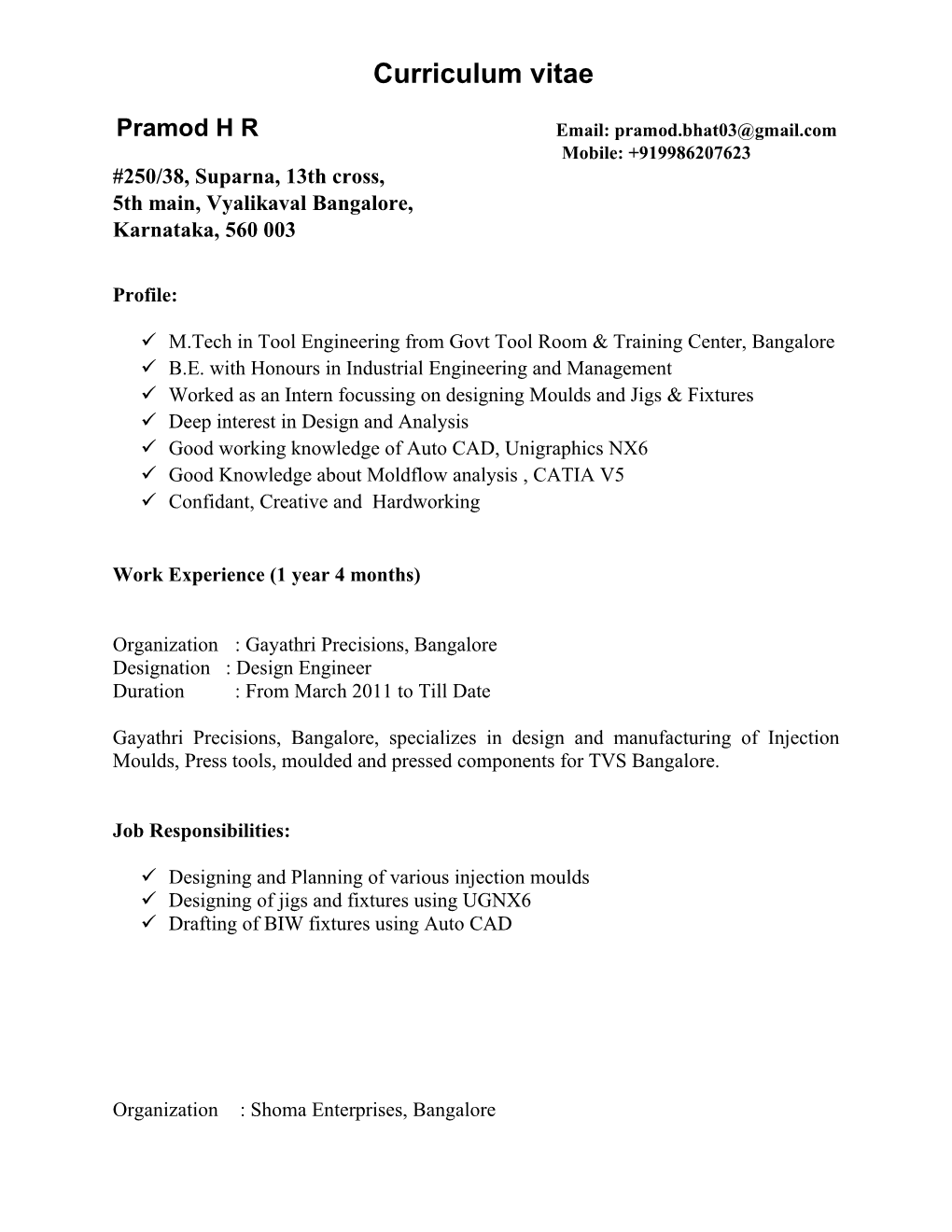

Curriculum vitae

Pramod H R Email: [email protected] Mobile: +919986207623 #250/38, Suparna, 13th cross, 5th main, Vyalikaval Bangalore, Karnataka, 560 003

Profile:

M.Tech in Tool Engineering from Govt Tool Room & Training Center, Bangalore B.E. with Honours in Industrial Engineering and Management Worked as an Intern focussing on designing Moulds and Jigs & Fixtures Deep interest in Design and Analysis Good working knowledge of Auto CAD, Unigraphics NX6 Good Knowledge about Moldflow analysis , CATIA V5 Confidant, Creative and Hardworking

Work Experience (1 year 4 months)

Organization : Gayathri Precisions, Bangalore Designation : Design Engineer Duration : From March 2011 to Till Date

Gayathri Precisions, Bangalore, specializes in design and manufacturing of Injection Moulds, Press tools, moulded and pressed components for TVS Bangalore.

Job Responsibilities:

Designing and Planning of various injection moulds Designing of jigs and fixtures using UGNX6 Drafting of BIW fixtures using Auto CAD

Organization : Shoma Enterprises, Bangalore Curriculum vitae

Designation : Design Engineer (Intern) Duration : From June 10 to feb11

Shoma Enterprises, an ISO 9001-2000 company, specializes in design and manufacturing of jigs and fixtures for automobile companies. jigs & fixtures are being to a our prestigious customers for these type of BIW fixtures are TOYOTA KIRLOSKAR MOTOR Bangalore , BHARATH EARTH MOVERS, MOOG CONTROLS, Etc.

Achievements/Key Contributions: Designed and manufactured a stretch forming die tool for BHARATH EARTH MOVERS Ltd. Designed Engine Holding Fixture for TOYOTA KIRLOSKAR MOTOR Bangalore.

Academic Projects: a. M.Tech Project: Design, Analysis and Manufacturing of Injection Mould Tool for BOBBIN Component:

The component is used in special purpose packaging machine (SPM). It’s 2-D drawings are modeled incorporating suitable changes in geometry using UGNX6 .Split core and finger cam principles are applied and designed as per standard procedure applicable to plastic injection moulding process and analyzed through mold flow analysis for its moulding characteristics with the objective of obtaining a defect free component. b. B.E Project: Process Capability Study

This Project was carried out to make a detailed study of the existing process to monitor the quality requirements at VST Tillers Tractors Ltd, Bangalore and to suggest improvements in the process thereby achieving better productivity by using techniques to detect and prevent causes of variations. Curriculum vitae

Academic Records: 2009 - 2011 Govt. Tool Room & Training Center, Bangalore Master of Technology (M.Tech.) Major: Tool Engineering (73% aggregate; Final year project submitted to university)

May 2009 Master Program in CAD using Autocad, CATIA, ProE & Unigraphics Central Institute of Plastics Engineering & Technology (CIPET Mysore)

2005-2009 Bangalore Institute of Technology, Bangalore, Karnataka Bachelor’s of Engineering (B.E), Major: Industrial Engineering and Management, B.E with Honours, 69%

2003-2005 Karnataka Science College, Dharwad, PUC (12th), Major: Science (PCMS), 60.5%

2002 - 2003 Karnataka Education Board, SSLC (10th), 84%

Computer Skills: Drafting Tools : Auto CAD, Solid works Design Tools : Unigraphics NX6, Moldflow analysis Office Productivity Tools : Microsoft Office – Word, Excel, Power Point, Outlook

Co-Curricular Activities:

Awards : NCC A Certificate Co-Curricular : Participated in all India Expedition Hobbies : Football, Drawing

Personal Details:

Passport : Valid Till: 2007-2017 Date of Birth : 03-May-1987 Languages : English, Hindi, kannada, Sanskrit