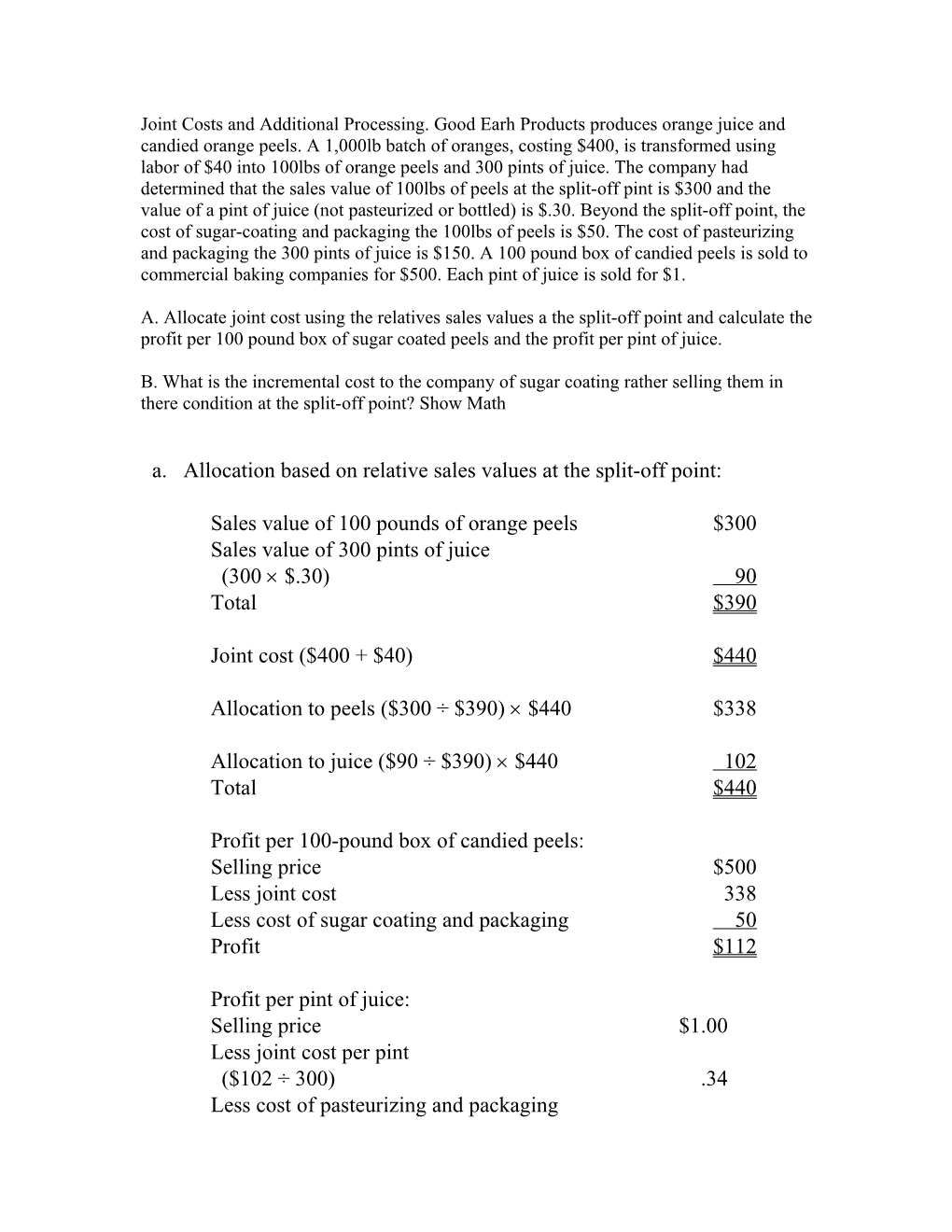

Joint Costs and Additional Processing. Good Earh Products produces orange juice and candied orange peels. A 1,000lb batch of oranges, costing $400, is transformed using labor of $40 into 100lbs of orange peels and 300 pints of juice. The company had determined that the sales value of 100lbs of peels at the split-off pint is $300 and the value of a pint of juice (not pasteurized or bottled) is $.30. Beyond the split-off point, the cost of sugar-coating and packaging the 100lbs of peels is $50. The cost of pasteurizing and packaging the 300 pints of juice is $150. A 100 pound box of candied peels is sold to commercial baking companies for $500. Each pint of juice is sold for $1.

A. Allocate joint cost using the relatives sales values a the split-off point and calculate the profit per 100 pound box of sugar coated peels and the profit per pint of juice.

B. What is the incremental cost to the company of sugar coating rather selling them in there condition at the split-off point? Show Math

a. Allocation based on relative sales values at the split-off point:

Sales value of 100 pounds of orange peels $300 Sales value of 300 pints of juice (300 $.30) 90 Total $390

Joint cost ($400 + $40) $440

Allocation to peels ($300 ÷ $390) $440 $338

Allocation to juice ($90 ÷ $390) $440 102 Total $440

Profit per 100-pound box of candied peels: Selling price $500 Less joint cost 338 Less cost of sugar coating and packaging 50 Profit $112

Profit per pint of juice: Selling price $1.00 Less joint cost per pint ($102 ÷ 300) .34 Less cost of pasteurizing and packaging ($150 ÷ 300) .50 Profit $0 .16 b. Incremental revenue of sugar coating: ($500 − $300) $200 Incremental cost 50 Net incremental benefit of sugar coating $150 c. Incremental revenue of packaged juice ($300 − $90) $210 Incremental cost 150 Net incremental benefit of pasteurizing and packaging $ 60 ÷ 300 = $.20/pint