator Tooth 0)

Resolver Stator Slot Rotary Transformer Stator Core (1 Fig. 3: Proposed axial flux resolver structure 1)

III. Resolver Model (1 In this study two methods are proposed to model the AFR. 2) The first model is based on d-q axis theory and in the later one time stepping finite element analysis is used to predict (1 the performance of the resolver. 3) A. D-Q Model Where P is the pole pair number, q is the number of slots This proposed model is based on d-q axis theory. The per pole per phase, Ro and Ri are outer and inner radius of following assumptions are considered in the analysis [14]: core, λs is specific slot leakage permeance, λo is specific a) Stator has two-layer distributed lap windings. overhang leakage permeance, λd is specific differential b) Rotor has a winding with sinusoidal supply. leakage permeance, λz is specific zig-zag leakage c) The inductances of AFR in d-q axis are unequal. permeance, g is effective air-gap length between the surface Fig. 4 shows the model of resolver windings. Each stator of stator and rotor, Ns and Nr are the number of stator and winding flux consists of leakage flux and main flux, the rotor turns, respectively in each phase. latter flux links the rotor [2]. The stator variables are transferred to the rotor reference frame which eliminates the time-varying inductances in the voltage equations. Park’s equations are obtained by setting the speed of the stator frame equal to the rotor speed. Fig. 4 Axial flux resolver windings model The expressions for the flux linkages are: Where F is each electrical variable (voltage, current, flux linkage), is a phasor which represents a sinusoidal quantity, (1 and are real quantities representing the constant steady state 4) variables of the synchronously rotating reference frame. And Hence: (15) (24) Then Substituting (22) into (24) yields: (16) (25)

By referring rotor variables to the stator windings, voltage For symmetrical resolver, Xd = Xq and ωe= ωb. So (25) can equations can be written as: be rewritten as: (17) (26) In order to obtain the equivalent circuits, equation (17) Where: should be replaced by equation (16). Thus, the voltage- current equations are as following: (27) (1 Considering above equations, the steady state equivalent circuit of resolver is shown in fig. 6. 8) Where: (19) Fig. 6 Steady state equivalent circuit of the AFR

And p is d/dt [2]. A.3. D-Q model Simulation The electrical equivalent circuits of the resolver are The state equations on the rotating d-q reference frame are presented in Fig. 5. introduced. MATLAB/Simulink software is used for The electromagnetic torque developed in the resolver is simulation. given by: Input, output, and state variables are: (20) In generalized theory of electrical machines, it is more And the mechanical equation of resolver in per unit can be convenient to use flux linkages as the state variables [20- written as: 21]. By this way, the differential operators change to (21) integral operators. Using Equation (16) and (18), the flux- linkages equations could be obtained as follow: Where H is inertia constant expressed in second, Tmech is load torque and Tdamp is frictional torque. (28)

(29) Fig. 5 Dynamic electrical equivalent circuits of the AFR in d-q axis (30) A.2. Steady State Model Where: In steady state, the electrical angular velocity of the rotor is (31) constant and equal to ωe. In this mode of operation the rotor windings do not experience any change of flux linkages (32) [20]. Thus, with ωr equal to ωe and the time rate of change of all flux linkages neglected, the steady state versions of And angular position, stator, and rotor currents can be (14) and (15) become: calculated as: (22) (33)

Here the ωe to ωb ratio is again included to accommodate analysis when the operation frequency is other than rated. In (34) the synchronously rotating reference frame and using uppercase letters to denote the constant steady state (35) variables [20]: (36) (23)

4 Because of the ability of proposed model to assume Maximum speed 8000-12000 rpm Air gap length 1 mm different values for Ld and Lq, it can consider the effect of eccentricity in AFR which is investigated in our outcoming Core outer /inner diameters 72/52 mm Core length, stator/rotor 10/10 mm paper. Duty cycle S1 - Fig. 7 shows a block diagram which is used in simulation. Number of turns, Stator/Rotor 1200/600 -

Fig. 7: Block diagram of AFR simulation. Table 2: The Equivalent Circuit Parameters of Tested AFR Parameter Value Unit

rs 290 Ω

r'f 17 Ω -3 Lm 3.41×10 H -3 L'lf 0.11×10 H -3 Lls 0.11×10 H J 9.13×10-4 kg.m2

B. 3D time stepping finite element Analysis

(a) The second method to evaluate the performance of the proposed axial flux structure is 3D time stepping finite element analysis. To increase the accuracy of the FE model, the effect of eddy current and saturation are considered simultaneously. Although, this analysis is very complex and time consuming, it is very accurate. So, it is a good choice to verify the results of proposed topology. Furthermore, to reduce computation time, rotor angular position is evaluated from the ratio of the out put signals which is formulated in Eq. (4).

Table 3: the geometrical dimensions of proposed AFR Item. Value (unit)

(b) Outer/Inner diameter of stator 72.0/52 mm Outer/Inner diameter of rotor 72.0/52 mm Fig. 8: AFR stator and rotor (a) Before winding (b) After winding Stator and rotor cores thickness 10 mm Stator/rotor number of slots 24/12 Fig. 8-(a) shows the stator and rotor of fabricated AFR Air gap length 1 mm before and after winding. This prototype has single stator Power source Sinusoidal, Vp = 5 V, 4 kHz 2 layer sinusoidal distribution and single rotor structure. Winding method The specifications of this AFR are presented in Table 1 and on slots the parameters of its equivalent circuit are given in Table 2. The maximum magnetic flux density of 0.08 T confirms that These parameters are obtained using DC-Pulse method [2]. the resolver’s core was not saturated. As shown in Fig. 8 the In this method stator winding is charged with its nominal B-H curve of resolver core, which is used in FEA, is DC current. The current signal is shown in Fig. 9 (with 1 investigated experimentally using modified Epstein test [22] mm air gap length). at 4 kHz.

