Microsoft® Business Solutions–Solomon®

Bill of Material

Bill of Material provides a comprehensive set of features in three important manufacturing categories:

. Bill of Materials

. Production Routings

. Product Costing

The foundation of any manufacturing system is its product definition function. Product structures must be defined, usually on a multi-level basis, along with the instructions for how to build the manufactured item. Cap it all off with the ability to use these definitions to establish and manage standard costs, and you have the support functions needed for costing and production of manufactured and assembled goods. Bill of Material will help you define, manage, and analyze the products your company produces.

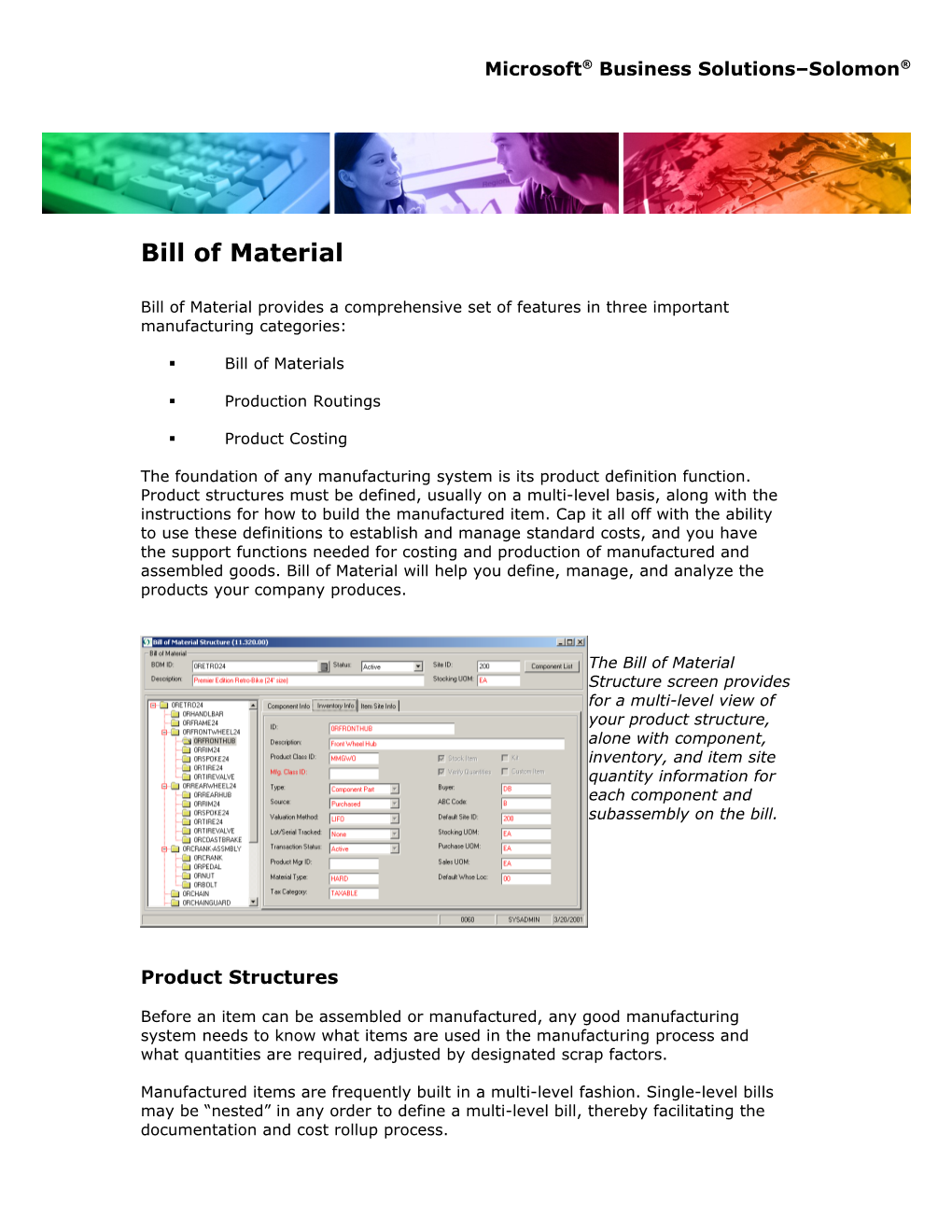

The Bill of Material Structure screen provides for a multi-level view of your product structure, alone with component, inventory, and item site quantity information for each component and subassembly on the bill.

