World Journal of Engineering DYNAMIC CHARACTERIZATION OF A DELAMINATED SHIP DECK PLATE

Ionel Chirica1, Elena-Felicia Beznea1, David Hui2 1 University Dunarea de Jos of Galati, Romania, 47, Domneasca Str., Galati-800008 2 University of New Orleans, USA2000, Lakeshore Dr., New Orleans, LA 70148

Introduction the ellipse’s diameters ratio of delaminated zone on the dynamic behavior of the Composite structures with viscoelastic composite plate is investigated. damping material are becoming widely used for ships, submarines and offshore structures Theory of the composite plates vibrations for reducing vibration and noises. Understanding viscoelastic properties of In the case of a thin, specially orthotropic composite materials is the most important plate, small amplitude vibrational behaviour issue of the design and analysis of the ship is governed by four elastic constants, for the structure in general. Offshore and ship simplest case in which shear and rotator structures are loaded by several dynamic inertia are ignored. We choose to use the forces. The reduction of structural vibration is constants D1, D2, D3 and D4 introduced in [1] one of the key design aspects and composite These are defined through the elastic strain materials are used to reduce vibration. energy of the plate as it vibrates in the x-y Specially, the loss factor and Young's plane with a centre-plane transverse modulus must be known to develop finite displacement in the z-direction 2 element codes for a composite structure. 2 w 2 w 2 w D The damping of an engineering structure is 2 2 2 2 h3 x x y important in many aspects of noise and U D dA 1 2 (1) 2 2 2 2 vibration control, fatigue endurance and so A w w D D 3 2 4 on, since it controls the amplitude of resonant y xy vibration response. As a result of energy where h is the plate thickness, subscripts x dissipation mechanisms in a structure, the and y denote partial derivatives and the inherent material damping contributes integral is taken over the area of the plate. significantly to the overall damping, and is The constants Di can be written in terms of often the primary means of controlling the the Young’s moduli along the two main structure’s dynamic behaviour. It is thus directions (x and y axes) of the plate, the two important to be able to control and predict the Poisson’s ratios between these directions level of inherent damping in such materials. xy and , and the in-plane shear modulus G . The linear elastic behaviour of the laminate yx xy D = E /12 D = E /6 = E /6 plates can be predicted from the properties of 1 x 2 xy y yx x the individual plies using laminate theory, that D3 = Ey/12 D4 = Gxy/3 (2) can also be used to predict the damping properties of such plates, through the concept (2) of “complex modulus”. where = 1 - xyyx. An orthotropic delamination model, descri- Note that, in broad terms, D1 is associated bing delaminating mode, by using with bending in the x direction, D3 with COSMOS/M soft package, is used in this bending in the y direction, D4 with twisting paper to analyze the behavior of the delamina- motion, and D2 with Poisson’s-ratio coupling ted composite plates during vibrations. So, the between the x and y directions. damaged part of the structures and the The material used for pates is E-glass/epoxy, undamaged part have been represented by having the mechanical characteristics: well-known finite elements (layered shell Ex =3.86GPa, Ey =8.27GPa, Ez=8.27GPa elements). The influence of the position and Gxy =4.1412GPa, Gxz =4.1412GPa,