2 . 5 . . .

2 ] T [ 1 . 5 y t i s n e D

x u

l 1 F

0 . 5

0 0 0 . 5 1 1 . 5 2 2 . 5 3 3 . 5 4 4 . 5 A m p e r - T u r n [ A ] x 1 0 5 (a) (b) Fig. 9: charge current of stator winding Fig. 10: (a) Modified Epstein circuit (b) Obtained B-H curve

Table 1: The Specifications of Tested Axial Flux Resolver In this paper, calculating 400 3D FE models for one rotor Parameter Value Unit revolution gives one period of resolver output signals Frequency 4000 Hz (which wastes the main time of this study). Peak to Peak input voltage 10 V Although, 3D FEM is an accurate method, the most reliable Maximum position error 10 Arcmin Pole number 2 - results are experimental ones. In this study, an experimental AFR with specification listed in Table 3 was made and tested (Fig. 8). Test results are obtained by using a special setup. This test setup is able to change the amount of SE and of air gap length. In addition, this rotary test bed had a precision rotary tycope was placed on it. So, different rotary positions are produced by this tycope in [0, 2π] radian. The structure devised test setup is shown in Fig.11. By using this setup, AFR output signals and simulation (c) results (including d-q model and 3D-FEM) are compared in Fig. 12: Studied AFR output signals without eccentricity (a) Resulted from each of these angular positions (The resolver output is d-q- model (b) Calculated by 3D FEM (c) Measured on oscilloscope obtained from arctangent of output voltages ratio).

a) (b) Fig 13: Comparison of calculated and measured signals (a) Amplitude of AFR cosine output voltage envelope (b) Relative error between calculated and measured signals

Generally, the resolver output signals are converted to position information by tracking resolver to digital converters. To do this, tracking RDCs use the envelope of the output signals. Therefore, in this study harmonic contents of an envelope of an output signal are taken into account, too. Figure 14 shows the normalized harmonic component of the cosine phase output current envelope. Almost all odd and even harmonics exist in this FFT plot. Fig. 11: Devised test setup of AFR The importance of FFT plot is revealed when it compared with eccentric AFR's FFT plot. This comparison will be IV. Results done in next section. A. AFR without Eccentricity In this research, position error is the difference between the Previous researches, usually have discussed just about real rotor position (which is obtained by means of test setup) position error distribution. But, in this paper, not only the and the determined rotor position of AFR (resulted from d-q position signal (Arctangent of the ratio of d-q voltages) but model and 3D-FEM). Figure 15 shows the comparison of also d-q voltages are reported, too. In practice, resolver simulated and measured output position of AFR and their output signals are fed to the resolver to digital converter difference. This figure shows the maximum position errors difference between measured and simulated results are 6 (RDC). The RDC input resistance is very high. Therefore, and 7 Arcmin at 245 and 45 degrees for d-q model and 3D the current in the stator coils of AFR, which apply to the FEM respectively. But, the maximum position error of RDC, is in the order of micro ampere [23]. Accordingly, simulated AFR versus ideal position are about 9, 7 and 5 .Fig. 12 shows the d-q, FEM and measured voltages of AFR Arcmin (FEM and d-q model) at 300ْ , 312ْ respectively excited with extra pure synthesized sinusoidal source (table The ideal position (θideal) can be calculated by home set of 3). Figure 13 shows the comparison of simulated and rotor position () (against stator position), pole number (p) experimental output voltages. Results show good agreement and rotor speed (f, revolution per second) that is: between test and simulated (d-q model and FEM) voltages. (37) Because of the maximum air gap flux density less than 0.08 Finally, Fig. 15-(a) shows that the AFR maximum position T (calculated by 3D-FEM) AFR works at linear part of its error is 0.15 Arcdeg (about 9 Arcmin). B-H curve. Therefore, it is expected that the amplitude of output simulated and measured signals are similar. Fig. 14: Harmonic components of output current envelope. 6 6 P o s i t i o n E r r o r 4 4 0.15 FEM Results 0.1 ] 2 ] d-q Model

V 2 V ] [ [

g e e Measured g g e a

a 0.05 t t l D l [ o

0 o

0 V V r

t t o u

u 0 r p p t r t u u - 2 E O - 2 O

n -0.05 o i t - 4 i - 4 s -0.1 o P -0.15 - 6 - 6 2 4 6 8 1 0 1 2 2 4 6 8 1 0 1 2 T i m e [ S e c ] - 3 x 1 0 T i m e [ S e c ] - 3 x 1 0 -0.2 0 50 100 150 200 250 300 350 400 (a) (b) Ideal Position [Deg] (a) ( M e a s u r e d - C a l c u l a t e d ) P o s i t i o n E r r o r 0.1 (Measured) - (FEM Results)

] (Measured) - (d-q Model Results)

g 0.05 e D [

e

c 0 n e r e f f

i -0.05 D

r o r r -0.1 E

-0.15 6 0 50 100 150 200 250 300 350 400 Ideal Position [Deg] P o s i t i o n E r r o r 0 . 1 5 F E M R e s u l t s 0 . 1 d - q M o d e l ]

g M e a s u r e d e 0 . 0 5 D [

r

o 0 r r E

n - 0 . 0 5 o i t i

s - 0 . 1 o P - 0 . 1 5

- 0 . 2 0 5 0 1 0 0 1 5 0 2 0 0 2 5 0 3 0 0 3 5 0 4 0 0 I d e a l P o s i t i o n [ D e g ]

