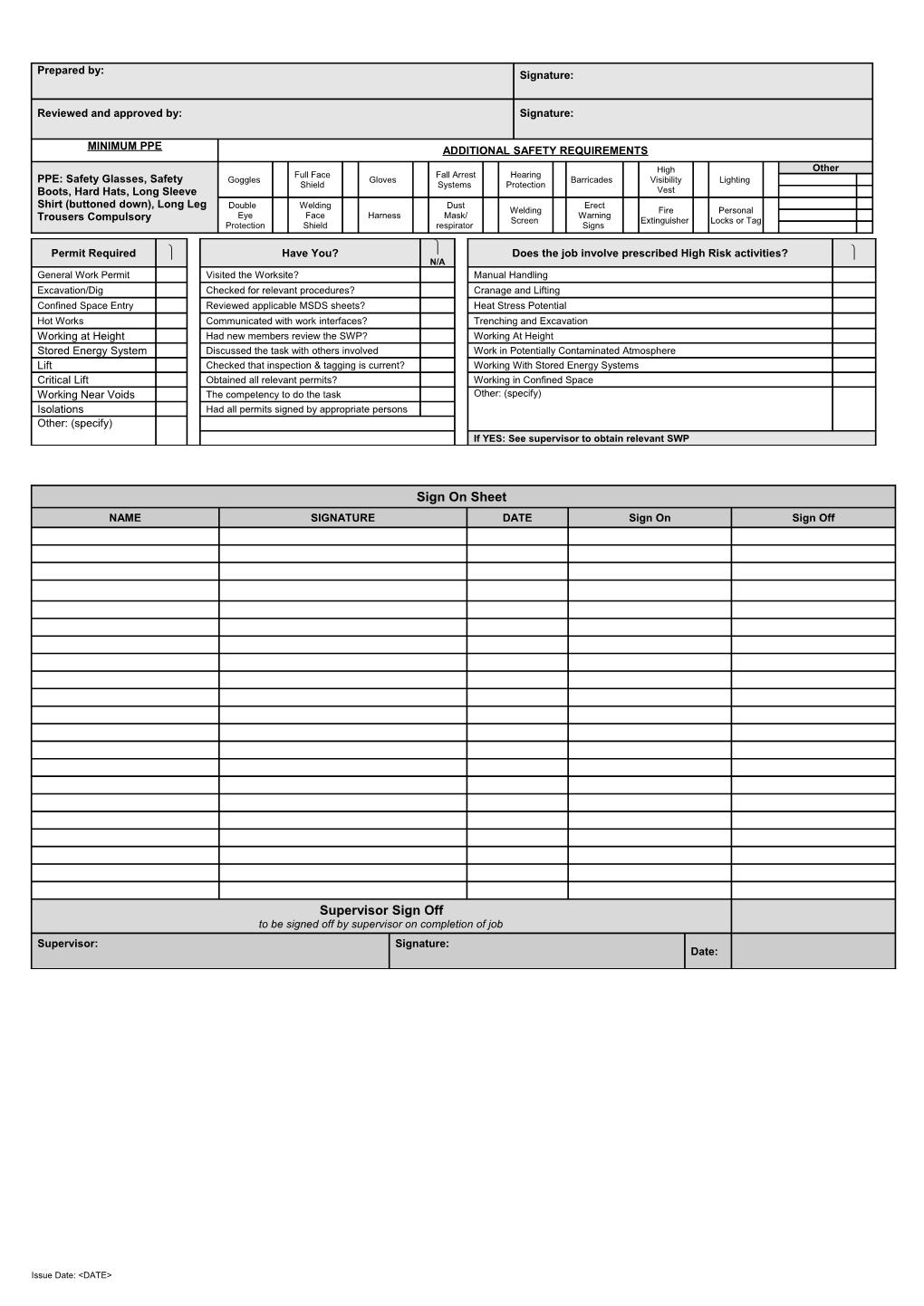

Prepared by: Signature:

Reviewed and approved by: Signature:

MINIMUM PPE ADDITIONAL SAFETY REQUIREMENTS

High Other Full Face Fall Arrest Hearing PPE: Safety Glasses, Safety Goggles Gloves Barricades Visibility Lighting Shield Systems Protection Boots, Hard Hats, Long Sleeve Vest Shirt (buttoned down), Long Leg Double Welding Dust Erect Welding Fire Personal Eye Face Harness Mask/ Warning Trousers Compulsory Screen Extinguisher Locks or Tag Protection Shield respirator Signs

