Improving Quality Using Microsoft Visio 2010

Reducing Cost of Quality Control with Minimal IT Investment

Introduction AdventureWorks is a bicycle manufacturer that markets high-end, handmade road bicycles. Each of their bicycles features the very best in OEM parts which are mounted to a custom built frame based on the customer’s unique specifications. AdventureWorks’ bicycles start at $2,000, and the average sales price for the 50,000 bicycles they sold last year was $3,000. The AdventureWorks team prides itself on the quality of their products, and each bicycle is sold with a full life-time warranty on all parts, including the custom built frame.

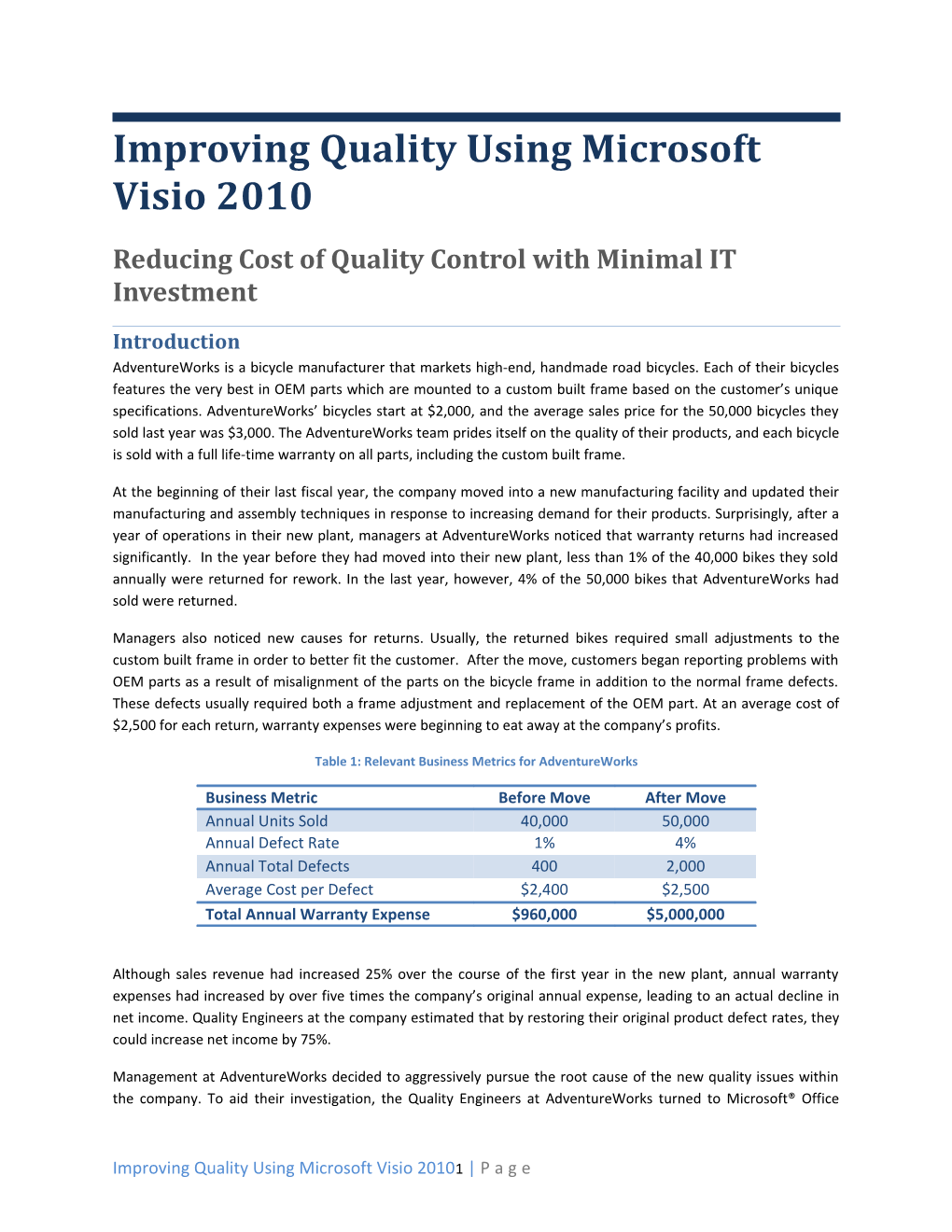

At the beginning of their last fiscal year, the company moved into a new manufacturing facility and updated their manufacturing and assembly techniques in response to increasing demand for their products. Surprisingly, after a year of operations in their new plant, managers at AdventureWorks noticed that warranty returns had increased significantly. In the year before they had moved into their new plant, less than 1% of the 40,000 bikes they sold annually were returned for rework. In the last year, however, 4% of the 50,000 bikes that AdventureWorks had sold were returned.