( M e a s u r e d - C a l c u l a t e d ) P o s i t i o n E r r o r 0 . 1 ( M e a s u r e d ) - ( F E M R e s u l t s ) the predicted winding resistances will not be accurate

] ( M e a s u r e d ) - ( d - q M o d e l R e s u l t s )

g 0 . 0 5

e enough and this is the main reason that predicted phase shift D [

e

c 0 by 3D-FEM in Fig. 16-(d) is not correct. In d-q model, n e r e

f winding resistances are determined by DC pulse response f

i - 0 . 0 5 D

r [2] which is an accurate method. o r r - 0 . 1 E For accurate comparison, the output position signals of - 0 . 1 5 0 5 0 1 0 0 1 5 0 2 0 0 2 5 0 3 0 0 3 5 0 4 0 0 symmetric and eccentric AFR are shown in Fig. 17. In this I d e a l P o s i t i o n [ D e g ] figure AFR detected position is calculated considering (b) Fig. 15: AFR position error (a) 3D-FEM, d-q model and measured data against arctangent of output voltages ratio. On this basis, Fig. 17-(a) ideal position (b) Error difference between measured and calculated data shows that the 10 μm rotor SE causes maximum 2.8 and 3.1 Arcdeg error in AFR detected angular position by FEM and B. AFR with Eccentricity d-q model respectively. In this figure although d-q predicted In proposed d-q model, d-q axis inductances are different error shape is not similar to FEM one but the amount of parametric variables. Therefore, by using unequal values for maximum calculated position error is in acceptable range. It Ld and Lq the effect of SE can be modeled. In this method seems that inaccurate predicted winding resistance affects the system differential equations which express its dynamic on position error shape. When a 47 Ω resistance is added in performance (17-21) should be linear. The methods of 3D-FEM model the q-d and FEM position error curve will linearization are divided into two categories: 1) analytic be similar. Therefore, if the winding resistance is corrected perturbing methods, and 2) software based methods. In the in FE model we can use 3D-FEM instead of d-q model former, the nonlinear differential equations are perturbed when the difficulty of the DC pulse response measurement around the operating point and in the latter, some functions is taken into account. So, the rest of this study uses just 3D- of SIMULIK/MATLAB software are employed [21]. In FEM modified by a series resistance. Also, Fig. 17-(b) software based method, the simulation block diagram of shows that the position error decreases from 2.8 to 0.5 AFR is plotted in Simulink. Then, the “LINMOD” function Arcdeg when the eccentricity increases from 10 to 70 μm of Matlab is used to obtain systems linear models of with a 1 mm air gap length. Furthermore, it is almost fixed ordinary differential equations (Odes). Finally, “TRIM” while the eccentricity is more than 70 μm. function is employed to find steady state parameters for the Simulink system. Both linearization methods were used. Comparison (a) between their results indicated that both of them had an (b) acceptable accuracy. Finally, the method of linearization used in this research leads to the following linear time- (c) (d) Fig. 16: Output voltages AFR with 10μm SE (a) d-q model (b) 3D-FEM (c) invariant system of equations: Amount of amplitude unbalance (d) Output signal phase shift than exciting (38) signal Equation (38) can be rewritten as below (using small perturbation around operating point): (39) (a) 3 . 5 F E M R e s u l t ( G a p L e n g t h = 1 m m ) Where: 3 d - q M o d e l ( G a p L e n g t h = 1 m m ) ]

g 2 . 5

(40) e D [

r 2 o r

The numerical coefficients of (38) can be calculated by r E

n 1 . 5 o i t i

using average DC pulse response of stator current [14 of s

o 1 P

Dyn]. Identified parameters confirmed that Ld ≈ Lq. To 0 . 5

0 investigate the performance of AFR with static eccentricity, 0 2 0 4 0 6 0 8 0 1 0 0 1 2 0 E c c e n t r i c i t y L e v e l [ m ] the parameters of the eccentric AFR were identified again. (b) This time, identified parameters indicate that Ld is unequal Fig. 17: Comparison of d-q model and 3D-FEM results on AFR position with Lq (Ld ≠ Lq). Finally, replacing these parameters in error (a) AFR position error in 1 mm gap length and 10 μm SE (b) AFR proposed d-q model AFR output signals were simulated. position error in 1 mm gap length and different SE level Figure 16-(a) shows normalized output voltages of eccentric axial flux resolver. Also, normalized time stepping 3D-FEM Another effects of SE on AFR output signals was indicated results is reported in Fig. 16-(b). The magnetic flux density when output signals envelope's harmonic components are of eccentric model increases 1.8 times in comparison with studied. Fig. 18-(a) shows an example of harmonic content healthy model and is not symmetry in the core. For these in an envelope of cosine current. Amplitude differences of reasons, the waveforms of SIN and COS are distorted in harmonic components compared with those of a resolver terms of amplitude and phase difference as shown in Fig. without eccentricity are shown in Fig. 18-(b). 16-(a,b) and compared in Fig. 16-(c). In FE analysis used in Harmonic components of envelopes show a significant this study, a winding assumed as a solid copper which its variation depending on the rotor eccentricity and the air gap induced voltage is multiplied by winding turns. Therefore, length. For example, Fig. 19 shows normalized amplitude difference of harmonic components in the model at the gap length of 1 mm and different SE level. This figure shows in 3 ] g static eccentricity shorter than 80 μm, amplitude differences e 2 D [

vary in the range of -0.05% to +0.12%, but they vary in a r 1 o r r

narrower range in other models. In eccentricity longer than E 0

n o i

80 μm, the amplitude variations of harmonic components, t - 1 i s

rd th th o except 3 , 7 and 9 component, show a tendency to remain P - 2 rd th th stable. The harmonic components of 3 , 7 and 9 also vary - 3 0 1 2 0 1 0 0 Air Gap Length= 1 mm 1 0 0 in a wide range in other gap length models. Air Gap Length= 1 mm 8 0 2 0 0 6 0 3 0 0 4 0 2 0 0

