Design of a Single Pilot Cockpit for Airline Operations Jonathan Graham, Chris Hopkins, Andrew Loeber, Soham Trivedi

Abstract—The commercial aviation industry has traditionally been a money-losing operation. This lack of profitability has caused the industry to be subject to high levels of financial volatility, which was exemplified following the collapse of the dotcom bubble. A strong need exists for airline companies to find new ways to stay afloat in such a challenging market.

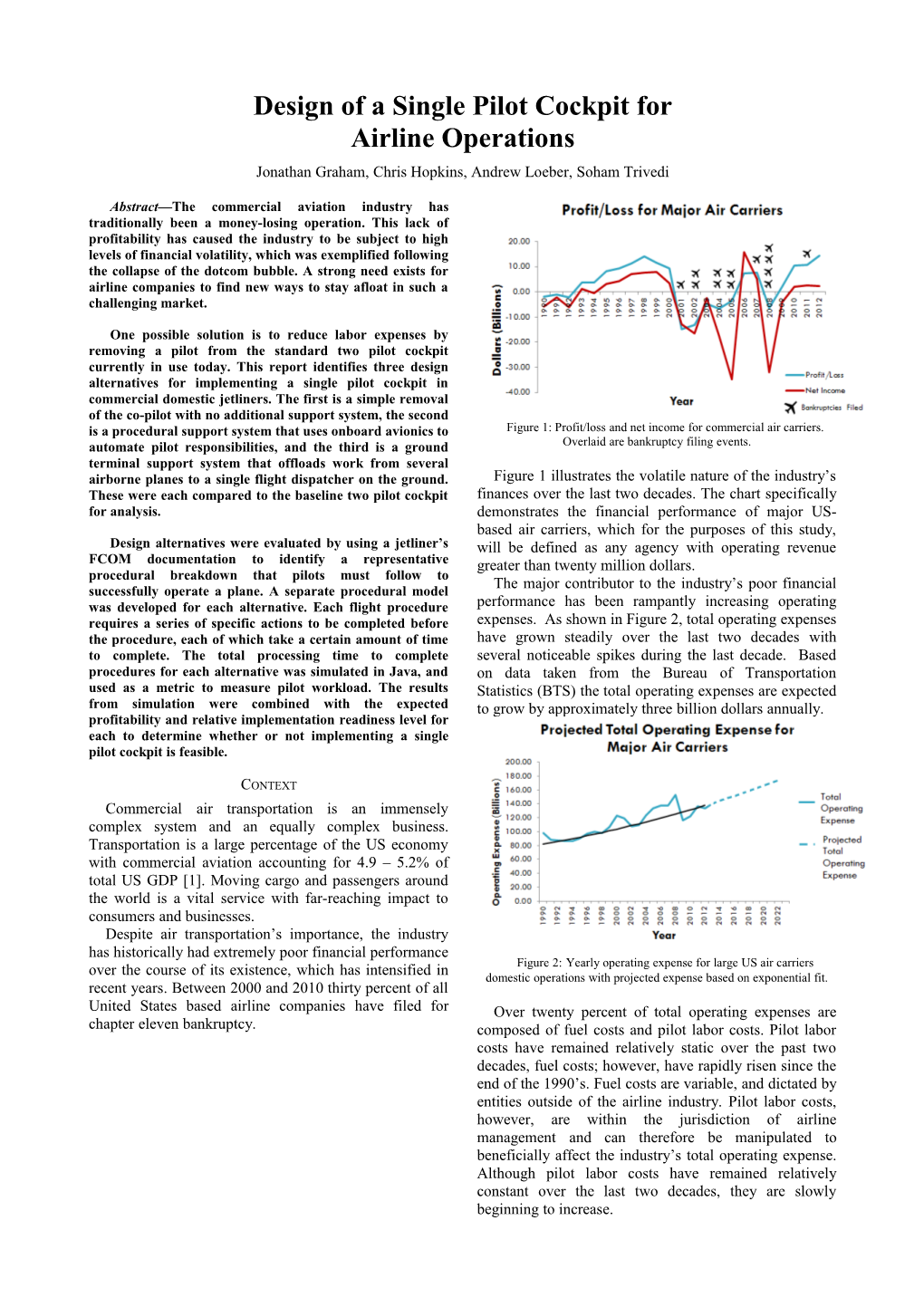

One possible solution is to reduce labor expenses by removing a pilot from the standard two pilot cockpit currently in use today. This report identifies three design alternatives for implementing a single pilot cockpit in commercial domestic jetliners. The first is a simple removal of the co-pilot with no additional support system, the second is a procedural support system that uses onboard avionics to Figure 1: Profit/loss and net income for commercial air carriers. automate pilot responsibilities, and the third is a ground Overlaid are bankruptcy filing events. terminal support system that offloads work from several airborne planes to a single flight dispatcher on the ground. Figure 1 illustrates the volatile nature of the industry’s These were each compared to the baseline two pilot cockpit finances over the last two decades. The chart specifically for analysis. demonstrates the financial performance of major US- based air carriers, which for the purposes of this study, Design alternatives were evaluated by using a jetliner’s will be defined as any agency with operating revenue FCOM documentation to identify a representative greater than twenty million dollars. procedural breakdown that pilots must follow to The major contributor to the industry’s poor financial successfully operate a plane. A separate procedural model was developed for each alternative. Each flight procedure performance has been rampantly increasing operating requires a series of specific actions to be completed before expenses. As shown in Figure 2, total operating expenses the procedure, each of which take a certain amount of time have grown steadily over the last two decades with to complete. The total processing time to complete several noticeable spikes during the last decade. Based procedures for each alternative was simulated in Java, and on data taken from the Bureau of Transportation used as a metric to measure pilot workload. The results Statistics (BTS) the total operating expenses are expected from simulation were combined with the expected to grow by approximately three billion dollars annually. profitability and relative implementation readiness level for each to determine whether or not implementing a single pilot cockpit is feasible.

CONTEXT Commercial air transportation is an immensely complex system and an equally complex business. Transportation is a large percentage of the US economy with commercial aviation accounting for 4.9 – 5.2% of total US GDP [1]. Moving cargo and passengers around the world is a vital service with far-reaching impact to consumers and businesses. Despite air transportation’s importance, the industry has historically had extremely poor financial performance Figure 2: Yearly operating expense for large US air carriers over the course of its existence, which has intensified in domestic operations with projected expense based on exponential fit. recent years. Between 2000 and 2010 thirty percent of all United States based airline companies have filed for Over twenty percent of total operating expenses are chapter eleven bankruptcy. composed of fuel costs and pilot labor costs. Pilot labor costs have remained relatively static over the past two decades, fuel costs; however, have rapidly risen since the end of the 1990’s. Fuel costs are variable, and dictated by entities outside of the airline industry. Pilot labor costs, however, are