APPLICATION FOR PERMIT TO WORK(PTW)

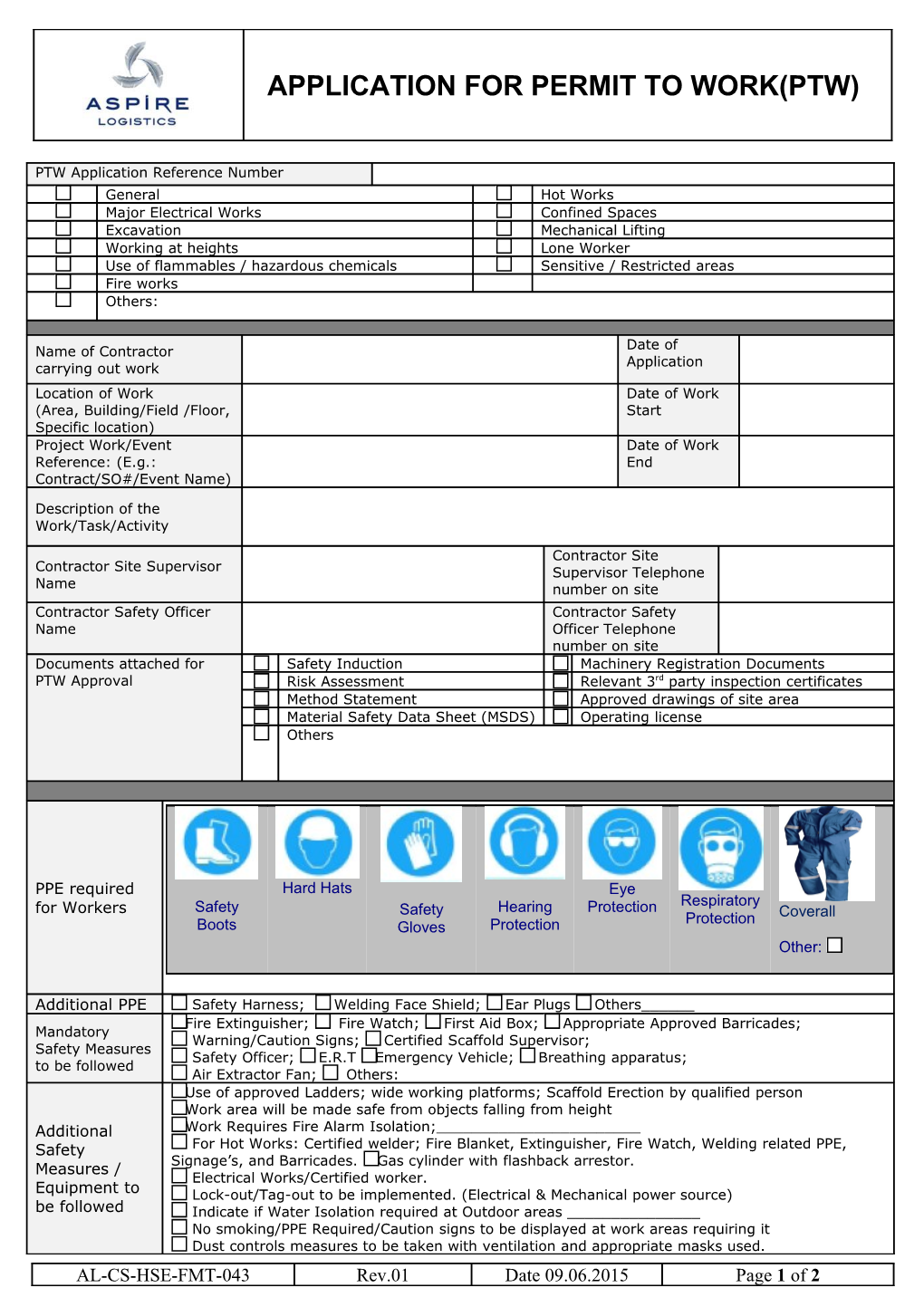

PTW Application Reference Number General Hot Works Major Electrical Works Confined Spaces Excavation Mechanical Lifting Working at heights Lone Worker Use of flammables / hazardous chemicals Sensitive / Restricted areas Fire works Others:

Name of Contractor Date of carrying out work Application Location of Work Date of Work (Area, Building/Field /Floor, Start Specific location) Project Work/Event Date of Work Reference: (E.g.: End Contract/SO#/Event Name)

Description of the Work/Task/Activity

Contractor Site Contractor Site Supervisor Supervisor Telephone Name number on site Contractor Safety Officer Contractor Safety Name Officer Telephone number on site Documents attached for Safety Induction Machinery Registration Documents PTW Approval Risk Assessment Relevant 3rd party inspection certificates Method Statement Approved drawings of site area Material Safety Data Sheet (MSDS) Operating license Others

PPE required Hard Hats Eye Respiratory for Workers Safety Safety Hearing Protection Protection Coverall Boots Gloves Protection Other:

Additional PPE Safety Harness; Welding Face Shield; Ear Plugs Others______Fire Extinguisher; Fire Watch; First Aid Box; Appropriate Approved Barricades; Mandatory Warning/Caution Signs; Certified Scaffold Supervisor; Safety Measures Safety Officer; E.R.T Emergency Vehicle; Breathing apparatus; to be followed Air Extractor Fan; Others: Use of approved Ladders; wide working platforms; Scaffold Erection by qualified person Work area will be made safe from objects falling from height Additional Work Requires Fire Alarm Isolation;______Safety For Hot Works: Certified welder; Fire Blanket, Extinguisher, Fire Watch, Welding related PPE, Signage’s, and Barricades. Gas cylinder with flashback arrestor. Measures / Electrical Works/Certified worker. Equipment to Lock-out/Tag-out to be implemented. (Electrical & Mechanical power source) be followed Indicate if Water Isolation required at Outdoor areas ______No smoking/PPE Required/Caution signs to be displayed at work areas requiring it Dust controls measures to be taken with ventilation and appropriate masks used. AL-CS-HSE-FMT-043 Rev.01 Date 09.06.2015 Page 1 of 2 APPLICATION FOR PERMIT TO WORK(PTW)

Night/Road Works - adequate lighting, reflective vests, beacon lights, barricades, etc. Safe Lifting methods will be used (Crane & other mechanical lifting equipment with 3rd party certification/Operator licensed/signal man available/Cordon/Insurance & valid license ) Safety for Hazardous chemical/flammable liquids used is considered and MSDS provided Confined Space: Rescue Tripod. Multi-Gas detectors to be used to confirm area free of Toxic gases. Watchman outside/No gas cylinders inside/No hot work inside w/o special permission. Communication equipment will be used (Radio sets/ Mobile Phones, etc.) ACKNOWLEDGEMENT AND UNDERSTANDING BY PTW APPLICANT / REQUESTOR

CONTRACTOR RESPONSIBILITIES It is the responsibility of the contracting company to ensure that all work undertaken using a ‘Permit-to-work system’ is fully monitored at all times, contractor safety officer is appointed and all laws/safety rules & regulations are followed.

CONTRACTORS 1. The contractor shall comply with the conditions of the PTW, Aspire Zone HSE Management Procedures, Contractors Rules & Regulations and applicable Qatar Laws.( contractor shall ensue to notify the daily work before Start work and End to Venue Building Management Staff). 2. Contractor shall provide suitable Risk Assessment and a “Safe Method Statement” addressing the work/event he is carrying out together with the application form in order to get a PTW approved. If these documents are not provided the PTW will not be approved and work/event will NOT be allowed to proceed). 3. Contractors & workers who are to be deployed for the work/event shall have valid Qatar work permits, copies of which must be surrendered to the Security Department together with the required application forms for ID Passes to enter into the work/event area or building. 4. Vehicle Passes shall be applied through the Security Department with copies of the driver’s valid license, valid vehicles insurance and registration card. The vehicle shall be in good working condition, exhaust not smoky and engine not leaking oils. Drivers shall comply with the speed limit of 40kmph within Aspire and lookout for pedestrians and buggy users. Driver’s to ensure that no unsafe loading/unloading, no passengers to be seated at the back of pickups, park only at the approved locations and when reversing to have an attendant to guide the vehicle. 5. Contractors are restricted to their area of work only and should not be loitering outside their work site. Contractors should not be sleeping or eating in Public areas where the image of Aspire Zone will be undermined. 6. Short/Long term tools lists shall be completed and submitted to security department for endorsement prior to work commencement of work and end of work/event. 7. Works carried out within Aspire shall be completed within the agreed time frame or face the possibility of penalties. 8. Work areas in Aspire Zone should be properly barricaded with necessary signage and shall not be visible to the public. 9. All equipment’s used shall have been inspected by a competent staff with the appropriate inspection stickers pasted and all specialized and high risk works shall be done by competent and certified staff. 10. For chemicals, MSDS shall be provided and available on site with the original containers clearly labeled. 11. Contractors shall have completed the Safety Induction conducted by Aspire Zone before work commencement. 12. The contracting company shall supply their own first aid box, first aider, suitable fire extinguisher at worksite. 13. For Hot Works contractor shall ensure Fire Blanket, fire Extinguisher, Fire Watch, PPE, Signage’s, Barricades are in place before start of work and the welder is a trained and competent person. 14. For Confined Space work contractor shall ensure Work area is regularly checked for hazardous/toxic gases before entry and during the period of entry and a suitable multi-purpose gas detector used to monitor the oxygen level in the confined space. 15. Scaffold shall be erected and dismantled by trained and competent workers. 16. HSE Officers from AL may issue STOP WORK order if any safety rules or regulations that are not followed and work shall not be allowed to continue till the safety issues have been satisfactorily corrected and implemented. 17. If the work of the contractor involves subcontractors, separate PTW applications must be submitted by these subcontractors for their own scope of work. UNDERTAKING BY CONTRACTOR WORKS SUPERVISOR (To be signed by the contractor/ sub-contractor who is responsible and will be held accountable for compliance.) As the person in charge of the work, I confirm that I have read and understand the contents of the Aspire Logistics procedures related to PTW. I confirm the above work location has been safety assessed, and all of the necessary safety precautions have been or will be taken, to control all potential risks and hazards to members of the public and workers. Workers will be provided with and wear the correct Personal Protective Equipment (PPE) till the conclusion of the works/task. Supervision will be present at all times and the signage used during the work will be removed on completion of works. I am aware of Aspire Logistics procedures and the penalties for nonconformance including the immediate suspension/stop of work among other penalties. I am aware that should there be a false fire alarm triggered in my work area a 5000 QR penalty will apply for each incident. Contractor Representative Designation Name Signature & Contact Number Date APPROVAL BY ASPIRE LOGISTICS HSE DEPARTMENT

Remarks

Name of HSE Signature Inspection and Date Officer

AL-CS-HSE-FMT-043 Rev.01 Date 09.06.2015 Page 2 of 2