Wisconsin Center for Applied Microelectronics

1550 Engineering Drive Phone: 608/262-6877 Madison, WI 53706 Fax: 608/265-2614

GENERAL PPURPOSE TUBE 22 PROCEDURES FFOR MMETAL AANNEALS

Rev. 4/27/18

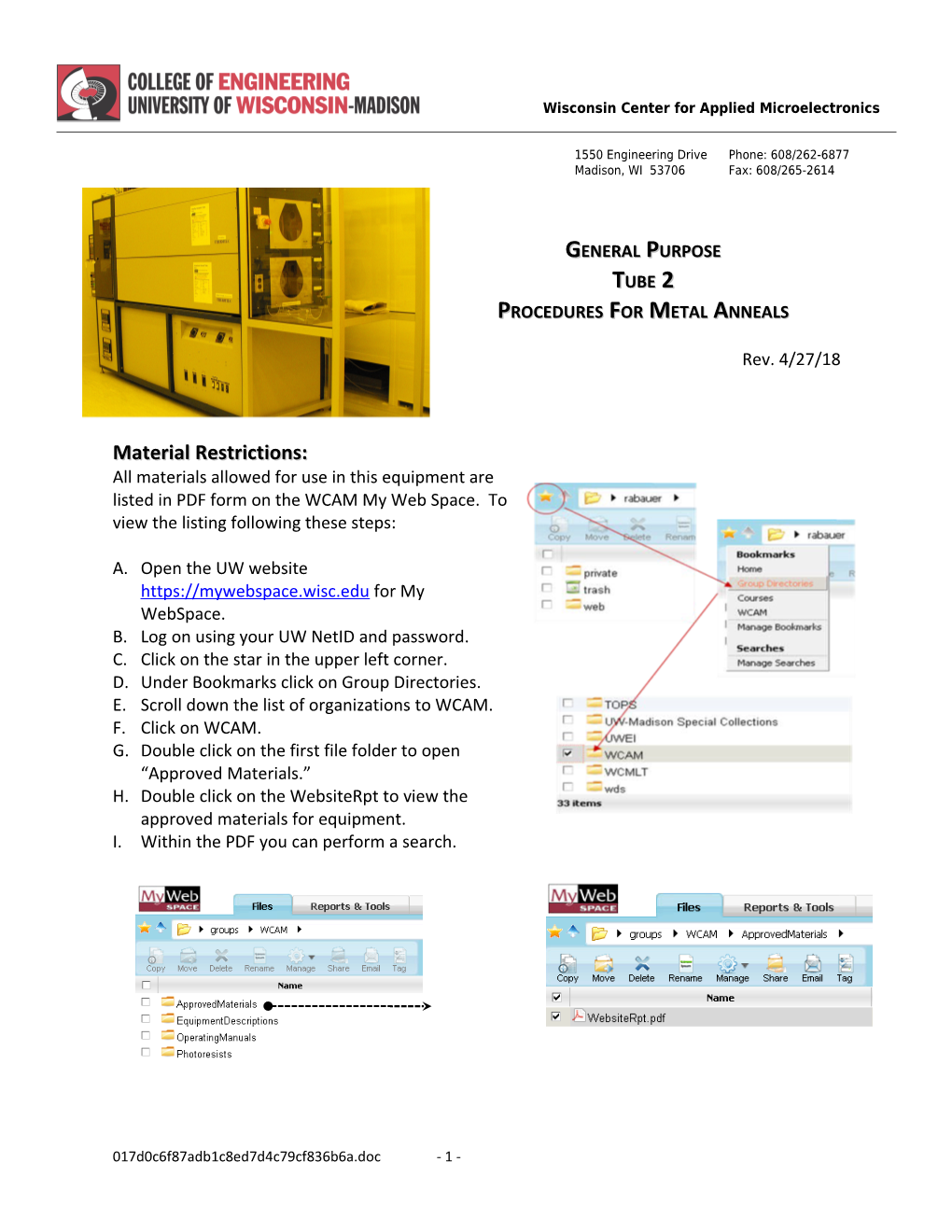

Material Restrictions: All materials allowed for use in this equipment are listed in PDF form on the WCAM My Web Space. To view the listing following these steps:

A. Open the UW website https://mywebspace.wisc.edu for My WebSpace. B. Log on using your UW NetID and password. C. Click on the star in the upper left corner. D. Under Bookmarks click on Group Directories. E. Scroll down the list of organizations to WCAM. F. Click on WCAM. G. Double click on the first file folder to open “Approved Materials.” H. Double click on the WebsiteRpt to view the approved materials for equipment. I. Within the PDF you can perform a search.

017d0c6f87adb1c8ed7d4c79cf836b6a.doc - 1 - Background CHANNEL 1 -- Nitrogen gas flow is in Liters/minute. CHANNEL 2 -- Forming gas flow is in Liters/minute.

Start-Up 1. ANNEAL equipment need: . 3” quartz wafer boat or the 4” quartz wafer boat . Sled or cradle . Hot gloves

2. Channel 1 flow is set at .075 L/min. nitrogen idle flow.

3. Set the desired furnace temperature by increasing the temperature on the CENTER controller located on the side of the system. . Set using the CENTER temperature controller ONLY. . Use the up/down arrows to change the set point. . The RED numerals on the temperature controllers are the measured temperature and the GREEN numerals are the set point. . The temperature will automatically ramp up at 10 C/min. . The center temperature controller will flash rP and the set temperature until the temperature has ramped up to the desired temperature.

Loading the Wafers 1. Prepare wafers for loading. On the shelf in front of the furnace, load the quartz wafer boat onto the sled. 2. Load your wafers into the slots in the quartz wafer boat. 3. Put on the "hot" gloves and remove the end cap from the tube.

BE VERY CAREFUL — THE END CAP HAS A SPOUT THAT CAN HIT THE METAL FRAME.

4. Pick up the sled and push the boat into the front of the tube using the ANNEAL pull-rod. 5. Slowly push the boat into the tube until the scratch on the pull-rod remains.

017d0c6f87adb1c8ed7d4c79cf836b6a.doc - 2 - Performing The Anneal Turn on the forming gas in the back of the furnace on the bottom Argus box labeled METAL ANNEAL.

. The Nitrogen should be on with the idle flow set at 0.75. . Turn the Display channel knob to position 2 to display forming gas flow. . Press the Channel 2 button to start the forming gas flow. . Adjust the forming gas flow by turning the second round FG set point knob until the display reads 2.50 . Press Channel 1 nitrogen button off. . Manually time the anneal.

Unloading the Wafers 1. Decrease the temperature on the Center temperature controller on the side of the system to 400. Adjust only the CENTER controller. Dial 0.75 2. The temperature will automatically ramp down at 10 C/min. The center temperature controller will flash rP and the set temperature until the temperature has ramped down to the idle 400 temperature. 3. Once the temperature is reduced to 400C, change to gas flow to nitrogen. Press Channel 1 Nitrogen button on. 4. Adjust the round Channel 1 Nitrogen set point knob until the display reads 0.75, the idle nitrogen flow. 5. Press the Channel 2 forming gas button off. 6. Put on the "hot" gloves and remove the end cap from the tube the tube. 7. Use the ANNEAL pull rod to pull the boat to the front of the tube. Be careful of spout on endcap 8. Pull the boat onto the ANNEAL sled. 9. Set the sled with the boat onto the load shelf on the front of the furnace. 10. Wait 15 minutes, and then remove your wafers from the boat. 11. Replace the boat to the shelf. Replace the sled to its shelf.

End Ensure the furnace temperature is 400 C by looking at the Center temperature controller on the side of the system.

RECORD YOUR USE OF THE SYSTEM IN THE LOG BOOK.

017d0c6f87adb1c8ed7d4c79cf836b6a.doc - 3 -