(a) (a) 0.02

0.01 1st 2nd 5th 6th 7th 3rd 4th 0

] 4 g e

-0.01 ] 3 D g [ e

D r

[ 2 8 r o o r r r -0.02 r 1

E E c c = 1 1 0 e - 6 m

6 E

0 n 200 600 o E c c = 1 0 0 e - 6 m n 400 800 1000 i 0 ] t i o g

s E c c = 9 0 e - 6 m 4 i e

Frequency [Hz] t o D

i - 1 P

[ E c c = 8 0 e - 6 m

s r o

o 2 E c c = 7 0 e - 6 m

r - 2 P (b) r

E E c c = 6 0 e - 6 m

0

n 0 E c c = 5 0 e - 6 m

o 5 0 Fig. 18: Normalized harmonic components of an envelope of AFR output i 2 t i E c c = 4 0 e - 6 m

s 1 0 0 cosine current at 1 mm air-gap length and 10 μm SE level (a) Normalized o - 2 1 . 5 E c c = 3 0 e - 6 m P 1 5 0 E c c = 2 0 e - 6 m - 4 2 0 0 Static Ecc. = 10 μm 1 amplitude ratios (b) Differences of amplitude ratio of harmonic E c c = 1 0 e - 6 m 2 5 0 0 . 5 - 6 3 0 0 components of the AFR compared with those of a resolver without 0 5 0 1 0 0 1 5 0 2 0 0 2 5 0 3 0 0 3 5 0 4 0 0 3 5 0 0 A i r G a p L e n g t h [ m m ] eccentricity R e a l P o s i t i o n [ D e g ] R e a l P o s i t i o n ( R o t a r y T y c o p e ) [ D e g ]

] (b) % [

t 3 n

] 0.15 e F E M R e s u l t ( E c c = 1 0 m , G a p L e n g t h = 1 m m ) ] f n % o o g

[ M e a s u r e d ( E c c = 1 0 m , G a p L e n g t h = 1 m m ) p

e e 2 t m c n D o n [ e 2nd

C 0.1

e

n r r c

i 1

o 3rd e o n f p o r f 4th i r m m r D o 5th E 0

a 0.05

e C H

6th n f d c o i u o

i

t 7th

e - 1 n i t c l o i

n 8th p s

e 0 m r r m 9th o e - 2 f a f A P i H D

e

d -0.05 - 3 u

t 0 5 0 1 0 0 1 5 0 2 0 0 2 5 0 3 0 0 3 5 0 4 0 0 i l 0 50 100 150 200 250 300 p I d e a l P o s i t i o n [ D e g ]

m Static Eccentricity [m]

A Static Eccentricity [μm] (c) Fig. 19. Normalized amplitude difference of harmonic components in the Fig. 20. Position error of AFR versus real position (a) at 1 mm air gap model at the gap length of 1 mm length and different static eccentricity (b) at 10 µm static eccentricity and different air gap length (c) Comparing 3D FEM results with measured ones In this study, the effect of air gap length, pole number and at 10 μm static eccentricity and 1 mm air gap length. excitation voltage harmonics on proposed AFR position error is investigated, too. Next, the effect of pole number in the proposed AFR As shown in fig. 20-(a), with 1 mm air gap length an position error has been studied. In this study the air gap increase in SE level from 10 μm to 110 μm causes an length and rotor eccentricity are 1 mm and 10 μm decrease in position error from -2.87 to +0.51 Arcdeg. But, respectively. Fig. 21 predicts that the AFR position error is at the rotor eccentricity more than 70 μm, the surface has a decreased while the pole number is increased. The position tendency to remain stable. Also, fig. 20-b regards that, error reduction can be attributed to the decrease in overhang considering 10μm static eccentricity, the position error leakage flux of stator winding due to reduction of overhang decreases while the air gap length changes from 0.4mm to length caused by increase in pole number [24]. Therefore, 2mm. Fig. 20-c compares the 3D FEM results with the position error is decreased while the pole number is measured ones at 1 mm gap length and 10 µm SE. increased. Finally, the effect of excitation voltage harmonics on the position error of AFR with 10 μm gap eccentricity and 1 mm air gap length is perused in Fig. 22. In all of the preceding analysis it was assumed that the resolver excitation signal was an extra pure synthesized sinusoidal source and contained no additional harmonics. In general, the excitation signal contains harmonics and thus the AFR output signals are simplified as: (41) As presented in (41) and Fig. 22, AFR position error increases when, its exciting current harmonic contents (part

8 A in (41)) increase. For example, when exciting current rotor Stator and rotor core harmonic contents increase upto 50%, AFR position error 10 mm 10 mm thickness increases even upto 4.6 Arcdeg. Stator/rotor number of 24/12 24/12 slots Air gap length 1 mm 1 mm sinusoidal, sinusoidal,

