Front End Alignment: Toe-In/Toe-Out Lesson #13

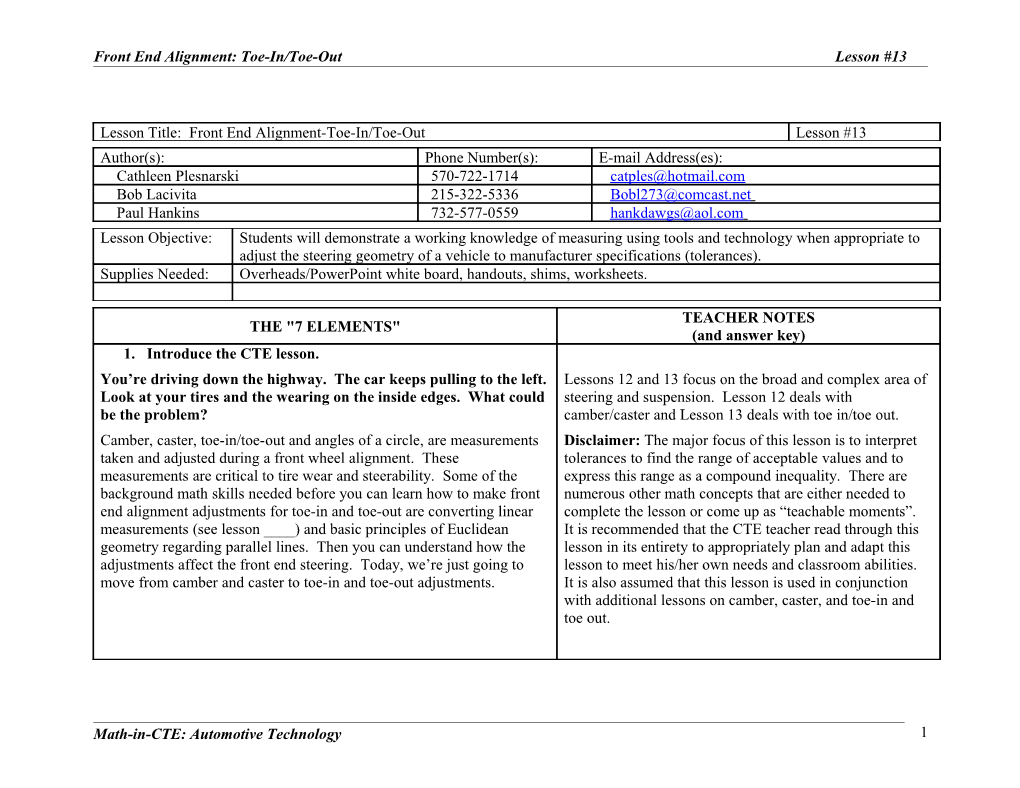

Lesson Title: Front End Alignment-Toe-In/Toe-Out Lesson #13 Author(s): Phone Number(s): E-mail Address(es): Cathleen Plesnarski 570-722-1714 [email protected] Bob Lacivita 215-322-5336 [email protected] Paul Hankins 732-577-0559 [email protected] Lesson Objective: Students will demonstrate a working knowledge of measuring using tools and technology when appropriate to adjust the steering geometry of a vehicle to manufacturer specifications (tolerances). Supplies Needed: Overheads/PowerPoint white board, handouts, shims, worksheets.

TEACHER NOTES THE "7 ELEMENTS" (and answer key) 1. Introduce the CTE lesson. You’re driving down the highway. The car keeps pulling to the left. Lessons 12 and 13 focus on the broad and complex area of Look at your tires and the wearing on the inside edges. What could steering and suspension. Lesson 12 deals with be the problem? camber/caster and Lesson 13 deals with toe in/toe out. Camber, caster, toe-in/toe-out and angles of a circle, are measurements Disclaimer: The major focus of this lesson is to interpret taken and adjusted during a front wheel alignment. These tolerances to find the range of acceptable values and to measurements are critical to tire wear and steerability. Some of the express this range as a compound inequality. There are background math skills needed before you can learn how to make front numerous other math concepts that are either needed to end alignment adjustments for toe-in and toe-out are converting linear complete the lesson or come up as “teachable moments”. measurements (see lesson ____) and basic principles of Euclidean It is recommended that the CTE teacher read through this geometry regarding parallel lines. Then you can understand how the lesson in its entirety to appropriately plan and adapt this adjustments affect the front end steering. Today, we’re just going to lesson to meet his/her own needs and classroom abilities. move from camber and caster to toe-in and toe-out adjustments. It is also assumed that this lesson is used in conjunction with additional lessons on camber, caster, and toe-in and toe out.