Permit Required Have You? Does the job involve prescribed High Risk activities? N/A General Work Permit Visited the Worksite? Manual Handling Excavation/Dig Checked for relevant procedures? Cranage and Lifting Confined Space Entry Reviewed applicable MSDS sheets? Heat Stress Potential Hot Works Communicated with work interfaces? Trenching and Excavation Working at Height Had new members review the SWP? Working At Height Stored Energy System Discussed the task with others involved Work in Potentially Contaminated Atmosphere Lift Checked that inspection & tagging is current? Working With Stored Energy Systems Critical Lift Obtained all relevant permits? Working in Confined Space Working Near Voids The competency to do the task Other: (specify) Isolations Had all permits signed by appropriate persons Other: (specify) If YES: See supervisor to obtain relevant SWP

Sign On Sheet NAME SIGNATURE DATE Sign On Sign Off

Supervisor Sign Off to be signed off by supervisor on completion of job Supervisor: Signature: Date:

Issue Date:

Job Safety Analysis TASK: (JSA)

Risk Residua Responsible Step Job Step Hazard Control Rank l Risk Person

Issue Date:

CONSEQUENCE RATINGS

Rating 1. Safety 4. Plant 5. Environment Endangering the project due t o

) unavailability of key assets or l Fatality or permenant disability a

c equipment performance Severe/long term damage to a the i t i

r natural environment.

C Long term health illness (

Extensive damage to plant, property or equipment >$250k Major impact on the project due LT I > 2 weeks to unavailability of key assets, or )

r equipment performance Major damage/medium term o j Long term disabling injury > 1 mt h impact on the nat ural a M

( Major damage to plant, property environment. Ongoing Health illness > 2 mths or equipment between $150k and $250k CONSEQUENCE Failure to meet some performance indicators due to unavailability of LT I < 2weeks LIKELIHOOD Insignificant Minor Moderate Major Critical )

e key assets or equipment t Localised short -term controllable a

r performance e Short term disabling injury <1 mth impact on t he natural d Almost Certain L5 M10 H17 VH21 VH25 o environment M

( P lant, property or equipment Short term healt h illness <2 mths damage between $50,000 and Likely L4 M9 H16 H19 VH24 $150,000

Minor or moderate impact on Possible L3 M8 M13 H18 VH23 performance due to unavailability of key asset s or equipment ) Unlikely L2 M7 M12 M15 VH22 r Incident that requires medical

o performance Localised impact on the natural n

i treatment by a qualified medical environment M

( practit ioner Rare L1 L6 M11 M14 H20 P lant, property or equipment damage between $10,000 and $50,000 Unavailability of assets or

) equipment performance , but no t n

a real impact on performance c

i Injury requiring first aid treatment Negligible impact on t he f

i indicators

n only environment. g i s n

I P lant, property or equuipment ( damage <$10,000

Work Component Hazard Type Hazard Definition Example

Exposure to weather Sun exposure Temperature Contact with extremes of hot or cold Hot pipes/components Biological Exposure to infectious bacteria or fungi First aid waste, Poor hygiene Environment Excessive sound pressure Noise from tools, plant and equipment Noise & Vibration Excessive vibration Machine vibration, Blast noise

Animals Contact with animals Snake or spider bite, Animals on road Inhalation, absorption, injection and Chemical splashes, spills, releases, Gas & Chemicals ingestion of chemicals Fume emissions Radiation Exposure to radiation source Density gauges, Sun burn, Welding flash Materials Electricity Contact with live electrical circuit Frayed leads, Damaged plugs High pressure air, Hydraulic hose failure, Stored Energy Exposure to stored energy systems Hydraulic rams moving, Actuators Stooping/leaning for long periods, Poor Tasks requiring awkward posture and Posture/Repetition ergonomics, Repetitive assembly and repetition disassembly People Lifting sample bags/machine parts, pulling a Lifting/Pushing/Pulling Manually handling objects rope or cable, dragging air hoses Working at height, Uneven surfaces, Slippery Gravitational Slips, trips and falls surfaces Mobile Contact with moving equipment Moving vehicle, Moving crane loads Rotating parts, Moving conveyors, Hydraulic Fixed Contact with powered equipment press Equipment Portable Use and condition of portable equipment Water contact, Rotating parts, Sharp edges Objects falling from above, Grinding, Oxy Gravitational objects Contact with falling or flying objects cutting, Rockfalls, Dust

Issue Date: