Corporation

TYPICAL PROPERTIES OF STYLE AG50BTL 50 DUROMETER BUTYL

Description: Style AG50BTL is a 50 durometer butyl gasketing material that is impermeable to air and is used in many applications that require a solid mechanical airtight rubber. 50 durometer butyl presents users with a service temperature of -40F to +180 F. Also known as Isobutylene-isoprene, Style AG50BTL is formulated to meet the ASTM D2000 M1AA 507 specification.

Atlantic Gasket’s solid rubber butyl material is available in a wide range of durometers, ranging from as soft as 40 Durometer (AG40BTL) to as hard as 70 Durometer (AG70BTL) with standard durometers in between. Style AG50BTL is available in the color black and can be manufactured in a wide range of standard thicknesses, ranging from as thin a 1/32” to as thick as 1/4”, with custom thicknesses available upon request. 50 durometer butyl has a smooth finish and can be converted into rolls ranging from as narrow as 1/4 wide up to 48” in width. Additional widths are available upon request. Send in a drawing, and let Atlantic Gasket die-cut or waterjet 50 durometer butyl to meet both prototype and production requirements.

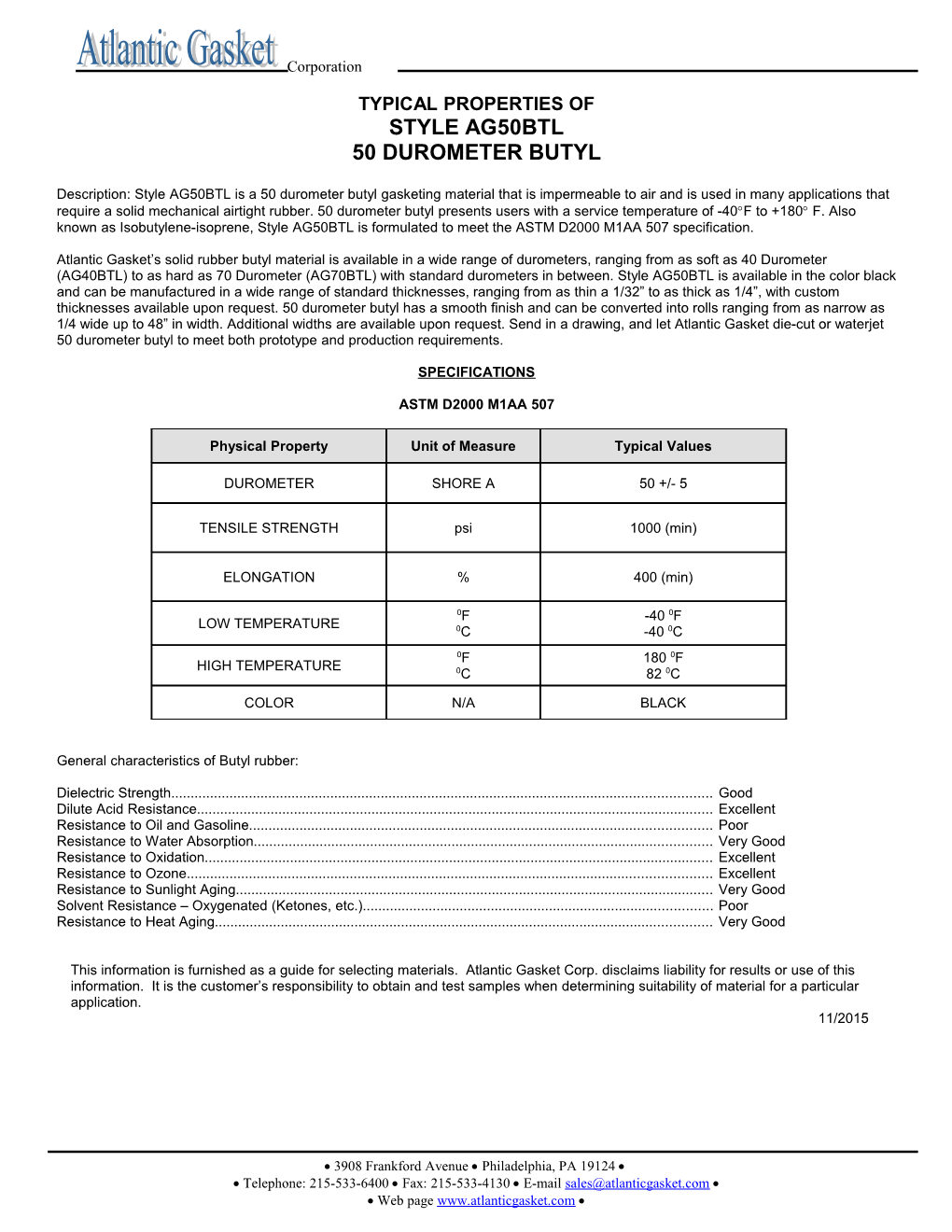

SPECIFICATIONS

ASTM D2000 M1AA 507

Physical Property Unit of Measure Typical Values

DUROMETER SHORE A 50 +/- 5

TENSILE STRENGTH psi 1000 (min)

ELONGATION % 400 (min)

0F -40 0F LOW TEMPERATURE 0C -40 0C 0F 180 0F HIGH TEMPERATURE 0C 82 0C

COLOR N/A BLACK

General characteristics of Butyl rubber:

Dielectric Strength...... Good Dilute Acid Resistance...... Excellent Resistance to Oil and Gasoline...... Poor Resistance to Water Absorption...... Very Good Resistance to Oxidation...... Excellent Resistance to Ozone...... Excellent Resistance to Sunlight Aging...... Very Good Solvent Resistance – Oxygenated (Ketones, etc.)...... Poor Resistance to Heat Aging...... Very Good

This information is furnished as a guide for selecting materials. Atlantic Gasket Corp. disclaims liability for results or use of this information. It is the customer’s responsibility to obtain and test samples when determining suitability of material for a particular application. 11/2015

3908 Frankford Avenue Philadelphia, PA 19124 Telephone: 215-533-6400 Fax: 215-533-4130 E-mail [email protected] Web page www.atlanticgasket.com