Product Structures

Before an item can be assembled or manufactured, any good manufacturing system needs to know what items are used in the manufacturing process and what quantities are required, adjusted by designated scrap factors.

Manufactured items are frequently built in a multi-level fashion. Single-level bills may be “nested” in any order to define a multi-level bill, thereby facilitating the documentation and cost rollup process. Bill of Material

Imagine being able to view these product structures using a familiar “explorer” type tool, navigating up and down the tree that represents the parent/child relationships between these parts.

If desired, a unique Bill of Material may be maintained for each site defined in your Inventory system. The same graphical representation is utilized when your task is to find where a particular part is used throughout your Bill of Material definitions.

Production Routings

Now that the parts that are going to be used in the manufacturing process have been identified, it’s useful to be able to define and document how those parts are to be assembled and processed. For each Bill of Material you define, you may define a corresponding Routing that does just that.

Define a simple routing, using minimal labor information, or make it more complex by getting down to move and queue time.

Standard Costing

Whether you are valuing your inventory at standard cost, or using one of the actual costing methods supported by Solomon Inventory, Solomon Bill of Material will build on the product structures and routings to help you roll up your standard costs.

If you recalculate your standard costs frequently, the robust tools to update and roll up costs will make your job easier.

Production Entry

Once you have established a multi-level Bill of Material, it may be used to relieve inventory for all components and increment inventory for the final assembly, using the rolled-up cost. Production Entry flexibly and easily converts your manufacturing plans into execution. Using backflushing inventory deductions, production entry can explode sub-assemblies into component requirements, ensuring that you keep accurate inventory levels for component, sub-assembly and finished goods items.

Support for Work Orders

When your requirement is to build the products you have engineered using work orders to track work-in-process, Manufacturing Work Order will make use of your product structures and production routings.

______Microsoft Business Solutions–Solomon Bill of Material

Business Issues How This Flexible Product Can Help Kitting and Assembly With robust Product definition including Parent/Child requirements are getting relationships, Product routing and full cost roll-up, this more complex single module can handle your production and assembly requirements. Controlling and planning Bill of Material supports multiple costing methods while Costs for material and labor providing cost roll-up for accurately costing your is critical production plans. Robust overhead allocations and variance distributions provide costing visibility in the planning and production of your finished goods. We need the flexibility to The ease of use and flexibility of Bill of Material allows build as planned or change your business plans to adapt to quickly changing the plan on-the- fly at a site production, material and labor requirements. level

Bill of Material Sample Reports include:

. Bill of Material List

. Component Where-used Lists

. Standard Cost Change Preview

. Actual Production Plan

. Production Preview

. Production Analysis

. Shortage Report

. Variance Analysis

. Routing List

. Work Center List

. Work Center Where Used Operation List

. Labor Class List

. Tool List

. Machine List

© 2002 Microsoft Corporation and Great Plains Software, Inc. All rights reserved. Microsoft, Microsoft Business Solutions, Solomon and Great Plains are either registered trademarks or trademarks of Microsoft Corporation, Great Plains Software, Inc. or Microsoft Business Solutions Corporation in the United States and/or other countries. FRx, instant!OLAP and DrillDown Viewer are either trademarks or registered trademarks of FRx Software Corporation. Both, Great Plains Software Inc. and Microsoft Business Solutions Corporation are wholly-owned subsidiaries of Microsoft Corporation. The names of actual companies and products mentioned herein may be the trademarks of their respective owners. ______Microsoft Business Solutions–Solomon