Student’s Name Student’s Lab Partner Mods

Empirical Formula of an Oxide of Tin

Purpose:

Within completing this lab, it was intended for the experimenter (student) to determine the empirical formula of an oxide of Tin by means of experimenting. This goal would be accomplished by finding the masses of the various substances experimented with, which 30 mesh tin, Tin Oxide, and Oxygen. These various measurements would then be used to determine the empirical formula of the Tin Oxide produced within the experiment.

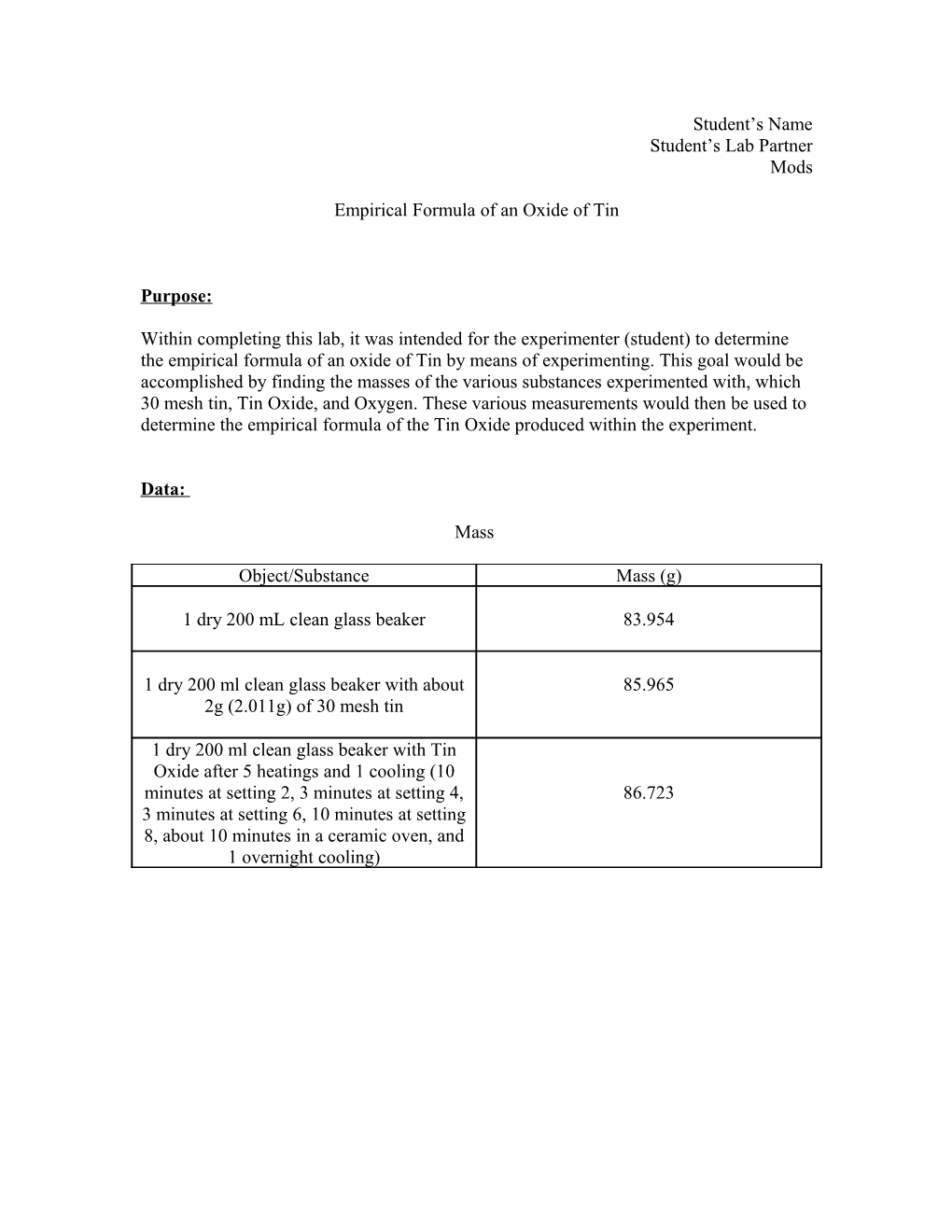

Data:

Mass

Object/Substance Mass (g)

1 dry 200 mL clean glass beaker 83.954

1 dry 200 ml clean glass beaker with about 85.965 2g (2.011g) of 30 mesh tin

1 dry 200 ml clean glass beaker with Tin Oxide after 5 heatings and 1 cooling (10 minutes at setting 2, 3 minutes at setting 4, 86.723 3 minutes at setting 6, 10 minutes at setting 8, about 10 minutes in a ceramic oven, and 1 overnight cooling) Observations Before, During, and After Heatings

Heat Amount Before, Heating Plate of Time During, Observations Number Setting (Minutes) or After Heatings When the nitric acid was added to the glass beaker filled with 2g of 30 mesh Tin, the mixture turned a gray, light brown color with a smooth appearance. In addition, the substance began to bubble, which then sped up after approximately 3 minutes and a brown 0 gas was released. After about 4 minutes (Combining 0 About 8 Before and 30 seconds, the mixture changed nitric acid from being gray, light brown in color, to with 2g of a creamy, gray, yellow, brown color. 30 mesh The smooth appearance remained within tin) the mixture. At this point, it seemed as though the largest amount of the brown NO2 gas was released. In addition, condensation began to form on the sides of the beaker. After approximately 8 minutes, the mixture changed to a slightly off white, light gray color that contained a few “specks” of a silver, gray substance. But, the substance remained its smooth texture. Also, the brown gas ceased to be produced from the mixture, and the bubbles had stopped forming and or popping. The slightly off white, light gray mixture with the gray “specks” had the appearance of having its contents separated. A separation between the speckled light gray, white mixture and a watery milk looking mixture could be 1 2 10 During seen after approximately 5 minutes within the experiment. After the 10 minutes of heating were completed, 3 layers could be seen within the mixture. All three of these layers had a smooth appearance as before. There was a thin very light white, almost clear top, a light milky white middle, and a white, gray speckled bottom. In addition, the top layer contained many small bubbles. During this heating, larger bubbles 2 4 3 During began to form within the mixture and the mixture seemed as if it were at an almost boiling simmer. At this point, the 3 layers formed two layers once again and included a watery milky white top and a speckled bottom. Large bubbles remained within the top layer of this mixture after the heating. Other than these bubbles, the mixture had the appearance of being very smooth. Many of the gray speckles that were held within the bottom layer of the mixture began to rise up through the mixture and formed bubbles that then popped. During this heating, the mixture came to a rolling boil that was a creamy 3 6 3 During white color with a smooth texture. Very large bubbles formed and popped within the middle of this heating. After the heating, a large amount of the substance had been splattered onto the sides of the beaker as a result of the numerous bubbles popping and the rolling boil. The rolling boil and large bubbles forming and popping continued after this heating. After only a minute or two, the mixture within the beaker began to make loud popping noises and began to release a large amount of a white, clear, cloud like gas. In addition, a lot of the substance began to not only splatter onto the sides of the beaker, but also to splatter outside of the beaker onto the table, hood, and heating apparatus. The mixture within the beaker had a very dry, rough, powdery look to it and was a 4 8 10 During off-white, gray color. Toward the middle of this heating, the bubbles began to slow, the popping noises stopped, but the gas continued to be released. The mixture within the beaker soon had a light yellow tint to it and the appearance of being more dry and powdery. With about 3 minutes left within the heating, the gas soon slowed and became more clear rather than the whitish gas that had been released previously. In addition, a small amount of the substance that had been splattered onto the sides of the beaker had fallen off the sides and landed within the main bottom part of the beaker. The substance that fell to the bottom of the beaker had a very dry, off-white, gray appearance. 5 Ceramic About 10 During - Oven (Done by Mrs. Marks) The Tin Oxide that had previously been “splattered” onto the sides of the beaker had fallen off of the sides and was then deposited into the bottom main part of the beaker. In addition, a rough, off white, beige, residue remained on the sides of the beaker where the Tin Oxide had previously been located. The main bottom part of the beaker was filled with - large pieces of Tin Oxide with a small (Cooling - amount of Tin Oxide that was smaller overnight (Not Overnight After than sugar granules but larger than after 5 heated) powder. Also, some of the small heatings) granule-like pieces of Tin Oxide were a pale, dull, light, yellow color while a majority of it remained the dull, gray, off white color. These pieces were also very course. The larger pieces of the resulting Tin Oxide were slightly curled at the edges and had the appearance of having many cracks on the surface. The edges appeared to be rough, while the surfaces of the pieces were smooth and covered with cracks. In addition, some of these larger pieces had the dull, gray, off white color on one side and the pale, dull, light yellow color on the other. Both of these sides appeared to be curled and rough on the edges, and smooth with many cracks on the surfaces. Also, the bottom of the beaker had cracked. Calculations:

Mass of Tin used:

Mass of the beaker with 30 mesh Tin– Mass of the beaker 85.965g – 83.954g 2.011g of Tin used Mass of Tin Oxide formed:

Mass of the beaker with Tin Oxide (beaker after 5 heatings) – Mass of the empty beaker 86.723g – 86.954g 2.769g of Tin Oxide

Mass of Oxygen used:

Final mass of Tin Oxide – initial mass of tin 2.769g – 2.011g 0.758g of Oxygen used within the final product

Moles of Tin in the final product:

Mass of the final product – mass of the Oxygen used within the final product 2.769g – 0.758g 2.011g of Tin within the final product

g of Tin* 1 mol of Tin/ the number of grams that equal1 mole of tin 2.011g of Tin* 1 mol of Tin/ 118.71g of tin 0.01694 mol of tin

Moles of Oxygen within the final product:

Final mass of Tin Oxide – the initial mass of Tin Oxide 2.769g – 2.011g 0.758g of Oxygen within the final product g of Oxygen within the final product * 1 mol of Oxygen / the number of grams that equal 1 mol of Oxygen 0.758g of Oxygen * 1 mol of Oxygen / 16.00g of Oxygen 0.0474 mol of Oxygen

The exact ratio of mole of Tin to moles of Oxygen:

Moles of Tin: moles of Oxygen 0.01694 mol of Tin: 0.0474 mol of Oxygen The whole number ratio of moles Tin: moles of Oxygen

(moles of tin) Moles of Tin: moles of Oxygen (moles of tin) 0.01694 mol of Tin/ 0.01694: 0.0474 mol of Oxygen / 0.01694 1 mol of Tin: 2.80 mol of Oxygen

1 mol of Tin: 2.80 mol of Oxygen (Round to whole number) 1 mol of Tin : 2.80 mol of Oxygen (Round to whole number) 1 mol Tin: 3 mol Oxygen Questions:

1. What is the empirical formula of the oxide of Tin synthesized in this procedure?

The empirical formula of the oxide of Tin synthesized within this procedure is SnO3.

2. What is the name of this Tin Oxide?

The name of the Tin Oxide produced within my experiment is Tin (VI) Oxide.

3. There are 2 known oxides of tin. Write the formulas and names of these 2 oxides.

A known oxide of Tin is Stannic Oxide [Tin (IV) Oxide] which has the formula SnO2. The other known oxide of Tin is Stannous Oxide [Tin (II) Oxide] which has the formula SnO.

4. How would your results for the exact ratio differ if the sample was not completely dry before determining the mass? Explain.

