5. Water Treatment

Mardi Water Treatment Plant

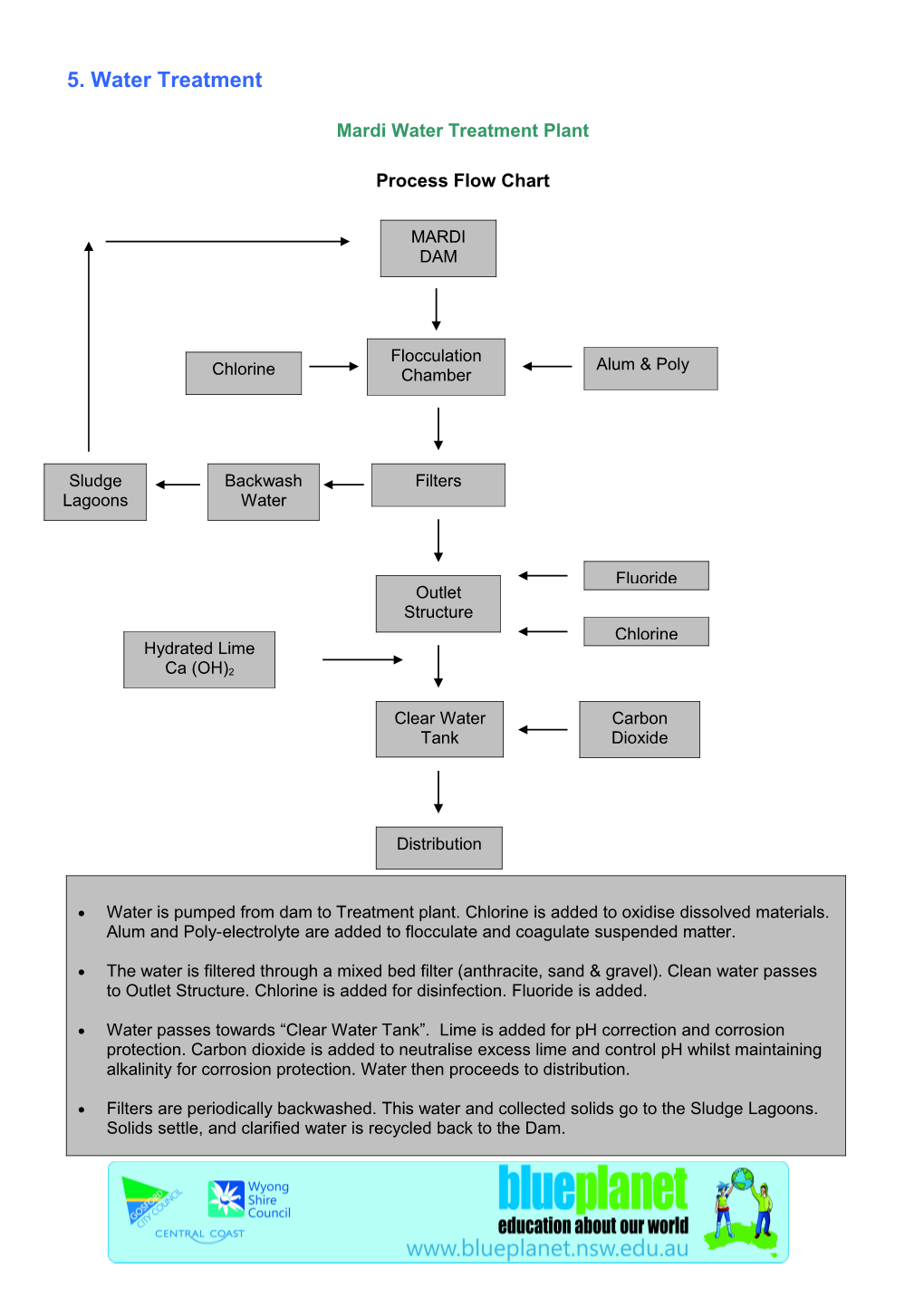

Process Flow Chart

MARDI DAM

Flocculation Alum & Poly Chlorine Chamber

Sludge Backwash Filters Lagoons Water

Fluoride Outlet Structure Chlorine Hydrated Lime Ca (OH)2

Clear Water Carbon Tank Dioxide

Distribution

Water is pumped from dam to Treatment plant. Chlorine is added to oxidise dissolved materials. Alum and Poly-electrolyte are added to flocculate and coagulate suspended matter.

The water is filtered through a mixed bed filter (anthracite, sand & gravel). Clean water passes to Outlet Structure. Chlorine is added for disinfection. Fluoride is added.

Water passes towards “Clear Water Tank”. Lime is added for pH correction and corrosion protection. Carbon dioxide is added to neutralise excess lime and control pH whilst maintaining alkalinity for corrosion protection. Water then proceeds to distribution.

Filters are periodically backwashed. This water and collected solids go to the Sludge Lagoons. Solids settle, and clarified water is recycled back to the Dam. Mangrove Creek Dam and Mardi Dam water is treated as follows

1. Chlorine is added to oxidise unwanted dissolved materials and make the water more receptive to flocculating chemicals.

2. Liquid alum (Aluminium Sulphate) and Polyelectrolyte (Polyacrylamide) are added and mixed to flocculate and coagulate the suspended particles.

3. The water containing the flocculated particles is then:- a. For Gosford Water Treatment Plant - settled in a sedimentation channel where the bulk of the flocculated particles fall to the bottom. The clearer top layer is then filtered through a bed of gravel, sand and anthracite. b. For Wyong Water Treatment Plant, filtered directly through gravel, sand and anthracite.

4. After filtration, the water is further chlorinated to disinfect it. It is then:- a. For Gosford, fluoridated for prevention of teeth decay, and adjusted for pH using soda ash to minimise corrosion in the system.

b. For Wyong, fluoridated for prevention of teeth decay, and pH corrected using lime and carbon dioxide for corrosion protection.

5. Water is then distributed to a series of roofed reservoirs before further distribution to consumers.

Reduction of risk of infection is achieved firstly by filtration where much of the bacteria are held back and all larger parasites such as Giardia and Cryptosporidium. Secondly, after filtration, the chlorination kills any bacteria which may still survive. These two processes are the main contributors to reducing the risk of infection. Roofing of storage reservoirs assists in providing a safe storage of treated water so that no re-contamination will occur by exposing the water to birds and atmospheric fallout.

Water quality is enhanced by chlorination, coagulation, flocculation and filtration; causing nuisance dissolved materials such as iron and manganese to be minimised and at the same time dirt and organic materials to be removed, enhancing colour and clarity. The pH correction minimises corrosion in the system: such corrosion could otherwise lead to the dirty appearance of water, to the staining of household fittings, baths and sinks, and to the spoiling of laundry processes resulting in the spotting of washed clothes.