Power source Vp = 5 V, Vp = 5 V,

] 3

g 4 kHz 4 kHz e ]

D 2 g

[ 2 layer 2 layer e

D r [

r o 1 sinusoidal sinusoidal o r r r r Winding method E

E n

0 distribution on distribution on o i n t i o s i slots slots

o - 1 t i P s

o - 2 Pole Number 2 2 P 0 5 0 6 Harmonic orders which 1 0 0 Ecc = 10 μm 5 1 5 0 has not any tendency to 3, 4 3, 7, 9 2 0 0 Air Gap Length = 1 mm 4 remain constant (Fig. 19) 2 5 0 3 3 0 0 2 Max. Position Error in 3 5 0 1 A i r G a p L e n g t h [ m m ] R e a l P o s i t i o n [ D e g ] 10 μm Static Eccentricity 8.1ْ 2.87ْ Fig. 21. AFR position error versus real position in 10% gap eccentricity and 1 mm gap length and different pole numbers Max. Position Error in μm Static Eccentricity 3.71ْ 3.62ْ 10 and 0.4 mm gap length Max. Position Error in 10 μm Static Eccentricity, 0.43ْ 2.2ْ 6 ]

g 1 mm gap length and e ] D g [

e 4

6 poles D r [

r o o r r r r 2 E

E

n o n i t i o 0 V. Optimization of AFR Structure s i t o i P s o - 2 The accuracy of the rotor position reported by an R/D P 0 5 0 6 0 converter is limited by the quality of the resolver signals 1 0 0 5 0 1 5 0 4 0 processed by the RDC. According to ISO492 or ABEC 2 0 0 3 0 2 5 0 2 0 standards and Fig. 20-(a), one of the most significant source 3 0 0 1 0 3 5 0 0 H a m o n i c C o n t e n t [ % ] R e a l P o s i t i o n [ D e g ] of position error which must be minimized through resolver Fig. 22. The effect of excitation voltage harmonics on the position error of design is the error incurred due to the intrinsic SE. AFR with 10 µm static eccentricity and 1 mm air gap length Although, in axial flux structure when SE occurs the air gap length does not change but the common effective iron C. AFR in Comparison with RFR surface between rotor and stator will change (Fig. 23(a)). To determine the capabilities of the proposed AFR (without The teeth shape or common effective iron surface between any optimization) table 4 compares two axial and radial flux rotor and stator can be calculated by solving the inverse resolver with the same design specifications. This electromagnetic field problem [1]. Generally speaking, the comparison shows that, the axial flux structure is more process of solving such an inverse electromagnetic field robust than radial flux one, against static eccentricity. Table problem will be, firstly, to assume one geometry shape and 4 emphasize that the capabilities of the AFR is related to its the corresponding stimuli distribution in the field area, then air gap length. In gap length less than 0.5 mm radial flux to calculate the field by using the finite-element method resolver is as precise as axial one. But, in typical gap length (FEM), then to optimize the geometry by employing certain (1 mm) axial structure is at least three times more accurate optimization methods [1]. than radial ones. Also, increasing the pole number in order to decrease the position error is more effective on AFR than A. Rotor Shaping by Solving the Inverse Problem RFR. Tooth schematic of the stator and rotor of the studied AFR However, although the axial flux structure performance is are shown in Fig. 23(a). Figure 23(b) shows, when static better than the radial structure but, when the eccentricity eccentricity occurs in proposed AFR the common effective ,occurs, the position error of AFR increases upto 3.62ْ. In this iron surface between rotor and stator will change. Therefore study, the proposed axial flux structure is optimized to the permeance, inductance and output voltage will change minimize the AFR sensitivity against static eccentricity. respectively. In the 3D FE analysis used to determine the optimal tooth parameters, it was found that no benefit was Table 4: Finite element analysis of Axial Flux Resolver (AFR) in gained by allowing the tooth slopes to be distinct. For that comparison with Radial Flux Resolver (RFR) reason, the tooth slopes were set equal to each other in all Value (unit) Item. RFR AFR the analysis conducted. Outer/Inner diameter of Correlations between items of the AFR, such as the position 72.0/52.0 mm 72.0/52.0 mm stator error, the yoke length, the rotor eccentricity and so on, are Outer/Inner diameter of 50.0/12.0 mm 72.0/52.0 mm evaluated by means of the multiple regression analysis [25]. The correlation between the error difference and the rotor Static eccentricity is not found in the linear regression analysis. Eccentricity Stator Teeth Therefore, the non-linear regression analysis is applied to evaluate two independent variables (eccentricity and the yoke length) which relate to the position error. Non-linear When Static Eccentricity analysis shows that the position error correlates with the Occurs cube of the rotor eccentricity and the square of yoke length. So, this problem is inherently a multidimensional optimization one, and nonlinearity exists. Therefore, traditional optimization methods such as grads method are Rotor Teeth not suitable for this problem. One way is to use the trial and AFR with Static Eccentricity AFR without Static Eccentricity error method, that is, to manually revise the shape after each (b) (a) trial. Certainly, this will consume long calculating times with only approximate results reached. Another way is to Static Eccentricity Stator Teeth adopt global optimization methods like the Genetic Algorithm (GA). A typical GA is tried in this case and the objective function is defined as below [26]:

(42) When Static Eccentricity Where ξ is error function which should be minimized, θreal is Occurs the real position of rotor, VSin and VCos are AFR output voltages which are related to eccentricity (ε) and rotor yoke length (yrot). The real position (θreal) can be calculated by a b home set of rotor position () (against stator position), pole number (p) and rotor speed (f, revolution per second) that is: Rotor Teeth (43) Optimized AFR with Static Eccentricity Optimized AFR without Static Eccentricity According to (42, 43), the following values of genetic (a≠b) (a=b) operators were used in the algorithm. (d) (c) 1) Initial population: N = 30 Fig. 23: Tooth geometry with and without static eccentricity (a,b) Proposed structure (c,d) Optimized topology 2) Probability of reproduction: pr = 0.25 3) Probability of mutation: pm = 0.05 4) Probability of crossover: pc = 0.05 After a certain number of successions, some results were obtained. One tooth of calculated rotor shape is shown in Fig. 23(c). This figure shows in optimized rotor shape (Fig. 23(c)) rotor yoke length is reduced. It can be concluded that, the latter case (optimized rotor shape) will be able to minimize the Variations of the common effective iron surface between rotor and stator. Because, in modified structure the iron surface of stator is (a) bigger than that of rotor (Fig. 23(c)). So, if the static eccentricity occurs (Fig. 23(d)), it is expected that, the variation of the permeance, inductance and output voltage either be minimized or even be eliminated. Optimized rotor was made and has been shown in Fig. 24. The main design parameters of the optimized AFR are shown in Table 5. Proposed Stator Proposed Rotor Optimized Rotor (b) Fig. 24: Optimized AFR (a) 3D-FEM schematic (b) Manufactured

Table 5: Geometrical dimensions of optimized AFR Item. Value (unit) Outer/Inner Diameter of Stator 72.0/52.0 mm Outer/Inner Diameter of Rotor 68.0/56.0 mm Stator/Rotor Core thickness 10/6 mm number of stator/rotor slots 24/12 Air gap length 1 mm

10 1 0 0 0 . 2 B. The Effect of Eccentricity on Optimized AFR C o n c e n t r i c A F R In order to evaluate optimized rotor of AFR it was made and A F R w i t h S t a t i c E c c e n t r i c i t y ] 5 0 0 . 1 ] g g e e D D [ [ replaced with initial rotor. Figure 25 shows the testing r n o o i r t r i 0 0 E s

o

results of the AFR with optimized rotor including the n P o

i r t i o s t o oscilloscope graphs, normalized output signals, and angular o P

R - 5 0 - 0 . 1 position in eccentric optimized AFR compared with those of

- 1 0 0 - 0 . 2 an AFR without static eccentricity. 2 2 . 5 3 3 . 5 4 4 . 5 5 5 . 5 6 6 . 5 - 3 T i m e [ S e c ] x 1 0 Fig. 26: Comparison of angular position in eccentric and symmetric optimized AFR with current sheet replaced with rotor windings

1 0 0 0 . 2 C o n c e n t r i c A F R Although, replacing current sheet instead of Arotor F R w i t h S t awindings t i c E c c e n t r i c i t y ] 5 0 0 . 1 ] g g e is not practical. But, it is suggested that to reduce the effect e D D [ [

r n o o r i t r ofi 0 the overhang leakage flux, it is better to increase radial 0 E s

o n P o

i r t

length of rotor coils. When, radial length of rotor coils i o s t o o P increasesR - 5 0 as 10% of outer diameter of optimized rotor the - 0 . 1 maximum position error of optimized AFR decreases to - 1 0 0 - 0 . 2 2 2 . 5 3 3 . 5 4 4 . 5 5 5 . 5 6 6 . 5 - 3 (a) 0.18 Arcdeg (fig. 27). T i m e [ S e c ] x 1 0 Sine 1 0 . 1 5 ] Cosine Amplitude

u 3 D F E M p

[ 0 . 5 Difference 0 . 1 M e a s u r e d s l a

n 0 . 0 5 g

i 0 S

t 0 u p

t - 0 . 5

u - 0 . 0 5 O - 1 - 0 . 1

2 2 . 5 3 3 . 5 4 4 . 5 5 5 . 5 6 6 . 5 - 0 . 1 5 - 3 T i m e [ S e c ] x 1 0 - 0 . 2 (b) 2 2 . 5 3 3 . 5 4 4 . 5 5 5 . 5 6 6 . 5 T i m e [ S e c ] - 3 1 0 02 1 x 1 0 C o n c eC n o t n r ic c e n A t r Fi c R A F R

] A F R wA i tF h R Sw i t t ah t S i ct a t E i c c E c c e c ne n t t r r i i c i i t ty y Fig. 27: Comparison of optimized AFR position error with current sheet g e ] 5 01 0 . 5 ] g g D e e