Math-in-CTE: Automotive Technology 1 Front End Alignment: Toe-In/Toe-Out Lesson #13

2. Assess students’ math awareness as it relates to the CTE lesson. Remind students that they learned how to do conversions What can you tell me about converting fractions to decimals? early on in the year.

What can you tell me about changing tolerances and angle measurements? Have you used this since geometry class? How? Do you remember how to convert inches to millimeters, and visa versa? 3. Work through the math example embedded in the CTE lesson. Solutions: Explain to the students that the following two examples will Solution 1: demonstrate affects of changing angles on tire wear and steerability. Step 1: Convert mm- in Example 1: You’re working on a Toyota Camry, and you’re toe-in and 3 mm x 1 in = 0.118 inches toe-out readings are as follows: 25.4 mm L +.15º Range of values 0 < v < .236 inches R +.78º Convert degrees to inches Manufacture specifications for this vehicle are as follows: 1º = 1 inch so L + 3 mm + 3 mm .15º = .15 inches R + 3 mm + 3 mm .78º = .78 inches Total toe = 3 mm + 3 mm Compare measurement to tolerance values: An adjustment of 1/8 of an inch is equal to .125º 0 < .15 < .236 inches True, within specs Is an adjustment necessary, if so what kind of adjustment. 0 < .78 < .236 inches False, out of spec

.78 - .118 = .662 inches Convert .662 inches to mm

Math-in-CTE: Automotive Technology 2 Front End Alignment: Toe-In/Toe-Out Lesson #13

.662 in x 25.4 mm = 16.8 mm 1 in.

Example 2: Find the toe-in in inches if the front measurement is 140.97 Solution 2: 0.635 cm x 1 in. = 0 .25 in. cm and rear measurement is 141.605 cm. 1 2.54 cm

4. Work through related, contextual math-in-CTE examples. Solutions:

Example 1: Find the toe-in if the front measurement is 54 ¼ in. and the Ex 1) 54 ¼ = 54 4/16 rear measurement is 54 9/16 in. 54 9/16 – 54 4/16 = 5/16 inch.

Example 2: One side of a crank shaft measures 2.030 inches and the Ex 2) 2.050 - .025 = 2.025 inches (minimum diameter) opposite side measures 2.045 inches. The original manufacturers Yes it can be reground. < 0.025 inch. specification was 2.050. The maximum undersize shim is .025 inches. You would have to cut at least .015 inch. Can this crank shaft be reground. What is the amount of metal that can be removed from this crankshaft if in spec?

5. Work through traditional math examples. Solutions:

Example 1: Find the range of values represented by the following specifications:

A. 5.675 + .125 A. 5.550 < v < 5.850

Math-in-CTE: Automotive Technology 3 Front End Alignment: Toe-In/Toe-Out Lesson #13

B. 4.355 + .375 B. 3.960 < v < 4.710

C. 4 5/16 + 1/16 C. 4 ¼ < v < 4 3/8

6. Students demonstrate their understanding. See Lesson Student Worksheet

7. Formal assessment. See Lesson Student Quiz

Math-in-CTE: Automotive Technology 4 Front End Alignment: Toe-In/Toe-Out Lesson #13

Worksheet

Name: ______Session: ______Date: ______

1. You’re working on a Toyota Tercel, and you’re toe-in and 1. Checking toe-out on turns, the left front wheel is at 20º . toe-out readings are as follows: The right front wheel is 23.5º . Specifications are 20º + L +.25º 2º. Is this vehicle within spec? R +.68º Manufacture specifications for this vehicle are as follows: L + 2 mm + 2 mm R + 2 mm + 2 mm Total toe = 2 mm + 2 mm 2. Using a full contact shim, we need to increase the left rear wheel toe-in .125º. What size shim do we need? An adjustment of 1/8 of an inch is equal to .125º Is an adjustment necessary, if so what kind of adjustment?

