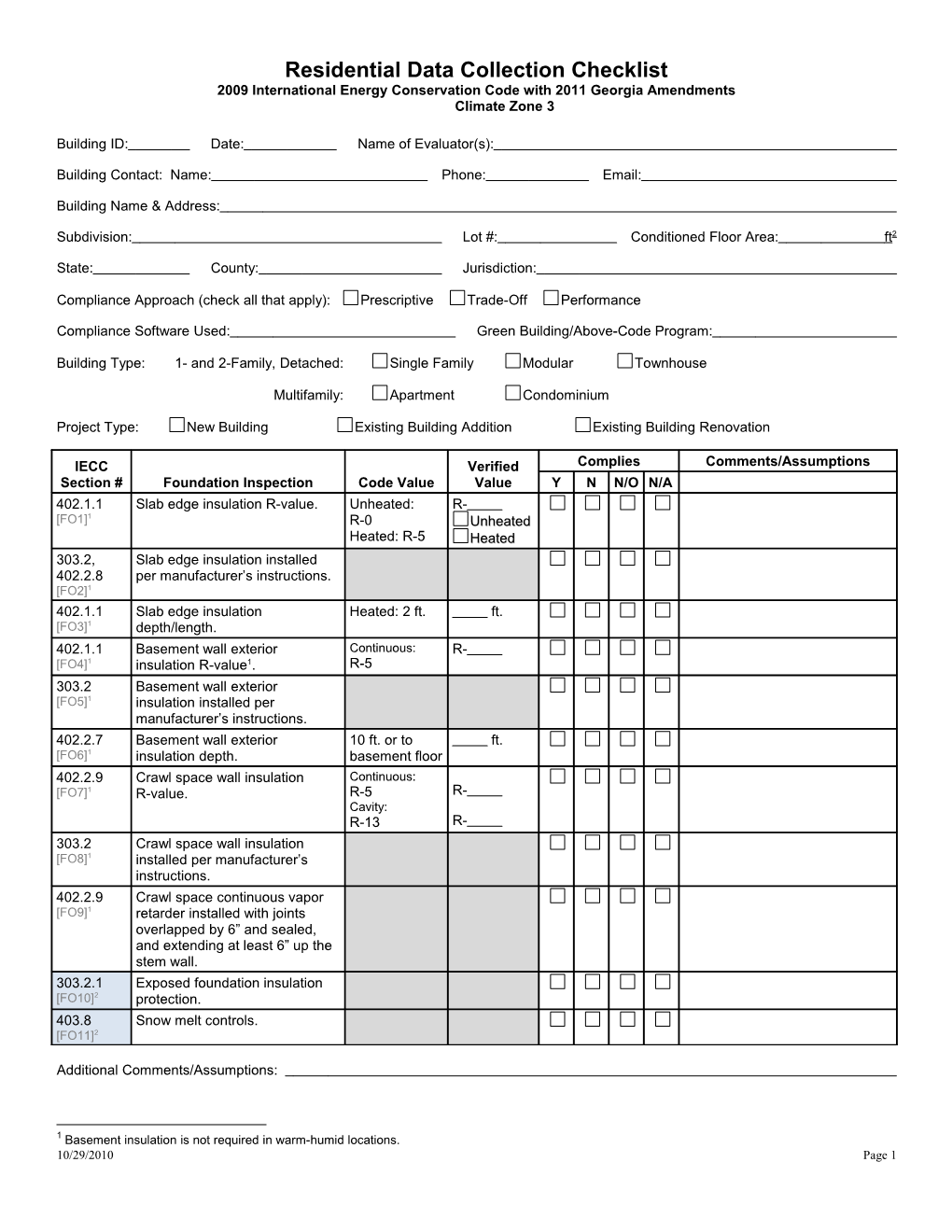

Residential Data Collection Checklist 2009 International Energy Conservation Code with 2011 Georgia Amendments Climate Zone 3

Building ID: Date: Name of Evaluator(s):

Building Contact: Name: Phone: Email:

Building Name & Address:

Subdivision: Lot #: Conditioned Floor Area: ft 2

State: County: Jurisdiction:

Compliance Approach (check all that apply): Prescriptive Trade-Off Performance

Compliance Software Used: Green Building/Above-Code Program:

Building Type: 1- and 2-Family, Detached: Single Family Modular Townhouse

Multifamily: Apartment Condominium

Project Type: New Building Existing Building Addition Existing Building Renovation

IECC Verified Complies Comments/Assumptions Section # Foundation Inspection Code Value Value Y N N/O N/A 402.1.1 Slab edge insulation R-value. Unheated: R- [FO1]1 R-0 Unheated Heated: R-5 Heated 303.2, Slab edge insulation installed 402.2.8 per manufacturer’s instructions. [FO2]1 402.1.1 Slab edge insulation Heated: 2 ft. ft. [FO3]1 depth/length. 402.1.1 Basement wall exterior Continuous: R- [FO4]1 insulation R-value1. R-5 303.2 Basement wall exterior [FO5]1 insulation installed per manufacturer’s instructions. 402.2.7 Basement wall exterior 10 ft. or to ft. [FO6]1 insulation depth. basement floor 402.2.9 Crawl space wall insulation Continuous: [FO7]1 R-value. R-5 R- Cavity: R-13 R- 303.2 Crawl space wall insulation [FO8]1 installed per manufacturer’s instructions. 402.2.9 Crawl space continuous vapor [FO9]1 retarder installed with joints overlapped by 6” and sealed, and extending at least 6” up the stem wall. 303.2.1 Exposed foundation insulation [FO10]2 protection. 403.8 Snow melt controls. [FO11]2

Additional Comments/Assumptions:

1 Basement insulation is not required in warm-humid locations. 10/29/2010 Page 1 General building information only required if different than above Building ID:

Date: Name of Evaluator(s):

Building Name & Address: Conditioned Floor Area: ft 2

Building Contact: Name: Phone: Email:

Compliance Approach (check all that apply): Prescriptive Trade-Off Performance

Compliance Software Used: Green Building/Above-Code Program:

IECC Code Verified Complies Comments/Assumptions Section # Framing / Rough-In Inspection Value Value Y N N/O N/A 402.1.1, Door U-factor. 2 U-0.50 U- 402.3.4 [FR1]1 402.1.1, Glazing U-factor (area-weighted U-0.50 U- 402.3.1, average). 3 Impact Rated: 402.3.3, 402.5 U-0.65 [FR2]1 402.1.1, Glazing SHGC value, including SHGC: 0.30 SHGC: 402.3.2, sunrooms (area-weighted (0.50 max)4 402.3.3 average). 4 [FR3]1 303.1.3 Glazing labeled for U-factor (or [FR4]1 default values used). 402.1.1, Skylight U-factor. 4 U-0.65 U- 402.3.3, 402.5 [FR5]1 402.1.1, Skylight SHGC value.4 SHGC: 0.30 SHGC: 402.3.3 (0.50 max)5 [FR6]1 303.1.3 Skylights labeled for U-factor (or [FR7]1 default values used). 402.3.5 Sunroom glazing U-factor. U-0.50 U- [FR8]1 Impact Rated: U-0.65 402.3.5 Sunroom skylight U-factor. U-0.65 U- [FR9]1 402.1.1 Mass wall exterior insulation R- R-55 R- [FR10]1 value. 303.2 Mass wall exterior insulation [FR11]1 installed per manufacturer’s instructions. 403.2.1 Duct insulation outside of building Attic Supply: R- [FR12]1 thermal envelope R-8 Other: R- R-6 403.2.4 Ducts sealed with mastic.. [FR13]1 403.2.3 Building cavities NOT used for [FR15]1 supply or return ducts. 402.4.5 Air-tight IC-rated recessed lighting [FR16]2 fixtures meet infiltration criteria. 403.3 HVAC piping insulation. R-3 R- [FR17]2

2 One side-hinged door up to 24 ft2 can be exempted from the prescriptive door U-factor requirements. Exemption cannot be applied to attic access. 3 Up to 15 ft2 of glazed fenestration, including skylights, may be exempted from U-factor and SHGC requirements under the prescriptive approach. 4 SHGC mandatory maximum using trade-offs. 5 If more than ½ the insulation is on the interior, mass wall interior insulation requirement applies (R-8). 10/29/2010 Page 2 403.4 Circulating hot-water piping R-2 R- [FR18]2 insulation. 403.5 Dampers installed on all outdoor [FR19]2 intake and exhaust openings. 402.4.4 Glazed fenestration air leakage. 0.3 cfm/ft2 [FR20]3 cfm/ ft2

402.4.4 Swinging door air leakage. 0.5 cfm/ft2 [FR21]3 cfm/ ft2 402.4.4 Fenestration and doors labeled for [FR22]3 air leakage.

Additional Comments/Assumptions:

10/29/2010 Page 3 General building information only required if different than above Building ID:

Date: Name of Evaluator(s):

Building Name & Address: Conditioned Floor Area: ft 2

Building Contact: Name: Phone: Email:

Compliance Approach (check all that apply): Prescriptive Trade-Off Performance

Compliance Software Used: Green Building/Above-Code Program:

IECC Code Verified Complies Comments/Assumptions Section # Insulation Inspection Value Value Y N N/O N/A 402.1.1, Floor insulation R-value. Wood: R- 402.2.5, R-19 Wood 6 402.2.6 Steel: Steel [IN1]1 See footnote 303.2, Floor insulation installed per 402.2.6 manufacturer’s instructions, and in [IN2]1 permanent continuous contact with the underside of the subfloor decking. 402.1.1 Wall insulation R-value. Wood: R- 402.2.5 R-13 Wood 7 402.2.4 Mass: Mass 1 [IN3] R-8 Steel Steel:8 See footnote 303.2 Wall insulation installed per [IN4]1 manufacturer’s instructions. 402.1.1 Basement wall interior insulation R- Continuous: [IN5]1 value. R-5 R- Cavity: R-13 R- 303.2 Basement wall interior insulation [IN6]1 installed per manufacturer’s Instructions. 402.2.7 Basement wall interior insulation 10 ft or to ft [IN7]1 depth. basement floor 402.2.11 Sunroom wall insulation R-value. R-13 R- [IN8]1 303.2 Sunroom wall insulation installed per [IN9]1 manufacturer’s Instructions. 402.2.11 Sunroom ceiling insulation R-value. R-19 R- [IN10]1 303.2 Sunroom ceiling insulation installed [IN11]1 per manufacturer’s instructions. 303.1 All installed insulation labeled or [IN13]2 installed R-value provided. 402.4.1, Air sealing of all openings and 402.4.2 penetrations: [IN14]3 Site-built fenestration Window/door openings Utility penetrations Attic access openings

6 Floor steel frame equivalent: R-19+R-6 in 2x6 or R-19+R-12 in 2x8 or 2x10 7 If more than ½ the insulation is on the exterior, mass wall exterior insulation requirement applies (R-5). 8 Wall steel frame equivalent: R-13+R-5; R-15+R-4; R-21+R-3; R-0+R-10 10/29/2010 Page 4 402.4.1, Air sealing of all envelope joints and 402.4.2 seams: [IN15]3 Dropped ceilings Knee walls Assemblies separating garage Tubs and showers Common walls between units Rim joist junctions

402.4.1, Air sealing of all other sources of 402.4.2 infiltration, including air barrier.. [IN16]3

Additional Comments/Assumptions:

10/29/2010 Page 5 General building information only required if different than above Building ID:

Date: Name of Evaluator(s):

Building Name & Address: Conditioned Floor Area: ft 2

Building Contact: Name: Phone: Email:

Compliance Approach (check all that apply): Prescriptive Trade-Off Performance

Compliance Software Used: Green Building/Above-Code Program:

IECC Verified Complied Comments/Assumptions Section # Final Inspection Provisions Code Value Value Y N N/O N/A 402.1.1, Ceiling insulation R-value. Wood: R- 402.2.1, R-30 Wood 9 402.2.2 Steel Truss Steel [FI1]1 Steel Joist10 303.1.1.1, Ceiling insulation installed per 303.2 manufacturer’s instructions. [FI2]1 Blown insulation marked every 300 ft2. 402.2.3 Access hatch and door insulation Hole cover: R- [FI3]1 and weatherstripping. R-19 Vertical doors/stairs: R-5 402.1.1 Attic kneewall insulation R-value R-18 R- [FI13ga] 1 with attic-side air barrier. 402.2.1.1 Wind wash baffle and dam for air- [FI14ga] 1 permeable insulation. 403.2.2 Duct tightness test complies with Rough-in Total % [FI4]1 thresholds. Results posted on Leakage, RIT: 6% compliance certificate. If all ducts Post- and equipment inside envelope, construction test not required and noted on Total Leakage, certificate. PCT: 12 % Post- Construction Leakage to Outdoors, PCO: 8 % 403.6 Heating and cooling equipment [FI5]1 type and efficiency on compliance certificate.

. 403.6.1 Electric-resistance heat NOT [FI15ga] 1 used as the primary heat source. 404.1 Lighting - 50% of lamps are high [FI6]1 efficacy or controlled via an occupancy or vacancy sensor. 402.4.2, Envelope tightness complies with ACH 50 < 7 ACH 50 = 402.4.2.1 sealing requirements via blower [IN12]1 door test. Results posted on compliance certificate. If multifamily (R-2 occupancy), verification via visual inspection instead of blower door test is allowed. 401.3 Compliance certificate posted at [FI7]2 electrical panel or air handler. 403.6 HVAC loads calculations and air kBtu:

9 Steel truss equivalent: R-38; R-30+R-3; R-26+R-5. 10 Steel joist equivalent: R-38 in 2x4 or 2x6 or 2x8; R-49 in any framing. 10/29/2010 Page 6 [PR2]2 handler cfm on compliance certificate: kBtu: Heating system size(s): Cooling system size(s): cfm:

402.4.3 Site built masonry wood burning [FI8]2 fireplace - gasketed doors and outdoor air for combustion. 403.1.1 Programmable thermostats [FI9]2 installed on forced air furnaces. 403..1.2 Heat pump thermostat or lockout [FI10]2 device installed on heat pumps. 403.4 Circulating hot water systems [FI11]2 have automatic or accessible manual controls. 403.9 Pool heaters, covers, and [FI12]2 automatic or accessible manual controls. 403.10 Power attic ventilators NOT [FI16ga]2 connected to the electric grid.

Additional Comments/Assumptions:

KEY 1 High Impact (Tier 1) 2 Medium Impact (Tier 2) 3 Low Impact (Tier 3)

10/29/2010 Page 7