[ (in 3D-FE analysis) and increased radial length of rotor coils (in practical

D D [ [

n

r n o o o

i test) i r t t r i i 0 0

0 E s

s o n o P o

i r P t i

o r s t o o o t P R - 5- 0 1 - 0 . 5 VI. Increasing the accuracy of proposed structure

o Sine R Cosine As discussed above, overhang leakage flux was the main - 1 0- 0 2 - 1 2 2 22 . 5 . 5 3 3 33 . 5 . 5 4 4 44 . 5 . 5 5 5 55 . 5 . 5 6 6 66 . 5 . 5 T i m e [ S e c ] - 3 factor in which, AFR sensitivity against SE was affected. x 1 0 - 3 Phase DifferenceT i m e [ S e c ] x 1 0 (c) So, the following methods are proposed to improve the Fig. 25: Testing results of AFR with optimized rotor. (a) Oscilloscope sensitivity of the AFR. Detailed analysis and experiments graph measured (Ch1: Exciting Voltage; Ch2, 3: Output signals). (b) will be presented in an upcoming paper. Normalized output signals of eccentric AFR versus time with 4000 Hz excitation. (c) Comparison of angular position in eccentric and symmetric However, by using time stepping 3D FE analysis with equal optimized AFR tooth slopes, the yoke widths which minimize the maximum AFR error are shown in Figure 20 for the air gap lengths g = For accurate comparison, the output position signals of 0.5, 0.1, 1.5 and 2 mm. symmetric and eccentric optimized AFR are shown in fig. The information in Fig. 26-28 illustrates several key 25(c). In this figure AFR detected position is calculated features to improve the sensitivity of the AFR against SE. considering arctangent of output signals ratio. On this basis, They are: (a) Minimizing the AFR sensitivity against SE is Fig. 25(c) regards that the rotor eccentricity of 10 μm causes proportional to radial length of rotor coils; i.e. longer radial maximum 0.8 Arcdeg error in detected angular position. In length of rotor coils leads to smaller SE sensitivity, (b) comparison with initial (non optimized) AFR the position Increasing pole umber decreases overhang length of coils, error decreases 71.4%. Although, the position error is overhang leakage flux and then SE sensitivity (c) the reduced substantially against SE but 0.8 Arcdeg position optimum yoke widths for a particular air gap length are not error is a significant error in comparison with initial AFR equal. Therefore, traditional optimization methods such as without eccentricity with maximum 0.1 Arcdeg position grads method are not suitable for this problem, (d) AFR error. It seems that the overhang leakage flux may be results position error caused by SE is inversely proportional to air this error. Because, when rotor is displaced by means of a gap length, therefore the larger the air gap length is the mechanical force the overhang leakage flux affects one side smaller the AFR error (caused by SE) is, and (e) The of stator more than others. Therefore, the 3D FE analysis optimum yoke widths vary relatively little with air gap repeated with current sheets insisted of windings. In this length variations. case, as shown in fig. 26 the position error of optimized AFR decreases to 0.16 Arcdeg. 12 Sensor)", atreceived 1389/2/5. Flat Angle (Superior "Singlsyns Company, Absolute Tamagawa of Katalog General [4] Proc.(IECON2006) Conf. Resolver", Variable-Reluctance of Type One on Based System Sensing "Rotor-Position Lu, Y. Sun, L. [3] Pap. 3(1&2), 42-52. 2007), (Jan. Current, Z. Stator Nasiri-Gheidari F., Tootoonchian Resolver a of UsingParameter of Charge Response Identification Brushless A., D. Khaburi [2] 2008. Aug. Resolvers", Reluctance L. [1] paper. upcoming Further be results an presented will in sinusoidaland winding a distributed adopting pattern. optimallength, tothe(changing increasing air one), gap the length rotor statorthe numberpoles,yoke decreasing of including areproposed, improvement methods increasing Finally,rotor increase should several about windings 10%. thislengthofeffect is the that radial of flux, it suggested the overhangleakage flux.mainly Toreduce from the come of rotor optimized be the that position concluded errors AFRminimize sensitivity In the againstit SE. addition, can the parameters rotor determined process which yoke steppingOptimization FEMusing time approach. 3D a (GA) applicationswith for algorithm optimized genetic precise motor commutationstructure AFR applications, but further. suchsufficient Although, is amost precision for be to anddecreased too position needs error increases occurs,AFR's resolvers. However,SE radial when flux than conventional AFRsSE aureate are2.79times level, length,statorslot…) airand(such and rotor number, gap as design parameters showed tests practical same with that error. 3D-FEM stepping and Usingd-q time model, position whichresolver inherent characteristics determine criticalbearing resolvershaft) as mounted resolver (or a and identified static eccentricityis operation reviewed was hasconsidered. Basic resolver been static eccentricity(SE) canrobust againstflux resolver (AFR) which be structure In work optimizationnovel axial this theof design and a

by solving the inverse electromagnetic fieldby solvingproblem electromagnetic the inverse AFR Position Error [Deg] u, "nlss ad Ipoeet o h tutr f Variable of Structure the on Improvement and "Analysis Sun, P o s i t i o n E r r o r [ D e g ] 5 . 0 5 . 1 5 . 2 0 1 0 1 2 3 Fig. 18: Fig. 18: Iranian Journal of Electrical & Electronic Engineering Electronic & Electrical of Journal Iranian 9

Testing results of results Testing withrotor. optimized AFR IEEE Trans. Magn Trans. IEEE 8 ] m m [ h t g n e L e k u Y Paris, France, 2006,pp.1162-1165. Paris,France, VII. Conclusion References http://tamagawa-seiki.com/pdfj/1579n3e.pdf 32 7 nd Static Annual IEEE Industrial Electronics Industrial IEEE Annual Ecc 6 ., vol. 44, no. 8, pp. 2002-2008, pp. 8, no. 44, vol. ., = . 2 10 μ m 5 . 1 ] m m [ h t g n e L p a G r i A 1 5 . 0