within the jurisdiction of airline management and can therefore be manipulated to beneficially affect the industry’s total operating expense. Although pilot labor costs have remained relatively constant over the last two decades, they are slowly beginning to increase. The Federal Aviation Administration (FAA) has STAKEHOLDER ANALYSIS predicted a six percent growth in demand for pilots Commercial aviation is a major provider of between 2012 and 2022 [2]. Unfortunately, due to transportation services. Since aviation is a large part of various changes in regulation there is an increasing gap the US economy, major advancements in the forms of between forecasted supply and demand. Error: Reference new systems have a large impact for all persons source not found4 graphically depicts the historic pilot regardless of personal air transportation utilization. The labor force with the projected labor supply and demand. commercial aviation industry has a diverse range of A single pilot cockpit system may help reduce the impact stakeholders involved in its continued operation, each to a projected pilot shortage and bring some stability for with its own motives, resources, and functions. The future labor supply. involved entities can be divided into four main categories: regulatory agencies (FAA, DoT), aviation workforce (pilots, air traffic controllers (ATC), and the unions representing them), aviation infrastructure (airports, aircraft manufacturers, and insurance agencies), and the customer base. Commercial Air Carriers

Commercial air carriers are primarily driven by their business objectives. Airline managers are entrusted to operate and monitor the business in accordance with their predefined business objectives. Just like any other Figure 4: Projected pilot labor growth based on FAA Forecast 2013- 2033 pilot growth rate. business, air carriers must make decisions around how profitability and costs are affected. Implementing a single pilot cockpit to reduce the need Historical Perspective for pilot labor will be a favorable option for commercial Removing pilots from the cockpit has been a strategy air carriers due to the potential cost savings. However, used in the past to help save on labor costs, as aircraft they would run into serious conflicts with many of the that require fewer pilots decrease the cost associated with aviation industry’s stakeholders, presenting a series of flying the aircraft.. Originally, a cockpit contained five potential challenges in moving forward with pilots, each filling a distinct role. Over time, the roles of implementation. In any market, ignoring the needs of navigators, flight engineers, and radio operators have other stakeholders is bad for profitability. Commercial been eliminated due to technological innovations in their aviation would not survive if it ignored customers, respective functional areas [4]. With the current need for employees, or regulators. increased financial stability and a solution for the FAA looming pilot shortage, moving from the current two- pilot paradigm to a single pilot cockpit may be the next As a regulatory body, the FAA’s primary objective is logical step. to create and enact policy with the express purpose of maintaining or improving aviation safety. The agency is The Two-Pilot Cockpit granted the power to regulate aviation and create policy In most major aircrafts there are two pilot roles filled in line with its mission to create a safe and efficient by the captain and co-pilot, they are the pilot flying (PF) airspace [5]. As such, the FAA holds the reins on and the pilot not flying (PNF). Both the captain and co- whether or not a single pilot cockpit system would be pilot can fill either role as needed and often switch to approved and allowed to operate. The agency would be fulfill training/certification requirements. The major very skeptical of a single pilot cockpit because it responsibilities