2. Find the toe-in in inches if the front measurement is 153.65 3. Using full contact shims, we need to decrease the right cm and rear measurement is 129.60 cm. rear wheel toe out by .0625º What size shim do we need?

Math-in-CTE: Automotive Technology 5 Front End Alignment: Toe-In/Toe-Out Lesson #13

Assessment

Name: ______Session: ______Date: ______

1. You’re working on a 2002 Pontiac GranAm. The customer 2. Find the range of values represented by the following states that the front tires are wearing unevenly on the inside specifications: tread area. You road test the vehicle and observe that the steering wheel is off-center. After taking the following A. 6.837 + 1.246 readings, what should you do? B. .698 + .103 Manufactures specification: Front and Rear Camber/Caster are not adjustable. The rear toe specs are: C. 3 3/8 + 7/8

Rear toe: 1º P + .5º Total toe: .25º+ .5º 3. The thickness specification on a crankshaft key lock is 0.050. The minimum thickness is .035. The key lock on the Front toe: 0º + .5º Total toe: 0º + .5º engine you’re working is worn 0.010 at one end. Can the key lock be ground and reused? Can this crank shaft be reground? You’re readings are: L/R .75º P R/R .25º N What is the amount of metal that can be removed from the key lock and still have it be in spec? L/F .5º P R/F .5º N 4. The diameter of a hollow cylinder is 11.375 inches. There is What is the rear total toe? What is the front total toe? a score on the cylinder wall that measures 0.009 inches deep. The maximum diameter of the cylinder can be machined to Is the vehicle within manufacturers total toe specs? 11.390 inches. Can this cylinder be machined? Using 1/8” full contact shim(s) in the rear, what size shim(s) will be needed to bring the vehicle in to spec?

Math-in-CTE: Automotive Technology 6 Front End Alignment: Toe-In/Toe-Out Lesson #13

Math-in-CTE: Automotive Technology 7 Front End Alignment: Toe-In/Toe-Out Lesson #13

Worksheet Answer KEY

Name: ______Session: ______Date: ______

1. You’re working on a Toyota Tercel, and you’re toe-in and toe-out readings are as follows: 1. Checking toe-out on turns, the left front wheel is at 20º . L +.25º The right front wheel is 23.5º . Specifications are 20º + R +.68º 2º. Is this vehicle within spec? Manufacture specifications for this vehicle are as follows: 18 < v < 22 L + 2 mm + 2 mm Left side within specs, right side out of spec. R + 2 mm + 2 mm Total toe = 2 mm + 2 mm 2. Using a full contact shim, we need to increase the left rear wheel toe-in .125º. What size shim do we need? An adjustment of 1/8 of an inch is equal to .125º Is an adjustment necessary, if so what kind of adjustment? .125 = 1/8 “ Yes Range of values: 0 < v < .156 Left side needs –0.172 and right side needs –0.602 3. Using full contact shims, we need to decrease the right rear wheel toe out by .0625º What size shim do we 2. Find the toe-in in inches if the front measurement is 153.65 need? cm and rear measurement is 129.60 cm. .0625=1/16” TOE-OUT 9.47”

Math-in-CTE: Automotive Technology 8 Front End Alignment: Toe-In/Toe-Out Lesson #13

Assessment KEY

Name: ______Session: ______Date: ______

Math-in-CTE: Automotive Technology 9 Front End Alignment: Toe-In/Toe-Out Lesson #13

1. A. Rear total toe: 1

B. Front total toe: 1

C. Total Toe not in spec

D. ¾ “, 6 shims that are 1/8” each

2. A. 5.591 < 6.837 < 8.803

B. .595 < .698 < .801

C. 2 ½ < 3 3/8 < 4 ¼ or

2.5 < 3.375 < 4.250

3. YES, 0.015”

4. 11.375 + 2c < 11.390

11.375 + .018 < 11.390

NO,11.393>11.39

Math-in-CTE: Automotive Technology 10