Managers also noticed new causes for returns. Usually, the returned bikes required small adjustments to the custom built frame in order to better fit the customer. After the move, customers began reporting problems with OEM parts as a result of misalignment of the parts on the bicycle frame in addition to the normal frame defects. These defects usually required both a frame adjustment and replacement of the OEM part. At an average cost of $2,500 for each return, warranty expenses were beginning to eat away at the company’s profits.

Table 1: Relevant Business Metrics for AdventureWorks

Business Metric Before Move After Move Annual Units Sold 40,000 50,000 Annual Defect Rate 1% 4% Annual Total Defects 400 2,000 Average Cost per Defect $2,400 $2,500 Total Annual Warranty Expense $960,000 $5,000,000

Although sales revenue had increased 25% over the course of the first year in the new plant, annual warranty expenses had increased by over five times the company’s original annual expense, leading to an actual decline in net income. Quality Engineers at the company estimated that by restoring their original product defect rates, they could increase net income by 75%.

Management at AdventureWorks decided to aggressively pursue the root cause of the new quality issues within the company. To aid their investigation, the Quality Engineers at AdventureWorks turned to Microsoft® Office

Improving Quality Using Microsoft Visio 20101 | P a g e Visio© 2010. After AdventureWorks solved their quality control problems, they again used Visio 2010 to enable a Design for Quality approach for new product development to avoid future quality issues.

1. Converting Static Process Diagrams to Visio 2010 In order to find the root cause of the quality issues at AdventureWorks, Quality Engineers began analyzing the part-creation processes. At first, this task appeared daunting since the new manufacturing processes that AdventureWorks had been designed using Microsoft Office Art was embedded within Microsoft® Office Excel® 2010 spreadsheets.

Several team members advocated recreating the existing process diagrams to Visio 2010 – an environment that would enable rich process analysis. However, the Quality team leader estimated that each process diagram would take an average of 5 hours to manually convert to Visio 2010, so the 120 unique processes across the plant would require 600 labor hours of effort. With only 5 team members, the conversion process alone might take 3 weeks. Although the team leader clearly understood the benefits of having flexible process diagrams for detailed analysis, he was concerned with the degree of time and effort required to convert the diagrams.

Importing Static Office Flowcharts into Visio 2010 for Process Analysis As the team debated the costs and benefits of converting the diagrams, a junior engineer discovered the Free Flowchart Converter Add-in for Visio 2010. After demonstrating the feature to the rest of the team, the junior engineer was able to tip the balance of the conversion discussion. For her discovery, she was rewarded with the task of converting all 120 process diagrams to Visio 2010 – a task she completed within a matter of hours. Once the team had their important process information stored in Visio 2010, they moved forward to uncover the root causes of the quality issues.

Figure 1: Static Excel 2010 based flowchart Figure 2: Visio 2010 flowchart, converted and formatted Benefits of Converting Static Process Diagrams to Visio 2010 Using the new automated Free Flowchart Converter Add-in for Visio 2010, the team was able to quickly convert static Excel based process diagrams to Visio 2010, where in depth process analysis could take place. Once the diagrams were in the Visio 2010 environment, the team could quickly rearrange process steps, add in observed data about the processes they were analyzing directly in Visio 2010, and generate detailed reports to identify areas of improvement. The user interface for Visio 2010 was updated with the same Ribbon common to all other Office 2010 products. With this interface, and other new automated formatting features of Visio 2010, like auto connecting shapes, a shape spacing feature that logically aligns selected shapes with a single mouse click, and the new extendable page feature which resizes the page as the Visio drawing grows.

The team saved an estimated 600 hours of labor and avoided $30,000 in extra labor costs for the project by using the converter, rather than manually recreating the flowcharts in Visio 2010. More importantly, the team was able to shave valuable cycle time from the project while enabling detailed process analysis. Since each day meant the chance for additional product defects, a shorter but more detailed approach to process analysis translated directly into real dollar savings from improved quality.

By using the Free Flowchart Converter Add-in for Visio 2010, the Quality team at AdventureWorks was able to:

Quickly and easily convert static Excel based process diagrams to rich Visio 2010 diagrams for process analysis Avoid an estimated $30,000 worth of additional labor and three weeks of additional project cycle time to convert diagrams to Visio 2010 Downloadable Examples: Original Main Bushing Flowchart (Excel 2010 Workbook) Converted Main Bushing Flowchart (Visio 2010 Drawing) Link to Free Flowchart Converter Add-in XXXXXXXXXXXXXXXXXXXXXXXX

2. Discovering the Business Impacts of Quality Issues After the team had analyzed a variety of manufacturing processes and isolated those that contributed to the greatest number of defects, the team began to formulate strategies to improve and control the processes. Again, the team turned to Visio 2010 to enable process control techniques.

Of the many manufacturing processes that the team analyzed in detail using the Visio 2010 process diagrams and associated data, the frame welding process stood out as causing the greatest number of defects. This process had been dramatically altered during the transition to the new plant. Previously, frames had been hand-welded, a process that was labor intensive and expensive.

The new process used a CNC welder, which was controlled by a computer and produced extremely accurate and repeatable welds for the bicycle frames. However, the CNC welder could not compensate for various inaccuracies in frame parts and in the jig setup the way a skilled human welder could. If a down tube was a millimeter too short, or if the top tube wasn’t perfectly aligned to the seat tube in the frame jig, the CNC welder would create a perfect, but misaligned, weld on the frame. Because each frame was customized to the rider it was intended for, each part in the frame was uniquely crafted. The new welding process was less forgiving to small inaccuracies along the entire manufacturing line.

The Quality team at AdventureWorks sought to track these small inaccuracies in the work flow. They established a Quality Control (QC) check station right after the CNC welding station which inspected each frame produced. The inspections were costly in terms of labor commitment, but they were critical in measuring the number and causes of defects.

Improving Quality Using Microsoft Visio 20103 | P a g e Using a Check Sheet Diagram to Track Quality Issues The team created a Check Sheet diagram from a template included in Visio 2010. The check sheet contained a list of the common problems that were caught by the QC station. The sheet was displayed on a large monitor on the manufacturing floor and updated in real time, giving workers along the entire manufacturing line visibility into the quality of their output. If a particular problem with the quality of intermediate parts persisted, the Quality team could quickly isolate the cause and improve the process to create the intermediate part.

Using the check sheet as a quality dashboard, the team ran the QC station for a month. Initially, nearly every cell was red in the check sheet each week, indicating the high number of errors caught by the QC station. As problems were uncovered and addressed and the workers themselves began to focus on the accuracy of their processes, the check sheet began to look bluer by the end of the month.

Figure 3: AdventureWorks Manufacturing Defect Check Sheet, Before and After Process Improvement

After a month, the team was satisfied that most quality issues had been removed from the manufacturing processes. They scaled back the number of frame inspections to every fifth frame off the line, and the check sheet stayed where it was to encourage each worker along the manufacturing line to remember quality first.

Benefits of Discovering Quality Issues By tracking QC issues in real time and proactively isolating and improving intermediate manufacturing processes, the Quality team at AdventureWorks was able to virtually eliminate frame defects. As a result, warranty returns stabilized to pre-transition rates after six months, saving the firm an estimated $3.5 million annually.

Business Metric After Move After Improvement Units Sold 50,000 50,000 Defect Rate 4% 1% Total Defects 2,000 500 Average Cost per Defect $2,500 $2,400 Total Cost of Defects $5,000,000 $1,200,000 Total Savings $3,800,000

Downloadable Examples: AdventureWorks Manufacturing Defect Check Sheet.vsd AdventureWorks Manufacturing Defect Check Sheet.xlsx AdventureWorks Manufacturing Defect Check Sheet (After).vsd AdventureWorks Manufacturing Defect Check Sheet (After).xlsx

3. Standardizing the Visio 2010 Design for Quality Environment As the Quality team made significant progress in improving the quality of AdventureWorks’ manufacturing operations, the team’s work attracted attention from other parts of the company. In particular, the Vice President of Research and Development decided to adopt the team’s techniques to promote a Design for Quality approach within the company’s R&D group. AdventureWorks continually collected pre and post-sales survey data from potential customers and actual customers in order to improve their products. Pre-sales data were collected using a survey in the form of a “Bicycle Wish List”. This survey sought to determine what product characteristics potential customers demanded in an AdventureWorks bicycle, and what price point they would pay for those characteristics. Post-sales data were collected through product surveys distributed to customers 180 days after they purchased an AdventureWorks bicycle. This survey was designed to determine what the customer liked or disliked about the bicycle after owning it for half a year.

Although each potential or actual customer had a unique opinion about what a quality bicycle should look like, common themes became apparent in the product survey data. This data was used by AdventureWorks product development teams to develop the best possible bicycle for the price. During the preliminary design of new products, product development teams consisting of engineers from the R&D department and analysts from the Marketing department worked to ensure that each new bicycle had all of the characteristics that would make it a desirable product.

Unfortunately, the tools that the Marketing and R&D departments used to collaborate during the preliminary product design phase were difficult to use and led to confusion among the interdisciplinary product development teams. In particular, the teams found it difficult to prioritize quality criteria. Quality criteria were the different aspects of the value proposition for the product, such as the product’s ride handling, overall weight, or affordability. Some engineering options, such as the choice of material for the bicycle frame, impacted these quality criteria in different ways. For instance, the choice of carbon fiber over aluminum as the material for a bicycle’s frame would increase ride handling and decrease overall weight, but also decrease affordability.

The debates to decide which criteria were the most important and which engineering options to use consumed valuable product development cycle time. More importantly, the product development teams were not sure that final product designs represented the best possible combination of engineering options.

Using the Prioritization Matrix to Standardize Prioritization of Quality Criteria In order to remedy the prioritization problem, the VP of R&D turned to the Prioritization Matrix template for Visio 2010. This specialized template allows product development teams to quickly communicate which quality criteria are the most important and how different engineering options impact quality criteria.

Using the template, product development teams could condense a large amount of survey data into a simple diagram that clearly indicated to executive management which criteria a particular product would emphasize. Since the template used a standard set of shapes and a standard format across every product development team, executives at AdventureWorks could easily compare and contrast how different products met the priorities of different customer segments.

Improving Quality Using Microsoft Visio 20105 | P a g e Figure 4: AdventureWorks Bicycle Frame Material Prioritization Matrix Summary Benefits of Standardizing the Visio 2010 Design for Quality Environment By standardizing the Visio 2010 design for quality environment, the AdventureWorks R&D department was able to standardize the methodology to prioritize quality criteria and the way in which criteria prioritization was presented across each product development team.

By customizing the Visio 2010 environment, the quality team at AdventureWorks was able to:

Reduce the time and effort to prioritize quality criteria Better communicate product portfolio plans to executive management through a standard presentation template Better match product designs to the demands of different customer segments Downloadable Examples: AdventureWorks Prioritization Matrix.vsd AdventureWorks Prioritization Matrix.xlsx

4. Automating a Diagram to Track Customer Satisfaction Once AdventureWorks had achieved its original product defect rate and had begun designing products that better met the expectations of their different customer segments, the management at AdventureWorks turned their attention to creating a continuous Design for Quality approach to new product development efforts.

Such a paradigm represented a strategic shift in AdventureWorks’ operating model. Under the old operating model, the company released a product, collected feedback from customers, started a new product development effort that incorporated knowledge gleaned from the customer feedback, released a new product, and then reiterated the process.

Under the new approach, the company would release a product and then immediately collect feedback from customers. Then, the company would offer new options to the base product in response to the feedback. For instance, if the company released a Series 201 Roadbike, sold 2,300 units, and then learned that customers did not like the rear derailleur set, the company would immediately offer an upgrade option for a newer derailleur set – as long as the new offering made economic sense. Using a Decision Matrix to Create New Product Options To facilitate the decision of which options to offer, the Vice President of Marketing developed a system to automate the information his department received from online customer surveys. Using the Visio 2010 Decision Matrix template, the marketing department created a diagram which automatically tracked customer responses and graphically displayed what customers liked and disliked about new products and which product quality criteria were affected by the responses. The display was updated in real time so that product managers could see customer reactions to new products as online surveys were submitted.

The R&D department used the diagram do decide if and when to conduct abbreviated product development projects to create a new add-on offering for an existing product. Using this approach, AdventureWorks could realize an improvement opportunity based on customer resections, create a new option, price the option, and begin offering the option for existing products in a matter of days.

Benefits of Enabling a Continuous Design for Quality Approach Overall, the company was able to cut nearly 40 hours of labor time out of each product option development effort by using the automated Decision Matrix diagram. Over an average of 20 distinct new products that the company released annually, and across an average of 10 options per product, the labor savings alone led to nearly $400,000 annually. Moreover, sales of new products increased by 10% due to the increase in customer responsiveness across each product line. Through strategically creating new offers for existing products, AdventureWorks was able to significantly increase the return on investment for each product line.

By using a Visio 2010 Decision Matrix to track customer responses to new products and identify improvement opportunities, the AdventureWorks R&D team was able to:

Reduce new product option offering development times Capture greater customer demand by offering custom options Improve overall product Return on Investment. Downloadable Examples: AdventureWorks Decision Matrix.vsd AdventureWorks Decision Matrix.xlsx

Improving Quality Using Microsoft Visio 20107 | P a g e 8. Using Visio Services to Provide Visibility into Quality Control Issues One of the most challenging aspects for manufacturing is retooling for a new product launch. Retooling involves physically changing both the tools and dies used to create parts, and the workflow through an assembly line. In every product launch effort, engineering mistakes are uncovered in the final stages of production design, just as the manufacturing firm is beginning its first product runs to fill the first orders for the product. Any delays in those first orders could mean the loss of large accounts – potentially costing the company millions of dollars in lost revenue. Quality Engineers at AdventureWorks recognized this unavoidable aspect of retooling, but struggled with how best to quickly communicate vital quality and manufacturing process performance data to key stakeholders across the organization – in real time.

The primary symptom of an engineering flaw is a slowdown along the manufacturing line that causes buildup of backlog at a manufacturing step. In the past, Quality Engineers visually inspected the manufacturing floor for such buildup of work-in-process. But this approach often meant that problems were uncovered too late, and simple engineering flaws inevitably caused large delays.

With upgrades to the manufacturing equipment following the move to their new manufacturing facility, Quality Engineers had the capability to monitor throughput through each manufacturing station. However, the group had no way of highlighting slowdowns and notifying the appropriate design engineer to investigate the problem and remedy the design.

Again, Quality Engineers turned to Visio 2010, to create a dashboard of the manufacturing floor that displays the real time data coming from the automated manufacturing equipment. Any slowdowns in throughput from the calculated acceptable rate would immediately be displayed using a red indicator. Since the Quality Engineers had little visibility into the Design Engineering teams, and had no knowledge of who designed what part, they decided to make the dashboard visible to every engineer in the Design Engineering group, and provide instant email notification when problems were uncovered.

Initially, this posed a problem, since the Design Engineering group lacked the appropriate number of licenses for Visio 2010. However, the Quality Engineering team decided to leverage the power of Visio Services for SharePoint®, which allowed the team to build the dashboard using a data connection to the manufacturing line systems, and publish the dashboard to SharePoint, accessible by all users through an ordinary web browser.

The solution ensured that all stakeholders at access to the same information at the same time. Stakeholders no longer had to search for the most recent version of the file, and the team only had to pass around a SharePoint link to give new stakeholders access to the information.

Using the new centrally managed dashboard solutions, Quality Control engineers could quickly catch manufacturing problems, notify the Design Engineering group, and develop a workaround without heavily impacting production schedules. Figure 5: AdventureWorks Factory Flow Dashboard Benefits of Using Visio Services to Provide Visibility into Quality Control Issues The company was able to reduce order delays for first run products by half, saving the company nearly $1.3 million in delay discounts, fees, and potential lost sales contracts. Across the 20 new products that the company released to production each year, 15 entered productions without the typical first-run delays.

By using Visio Services for SharePoint, the AdventureWorks was able to:

Reduce delays in new product retooling and production efforts Save money and avoid lost sales by delivering new products on time Reduce labor effort during new manufacturing runs Downloadable Examples: AdventureWorks Manufacturing Flow Dashboard.vsd

Improving Quality Using Microsoft Visio 20109 | P a g e About the Author Value Prism Consulting, LLC is a management consulting and financial analysis firm located in Atlanta, GA, and Seattle, WA, specializing in the area of Business Process Improvement (BPI). Value Prism’s BPI Services are designed to help companies assess and redesign their business processes to take full advantage of current and future technology investments. Effective alignment of technology with business processes empowers organizations to reduce costs, increase productivity, and derive more business value from technology investments.

Value Prism Consulting also provides 1- and 2- day workshops to help businesses identify and improve BPM with Microsoft Office Visio 2010. These workshops demonstrate how Visio 2010 can be leveraged to quickly design, communicate, monitor and revise important business processes.

For more information about Value Prism, please visit their website at www.valueprism.com.