CHAPTER 8

FAILURE

PROBLEM SOLUTIONS HW7: 8.15, 18, 23, 25, 31, 40, 48

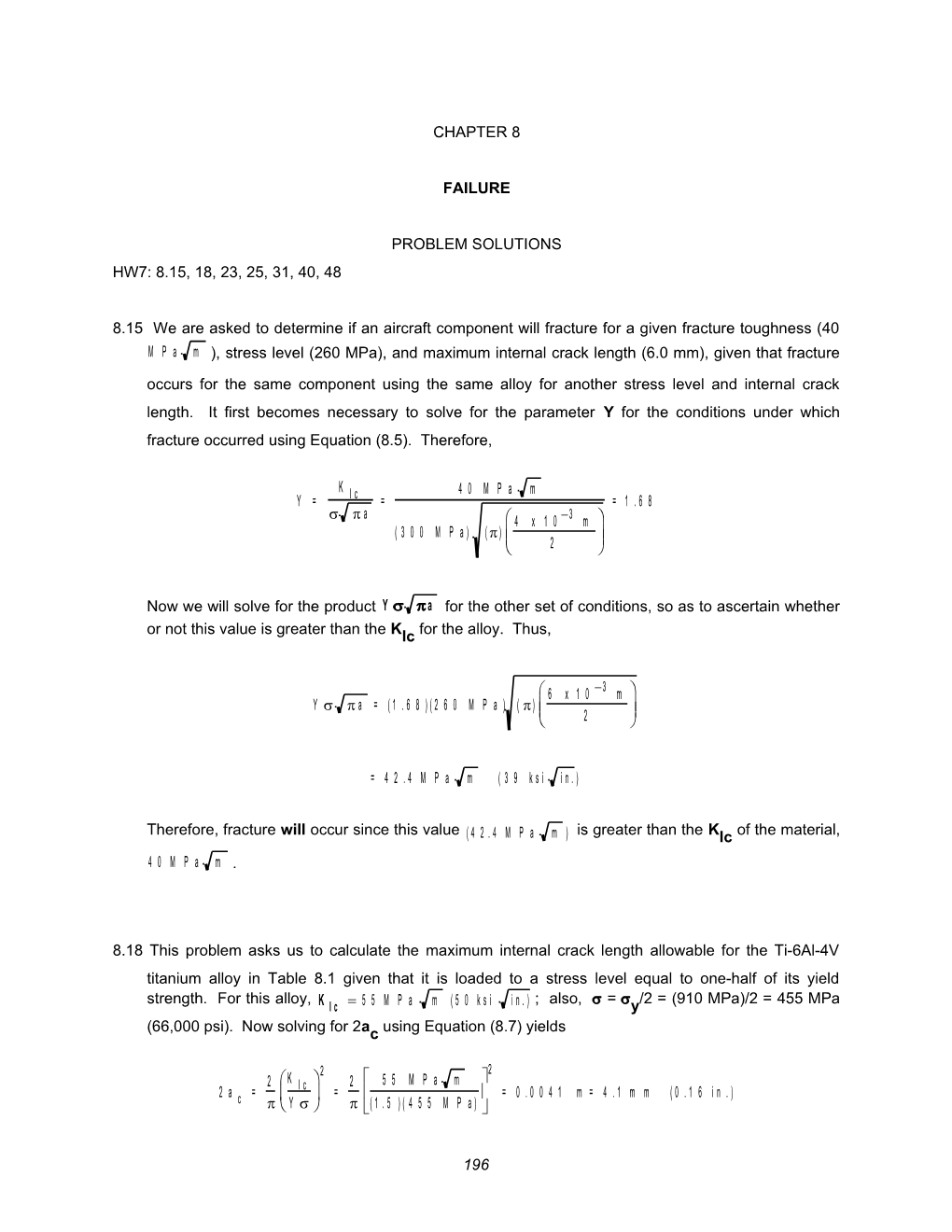

8.15 We are asked to determine if an aircraft component will fracture for a given fracture toughness (40 M P a m ), stress level (260 MPa), and maximum internal crack length (6.0 mm), given that fracture

occurs for the same component using the same alloy for another stress level and internal crack length. It first becomes necessary to solve for the parameter Y for the conditions under which fracture occurred using Equation (8.5). Therefore,

K 4 0 M P a m Y = I c = = 1 . 6 8 a 4 x 1 0 3 m ( 3 0 0 M P a ) ( ) 2

Now we will solve for the product Y a for the other set of conditions, so as to ascertain whether or not this value is greater than the KIc for the alloy. Thus,

6 x 1 0 3 m Y a = ( 1 . 6 8 ) ( 2 6 0 M P a ) ( ) 2

= 4 2 . 4 M P a m ( 3 9 k s i i n . )

Therefore, fracture will occur since this value ( 4 2 . 4 M P a m ) is greater than the KIc of the material, 4 0 M P a m .

8.18 This problem asks us to calculate the maximum internal crack length allowable for the Ti-6Al-4V titanium alloy in Table 8.1 given that it is loaded to a stress level equal to one-half of its yield strength. For this alloy, ; also, = /2 = (910 MPa)/2 = 455 MPa K I c 5 5 M P a m ( 5 0 k s i i n . ) y (66,000 psi). Now solving for 2ac using Equation (8.7) yields

2 2 2 K I c 2 5 5 M P a m 2 a c = = = 0 . 0 0 4 1 m = 4 . 1 m m ( 0 . 1 6 i n . ) Y ( 1 . 5 ) ( 4 5 5 M P a )

196 8.23 The plot of impact energy versus temperature is shown below.

