INTERCOMPANY MEMORANDUM

CAL CHEM CORPORATION

To: CHE Juniors Date: Winter Quarter File: CHE 333 From: CHE faculty Laboratory Managers

Subject: Gas Separation Membrane Experiment

http://www.medal.com/en/membranes/nitrogen/index.asp

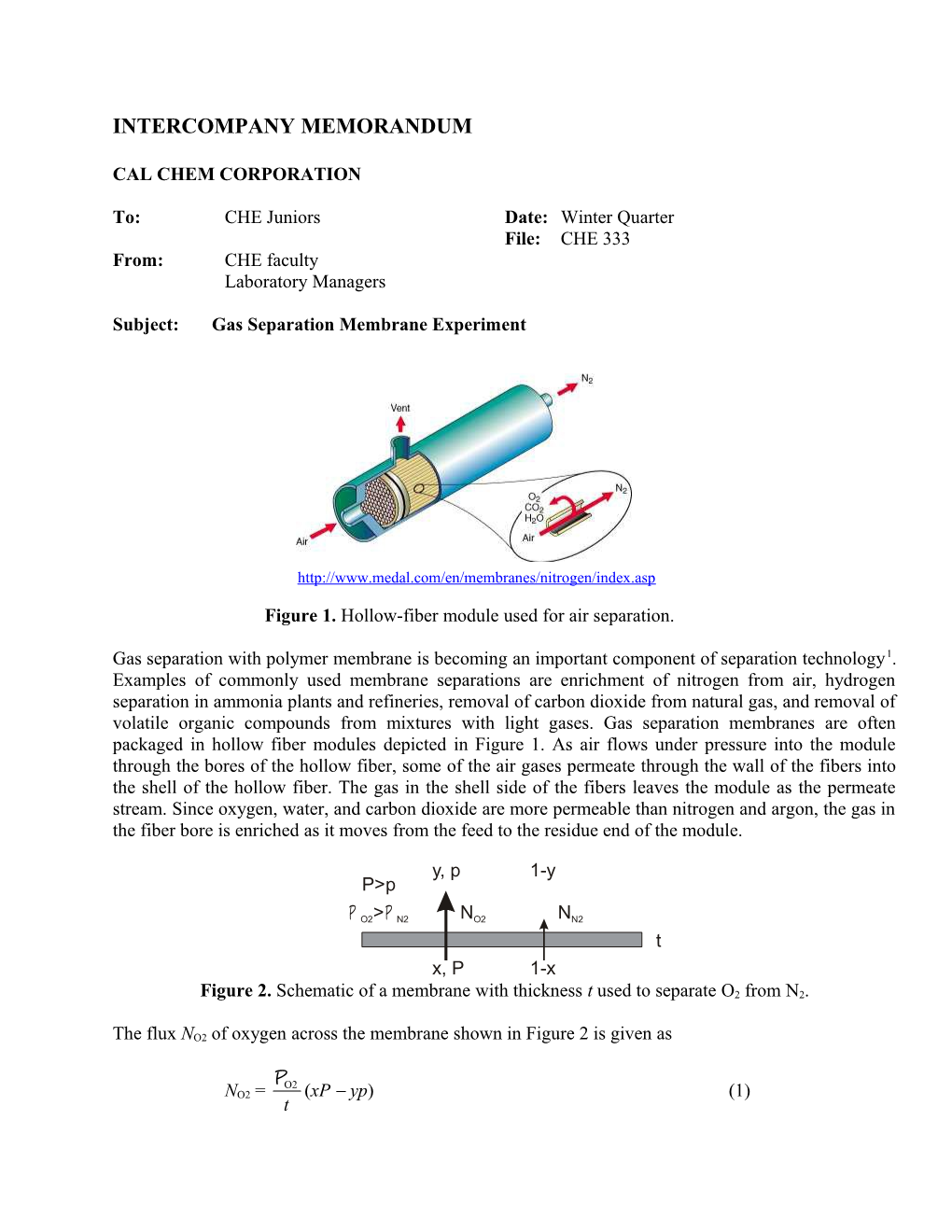

Figure 1. Hollow-fiber module used for air separation.

Gas separation with polymer membrane is becoming an important component of separation technology1. Examples of commonly used membrane separations are enrichment of nitrogen from air, hydrogen separation in ammonia plants and refineries, removal of carbon dioxide from natural gas, and removal of volatile organic compounds from mixtures with light gases. Gas separation membranes are often packaged in hollow fiber modules depicted in Figure 1. As air flows under pressure into the module through the bores of the hollow fiber, some of the air gases permeate through the wall of the fibers into the shell of the hollow fiber. The gas in the shell side of the fibers leaves the module as the permeate stream. Since oxygen, water, and carbon dioxide are more permeable than nitrogen and argon, the gas in the fiber bore is enriched as it moves from the feed to the residue end of the module.

y, p 1-y P>p

PO2> P N2 NO2 NN2 t x, P 1-x

Figure 2. Schematic of a membrane with thickness t used to separate O2 from N2.

The flux NO2 of oxygen across the membrane shown in Figure 2 is given as

PO2 NO2 = (xP yp) (1) t where PO2 is the permeance of the membrane to oxygen, x is the mole fraction of oxygen on the upstream, or high pressure P, side of the membrane, and y is the mole fraction of oxygen on the downstream, or low pressure p, side of the membrane. The ratio of permeance to membrane thickness is called the permeability PO2 of the membrane to oxygen. The permeability can be viewed as a mass transfer coefficient that connects the flux with the driving force for transport, which is the partial pressure difference between the upstream and downstream sides of the membrane.

We now need to consider the fact that as the feed gas travels through the hollow fibers, its composition changes as selective permeation depletes the more permeable components from the feed gas mixture. Figure 3 illustrates the ideal countercurrent flow pattern for the binary mixture of oxygen and nitrogen moving through the fiber module.

Permeate p yP , n P = n F d(yn) yi

dA xn P xn+d(xn) Feed Retentate

xF , n F xR , n R Figure 3. Ideal countercurrent flow pattern through the separator.

2 The total mole and O2 species balances around the separator are

nF = nR + nP (2)

xFnF = xRnR + yPnP (3) where nF, nR, and nP are the molar flow rates of the feed, retentate, and permeate streams, respectively, and xF, xR, and xP are the feed, retentate, and permeate O2 mole fraction, respectively. The molar flux of oxygen through a differential area dA in the membrane is given by equation (1) or by

d(xn) N = = PO2 (xP yp) = Q’ (xP yp) O2 dA t O2

Therefore d(xn) = Q’O2(xP yp)dA = d(yn) (4)

The above equation is just the O2 species balance around the differential volume element in the membrane. The reduction in the O2 molar flow rate d(xn) of the retentate stream provides the same O2 molar flow rate d(yn) through the membrane. P and p are the average retentate and permeate side pressures, respectively. Similar species balance for nitrogen around the differential volume element in the membrane yields d[(1x)n] = Q’N2 [(1x)P (1y)p)]dA (5)

Dividing equation (4) by equation (5), we obtain

d(xn) Q' xP yp = O2 (6) d[(1 x)n] Q' N 2 (1 x)P (1 y) p

d(xn) The ratio is just the molar flow rate of oxygen over that of nitrogen in the permeate d[(1 x)n] stream, therefore it is equal to the ratio of the mole fraction of oxygen over that of nitrogen y Q' as shown schematically in Figure 4. Let * = O2 , equation (6) becomes 1 y Q' N 2

y xP yp = * (7) 1 y (1 x)P (1 y) p

Permeate d(yn) p yP , n P = n F yi

xn xn+d(xn) Feed P Retentate

xF , n F xR , n R

Figure 4. Molar flow rate ratio is equal to mole fraction ratio.

The separation factor * is assumed to be constant. The permeate composition at the capped end of the hollow fibers is obtained from equation (7) by replacing y with yi and x with xR.

y x P y p i = * R i (7) 1 yi (1 xR )P (1 yi ) p

When the change in feed mole fraction of oxygen is less than 50%, the driving force for diffusion across the membrane, = xP yp, is assumed to be a linear function of the change in the molar flow on the feed side of the membrane

(xn) (xn) d(xn) = R F d (8) R F

From the species balance around the separator xFnF = xRnR + yPnP (xn)R (xn)F = (yn)P (9)

Combine equations. (8) and (9) with equation (4) d(xn) = Q’O2(xP yp)dA, we obtain

d yPnP = Q’O2dA R F

Separate the variables and integrate

R d Am yPnP = Q’O2 (R F) dA F 0

R ln F yPnP = Q’O2 (R F)Am

yPnP = Q’O2lm Am (10)

where the log mean average lm is defined as

R F (xP yp)R (xP yp)F (xP yp) lm = ln R = (xP yp)lm = ln R (11) F (xP yp)F

Equation (10) expresses the molar flow rate yPnP of oxygen as a function of the permeance Q’O2 or mass transfer coefficient, area of membrane Am for mass transfer, and an average driving force

lm across the membrane. Similarly, the molar flow rate of nitrogen in the permeate stream can be found

(1yP)nP = Q’N2 [(1x)P (1y)p)]lmAm (12)

The oxygen species balance, xFnF = xR( nF nP) + yPnP, can be written in dimensionless form using the definition of the cut = nP/nF,

xF = xR( 1 ) + yP (13)

Similarly, equations (7), (10), and (12) in dimensionless forms are

y x r y i = * R i (14) 1 yi (1 xR )r (1 yi )

nR 1 nR 1 yPnP = Q’O2lm Am nF Q' N 2 nF Q' N 2 n n n Q' y R P = 1 P O2 (xr y) P Q' A p n Q' lm N 2 m F nF N 2

* yPKR = (1 ) (xr y)lm (15)

where (xr y)lm is defined by Eq. (11)

(1yP) KR = (1 )[(1x)r (1y))]lm (16)

where [(1x)r (1y))]lm is defined by Eq. (11) with x’s and y’s replaced by (1-x)’s and (1-y)’s

nR where r = P/p and KR = Q'N 2 Am p

The algebraic model equations (13-16) represent a system with four equations in eight variables: * xF, xR, yP, r, yi, , , and KR. The system can be solved with measured values of xF, xR, yP, and r, * leaving yi, , , and KR as unknowns in the solution.

The algebraic equations (13) through (16) can be solved by the following iterative method using * EXCEL. Imagine that if you could combine equations (13-16) by eliminating , , and KR, then you would have one equation and one unknown yi. Because of the non-linear nature of these equations, you cannot combine them algebraically and you have to solve for yi by trial-and error. The following is a procedure that you can use.

Step (1) Calculate using Equation (13) from measured values of xF, xR and yP Step(2) Guess a value for yi. Choose a value for yi such that xR P > yi p or yi< xR P/ p to ensure that the log mean driving force defined by equation(11) is valid. Step (3) Calculate using Equation (14) Step (4) Calculate KR using Equation (15) Step (5) Calculate the Left Hand Side (LHS) and Right Hand Side (RHS) of Equation (16). Step (6) Use SOLVER in EXCEL to find the value of yi such that the absolute value of (RHS-LHS) equals zero.

The algebraic equations (13) and (16) can also be solved by Newton’s method presented in Appendix A

Experimental Procedure

Compressed air at about 110 psig is supplied to the membrane module through an air regulator. The supplied air pressure can be controlled by turning the knob on top of the regulator. The oxygen concentration is measured by a portable oxygen analyzer model GPR-30. You can calibrate the oxygen analyzer by turn it on while in the ambient air and set the oxygen concentration to 21.0 %. Adjust the inlet pressure of the membrane module to 30 psig. Read the flow rate on the permeate side of the membrane and set the same flow rate for the retentate. Record the oxygen concentrations on both sides of the membrane when the system reaches steady state. The permeate pressure p is assumed to be the ambient pressure and the retentate pressure P is the average of the feed and retentate pressures as measured by the pressure gages.

Measure the oxygen concentrations and the retentate pressures again at the retentate flow rates of twice and four times the permeate flow rate. Repeat the procedure at 40, 50, 60, 70, and 80 psig.

Analysis

1. Plot the experimental separation factor * as a function of r (= P/p) and discuss the results.

2. Compare calculated cut with experimental (= nP/nF) and plot the experimental and

calculated cut (= nP/nF) as a function of r and discuss the results.

3. If you are using the Newton’s method, present one iteration at 30 psig and = 0.5 using the * guessed values yi = 0.2, = 0.5, = 6, and KR = 2. Clearly indicate how you evaluate the Jacobian matrix.

4. Explain the difference in the diffusion rates of gases through the membrane.

References

1. Coker, D. T., Prabhakar, R., Freeman, ”Tools for Teaching Gas Separation Using Polymers,” Chemical Engineering Education, 36, Winter 2002, 60

2. Davis, R. A., Sandall, O. C., “A Simple Analysis for Gas Separation Membrane Experiments,” Chemical Engineering Education, 36, Winter 2002, 74

3. Welty, J. R., Wicks, C. E., Wilson, N. E., and Rorrer, G. L., Fundamentals of Momentum, Heat and Mass Transfer, John Wiley and Son, (2001)