If the sample was not completely dry before determining the mass of the Tin Oxide, then the mass of the sample would be higher than it was supposed to be. This would in turn cause the appearance of the Oxygen having a greater mass thus causing the exact ratio to differ by having the Oxygen’s mass augmented from its true form. This would occur due to the sample including other substances, such as water (H2O) that would add their masses to the total mass of the Tin Oxide when measuring. If the total mass of the Tin Oxide were to be higher that it actually was due to the water adding its mass to the mass of the Tin Oxide, then the Oxygen would appear to have a higher mass that it actually had due to the added mass of the water. In turn, this would affect the exact ratio of the components within the sample by having the Oxygen to have an incorrect calculated mass, due to the water’s added mass, thus creating an incorrect ratio between the Tin and the Oxygen. Conclusion:

Within the scope of this experiment, the empirical formula of the Tin Oxide created was found to be SnO3. By calculating the empirical formula by means of creating the Tin Oxide and calculating the masses of the Tin and Oxygen within the resulting Tin Oxide, I have learned many things. First, I have learned that because you are not able to measure all things directly, such as the mass of the Oxygen within the Tin Oxide, that you are still able to calculate the mass by using simple calculations such as subtracting the mass of the Tin Oxide by the mass of the initial Tin used. Also, I have learned what scientists must do in order to calculate the empirical and chemical formulas of substances from first creating the substance to actually calculating the formula. And finally, I have learned that many factors within the experiment may not always be able to be controlled, thus always allowing some sort of error to occur. Through this experiment, it was determined that the Tin Oxide produced had the empirical formula of SnO3.

Within this experiment numerous errors occurred that could not be controlled, thus resulting in inaccurate data when calculating the empirical formula of the Tin Oxide after the experiment. Some of these errors include a large amount of the Tin Oxide “splattering” out of the beaker thus landing onto the heating apparatus, hood, and tables, the Oxygen’s mass being in accurate due to it not actually being measured, and some of the Tin not fully reacting with the Nitric Acid. When the some of the Tin Oxide “splattered” out of the beaker and onto the objects surrounding it, this caused the mass of the Tin Oxide produced to become decreased by not including the mass of the Tin Oxide outside of the beaker after the heatings. This in turn would have created an inaccurate mass of the Tin Oxide produced due to a large portion of the Tin Oxide produced not being included within the final mass of the beaker and Tin Oxide after the heatings. This in turn would have led to inaccurate calculations when finding the amount of Oxygen used to produced the Tin Oxide.

In addition, because the mass of the Oxygen within the Tin Oxide could not be directly measured, the mass may be inaccurate. This inability to directly measure the mass of the Oxygen within the Tin Oxide allows errors in the measurement to be present. Also, the measurement of the amount of Oxygen used to produce the Tin Oxide would have an inaccuracy to it due to the possibility of the Tin Oxide produced containing various substances such as water, if the Tin Oxide were to not be fully dry when finding the mass of the Tin Oxide, or NO2, if the brown gas were to not have been completely evaporated before beginning the heatings. Having these substances within the resulting Tin Oxide when finding the mass of the beaker and Tin Oxide would result in inaccurate results when calculating the amount of Oxygen used to produce the Tin Oxide due to them adding their mass to the calculated mass of Oxygen.

Also, if the Tin were to not have fully reacted with the Nitric acid, this would have also caused some inaccuracy within the results due to the Tin Oxide produced containing other substances, thus not being pure Tin Oxide. Due to some of the Tin Oxide produced within my experiment having the appearance of being a dull, light, pale, yellow color, I can infer that the Tin Oxide produced contained some other substances and was not pure Tin Oxide. Due to this, it can be inferred that the Tin Oxide produced may have had some other substances held within, and was not pure Tin Oxide, thus causing the calculated mass of the Oxygen held within the Tin Oxide to be higher than it actually was. Overall, these inevitable errors would have caused some degree of inaccuracy within my results when calculating the empirical formula of the Tin Oxide produced within the experiment.