101 World Journal of Engineering

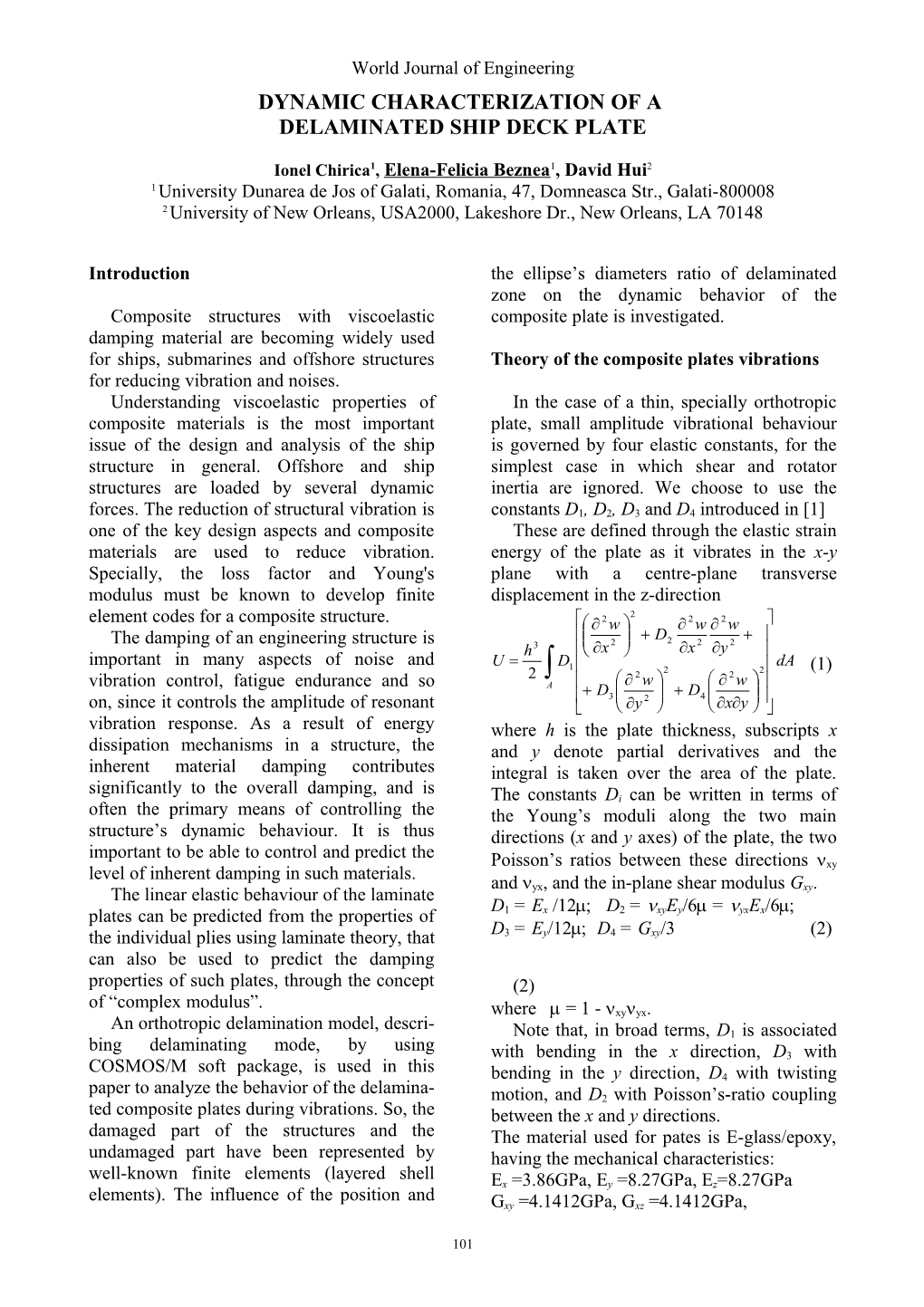

Gyz =4.1412GPa, xy = yz = xz =0.26. with clamped edge conditions have been Table 1. Plate lay-up reported in this work. Macro Number Fibers’ Thickness The test procedures employed in this study, layer of direction [mm] based on simple observation of vibration No. layers [degrees] frequencies and damping factors of rectangular plates, might form a basis for non- 1 2 0 0.62 destructive testing for quality control. 2 1 45 0.31 It has been verified that thin-plate bending 3 2 90 0.62 theory can be used with confidence to predict 4 1 45 0.31 the low-frequency vibration behaviour of 5 2 0 0.62 clamped edged, CFRP laminates and that 6 2 0 0.62 laminate theory is capable of predicting 7 1 45 0.31 elastic behaviour with sufficient accuracy to 8 2 90 0.62 enable frequency and mode shape predictions 9 1 45 0.31 to be made. It has also been shown that 10 2 0 0.62 laminate theory can be extended to predict damping properties. Results have been presented in terms of an unfamiliar combination of elastic constants, introduced in earlier studies and defined in equations (1) and (2). These constants are a convenient set to use when discussing thin-plate deformation or vibration. They are also the constants which occur naturally in the expression for the strain energy in terms of the plate centre- plane displacement, so that they lend Fig.1 Natural frequencies versus delaminated themselves to use in Finite-Element area (without damping) for Dx/Dy=0.5 computations. The elastic and damping properties of the plies of the laminate were deduced from measurements on the complete laminate, using inverse laminate theory. This approach might have advantages in some circumstan- ces: it allows the necessary parameter values to be deduced from a standard “production” laminate, and it obviates the need to make special unidirectional laminates for Fig.1 Natural frequencies versus delaminated calibration purposes. area (damping ratio=0.14) Elastic constants and, particularly, damping constants are likely to be sensitive to In figures 1 and 2, the variations of frequency variations of manufacture. Delaminatios, versus delaminated area for diameters ratio incomplete bonding between plies is likely to Dx/Dy=0.5 are presented (delamination between macro-layers 1 and 2). As it is seen in figure 2, the lead to reduced stiffness and greatly increased natural frequency is decreasing since the damping. delaminated area is in-creasing, when the plate damping is taken into account. Acknowledgements The work has been performed in the scope of Conclusions the Romanian Project PN2 - IDEI, Code 512 (2009-2011). The three-dimensional continuum vibration solutions for laminated composite plates with elliptical delaminations (Dx/Dy=0.5; 1; 2),

102 World Journal of Engineering References 1. J. P. Talbot, J.P. and Woodhouse, J. The vibration damping of laminated plates, Composites Part A, 28A, pp. 1007-1012, 1997.

103