of the PF include flying the aircraft, represents such a significant departure from current confirming callouts and inspecting instruments. The PNF aviation systems. A single pilot cockpit is inherently handles of interactions with ATC, performs cockpit counter to the FAA’s objectives because it lowers aircraft callouts, inspects and manipulates instruments and, if reliability by decreasing pilot redundancy within the needed, takes over the responsibility of flying the aircraft. cockpit. All of their responsibilities are described within an Action to resolve conflicts between air carriers and the official FAA approved document called the Flight Crew FAA would be very laborious and time consuming. Operating Manual (FCOM). An FCOM details flight Rigorous testing and analysis would have to be procedures for all potential situations that a plane may be completed to demonstrate to the FAA that the single pilot in for both on the ground and in the air operations. cockpit is feasible from a safety and reliability Within the FCOM a procedure is decomposed into a standpoint, as well as prove that the established minimum series of tasks which are in turn assigned to either the PF reliability standards will be met. System design or PNF for execution. For the purposes of this project the alternatives will have to meet regulatory standards and team has analyzed the procedures and tasks described include long term impact to pilot certification, air traffic within the FCOM for a Swiss Airlines owned and control, aircraft certification, and airports. The FAA operated RJ100 aircraft. would be the authority on any impact to the National Airspace System (NAS) in addition to its regulatory role. Objectives may greatly vary from each segment of the Sponsor area NAS. Even if all other stakeholders are brought into for a higher profitability, aircraft manufactures would agreement on a particular single pilot system, the FAA likely be the only stakeholder besides the airlines will be the ultimate hurdle for aviation companies to themselves to push for implementing a single pilot overcome, as they are required to give the legal system. authorization to operate such a system. Aviation insurance companies will be keenly aware of the increased level of risk that introducing a single pilot Customer Base system may have on flight safety. As such, they will The customer base for commercial aviation are mostly likely require a probationary period for testing a plane concerned about getting from point A to point B as newly-developed to operate under the single pilot cheaply, comfortably, safely, and timely as possible. paradigm in order to collect enough data to make the They may be concerned about both cost and safety and appropriate adjustments to their premiums. As long as may be skeptical of flying on aircraft with only one pilot, insurance agencies are given enough time to adapt their when they have become so accustomed to flying on insurance plans to the shifting aviation landscape, they planes with two or more pilots onboard. Over time, the are not likely to have much of an issue with the move to a fact that one pilot is flying would become less single pilot cockpit. controversial just like any other instance of technology Airports serve as departing and arrival junctions for air replacing pilots (navigator, radio operator, and engineer). transportation. The infrastructure required to meet these Passengers may take longer to become accustomed to the needs is very complex and requires significant capital single pilot system due to the perceived lack of failover investment. Changes to the system would greatly impact capability, such as the fear that a major accident could operations and may be a significant bottleneck in terms of occur if the one pilot in the cockpit became incapacitated system operations. Airports may develop conflicts with without a co-pilot to provide backup. the airline companies because they are balancing operations for all sizes of air carriers, different Aviation Workforce schedules/capacities, and are pressured to ensure there are no gaps in service. Implementing new systems would The aviation workforce is comprised of pilots, air be perceived as risky and costly regardless of long run traffic controllers, and the unions that represent them. benefits or intent, so airports would need to be assured They are primarily interested in preserving existing job that the added complexity from implementing a new and wage stability, as well as ensuring that current levels system would not be significant enough to of workload and safety conditions are maintained. Pilots overcomplicate their business operations. and unions alike would be extremely worried that a reduction in pilot labor demand from moving to a single Stakeholder Win-Win pilot cockpit would put thousands of pilots out of work, likely leading them to push back against the efforts of air Given the complicated stakeholder relationship for the carriers to implement such a system. single pilot cockpit system, a win-win will not be The ATC has an immense responsibility to ensure the established by selecting a particular alternative, rather it National Airspace System is safe and well managed. will be an outcome of a long-term “implementation ATC’s objectives are much like the pilot’s in that they roadmap” that will give each stakeholder time to evaluate want to maintain employment, bring home a stable and assimilate to change. Error: Reference source not salary, maintain workload, work in a safe environment, found shows a notional roadmap for implementing and and have career growth opportunities. ATC will be evaluating the single pilot cockpit system. primarily concerned that their operational procedures would significantly change under a new system. In addition to changing their procedures, increasing ATC task load would be unacceptable from their standpoint. Figure 6: Notional single pilot cockpit system implementation Systems that seamlessly integrate existing procedures and roadmap ATC protocol may be acceptable, though some initial skepticism is expected. In the win-win scenario, the design alternative will be integrated into the baseline two pilot cockpit. After Aviation Infrastructure several years of evaluation and redesign, the two pilot Aviation infrastructure includes aviation insurance cockpit will be reduced to the single pilot cockpit. This companies, airports, and aircraft manufacturers. In ensures there is ample time for pilot training, ATC general, these agencies are primarily driven by coordination, FAA evaluation, and aviation industry maintaining consistent revenue, market predictability, evaluation. and a low risk profile, as well as holding onto and Extending the phase-in process will allow regulatory expanding on their current customer base. agencies time to observe the effects of implementing a Aircraft manufacturers have a vested interest in selling single pilot solution in existing two pilot cockpits and and leasing their airplanes to airlines. The move to a collect the necessary reliability and safety data that they single pilot cockpit could prove to be a good opportunity require before giving final approval, preventing them to develop a new, unique product that can be sold or from having to perform damage control if the system is leased for an increased profit compared to older models. unexpectedly unstable. As long as the R&D costs involved in redesigning the The aviation workforce’s fear of layoffs can be firm’s existing plane models doesn’t outstrip the potential mitigated by spreading out the reduction of pilot labor demand over several decades, serving to allow job stability to remain relatively constant over the pilot- removal phase as well as giving pilots ample time to grow accustomed to the new system. The customer base’s fears of flying in a plane with only one pilot will be mitigated as positive information on the relative safety of flying with only one pilot in the cockpit is released to the public. Fliers will slowly become more comfortable with the concept, and residual resistant attitudes are likely to shift with time. Aviation infrastructure’s fears of wasting resources can be assuaged by allowing these organizations enough time to adapt their operations, products, and business Figure 7: Total and domestic passenger miles based on a regression plans to the current phase of single pilot cockpit fit of R2=0.86 and R2=0.78, respectively. deployment. This prevents them from potentially wasting their resources on adjusting their processes around a Increasing demand for air transportation, a projected system that may or may not actually be utilized. pilot labor shortage, and rising operating expenses will continue to negatively impact commercial aviation’s ability to attain stable financial performance. Commercial PROBLEM AND NEED STATEMENT aviation needs to implement systems that will reduce Commercial aviation is projected to have increasing operating expense so that operating revenue will be larger operating expense from 2013 to 2022 at an increase of than operating expense. 30% based on an exponential regression fit. Growing operating expenses are presumed to relate to growing demand for air transportation. Figure 0 shows the projected demand in terms of yearly revenue passenger miles. Although passenger transportation is not the only demand data point, is arguably the largest. According to the FAA’s Aerospace Forecast FY 2013- 2033 a 3% yearly increase in revenue passenger miles is projected over the period of 2012-2022 [2]. That is equivalent to a 30% increase in passenger demand by the end of the next decade. Using BTS data as the baseline for comparing passenger miles demand with operating expense, it is shown that there is a 26.95% increase in passenger miles (slightly less than FAA forecasts) from Figure 8: Operating revenue to expense ratio from 1990-2012. 2012-2022 [6]. Since the scope of the analysis is Assume red dotted line is the profitability target fixed based on concerned with domestic operations, the total increase in historical levels. demand for domestic passenger miles is projected to increase 33.28% based on the same BTS data when fitted The GAP in Error: Reference source not found for domestic passenger miles only. As it is shown in graphically describes the problem: operating revenue as a Figure , domestic passenger demand comprises the ratio to operating expense is smaller or close to one over majority of passenger miles flown. the past twelve years. Assuming that the ratio is an The projected shortage of pilots will ultimately cost indicator of profitability, bringing the ratio back to the the airlines in terms of lost flight hours and increasing levels of the 1990’s would produce a financially stable pilot pay. As the number of available pilots decreases, the industry. Measures that reduce targeted portions of cost for pilot labor increases and consequently, increases operating expense, i.e. pilot labor, would have an impact the overall operating expense. A single pilot cockpit on decreasing the gap. Referring back to Error: Reference could potentially mitigate the effects of a pilot labor source not found, it is shown that operating expense on shortage by reducing crew requirements allowing the items like fuel and pilot labor are two significant line existing labor pool to be spread out more evenly. items that account for a large portion of yearly operating expenses. If a two pilot cockpit is reduced to a one pilot cockpit, the total operating expense of air carriers can be reduced and increase operating revenue. This reduction would impact commercial aviation’s ability to reduce long term operating expense and attain less extreme deviations in profitability.

REQUIREMENTS Requirements drive the design, simulation, and analysis of the system. The mission requirements represent the high level super system requirements for the design alternatives. The overwhelming focal point of these requirements is safety and cost. Requirements system design alternative takes flight state data and input should have traceability to one or more of these four from ground based entities and the single pilot. The data mission requirements. Traceability ensures there is is used to execute predefined tasks such as those validity within the requirement document. designated in a flight crew operating manual (FCOM). Automated tasks will fill the void left by the absence of a M.1 The single pilot cockpit system shall reduce or co-pilot. Feasibility for the task automation system is maintain the baseline pilot flying task load of TBX.1 evaluated in terms of task load on the pilot flying and total lifecycle cost. If safety is impacted, i.e. increased M.2 The single pilot cockpit system shall meet pilot task load or full lifecycle cost is too high, the system ARP4761 Level A assurance of 1 failure per billion flight won’t be a viable alternative. Error: Reference source not hours. found shows the functional flow of the task automation system. M.3 The single pilot cockpit system shall decrease yearly pilot labor operating expense. Ground Pilot Terminal If UAVs can be flown via ground based command and M.4 The single pilot cockpit system shall have a total control, can the co-pilot role be moved to a ground based lifecycle cost no greater than TBX.2 dollars. pilot terminal? The design alternative will communicate with flight hardware to give a “virtual” representation of flight dynamics to the ground co-pilot. The avionics are DESIGN ALTERNATIVES extended from the aircraft to the ground through a System design alternatives are described as a black command downlink (CDL) with a ground based box system. The nature of the design and analysis relies command uplink (CUL) to the aircraft. The design on the fact these technologies are largely absent within assumes the ground terminal can be assigned to multiple the current scope and context (outside of the baseline flights. Just like an air traffic controller or flight case). Although the component technologies are dispatcher tracks and hands off flights, the ground based available, the integration of these components terminal will have the ability to be net-centric and specifically for task automation/pilot replacement is handoff flight control. unfounded. It is the assumption that the feasibility of The system will have to augment procedures to such designs is derived from the task hierarchy and task account for queuing of multiple flights. The procedure performance associated with each alternative. simulation and business model will determine what the thresholds are in terms of performance and cost. Other Two Pilot Cockpit factors may be added into the simulation through The baseline cockpit system shall be the two pilot scenarios such as CDL link loss or complete ground cockpits. The majority of aircraft used for air transport failure. In any alternative, the ability for a pilot to require, at a minimum, two pilots to fly. Some aircraft perform with automation failure should be addressed may have requirements for larger crew sizes, but the within the scope of the simulation and its assumptions. scope of this analysis is domestic operations; which presumably eliminates aircraft that may require more SIMULATION METHODOLOGY than two crew because of aircraft size or flight time. The design alternatives provide a mechanism to The RJ100 FCOM will be used as the baseline augment the pilot role being replaced for the single pilot procedural model for the two pilot cockpits. These cockpit system. Two important factors are analyzed: how procedures will be manipulated per the technological the procedures change relative to the baseline two pilot capabilities of each subsequent alternative. case, and how does each alternative impact airline Single Pilot No Support operating expense. The single pilot cockpit is driven by market forces in both the commercial aviation industry, Evaluating a system where only a single pilot flies the and the commercial pilot labor market. A design aircraft with no support for the pilot not flying roles is alternative that can improve the outlook in both areas will necessary to see what the change in workload will be for be evaluated. a pilot with and without some sort of technology to Procedure Model replace the flying and support role of the pilot not flying. Procedures where the pilot interacts with the co-pilot will Procedure models offer insight into how users operate be dropped, but some of the actions performed by the a system. In a cockpit scenario, procedure models can pilot not flying will be transitioned to the pilot flying. help isolate pilot performance bottlenecks and sources of Potentially, the component tasks of the procedures maybe error [7]. Analysis of flight crew operating procedures is reduced. Costs would certainly be reduced by simply done to create a baseline two-pilot performance for