(b) The average of the maximum and minimum impact energies from the data is

7 6 J 2 J A v e r a g e = = 3 9 J 2

As indicated on the plot by the one set of dashed lines, the ductile-to-brittle transition temperature according to this criterion is about 10C. (c) Also, as noted on the plot by the other set of dashed lines, the ductile-to-brittle transition temperature for an impact energy of 20 J is about -2C.

8.25 (a) Given the values of m (70 MPa) and a (210 MPa) we are asked to compute max and min. From Equation (8.14)

= m a x m i n = 7 0 M P a m 2 Or, max + min = 140 MPa

Furthermore, utilization of Equation (8.16) yields

197 = m a x m i n = 2 1 0 M P a a 2 Or, max - min = 420 MPa

Simultaneously solving these two expressions leads to

m a x = 2 8 0 M P a ( 4 0 , 0 0 0 p s i ) m i n = 1 4 0 M P a ( 2 0 , 0 0 0 p s i )

(b) Using Equation (8.17) the stress ratio R is determined as follows:

1 4 0 M P a R = m i n = = 0 . 5 0 2 8 0 M P a m a x

(c) The magnitude of the stress range r is determined using Equation (8.15) as

r = m a x m i n = 2 8 0 M P a ( 1 4 0 M P a ) = 4 2 0 M P a ( 6 0 , 0 0 0 p s i )

8.31 (a) The fatigue data for this alloy are plotted below.

198 (b) The fatigue limit is the stress level at which the curve becomes horizontal, which is 290 MPa (42,200 psi). (c) From the plot, the fatigue lifetimes at a stress amplitude of 415 MPa (60,000 psi) is about 50,000 cycles (log N = 4.7). At 275 MPa (40,000 psi) the fatigue lifetime is essentially an infinite number of cycles since this stress amplitude is below the fatigue limit. (d) Also from the plot, the fatigue strengths at 2 x 104 cycles (log N = 4.30) and 6 x 105 cycles (log N = 5.78) are 440 MPa (64,000 psi) and 325 MPa (47,500 psi), respectively.

8.40 Creep becomes important at 0.4T , T being the absolute melting temperature of the metal. m m

For Ni, 0.4T = (0.4)(1455 + 273) = 691 K or 418C (785F) m

For Cu, 0.4T = (0.4)(1085 + 273) = 543 K or 270C (518F) m

For Fe, 0.4T = (0.4)(1538 + 273) = 725 K or 450C (845F) m

For W, 0.4T = (0.4)(3410 + 273) = 1473 K or 1200C (2190F) m

For Pb, 0.4T = (0.4)(327 + 273) = 240 K or -33C (-27F) m

For Al, 0.4T = (0.4)(660 + 273) = 373 K or 100C (212F) m

8.48 (a) We are asked to estimate the activation energy for creep for the low carbon-nickel alloy having the steady-state creep behavior shown in Figure 8.29, using data taken at = 55 MPa (8000 psi) and temperatures of 427C and 538C. Since is a constant, Equation (8.20) takes the form

199 Q Q n c ' c Ý = K e x p = K e x p s 2 R T 2 R T where ' is now a constant. (Note: the exponent n has about the same value at these two K 2 temperatures per Problem 8.47.) Taking natural logarithms of the above expression

Q l n Ý = l n K ' c s 2 R T

For the case in which we have creep data at two temperatures (denoted as T1 and T2) and their Ý Ý s s corresponding steady-state creep rates ( 1 and 2 ), it is possible to set up two simultaneous equations of the form as above, with two unknowns, namely ' and Q . Solving for Q yields K 2 c c

Ý Ý R l n s l n s 1 2 Q c = 1 1 T 1 T 2

Let us choose T1 as 427C (700 K) and T2 as 538C (811 K); then from Figure 8.29, at = 55 MPa, Ý Ý s -7 -1 s -5 -1 1 = 0.01 %/1000 h = 1 x 10 (h) and 2 = 0.8 %/1000 h = 0.8 x 10 (h) . Substitution of these values into the above equation leads to

( 8 . 3 1 J / m o l - K ) l n 1 0 7 l n 0 . 8 x 1 0 5 Q = c 1 1 7 0 0 K 8 1 1 K

= 186,200 J/mol

Ý (b) We are now asked to calculate s at 649C (922 K). It is first necessary to determine the value of ' , which is accomplished using the first expression above, the value of Q , and one value each K 2 c Ý of Ý and T (say s and T ). Thus, s 1 1

Q K ' = Ý e x p c 2 s R T 1 1

200 7 1 1 8 6 , 2 0 0 J / m o l 6 - 1 = 1 0 ( h ) e x p = 8 . 0 x 1 0 ( h ) ( 8 . 3 1 J / m o l - K ) ( 7 0 0 K )

Ý Now it is possible to calculate s at 922 K as follows:

Q ' c Ý = K e x p s 2 R T

6 1 1 8 6 , 2 0 0 J / m o l = 8 . 0 x 1 0 ( h ) e x p ( 8 . 3 1 J / m o l - K ) ( 9 2 2 K )

= 2.23 x 10-4 (h)-1 = 22.3 %/1000 h

201