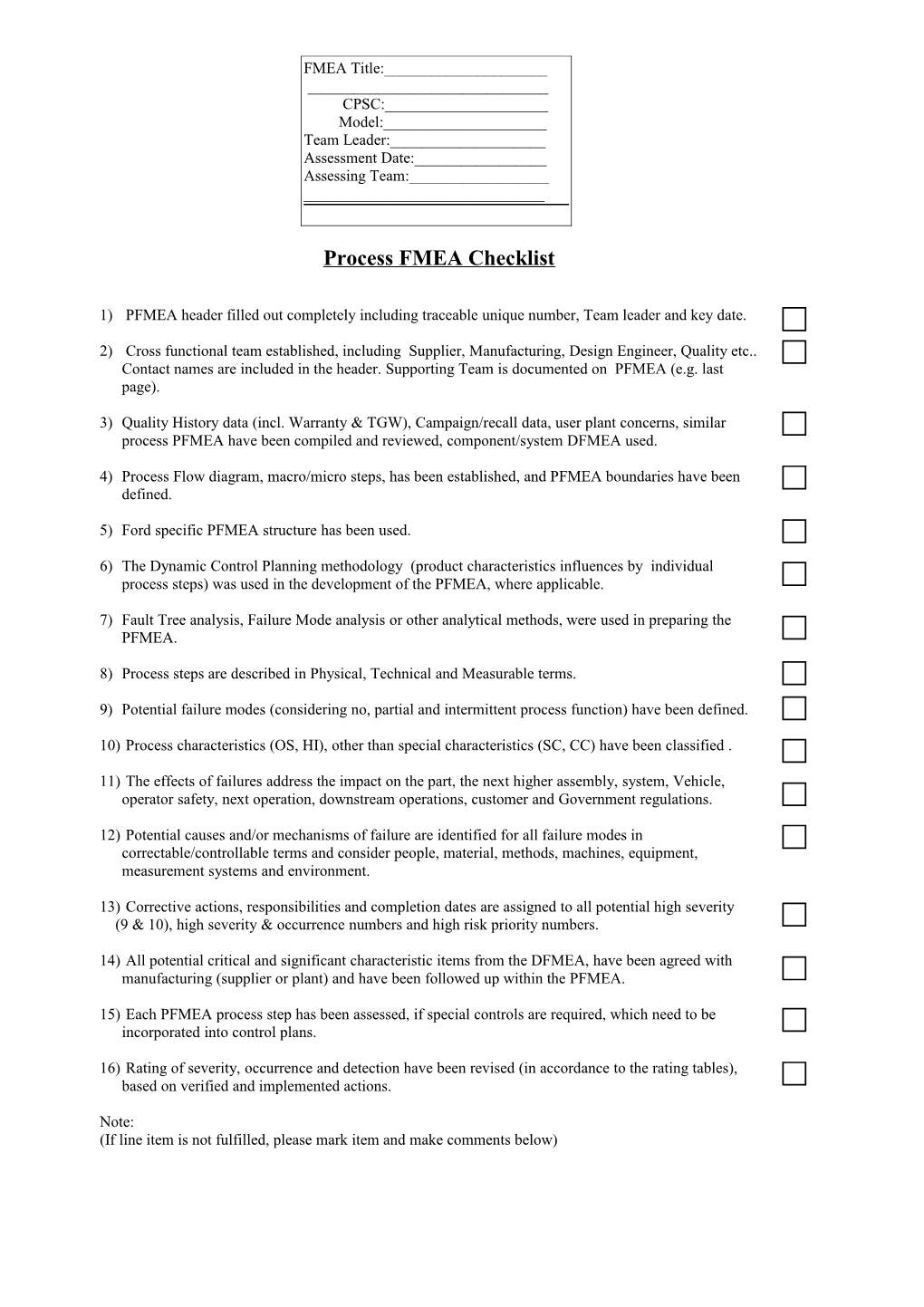

FMEA Title:______CPSC:______Model:______Team Leader:______Assessment Date:______Assessing Team:______

Process FMEA Checklist

1) PFMEA header filled out completely including traceable unique number, Team leader and key date.

2) Cross functional team established, including Supplier, Manufacturing, Design Engineer, Quality etc.. Contact names are included in the header. Supporting Team is documented on PFMEA (e.g. last page).

3) Quality History data (incl. Warranty & TGW), Campaign/recall data, user plant concerns, similar process PFMEA have been compiled and reviewed, component/system DFMEA used.

4) Process Flow diagram, macro/micro steps, has been established, and PFMEA boundaries have been defined.

5) Ford specific PFMEA structure has been used.

6) The Dynamic Control Planning methodology (product characteristics influences by individual process steps) was used in the development of the PFMEA, where applicable.

7) Fault Tree analysis, Failure Mode analysis or other analytical methods, were used in preparing the PFMEA.

8) Process steps are described in Physical, Technical and Measurable terms.

9) Potential failure modes (considering no, partial and intermittent process function) have been defined.

10) Process characteristics (OS, HI), other than special characteristics (SC, CC) have been classified .

11) The effects of failures address the impact on the part, the next higher assembly, system, Vehicle, operator safety, next operation, downstream operations, customer and Government regulations.

12) Potential causes and/or mechanisms of failure are identified for all failure modes in correctable/controllable terms and consider people, material, methods, machines, equipment, measurement systems and environment.

13) Corrective actions, responsibilities and completion dates are assigned to all potential high severity (9 & 10), high severity & occurrence numbers and high risk priority numbers.

14) All potential critical and significant characteristic items from the DFMEA, have been agreed with manufacturing (supplier or plant) and have been followed up within the PFMEA.

15) Each PFMEA process step has been assessed, if special controls are required, which need to be incorporated into control plans.

16) Rating of severity, occurrence and detection have been revised (in accordance to the rating tables), based on verified and implemented actions.

Note: (If line item is not fulfilled, please mark item and make comments below)