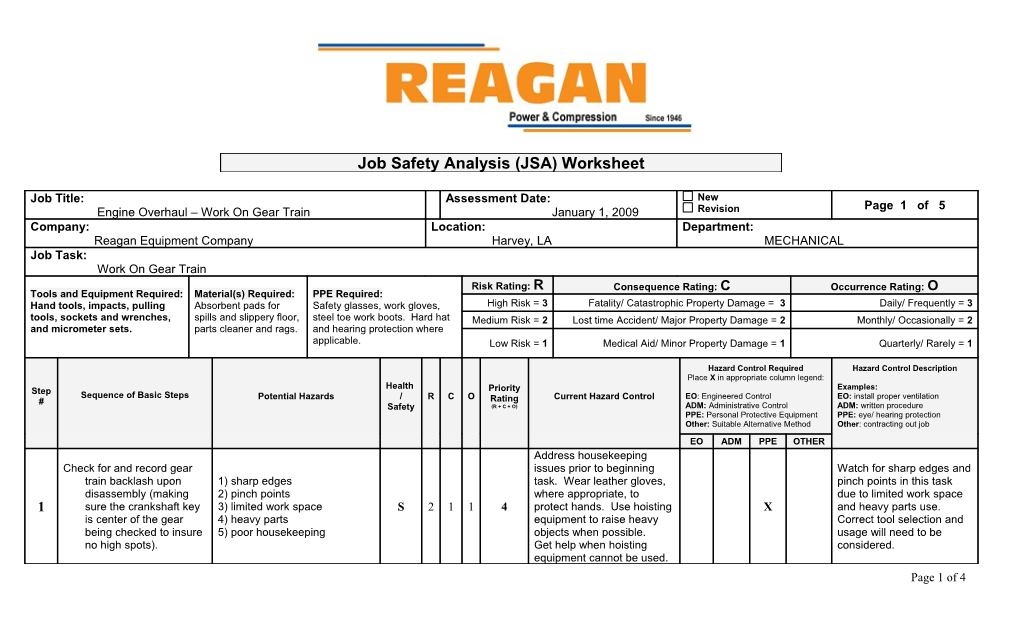

Job Safety Analysis (JSA) Worksheet

Job Title: Assessment Date: New Page 1 of 5 Engine Overhaul – Work On Gear Train January 1, 2009 Revision Company: Location: Department: Reagan Equipment Company Harvey, LA MECHANICAL Job Task: Work On Gear Train Risk Rating: R Consequence Rating: C Occurrence Rating: O Tools and Equipment Required: Material(s) Required: PPE Required: Hand tools, impacts, pulling Absorbent pads for Safety glasses, work gloves, High Risk = 3 Fatality/ Catastrophic Property Damage = 3 Daily/ Frequently = 3 tools, sockets and wrenches, spills and slippery floor, steel toe work boots. Hard hat Medium Risk = 2 Lost time Accident/ Major Property Damage = 2 Monthly/ Occasionally = 2 and micrometer sets. parts cleaner and rags. and hearing protection where applicable. Low Risk = 1 Medical Aid/ Minor Property Damage = 1 Quarterly/ Rarely = 1

Hazard Control Required Hazard Control Description Place X in appropriate column legend: Health Step Priority Examples: Sequence of Basic Steps Potential Hazards / R C O Current Hazard Control EO: Engineered Control EO: install proper ventilation # Rating Safety (R + C + O) ADM: Administrative Control ADM: written procedure PPE: Personal Protective Equipment PPE: eye/ hearing protection Other: Suitable Alternative Method Other: contracting out job EO ADM PPE OTHER Address housekeeping Check for and record gear issues prior to beginning Watch for sharp edges and train backlash upon 1) sharp edges task. Wear leather gloves, pinch points in this task disassembly (making 2) pinch points where appropriate, to due to limited work space 1 sure the crankshaft key 3) limited work space S 2 1 1 4 protect hands. Use hoisting X and heavy parts use. is center of the gear 4) heavy parts equipment to raise heavy Correct tool selection and being checked to insure 5) poor housekeeping objects when possible. usage will need to be no high spots). Get help when hoisting considered. equipment cannot be used. Page 1 of 4 Job Safety Analysis (JSA) Worksheet Make a visual inspection of Wear safety glasses with Wear safety glasses with all gears to insure they have Possible airborne debris S 1 1 1 3 X 2 side shields. side shields. not been overheated. Watch for sharp edges and Wear leather gloves, where pinch points in this task 1) sharp edges appropriate. Use hoisting Inspect all teeth. Inspect due to limited work space 2) pinch points equipment to raise heavy bores for wear and inspect S 1 1 1 4 X and heavy parts. Correct 3 3) heavy parts objects when possible. shafts. tool selection and usage 4) limited work space Get help when hoisting required. equipment cannot be used. Remove all gears and 1) sharp edges Watch for sharp edges and Wear leather gloves, where package to insure they are 2) pinch points S 2 1 1 4 X pinch points in this task. 4 appropriate. not damaged. 3) limited work space Watch for sharp edges on nuts, screws. Watch for sharp edges and pinch Wear leather gloves, where points in this task due to appropriate. Be aware of 1) sharp edges limited work space and Remove all inter front cover body and hand position in 2) pinch points S 2 1 1 4 X heavy parts also slips, 5 and gear oilers. tight work space. Remove 3) limited work space straining, posture, and all tripping and slip hazards proper tool selection and in work area. usage will need to be considered.

1) pinch points Be aware of body and hand Be aware of pinch points, Check all torque on gear 2) sharp edges position. Watch for sharp edges, straining, and S 2 1 1 4 X 6 spindles. 3) possible strain balance, traction and grip posture. 4) balance while using torque wrench. Parts Cleaning & Upon completion of the H Re-Installation disassembly and all the Page 2 of 4 Job Safety Analysis (JSA) Worksheet inspections are completed, the parts will be cleaned and made ready for reassembly. Close attention must be paid in order to insure cleanness of parts and checking for damage to parts. NOTE: Safety is a key part of these tasks due to multiple jobs going on at the same time. This can include: air tools (flying objects), hand cleaning (sharp edges or tools), chemicals, etc. Be aware of sharp edges. 1) slippery parts Use hand protection and fall Watch for and remove 2) sharp edges protection where deemed slip/trip hazards. Use 3) reaching, climbing, straining necessary. Remove slip/trip Inspect all teeth. S 1 1 1 3 X caution when rigging and 1 4) slipping, tripping, falling hazards. Inspect crane and during hoist use. Use fall 5) rigging hoist equipment prior to protection where use. applicable. 1) slippery parts Use hand protection and fall 2) sharp edges protection where deemed Inspect bores for wear. 3) reaching, climbing, straining necessary. Remove slip/trip Be aware of hand and S 1 1 1 3 X 2 4) slipping, tripping, falling hazards. Inspect crane and body position. 5) rigging hoist equipment prior to use. Inspect shafts. 1) slippery parts S 1 1 1 3 Use hand protection and fall X Use hand protection and 3 2) sharp edges protection where deemed fall protection where 3) reaching, climbing, straining necessary. Remove slip/trip deemed necessary. Page 3 of 4 Job Safety Analysis (JSA) Worksheet 4) slipping, tripping, falling hazards. Inspect crane and Remove slip/trip hazards. 5) rigging hoist equipment prior to Inspect crane and hoist use. equipment prior to use. 1) slippery parts Use hand protection and fall Check and record gear 2) sharp edges protection where deemed backlash for each gear 3) reaching, climbing, straining necessary. Remove slip/trip Be aware of hand and during final assembly making S 1 1 1 3 X 4 4) slipping, tripping, falling hazards. Inspect crane and body position. sure the key is center of the 5) rigging hoist equipment prior to gear being checked. use. NOTE: Watch for sharp edges and pinch points. Use correct tooling.

Page 4 of 4