transitioning to the single unsupported pilot, though the comparing design alternative’s performance. Procedure load from the procedures will more than likely be performance is assumed to be directly related to safety unsuitable relative to the baseline case. and reliability for the purpose of determining design feasibility. Onboard Procedure Support System The procedure model represents the standard Noting that the technology does not exist currently, a operating procedure for flying a sophisticated jet aircraft. “black box” system will be designed to implement We first extract each procedure specification section from automation that handles the task load of a co-pilot. This the RJ100 FCOM into an Excel spreadsheet to identify the responsible entities to execute a task. The procedure sequential fashion. Statistics are gathered for each model is decomposed further into a custom XML schema replication of the task model. so that it can later be easily parsed into the simulation The complex nature of flying operations leads the program. simulation to operate based on several assumptions. The The tasks are composed of functions that require following is the list of assumptions used in the specific physical and/or mental actions to be performed simulation: by one or both pilots. Actions are described in Error: 1. The time for a pilot to perform physical or mental Reference source not found. The use of actions to actions is modeled by a lognormal distribution for describe the task is driven by the need to assign a each categorical action. performance measure to the overall structure. The ability to design a full human factors experiment with live pilots 2. Cognitive and physical actions are approximated as experimental subjects is outside the scope of this by parameters from keystroke level human systems design and analysis. Simplifications are made to computer interaction studies. facilitate a high level representation of psychomotor and cognitive performance. The procedure simulation section 3. Lower level human factors out of scope. will discuss limitations in greater detail, to include experimental design and input modeling. 4. RJ100 FCOM used to model procedures is representative for other two pilot jet airliners. Name Description Example Physical Instrument Classifies tasks that require an Pushing Throttle Manipulation entity interact physically with Forward 5. Procedure model is a complete representation of avionics or controls flight Verbal Cockpit Tasks that require specific Announce Checklist is Callout verbal messages to be Completed broadcasted for all crew to hear 6. Ignore company specific tasks outside of FCOM. Physical Flight Extended interaction with the Inputting Flight Plan Computer Interaction flight computer comprises several defined actions so it is described by its own category Based on the assumptions above, distributions must be Auditory Reception Tasks requiring directed Listening to Radio used to generate random variables within the simulation. interaction and listening states fall into this category These variables describe the time it takes to perform a Memory Action Actions that are to be Perform Emergency physical and/or mental action within the task execution performed based on abnormal Task and emergency scenarios process. Equation 1 shows the notional representation of Visual Instrument Observing and checking that an Check Warning Light the stochastic action times. The parameters of the Inspection instrument has a target value On distributions are approximated using keystroke level Visual Environment Observing the outside of the Look Out for Runway Inspection airplane (flight environment) on Approach model functions. The total time to complete the task Verbal External Extended periods of ATC Communications based on the actions required will be treated as the Communication conversation requiring specific focus estimator for the mean and variance of the distribution. The random variables at the action level of the procedural model represent the bottommost structure of Table 1: Definitions and examples of the eight action classifications delineated for the procedure model. the overall tree. Each alternative will manipulate the number of tasks and actions in a procedure. The The procedure model is assumed to be authoritative simulation iterates through the tree and replicates the when instantiated for specific flight scenarios, that is, simulation results in a Monte Carlo simulation fashion behavior (if any) outside the scope of the FCOM will not governed by the following equation (following a be considered. An individual procedure model is created lognormal distribution for action times): for each design alternative before being input into the simulation program. The procedure model abstracts the capabilities of each technology in the form of functional Equation 1: Distribution form for action times performance. The functionality manipulates which component tasks and actions can be handled by a new The alternative processing time is an expected value system replacing a pilot. The remaining pilot in each generated from several replications of the simulation for