, , [14] Sensors Conf. Proc resolver of electricanalysis reluctance vehicle", variable for Hwang,[13] K. Kim, K. S. Kim, on Y. the "A diagnosis Sung, study fault Reluctance Proc. "Variable Favre, E. (IMCSD) Devices and Systems Control Motion Incremental on Symposium Wyss, W. Jufer, Detection", Error Position Angular and Modelisation Resolver M. Crivii, M. [12] 245, no.2002. 2,pp.1202–1205,April Rotor", Eccentric An with Rresolver 8X-VR An of Analysis Error "Angular Wakiwakac, H. Kamiyac, A. Kikuchib, Y. Kitazawab, K. Yamamotoa, Y. Nireia, M. [11] 169. Proc. Conf. Drives and Machines Electrical Synchros", and Resolvers Slab Precision High of Regions End the in Distribution Flux "Magnetic Jack, G. A. and Burke M. D. [10] 297-300, 2000. Rotor”, Eccentric Skewed and Yamada, FieldWakiwaka, H. Resolver A Analysis “Magnetic of with A [9] Masaki,M. ,H. K. Nirei Mimura, Tsuchimichi Kitazawa,H. ,K. K. Applications,on Industry Eccentricity”, Static Inclined with Machine Induction [8] atreceived 1389/2/5. "Smartsyn-08", Resolvers Signalsyn)", (Smartsynand Company, Encoder for[7] from "Instruction Technical TechnologyBook note LTD, Tamagawa http://www.encoder-technology.com of Encoder[6] from "SmartsynFA-Solver", Technical Technology note LTD, Katalog http://www.encoder-technology.com General [5] 2000. shapes", to motor design pole andLu,[26] of Sun, Ping L. Y. Zhang, G. algorithms "Application genetic IEEE onMagn Trans. Laser Method", Form of Based Actuator Design Scanning on Statistical Y.[25] Kohayashi K. M. and"Torque Nirei, Yamainoto, Maruyama, T. at 470-69516-6 2008 (H/B), presented Datasheets”, Machines", Rotating Electrical “RDC T.[24] J. H. Pyrh¨onen, Hrabovcov´a, V. Jokinen, "Design Niemel¨a, of Company, Device http://www.analog.com Analog [23] Superconductivity, in DC-BiasedMagnetizing Current Transformers", Curve Calculation B-H "Measurements Core- and of Based W. Cheng, [22] Liu,Z. and Zhao, Z. Yan, Fan, Liu,J. F. Y. L. Zhang, 1998. Matlab/Simulink”, Machinery Ong,[21] Electric Using of C.M. Simulation “Dynamic in & engineering, electrical Power energy Machinery”, Electrical of “Analysis Krause, P.C. [20] 1,pp.572-577.Singapore, 29Oct. 27- 2010,vol. and (IPEC & 2010) International Power Energy Conf. Design Synchronous and Motorof PM Induction Flux Axial Motor Machines [19] C. Z Electrical “Axial-Field 294-300, 1987. June Chan, Applications”, C.C. [18] 1988. 638, January Motors with Disk Rotor”, in Induction Kubzdela B.[17] “Magnetodielectrics Weglinski, S. and 137-144, 1986. June Motors”, of[16] Varga, and Induction J. Properties S. “Magnetic Dimensional Axial Proc.(IECON'89) Conf. Resolver Guidelines", Design IECON, [15] Resolver”, Brushless Electronic Engineering, Electrical & of Prediction Performance X. Li, Q. Wu, and S. Nandi, “Performance Analysis of a Three-Phase a of Analysis “Performance Nandi, S. and Wu, Q. Li, X. D. A. Khaburi, F. Tootoonchian and Z. Nasiri-Gheidari, “Dynamic Nasiri-Gheidari, Z. and Tootoonchian F. Khaburi, A. D.

D. C. Hanselman, R. E. Thibodeau, D. E."Variable-Reluctance C.D. R. Hanselman, J. Thibodeau, Smith, , Berkeley, Canada, July Canada, , Berkeley, 2000,pp.139-144. HANGE IEEE onEnergy Conversion Transactions IEEE Tran. on Energy Conversion Energy on Tran. IEEE , K.J.T Journal of Magnetism and Magnetic Materials Magnetic and Magnetism of Journal vol. 20,no. 3,pp.1131-1134, 2010. vol. June Prentice Hall PTR. Upper Saddle HallPrentice PTR. Upper River , Kona HI, Nov.2010,pp.290–295. USA, 1-4 ., vol. 33,no. 5,Sept. 1997. ., vol. SENG , received at, received 2010. 10Nov. , New York, USA,, New1989,pp.203-208. York, vol. 43,no. 2,pp.531-541, 2007. vol. March/April . IEEE onMagn. Trans.

AND J. Harbin Inst. Technol.J. Harbin Inst. Elsevier Trans. SensorsandActuators Elsevier Trans. John Wiley and Sons LtdJohn WileyandSons T.D. N , received at 2010/10/1. at , received 2011/2/5. at , received vol. 4,no. 3,pp.94-103,2008. vol. July http://www.encoder-technology.com IEEE Industrial Electronics IEEE Industrial GUYEN , 1986. , London, UK, 1991, pp. 165- pp. 1991, UK, London, , , “ Analysis and Comparison Analysis and , vol. 24,no. 1,pp.635-

Proc., Suntec, IEEE onApplied Trans. , vol. no. 2,pp. EC-1, , vol. EC-2, no. 2, pp. 2, no. EC-2, vol. , , no. 1,pp.71–74, rna ora of Journal Iranian McGraw-Hill series McGraw-Hill IEEE Transactions IEEE ., ISBN: 978-0-ISBN: , New Jersey, 5 ”, th 9 International th 9th IEEE 9th IEEE 29th Annual 29th , vol. 242- vol. , , pp. ,