procedure model will have changes to their procedure a target confidence interval. The processing time is the based on hypothetical interaction with each design weighted summation of the procedures as defined by alternative. each alternative’s unique procedure model. Statistical tests are used to determine if there is a significant Procedure Simulation difference in the expected alternative processing time The simulation is coded in Java with several additional relative to the two pilot cockpit baseline system design. libraries to provide enhanced statistical and math Because system dynamics are out of scope of the functionality. The program begins by loading the task research, the simulation makes simplifications for the model and parsing the XML structure into different processing time of each alternative in the form of a classes. The task structure is preserved through the class uniform and triangular distribution. structure. In this way, several task models can be loaded and ran in the same replication. Tasks are executed through the iteration of each task, subtask, and step in a Equation 2: Lifecycle Cost Model

The above equation is used to generate the lifecycle cost for a period of years where will be the average fleet age of the Boeing 737-300’s reported through Form 41 filings to the US DoT. The cost for each alternative is estimated using a triangular distribution which picks a best, worst, and most likely case. The parameters are Figure 9: Formulas used for the procedure simulation and statistical unknown due to the undeveloped state of most of the testing alternatives, but historical avionics systems will be used Procedure Simulation Design of Experiment where appropriate to estimate the unit cost of the alternative. Output Inputs s Business Case Design of Experiment P r Alte Inputs Outputs o rnat c ive Expected Alter e Ta Pro Other Labor & Aircraft nativ Actions Alternative Alternative Cost d sks cess Maintenance Lifecycle e u ing Cost r Tim Baseline e e -- Triangular(a,b,c) TBD s Two Pilot

Two Pilot P1… T1m… Lognormal~A1r…Amr TBD Pn Tnm Single Pilot Triangular(a,b,c) Triangular(a,b,c) TBD No Support Single Pilot P1… T1o… No Lognormal~A1r…Aor TBD Pn Tno Procedure Triangular(a,b,c) Support Triangular(a,b,c) TBD Support

Ground Procedure Pilot Triangular(g,h,i) Triangular(a,b,c) TBD P1… Lognormal~A1r Support T1p…Tnp Uniform~A1r… TBD Terminal System Pn …Apr Apr Table 3: Design of experiment for the business model and simulation

Ground RESULTS P1… T1q… Lognormal~A1r Pilot Triangular~A1r TBD Terminal Pn Tnq …Aqr …Aqr Results are currently pending simulation completion and outputs. At this time, the procedure support system is Table 2: Breakdown of random variable distributions considered for predicted to be the best performing alternative with each alternative respect to cost and procedure processing time. Business Case

The business model aims to determine the cost feasibility of each design alternative. Based on a set of input assumptions, how do the operating costs of major air carriers respond to the decrease of pilot labor? To answer this question, a business case is developed to evaluate each design alternative against each other. If the expected lifecycle cost is less than the two pilot baseline case, then the design may be evaluated as a suitable Figure 1: Value hierarchy for recommendations system depending on factors such as significance and sensitivity to change. RECOMMENDATION AND CONCLUSION The lifecycle model is based on the operating cost of Pending sensitivity analysis of the results, the most popular commercial jet airliner – the Boeing recommendations will be made in line with a value 737-300 [8]. Random variables are used for each of the hierarchy developed to support the win-win of the costs and are derived from triangular distributions based stakeholders. The value hierarchy is shown in Figure 1. on historical BTS data as shown in the design of Each alternative will have a utility cost function created experiment Table . A Monte Carlo simulation is used to to evaluate each design. produce the expected lifecycle cost based on several thousand replications for a target confidence interval. REFERENCES G. Eason, B. Noble, and I. N. Sneddon, “On certain integrals of K. Elissa, “Title of paper if known,” unpublished. Lipschitz-Hankel type involving products of Bessel functions,” R. Nicole, “Title of paper with only first word capitalized,” J. Name Phil. Trans. Roy. Soc. London, vol. A247, pp. 529–551, April Stand. Abbrev., in press. 1955. (references) Y. Yorozu, M. Hirano, K. Oka, and Y. Tagawa, “Electron spectroscopy J. Clerk Maxwell, A Treatise on Electricity and Magnetism, 3rd ed., studies on magneto-optical media and plastic substrate interface,” vol. 2. Oxford: Clarendon, 1892, pp.68–73. IEEE Transl. J. Magn. Japan, vol. 2, pp. 740–741, August 1987 I. S. Jacobs and C. P. Bean, “Fine particles, thin films and exchange [Digests 9th Annual Conf. Magnetics Japan, p. 301, 1982]. anisotropy,” in Magnetism, vol. III, G. T. Rado and H. Suhl, Eds. M. Young, The Technical Writer’s Handbook. Mill Valley, CA: New York: Academic, 1963, pp. 271–350. University Science, 1989.